It would appear that the years of a desk job is starting to catch up with me lol... 3 days of working on the car and I am stiff as a board (fnarr!)... anyhoo... more done today

First job was to fabricate the turbo coolant lines...

...done... well... nearly... waiting on a 'barb' to weld onto the end of the shorter line so I can connect it up to the hose that feeds it...

Next up... I fabricated the charge pipe... main reason for this was I need to work out how much room I have to play with for the turbo after run pump that will be fitted under the battery cover... in order to do this I need the parts that have little room for adjustment in so I cracked on with that...

Happy with the way it runs... need to finalise a few things as waiting on hoses etc and need to work out how to secure it to the side of the head but its coming together how I visualised it... I also positioned the dump valve...

...yes, its a BOV bruv... but I am on standalone ECU using speed density so its fine

Last job was to sort the oil feed to the turbo... there appears to be a few ways that this can be achieved on a VR6 turbo conversion... the information (as always) is suitably vague but... some people weld a fitting to the top of the oil filter housing but this seems a little sketchy to me as the top of the housing is just a void and while it is the filtered side it seems that it could drain down between starts so maybe cause air to be drawn into the feed leading to a small chance of oil starvation...

I am sure that in reality its fine but just didn't feel right to me... so another option was to use the adaptor I bought a while back that you fit teh timing chain tensioner through so it can feed from there... however it seems that a larger plunger is needed to make up for the way the oil take off spaces the tensioner away from the chain... this seems to be something HPA sells along with a longer top chain so decided I will wait until I have those parts ($225 plus shipping!) before I decide on using the adaptor... that will also wait until I am ready to swap to the DSG box as you need the box off to play with chains..

So I went for plan Z and fitted a 10x1 to AN4 stainless fitting to the end of the oil pressure t-piece...

..to which I fitted the oil feed pipe... All a bit tight there but have cable tied and spaced to make sure it doesn't end up in the fans....

The only real issue with this solution is that the oil from the oil pressure switch side is not filtered... so I got an inline filter with AN4 fitting... its a 149 micron mesh filter that is cleanable and will do the job nicely...

I may well review this at a later date once I have the parts from HPA but happy with the solution as it stands... I just need to take the front off the car to feed it more elegantly but will address that when I take the inlet off to be powder coated again

While I was faffing about the hero that is Alex welded up my downpipe..

This means that tomorrows work will be sorting the wastegate and getting that fed into the down pipe along with finalising EGT and lambda boss locations...

All in all I am happy with progress... waiting for parts is a pain but they are bits I wasn't sure of needing until I had worked out how it was all going together..

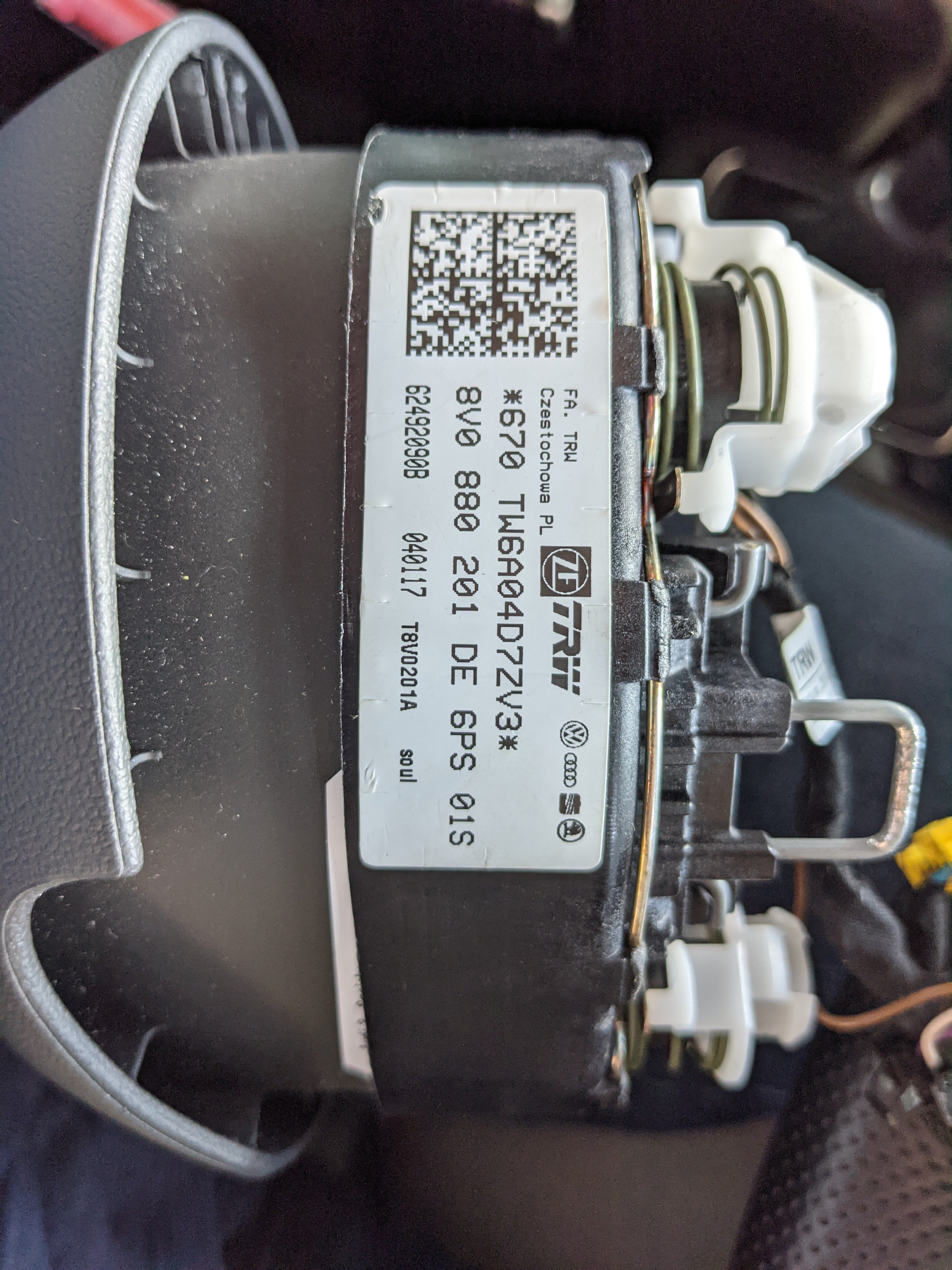

My S3 however is clearly not happy about me not giving her much attention over the past 2 years and so is making me pay for it lol...

Nice engine bay rash from building the downpipe...

Nice burn from linishing the cut ends of the downpipe bends... stupidly managed to grab the hot bit while turning the cut piece around...

After realising I was TIG welding without heat resistant gloves (just had nitrile gloves on) I managed to stab myself with the hot end of the filler rod while putting stuff down to grab the gloves...

Lastly... managed to pinch my finger (somehow) whilst doing something in the vice!!... nice bulge too!..

I expect to bleed a bit when I do car stuff as that is the nature of things but its getting out of hand now LOL...

<tuffty/>