I don't know if I am setting this up right but I'm going to attempt to start a thread about a big turbo build I am doing on my audi s3 where hopefully people can input information and help with and questions I may have. if people could let me no they see this would be much appreciated and will start adding more substance to this thread. cheers

1.8t 20v BAM gt3071r BT build

- Thread starter hrp81134

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ah perfect. was starting to give up hope that this was going anywhere last night. well I will start with a bit of background on the car and the time I have had it so far. it started of life as a standard 1.8t AMK audi s3 2001 that I brought late 2014. got it for a fairly good price of £4500 with 96000 on the clock. I'm a keen car enthusiast but have never really undertaken any major modifications until I had this car. when I got some money together I brought and installed the following parts.

H&R anti roll bars

adjustable drop links

full apex coil over kit

braided brake lines

brembo drilled and groved disks

brembo pads.

full jettex 3" exhaust system including decat

jettex air filter

modified heat shied for air filter

forge intercooler and pipework

forge hard boost pipe

forge intake pipe

forge blow off/diverter valve

had a decent remap also

at this stage the car was pushing 260bhp on the dyno. now this was all fun and games untill I had the engine mount strip it's threads on the timing side which caused the whole engine to drop and the prob had scuffed up my nice new H&R bars

although this was a simple fix and didn't leave any lasting damage other than the scuff on the antiroll bar me being me I took this opportunity to strip the engine bay right back to check for any other problems alone with mirror polishing alot of parts because I'm a bit odd like that.

finally got round to getting it all back together and changed all the fluids while I was at it. now a rather sad/annoying thing happened in the coming days... for some reason my temperature guage stopped working and at the same time the coolant hose at the bottom of the radiator on that stupid clip managed to work itself off causing all my coolant to exit the engine.. this threw up the coolant level sensor on the dash but as my temp guage wasn't rising I though I will pull over next services and top it up.. it must of been 2-3 miles down the road and everything stopped throwing up many dash lights. it soon become apparent that my freshly put back together car has now got a ruined seized engine. the car was then put under cover up til I saved up some funds to decide what to do with her..

it was put under cover last October and during that time I have been busy researching and getting information on a big turbo upgrade including all supporting mods to hopefully fingers crossed get this car to between 400-410BHP with torque of a similar. I have already been busy with collecting parts for the build and will get some more info up with regards to the specs I have gone for when I get chance. many parts are coming from USA.

H&R anti roll bars

adjustable drop links

full apex coil over kit

braided brake lines

brembo drilled and groved disks

brembo pads.

full jettex 3" exhaust system including decat

jettex air filter

modified heat shied for air filter

forge intercooler and pipework

forge hard boost pipe

forge intake pipe

forge blow off/diverter valve

had a decent remap also

at this stage the car was pushing 260bhp on the dyno. now this was all fun and games untill I had the engine mount strip it's threads on the timing side which caused the whole engine to drop and the prob had scuffed up my nice new H&R bars

although this was a simple fix and didn't leave any lasting damage other than the scuff on the antiroll bar me being me I took this opportunity to strip the engine bay right back to check for any other problems alone with mirror polishing alot of parts because I'm a bit odd like that.

finally got round to getting it all back together and changed all the fluids while I was at it. now a rather sad/annoying thing happened in the coming days... for some reason my temperature guage stopped working and at the same time the coolant hose at the bottom of the radiator on that stupid clip managed to work itself off causing all my coolant to exit the engine.. this threw up the coolant level sensor on the dash but as my temp guage wasn't rising I though I will pull over next services and top it up.. it must of been 2-3 miles down the road and everything stopped throwing up many dash lights. it soon become apparent that my freshly put back together car has now got a ruined seized engine. the car was then put under cover up til I saved up some funds to decide what to do with her..

it was put under cover last October and during that time I have been busy researching and getting information on a big turbo upgrade including all supporting mods to hopefully fingers crossed get this car to between 400-410BHP with torque of a similar. I have already been busy with collecting parts for the build and will get some more info up with regards to the specs I have gone for when I get chance. many parts are coming from USA.

Attachments

-

20150516_145438.jpg7.6 MB · Views: 913

20150516_145438.jpg7.6 MB · Views: 913 -

20150520_141127.jpg7 MB · Views: 843

20150520_141127.jpg7 MB · Views: 843 -

20150517_165435.jpg1.8 MB · Views: 608

20150517_165435.jpg1.8 MB · Views: 608 -

20150516_153638.jpg2.6 MB · Views: 635

20150516_153638.jpg2.6 MB · Views: 635 -

20150627_173127.jpg5.4 MB · Views: 705

20150627_173127.jpg5.4 MB · Views: 705 -

20150517_165415.jpg1.9 MB · Views: 581

20150517_165415.jpg1.9 MB · Views: 581 -

20150627_173122.jpg1.9 MB · Views: 626

20150627_173122.jpg1.9 MB · Views: 626 -

20150627_134557.jpg2.5 MB · Views: 589

20150627_134557.jpg2.5 MB · Views: 589 -

20150723_231552.jpg297.2 KB · Views: 563

20150723_231552.jpg297.2 KB · Views: 563 -

20150723_231543.jpg322.2 KB · Views: 580

20150723_231543.jpg322.2 KB · Views: 580 -

20150723_231602.jpg355.7 KB · Views: 579

20150723_231602.jpg355.7 KB · Views: 579

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,077

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

There are a fair few big turbo build threads on here dude that will help in your research...

Don't plan on keeping the Forge FMIC if going GT3071... barely big enough for the power you are running now... been there and got the t-shirt

<tuffty/>

Don't plan on keeping the Forge FMIC if going GT3071... barely big enough for the power you are running now... been there and got the t-shirt

<tuffty/>

hey there tuffty. was hoping you would pop up on this tread with some useful advice as I have seen your name popping up all over these forums will great advice and knowledge.

no no don't worry that intercooler is well and truely gone everything that I don't need has basically been sold on so the money has helped with getting other bits for the build.

I do have to bam pistons and rod assemblies that still need a loving home if anyone is interested.

so yeah will carry on with this thread.

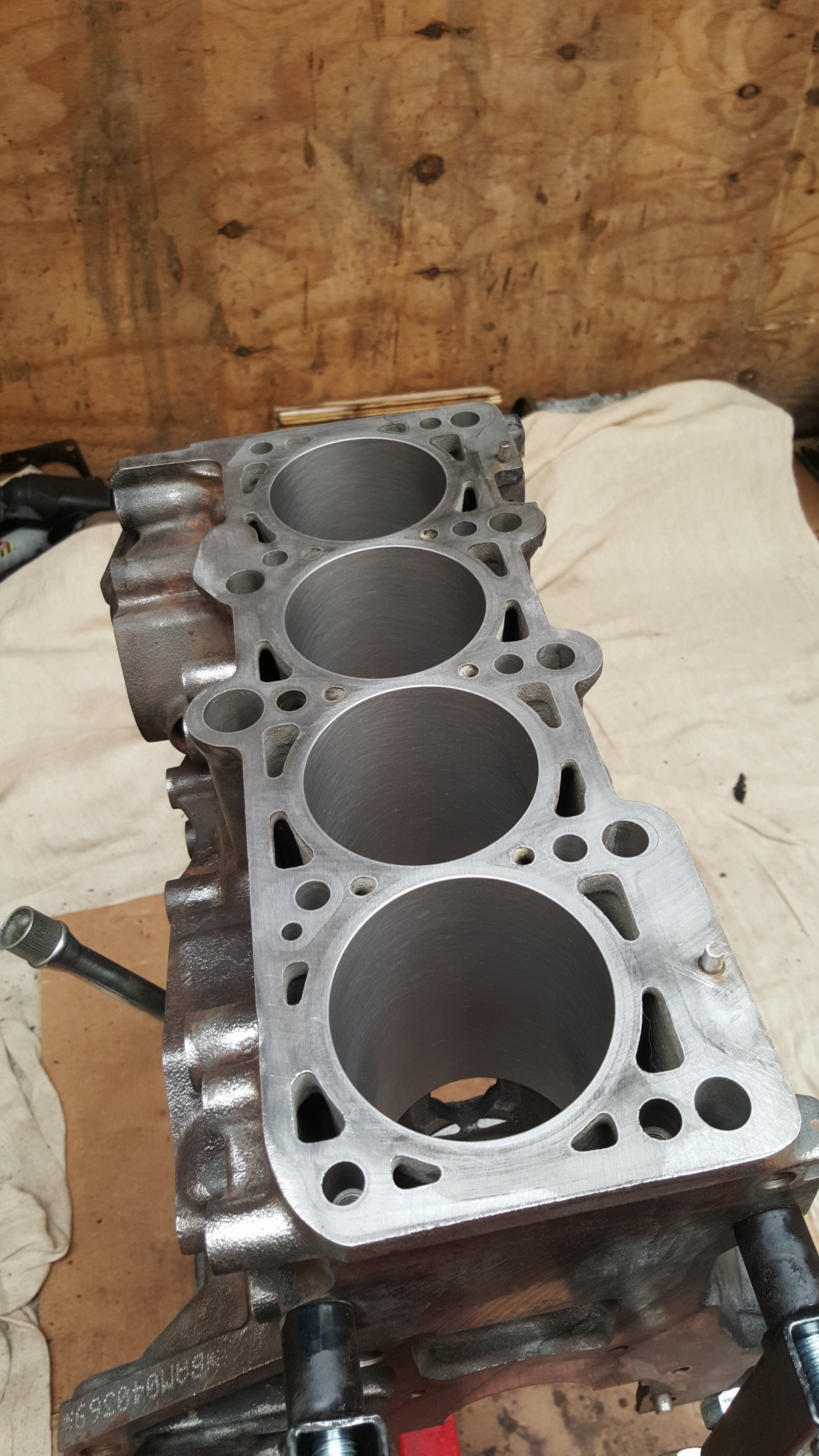

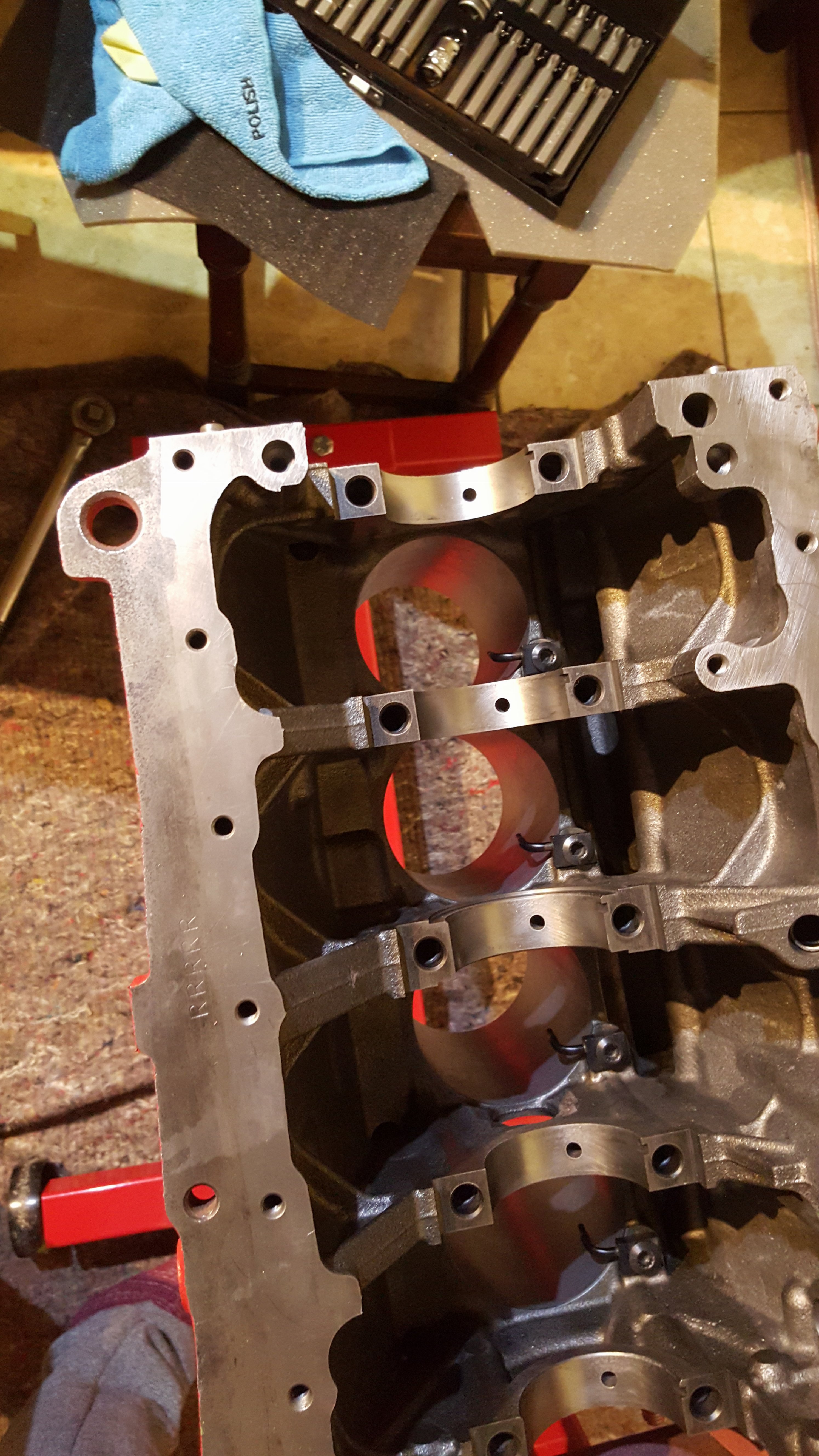

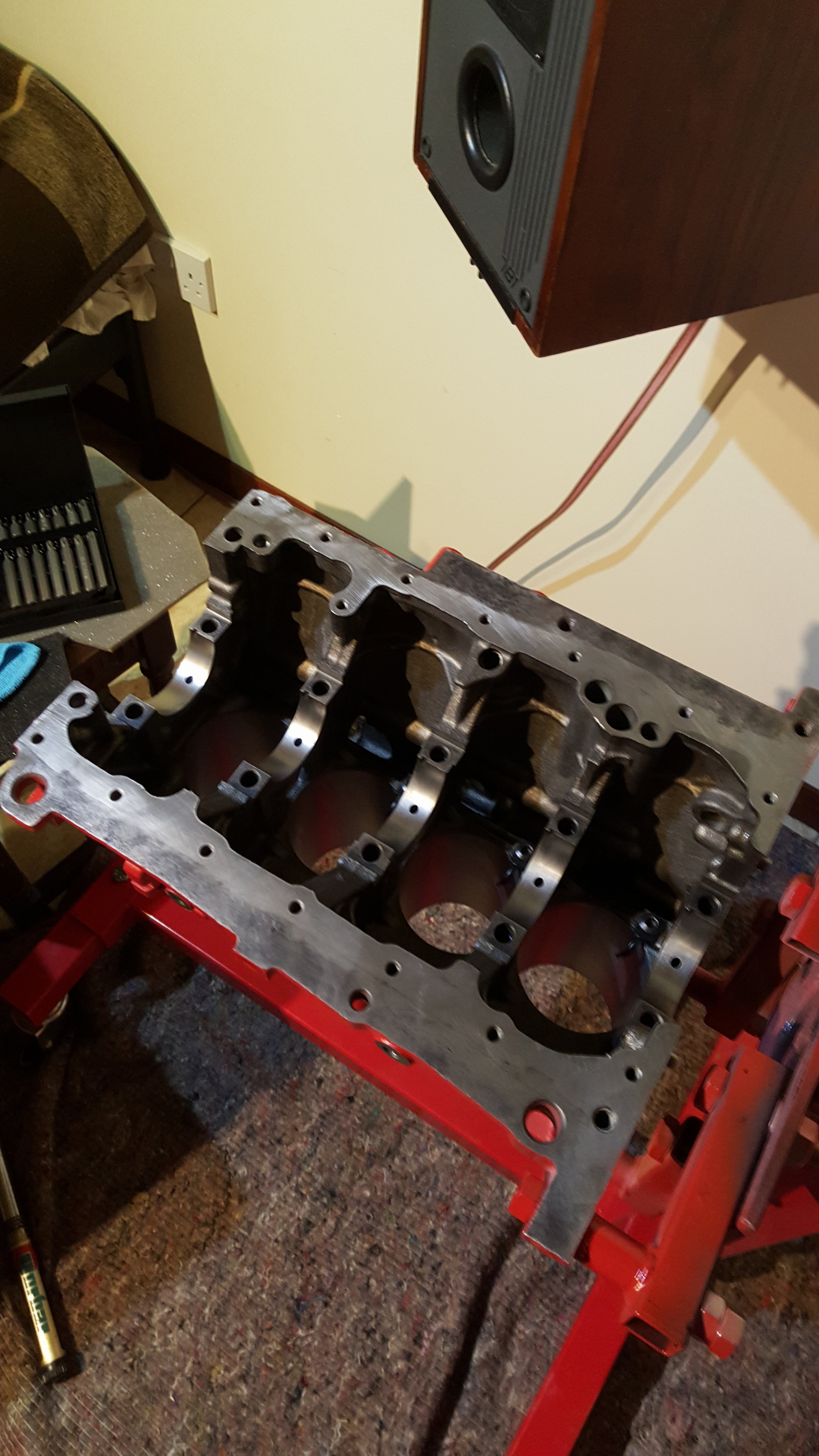

after inspection of the damage to my amk block and head ect I decided to get rid and start a fresh. I brought a low milage 225 BAM engine with 50000 miles on it for just shy of a grand with basically everything bolted on as standard. (this is where the bam pistons come from not the knackered amk block) and work began stripping down the new engine and getting the block off to the machine shop. as pictured. everything withing the engine is being replaced weather it needs to or not for this power but doing it more for piece of mind as want a relatively reliable build.

the spec I have gone for for the engine build is as follows.

oversized 81.43mm wossner pistons with a bore size of 81.50 allowing for the 0.07mm bore to piston clearance

forged zrp H-beam light weight connecting rods

all acl main and rod bearings

all arp. (head..main..rod..crank gear ect)

brand new oil pump and pickup + chain and tensioner

both new seals on crank

new sump (unsure weather to buy a baffle plate)

I/E press fit crank gear kit as suppositivly better than pegging.

I/E manual timing kit which includes the following..

billet idler roller kit

billet spacer

timing belt tensioner roller

mechanical tensioner hardware kit

metal water pump

gates racing kevlar belt

every sensor is being replaced with new

performance head gasket (not sure what yet)

need to get a good clutch (unsure)

have the head currently being worked on to replace all parts with supertech to support higher revving. (valves, springs ect)

the head will still remain small port with standard manifold.

be running 630cc injectors after breaking in on standard injectors with boost set at minimum.

will be looking at getting cams after break in but unsure as to what route to take yet.

unsure if oil cooler will need upgrading to radiator type but will deal with that later on down the line.

obviously all new gaskets and seal and thermostat for coolant.

I pretty much have all the parts I need other than the oil seal on the crank gear side but will have to source than unless anyone can help out.

I have also purchased a gt3071r turbo kit from CTS turbo where the guys there were a great help with questions I had. it is currently in transit from America and will hopefully be here in the coming weeks so will get pics up of those parts when I have them. the turbo kit I am buying will come with the following parts.

gt3071r turbocharger ( will look to run in the 24-26psi range)

630 high impedance injectors

Walbro GSL 392 Inline fuel pump

high flow fuel filter

cts 1" diverter valve

CTS 1.8T T3 Turbo Manifold

Thermal coated turbine housing

Thermal coated exhaust manifold

3" Stainless Steel O2 Housing with integrated wastegate recirculation (external dump)

3" Stainless steel downpipe with rear Vband section

3" Stainless steel rear catalytic converter eliminator section

Stainless Steel Turbo Heat Shield

Thermal wrap for upper downpipe

3" Inlet Pipe Kit w/ silicon and Advanced Flow Engineering (AFE) Re-useable Air Filter

Stainless steel compressor outlet pipe (to connect to factory dual SMIC piping)

Stainless steel oil feed line kit

Oil drain line kit and required fittings

Coolant line relocation kit for oil cooled T3T4 turbos

Precision 39mm External Wastegate

All Gaskets, Studs, Nuts, Clamps for installation

I'm sure I have missed parts out that I have but will add if I can remember.

so as I stand at the moment I should be getting the block back from the machine shop this week so can get on with prep work for a respray (red to my taste) and just really waiting for parts to arrive from the states so I can crack on with getting this engine back together. will put pictures up I have on my phone but will take more when parts arrive. Cheers everyone for reading and like I said if any one can give advice and info on anything related whether I know or not it will all be appreciated.

just to add all engine mounts will be uprated as don't want stripping to occur again and all silicone hoses will be new along with high flow radiator and a good decent intercooler for this set up to suit.

no no don't worry that intercooler is well and truely gone everything that I don't need has basically been sold on so the money has helped with getting other bits for the build.

I do have to bam pistons and rod assemblies that still need a loving home if anyone is interested.

so yeah will carry on with this thread.

after inspection of the damage to my amk block and head ect I decided to get rid and start a fresh. I brought a low milage 225 BAM engine with 50000 miles on it for just shy of a grand with basically everything bolted on as standard. (this is where the bam pistons come from not the knackered amk block) and work began stripping down the new engine and getting the block off to the machine shop. as pictured. everything withing the engine is being replaced weather it needs to or not for this power but doing it more for piece of mind as want a relatively reliable build.

the spec I have gone for for the engine build is as follows.

oversized 81.43mm wossner pistons with a bore size of 81.50 allowing for the 0.07mm bore to piston clearance

forged zrp H-beam light weight connecting rods

all acl main and rod bearings

all arp. (head..main..rod..crank gear ect)

brand new oil pump and pickup + chain and tensioner

both new seals on crank

new sump (unsure weather to buy a baffle plate)

I/E press fit crank gear kit as suppositivly better than pegging.

I/E manual timing kit which includes the following..

billet idler roller kit

billet spacer

timing belt tensioner roller

mechanical tensioner hardware kit

metal water pump

gates racing kevlar belt

every sensor is being replaced with new

performance head gasket (not sure what yet)

need to get a good clutch (unsure)

have the head currently being worked on to replace all parts with supertech to support higher revving. (valves, springs ect)

the head will still remain small port with standard manifold.

be running 630cc injectors after breaking in on standard injectors with boost set at minimum.

will be looking at getting cams after break in but unsure as to what route to take yet.

unsure if oil cooler will need upgrading to radiator type but will deal with that later on down the line.

obviously all new gaskets and seal and thermostat for coolant.

I pretty much have all the parts I need other than the oil seal on the crank gear side but will have to source than unless anyone can help out.

I have also purchased a gt3071r turbo kit from CTS turbo where the guys there were a great help with questions I had. it is currently in transit from America and will hopefully be here in the coming weeks so will get pics up of those parts when I have them. the turbo kit I am buying will come with the following parts.

gt3071r turbocharger ( will look to run in the 24-26psi range)

630 high impedance injectors

Walbro GSL 392 Inline fuel pump

high flow fuel filter

cts 1" diverter valve

CTS 1.8T T3 Turbo Manifold

Thermal coated turbine housing

Thermal coated exhaust manifold

3" Stainless Steel O2 Housing with integrated wastegate recirculation (external dump)

3" Stainless steel downpipe with rear Vband section

3" Stainless steel rear catalytic converter eliminator section

Stainless Steel Turbo Heat Shield

Thermal wrap for upper downpipe

3" Inlet Pipe Kit w/ silicon and Advanced Flow Engineering (AFE) Re-useable Air Filter

Stainless steel compressor outlet pipe (to connect to factory dual SMIC piping)

Stainless steel oil feed line kit

Oil drain line kit and required fittings

Coolant line relocation kit for oil cooled T3T4 turbos

Precision 39mm External Wastegate

All Gaskets, Studs, Nuts, Clamps for installation

I'm sure I have missed parts out that I have but will add if I can remember.

so as I stand at the moment I should be getting the block back from the machine shop this week so can get on with prep work for a respray (red to my taste) and just really waiting for parts to arrive from the states so I can crack on with getting this engine back together. will put pictures up I have on my phone but will take more when parts arrive. Cheers everyone for reading and like I said if any one can give advice and info on anything related whether I know or not it will all be appreciated.

just to add all engine mounts will be uprated as don't want stripping to occur again and all silicone hoses will be new along with high flow radiator and a good decent intercooler for this set up to suit.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,077

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Wossners are ok but tbh I would have gone at least 82mm even 82.5mm

ZRP rods have (or had) issues...no mention if the they are drilled or not but ideally rifle drilled are the ones to have and the ZRP's have a groove and holes on the small ends that could impact small end lubrication and potentially drop oil pressure

Oil pump should ideally be an OE one... I have used topran before but seems suppliers vary in where these are sourced and have seen a pump fail (wasn't a topran one I should mention)... I had a few oil pressure issues but after buzzing my engine I replaced it with an OE one and not looked back since

Sump wise I would look at a Forge one but just make sure all the mating surfaces are ok and the holes are deburred... you will also need to clearance the sump for ARP mains studs on cap 5

Metal water pumps leak through the shaft... just buy OE and factor in changing it every 60k

Gates kevlar belts are a marketing ploy... previously they are know to just snap.. use an OE one

OE/elring head gasket is all you need... no such thing as a 'perfomance' one

I still use an LuK DMF, LuK std pressure plate with a Sachs 4 puck paddle plate as a clutch... works well

Get the valves seats and valve guides checked on the head... pressure test is worth while as AMK/BAM are prone to cracking

CTS turbo kit? hummm... cast mani with an external gate? 2.5" DP out the turbo opening up to 3"... not the best or easiest kit in the world to fit... you will need to get an EGT bung welded in

630 injectors? not Siemens dekas I hope...

<tuffty/>

ZRP rods have (or had) issues...no mention if the they are drilled or not but ideally rifle drilled are the ones to have and the ZRP's have a groove and holes on the small ends that could impact small end lubrication and potentially drop oil pressure

Oil pump should ideally be an OE one... I have used topran before but seems suppliers vary in where these are sourced and have seen a pump fail (wasn't a topran one I should mention)... I had a few oil pressure issues but after buzzing my engine I replaced it with an OE one and not looked back since

Sump wise I would look at a Forge one but just make sure all the mating surfaces are ok and the holes are deburred... you will also need to clearance the sump for ARP mains studs on cap 5

Metal water pumps leak through the shaft... just buy OE and factor in changing it every 60k

Gates kevlar belts are a marketing ploy... previously they are know to just snap.. use an OE one

OE/elring head gasket is all you need... no such thing as a 'perfomance' one

I still use an LuK DMF, LuK std pressure plate with a Sachs 4 puck paddle plate as a clutch... works well

Get the valves seats and valve guides checked on the head... pressure test is worth while as AMK/BAM are prone to cracking

CTS turbo kit? hummm... cast mani with an external gate? 2.5" DP out the turbo opening up to 3"... not the best or easiest kit in the world to fit... you will need to get an EGT bung welded in

630 injectors? not Siemens dekas I hope...

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,386

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

that's what I like tuffty.. straight to the point with advice ect with no bulls**t. ☺

seems I was miss led with regards to the piston sizing but it's too late now as have already had the block work done and pistons and rods brought... what is the main disadvantaged I will see then with these smaller pistons? slow spool up I'm guessing?

the only reason I got these rods as they came in a decent priced kit with the wossner pistons. they are rifle drilled yes so hopefully I won't have any problems with them.

the oil pump is a genuine OE one with OE pickup and chain/tensioner so hopefully got a good one.

with regards to sump I have already brought a standard OE bam sump.. It never crossed my mind with regards to arp main stud sump clearances.. could you elaborate a bit more if you don't mine mate?

will get rid of that metal water pump I have then and go OE like you suggest as don't want any silly problems like that so thanks for the heads up.

the gates belt came with the manual timing kit I am getting so would you use OE like you say or hope for the best?

OE head gasket it is then. will a standard size one be ok as I'm not really going massive on the boring of bores ect? recommend any good make or just get genuine?

will have a look into that clutch set up then.. I was looking for a clutch and flywheel set up so will have a look. also are arp flywheel bolts recommended or not nessesary?

I'm hoping that where the head is all that work is going to be done but will drop them an email just to check. costing 1500 for head to be sorted which I didn't think was too bad.

I will get some pics up of the turbo kit when it arrives but I have set myself up with expecting modifications needed as I'm sure you agree it's never usually a direct fit yer I was going to wait to see if there are any provision for the egt but like you say will prob have to get one put in but will cross that bridge when I come to it.

the injectors are 630cc siemens 60lb high impedance.. what are your concerns with these as was guided to these from CTS with regards to the kit I have purchased.

thanks again for your replies and assistance buddy.

seems I was miss led with regards to the piston sizing but it's too late now as have already had the block work done and pistons and rods brought... what is the main disadvantaged I will see then with these smaller pistons? slow spool up I'm guessing?

the only reason I got these rods as they came in a decent priced kit with the wossner pistons. they are rifle drilled yes so hopefully I won't have any problems with them.

the oil pump is a genuine OE one with OE pickup and chain/tensioner so hopefully got a good one.

with regards to sump I have already brought a standard OE bam sump.. It never crossed my mind with regards to arp main stud sump clearances.. could you elaborate a bit more if you don't mine mate?

will get rid of that metal water pump I have then and go OE like you suggest as don't want any silly problems like that so thanks for the heads up.

the gates belt came with the manual timing kit I am getting so would you use OE like you say or hope for the best?

OE head gasket it is then. will a standard size one be ok as I'm not really going massive on the boring of bores ect? recommend any good make or just get genuine?

will have a look into that clutch set up then.. I was looking for a clutch and flywheel set up so will have a look. also are arp flywheel bolts recommended or not nessesary?

I'm hoping that where the head is all that work is going to be done but will drop them an email just to check. costing 1500 for head to be sorted which I didn't think was too bad.

I will get some pics up of the turbo kit when it arrives but I have set myself up with expecting modifications needed as I'm sure you agree it's never usually a direct fit yer I was going to wait to see if there are any provision for the egt but like you say will prob have to get one put in but will cross that bridge when I come to it.

the injectors are 630cc siemens 60lb high impedance.. what are your concerns with these as was guided to these from CTS with regards to the kit I have purchased.

thanks again for your replies and assistance buddy.

send all the luck you can matey. this is my first project so there are going to be lots of problems to overcome. kind of looking forward to them.CTS kit - good luck with that fitting

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,077

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Firstly... if you haven't already then have a read of my build thread... you can start at the beginning as thats when I first did my GT3071 build or jump over that for now and go to the most recent part of the build here

http://www.audi-sport.net/xf/threads/my-minor-modding-thread.76389/page-53#post-1911525

Your questions on the sump will be answered there also rather than me linking to it again...

Gates belt... I would just go with an OE one... "hope for the best" is not a phrase typically used for a component that stands a chance of ruining the whole engine

OE head gasket will support up to 82.5mm bore... GSF sell elring gaskets, use one of those or just buy genuine (use the ASN parts request... genuine parts at very good prices)

Clutch setup is in my thread too... you can only use OE bolts on a DMF as ARP don't make any that I am aware of (else I'd use them myself)... just ALWAYS use new bolts

Dekas are non linear at the low pulse widths used at idle... this means the ECU is constantly fighting them to keep fuelling in check and it can escalate into the ECU heavily over fuelling and not being able to pull it back quickly enough... this can lead to fuel saturated oil, bore wash and poor low rpm running on cruise and idle...

I ran Bosch 550's and a 4bar FPR on my GT30... sweet as a nut...

<tuffty/>

http://www.audi-sport.net/xf/threads/my-minor-modding-thread.76389/page-53#post-1911525

Your questions on the sump will be answered there also rather than me linking to it again...

Gates belt... I would just go with an OE one... "hope for the best" is not a phrase typically used for a component that stands a chance of ruining the whole engine

OE head gasket will support up to 82.5mm bore... GSF sell elring gaskets, use one of those or just buy genuine (use the ASN parts request... genuine parts at very good prices)

Clutch setup is in my thread too... you can only use OE bolts on a DMF as ARP don't make any that I am aware of (else I'd use them myself)... just ALWAYS use new bolts

Dekas are non linear at the low pulse widths used at idle... this means the ECU is constantly fighting them to keep fuelling in check and it can escalate into the ECU heavily over fuelling and not being able to pull it back quickly enough... this can lead to fuel saturated oil, bore wash and poor low rpm running on cruise and idle...

I ran Bosch 550's and a 4bar FPR on my GT30... sweet as a nut...

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,386

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

we've used a CTS kit. ill fitting shyte thingsend all the luck you can matey. this is my first project so there are going to be lots of problems to overcome. kind of looking forward to them.

what we're your main fitment problems? dp clearance?we've used a CTS kit. ill fitting shyte thing

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,386

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

poor quality parts supplied, hose4s, it simply did not line up on external wg to downpipe (twice)...what we're your main fitment problems? dp clearance?

perfect cheers for all the info guys. much prefer to get advice from people who have actually undertaken this work. I'm not going to lie that thread is epic tuffty so will get on and have a good read of it again and if there are any more questions I have will get back on here.

I will stick with the OE belt then as snapping isn't really an option I like the sound of

will get rid of these 630cc I have then and get me some 550s ☺ does anyone have clearance specs for the bottom end main and rod bearings as I can't seem to find those.. or a link to a Bentley manual I can get. thanks again in advance if anyone can help.

the block and crank will be returning end of the week so will get some more pictures up of parts as and when.

I will stick with the OE belt then as snapping isn't really an option I like the sound of

will get rid of these 630cc I have then and get me some 550s ☺ does anyone have clearance specs for the bottom end main and rod bearings as I can't seem to find those.. or a link to a Bentley manual I can get. thanks again in advance if anyone can help.

the block and crank will be returning end of the week so will get some more pictures up of parts as and when.

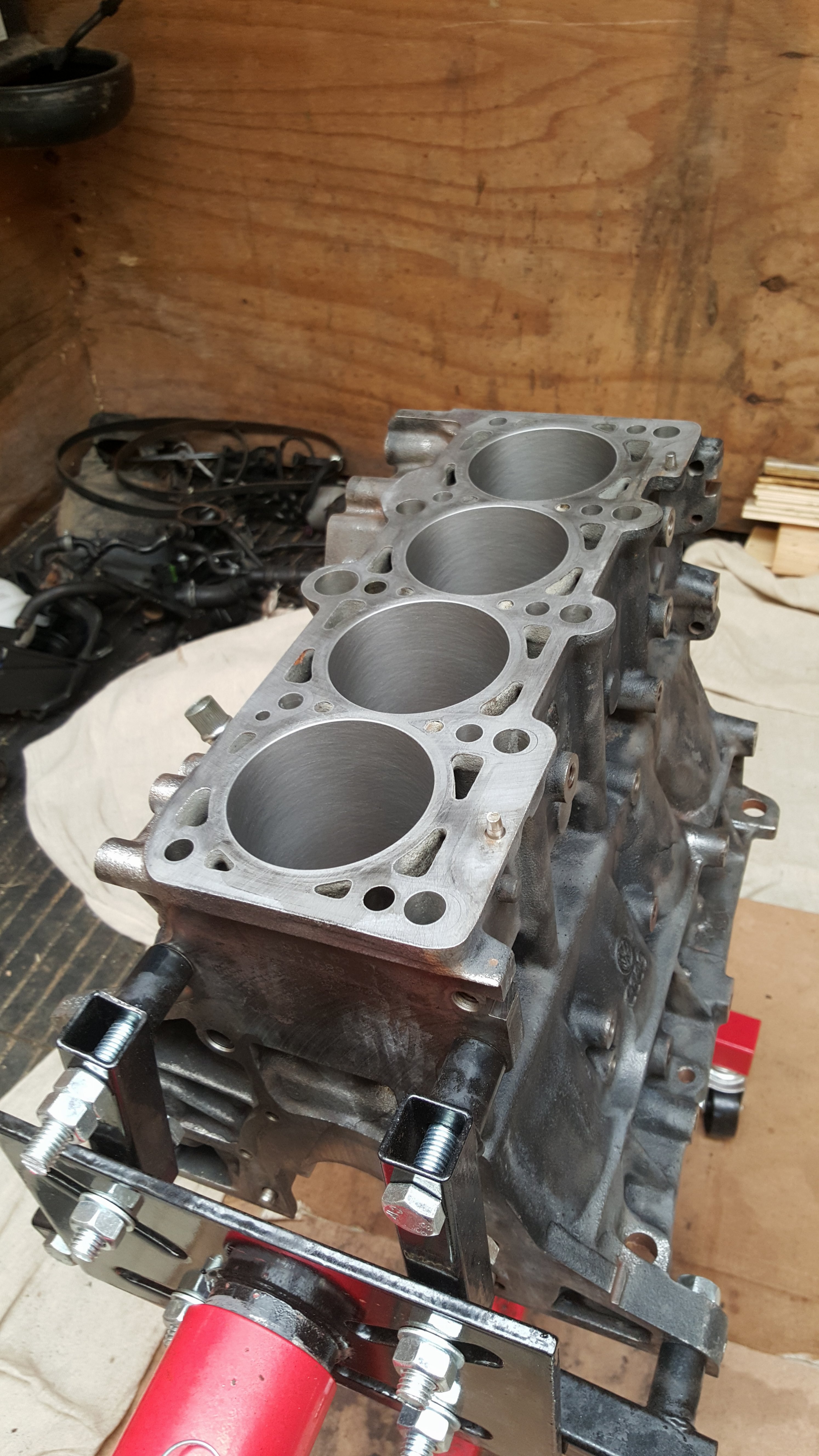

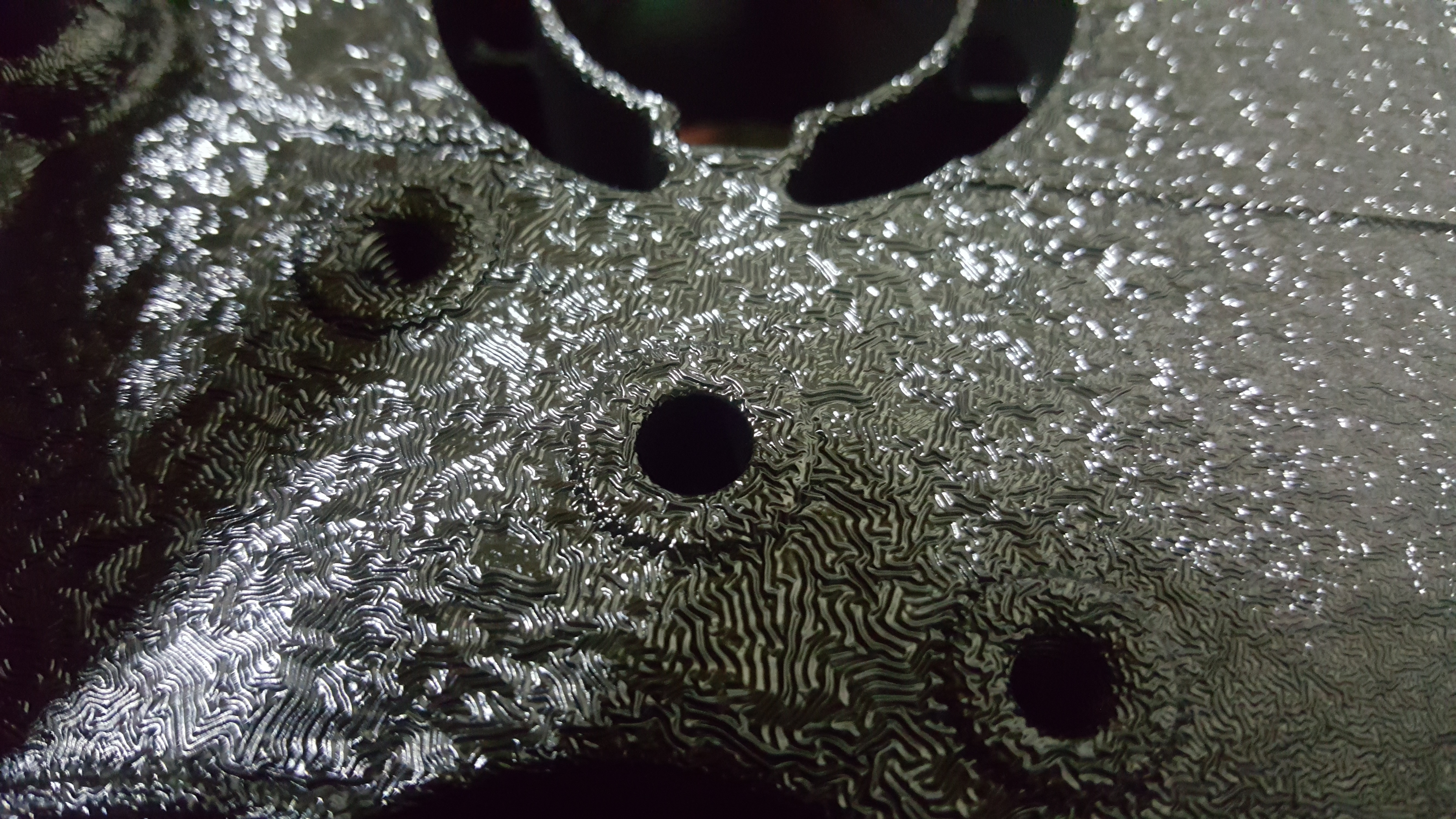

so got the block back this morning all bored out. next step is to prep and clean the block ready for a fresh re spray (red) engine stand and few other bits come this week. will get engine on stand and start the prep work when I have a free afternoon this easter.. is it correct that the bolts needed for stand are 12mm X1. 5 just so I can pop out and get some bolts. haven't had chance to take other engine out and check those bolts on the bellhousing. few pics of parts got already. just waiting on the post now.

quick update on progress. managed to find a free day on easter weekend so got on with cleaning/prepping the block ready for paint.

first gave it a good soapy bath to get rid of any crap that was left in there from the machine shop. I compleatly degreased the who block inside and out cleaning all water/oil channels including chasing the threads again. (lots of compressed air)

once I got it all cleaned and degreased I applied a bit of oil on a rag to each bore to stop any rust ect ect as there is nothing on it now protecting.

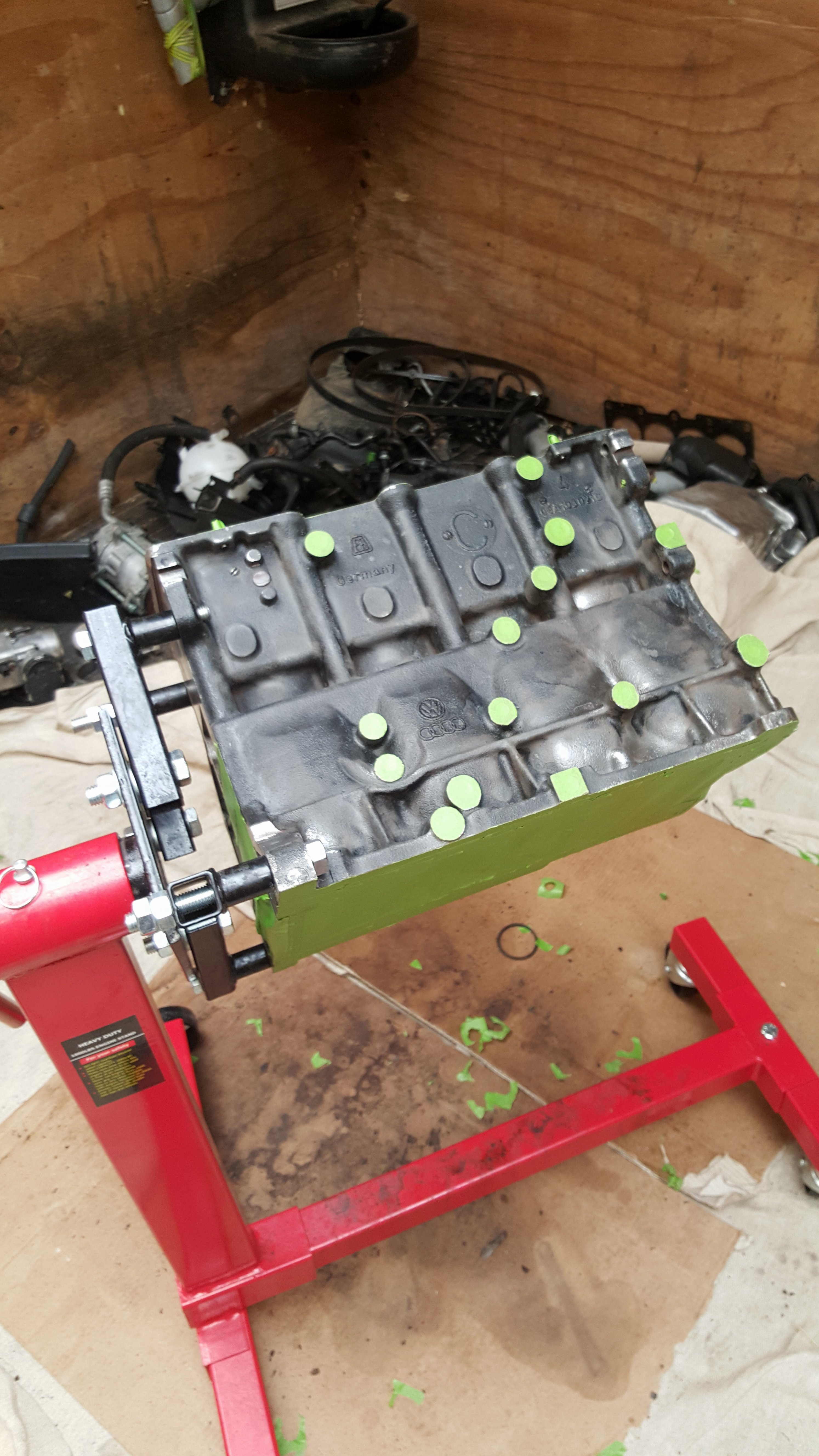

then got on will the long task of masking of all areas I didn't want the spray. frog tape is the tape to use. quality is all in the prep.

time for the spray now. I will be using the VHT engine paint (primer, color and clear top gloss) lots of even coats.

after painting realised it needed to be cured in oven to make chemical resistant. luckily it fitted in my oven so ****** it for recommended time. (took a while to cool down down tho). was now left to sit for a few days.

first gave it a good soapy bath to get rid of any crap that was left in there from the machine shop. I compleatly degreased the who block inside and out cleaning all water/oil channels including chasing the threads again. (lots of compressed air)

once I got it all cleaned and degreased I applied a bit of oil on a rag to each bore to stop any rust ect ect as there is nothing on it now protecting.

then got on will the long task of masking of all areas I didn't want the spray. frog tape is the tape to use. quality is all in the prep.

time for the spray now. I will be using the VHT engine paint (primer, color and clear top gloss) lots of even coats.

after painting realised it needed to be cured in oven to make chemical resistant. luckily it fitted in my oven so ****** it for recommended time. (took a while to cool down down tho). was now left to sit for a few days.

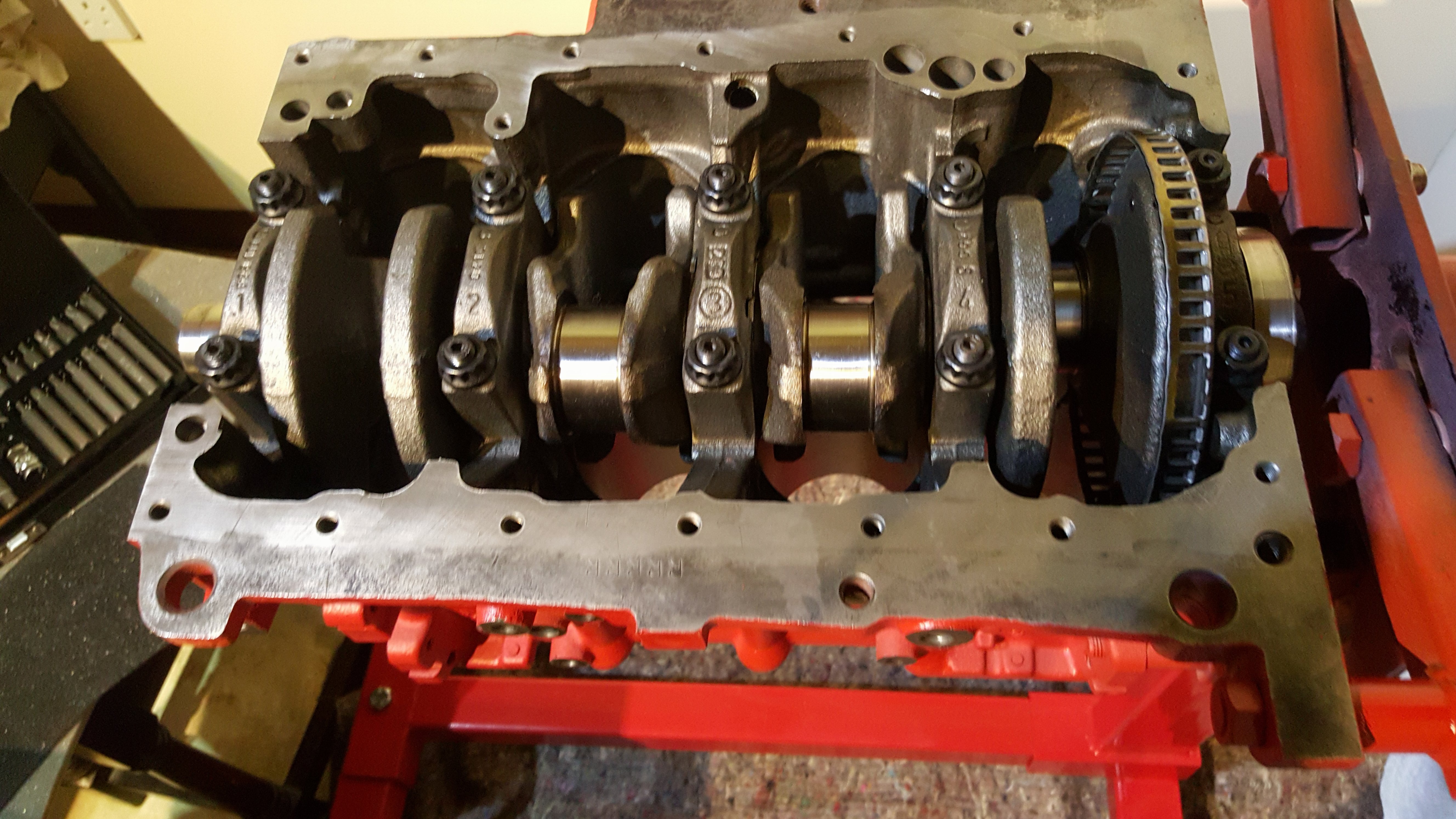

got another free night last night so managed to get the crank in and torqued up after checking bearing clearances along with oil squirter.

I done the clearances with green plastigage.. I know it's not the most accurate way but I was happy as machine shop measured all clearances so was just fancying my hand at a bit of plastigage.

once I was happy with everything and got the oil squirters in a torqued up I push all the main bearings into place and applied lucas assembly lube to all friction surfaces including thruss washers and crank journals.

the arp main studs went in at this stage (hand tight using the supplied arp lube)

caps were now all in place, right way around and number ordered.

torqued up in 3 separate stages to 60ftlbs in order 32415.

gave the crank a quick spin to check was all moving freely and felt alright.

next stage is gapping the rings and doing piston to rod assembly including ring install, plastigage rod bearing clearances and install. Hopefully will be able to crack on later this week will update as and when.

I done the clearances with green plastigage.. I know it's not the most accurate way but I was happy as machine shop measured all clearances so was just fancying my hand at a bit of plastigage.

once I was happy with everything and got the oil squirters in a torqued up I push all the main bearings into place and applied lucas assembly lube to all friction surfaces including thruss washers and crank journals.

the arp main studs went in at this stage (hand tight using the supplied arp lube)

caps were now all in place, right way around and number ordered.

torqued up in 3 separate stages to 60ftlbs in order 32415.

gave the crank a quick spin to check was all moving freely and felt alright.

next stage is gapping the rings and doing piston to rod assembly including ring install, plastigage rod bearing clearances and install. Hopefully will be able to crack on later this week will update as and when.

I'm running a cts turbo kit. the manifold, down pipe, wastegate and everything all bolted together fine. Needed to grind a tiny bit off the manifold to fit it to the head, no big deal. Just a lot of customisation needed to be done to lines at the back of the engine bay. Also made a little heat shield or two for things like the timing belt cover. Pics in my thread.

I'll admit it isn't the best kit in the world but it's working for me so far

I'll admit it isn't the best kit in the world but it's working for me so far

ah that's good to hear. lots of bad press about cts but clay (the person who sorted everything for me) seems to know what he is on about and was very helpful. I'm expecting lots of work to the lines tbh but have a lot of experience with oil line assembly ect so hopefully that will aid me ☺ will definitely be making some sort of heat shield for the cambelt cover as looks very close in your pics. nice build btw just out of interest what did you gap your rings too as will be getting on with installing rods and pistons end of the week. what sort of BHP goals are you hoping for? I was thinking of keeping my standard ecu and have a map put on that.. will this present problems as I saw you used a different ecu?

I didn't build my engine as I'm no mechanic so I can't really answer that question about the rings. Clay also helped me out he's a great guy.

Are you in England? If I lived there I would have badger5 tuning the car. But since I live in Australia I would need to pay someone to scale the MAF from scratch which I imagine would take many many hours + I wouldn't be able to run a flex fuel sensor and e85. So that's the reason I got the after market ecu.

My goal is 400 wheel hp. Any extra would be a bonus.

Are you in England? If I lived there I would have badger5 tuning the car. But since I live in Australia I would need to pay someone to scale the MAF from scratch which I imagine would take many many hours + I wouldn't be able to run a flex fuel sensor and e85. So that's the reason I got the after market ecu.

My goal is 400 wheel hp. Any extra would be a bonus.

I didn't build my engine as I'm no mechanic so I can't really answer that question about the rings. Clay also helped me out he's a great guy.

Are you in England? If I lived there I would have badger5 tuning the car. But since I live in Australia I would need to pay someone to scale the MAF from scratch which I imagine would take many many hours + I wouldn't be able to run a flex fuel sensor and e85. So that's the reason I got the after market ecu.

My goal is 400 wheel hp. Any extra would be a bonus.

yer I have had a few varying opinions on the rings but will probably stick with what wossner recommend.

I do live in England yes so will prob give badger a shout in a few months as quite a way off tuning the ecu yet

same goals as me tbh so as we have pretty much the same kit from CTS be interested in what your car makes ☺

keep your thread alive mate!

quick update on progress..

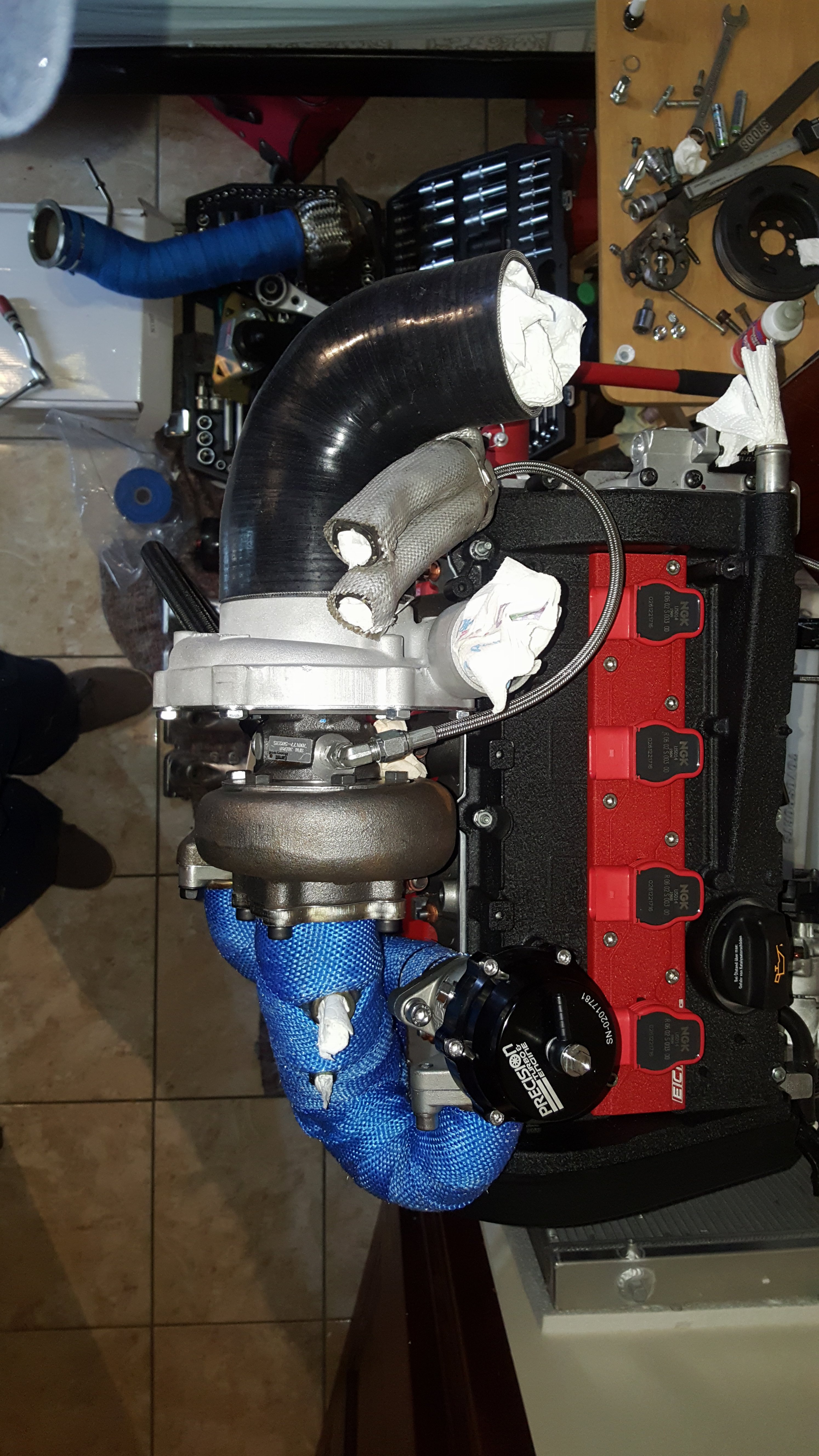

turbo kit arrived yesterday so unpacked in and look all ok but won't know about fitment until I mock assembley when engine is built in the coming weeks. looks like there is a EGT bung already welded in by the O2 sensor so that will save me the hassle of getting that done.

currently waiting on head to be delivered back after work has been done uprating all the supertech/porting ect ect.

ordered clutch/flywheel and pressure plate as recommended by tuffty so cheers for that. few pictures below of kit.

turbo kit arrived yesterday so unpacked in and look all ok but won't know about fitment until I mock assembley when engine is built in the coming weeks. looks like there is a EGT bung already welded in by the O2 sensor so that will save me the hassle of getting that done.

currently waiting on head to be delivered back after work has been done uprating all the supertech/porting ect ect.

ordered clutch/flywheel and pressure plate as recommended by tuffty so cheers for that. few pictures below of kit.

They have made a few improvements to the kit since I got mine which is nice to see. hopefully it all goes well for you. btw ditch the intake pipe they provide, for me it hit the coolant hoses to the heater matrix. I just got some 4" aluminium bends and made my own intake - very easy to do

They have made a few improvements to the kit since I got mine which is nice to see. hopefully it all goes well for you. btw ditch the intake pipe they provide, for me it hit the coolant hoses to the heater matrix. I just got some 4" aluminium bends and made my own intake - very easy to do

yer they have made a few needed improvements. I did spot that on your build so cheers for the heads up

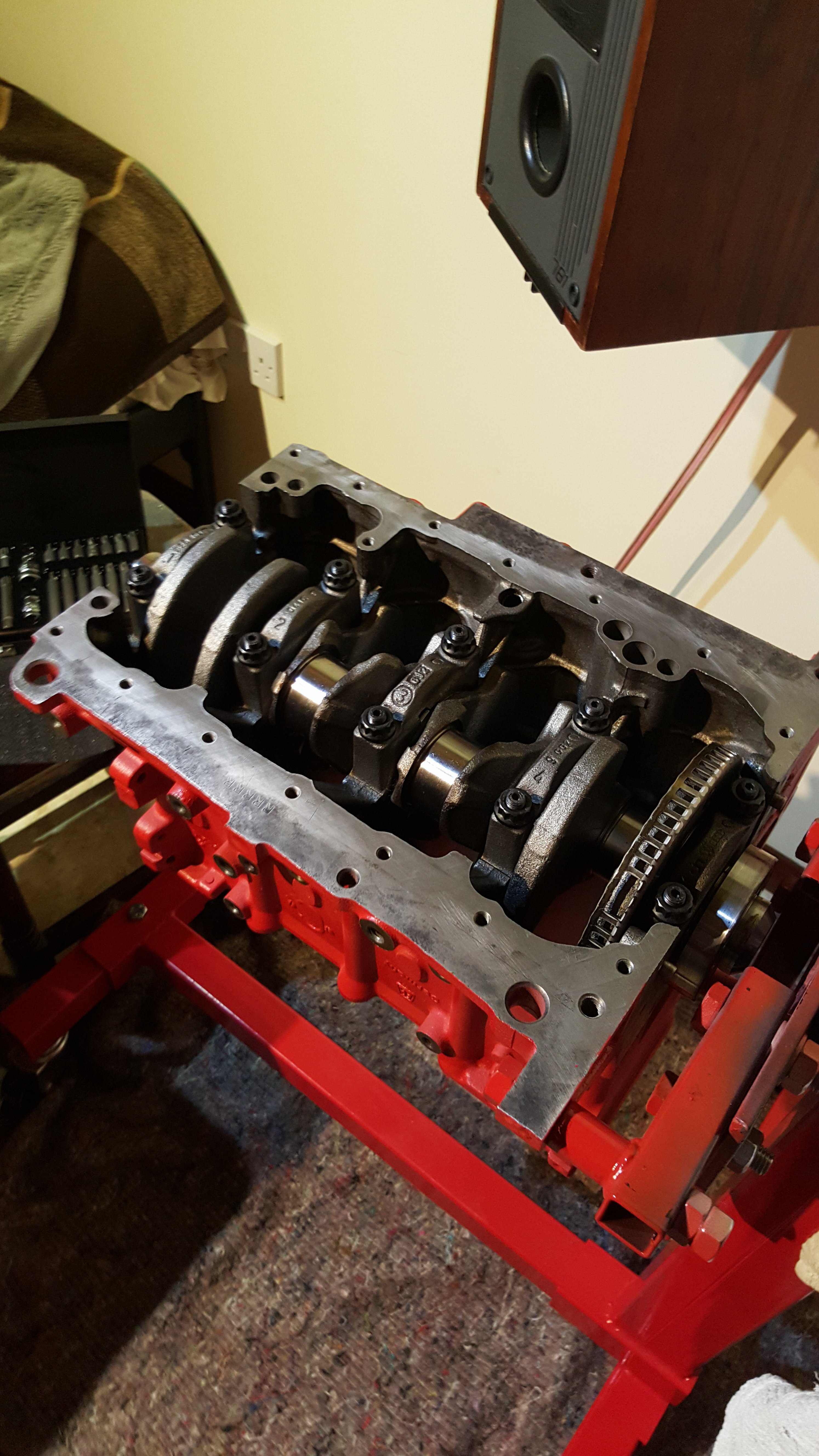

- so busy afternoon today doing the tedious task of gapping the rings and piston to rod assembly. I settled on the gapping being 16/20/15. quick to learn patience is the key to gapping as making sure the ring ends are perfectly parallel is a must for this task to avoid problems further down the build. managed to get 2 pistons and rings all assembled. just 2 left to do tomorrow if the Mrs allows

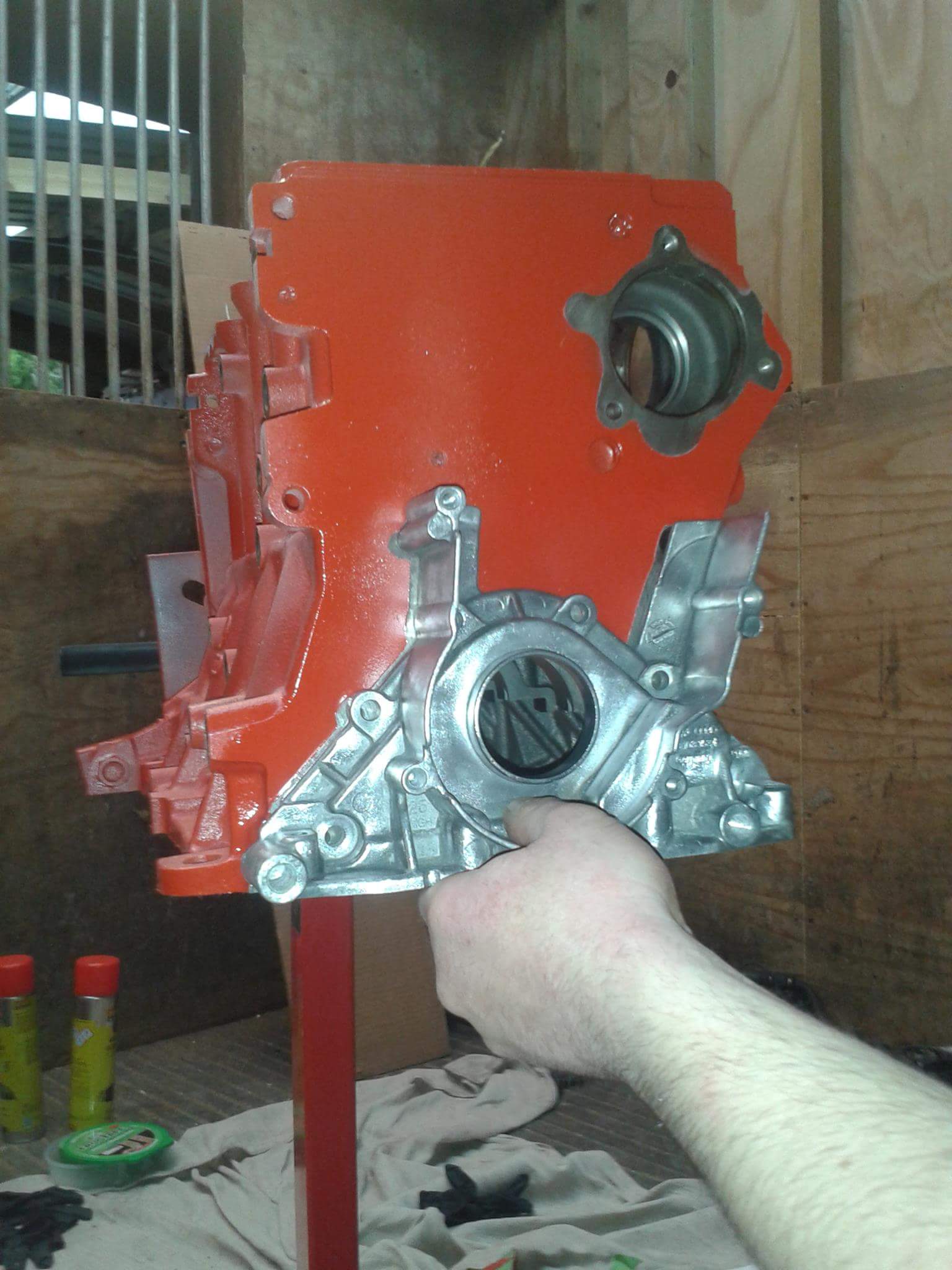

- also managed to get water pump on and cam seal on the flywheel side all all. dont worry the cam gear isn't on yet.. just resting on there

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,386

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

checked oil squirter clearances at bdc yet ?

yes I managed to get that done the other night.. all looking good to me. just currently waiting on a new ring set as broke a ring installing onto number 4 pistons the other night which is a pain in the *** to say the least. will do another update soon.

replacement rings come so managed to get the final piston/rod installed. along with that I got the oil pump and pickup all sorted. I got a bit carried away today and didn't take many pictures but basically bottom end is all done and few other bits like alternator and water lines installed. took a little while to get the TSR baffle insert all in and stilling nicely as was fouling on the sump, arp studs and black plastic oil return cover. sump all on and enough but not too much sealant used. must say it's looking rather lovely now.. just got to wait for the head but in the mean time will prob crack on and get the other engine out the s3 ready for this.

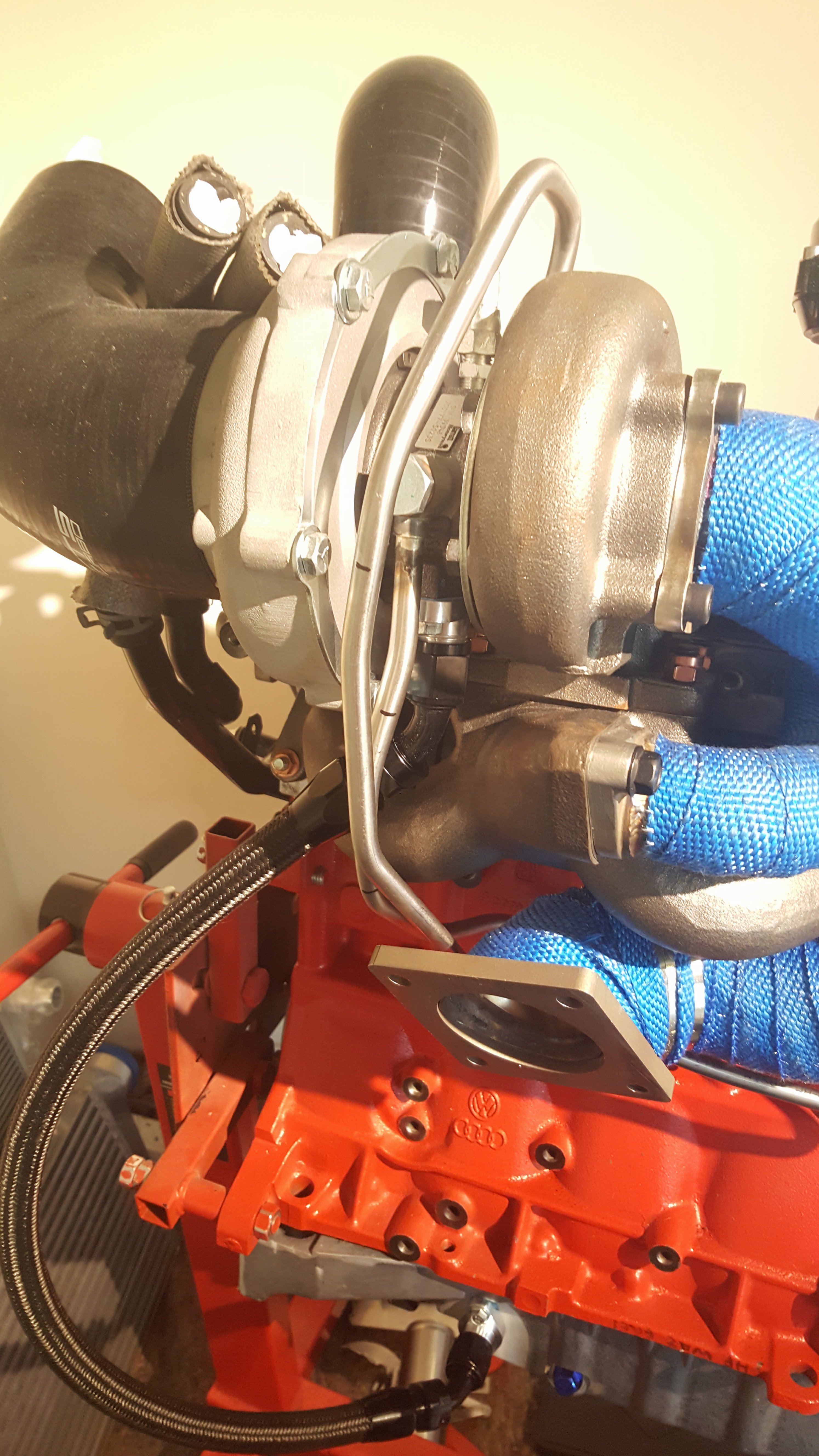

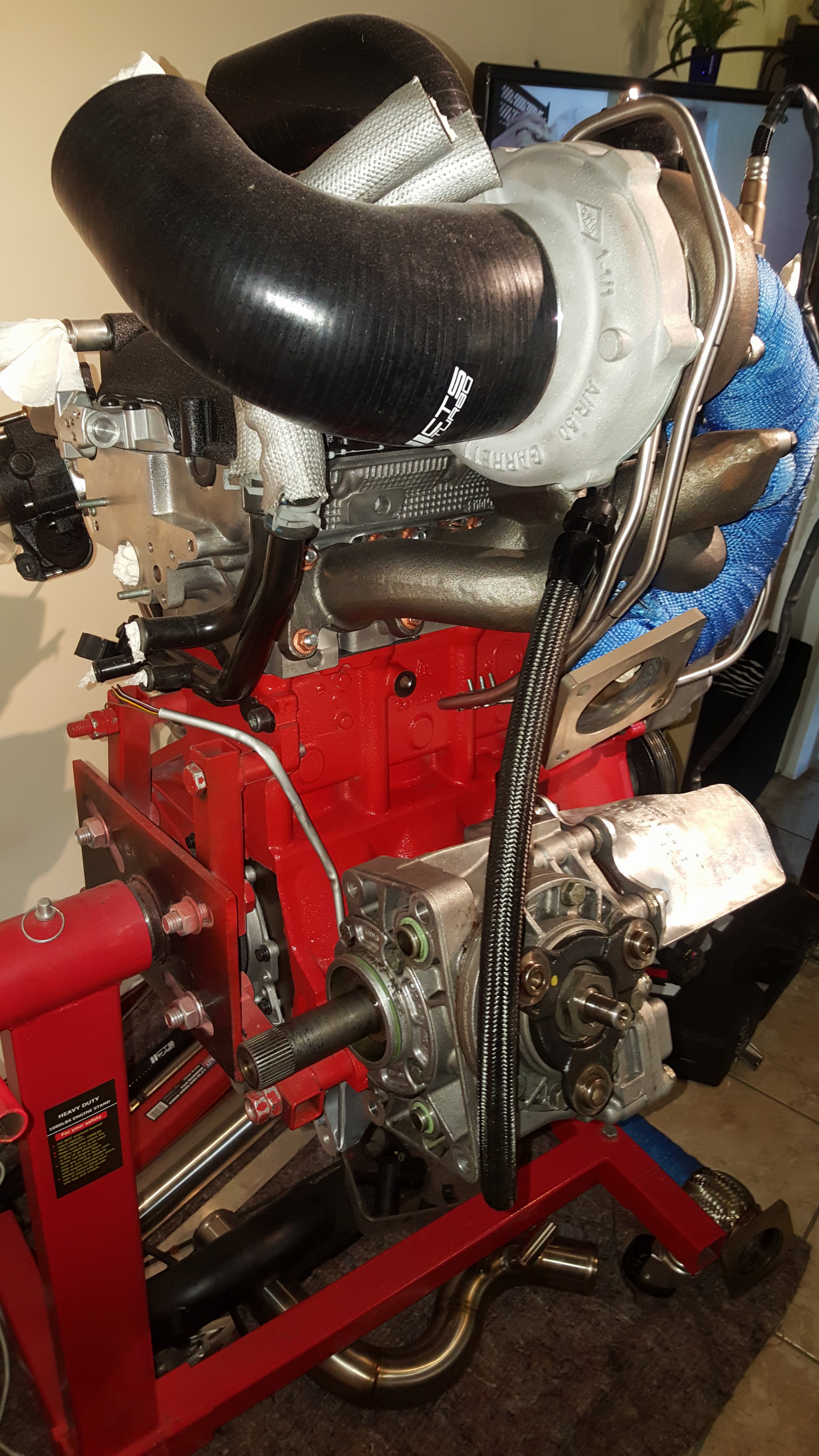

Well I think it's fair to say I have been rather lazy with update on here. But good news is engine is basically built with just the remaining coolant feed and return lines fitted after I have finished making them up. Going for hard ss lines as wasn't happy with the **** cts sent as be running very close to manifold. Going to be a rather picture heavy post but hopefully it looks OK.

First of is the head come back and after sitting it on top of the block and checking everything I noticed that the wrong head gasket had been sent to me so more waiting around for correct one

to come..

to come..

While waiting around I got the old engine out the car and split the box off along with painting on the rocker cover and other bits and bobs.

Will be getting the box all cleaned up this weekend hopefully as can't have a dirty box with a fresh engine

Head gasket come along with a load of other bits I was waiting for like head bolts and few bits off badger.

It soon went from this

To this over a weekend

The uprated coil packs were also fitted along with the plate. I'm not sure tho if the hard boost pipe has been made correctly as I don't see any way of joining to the pipes on the underside so will prob make something up unless anyone has any advise..

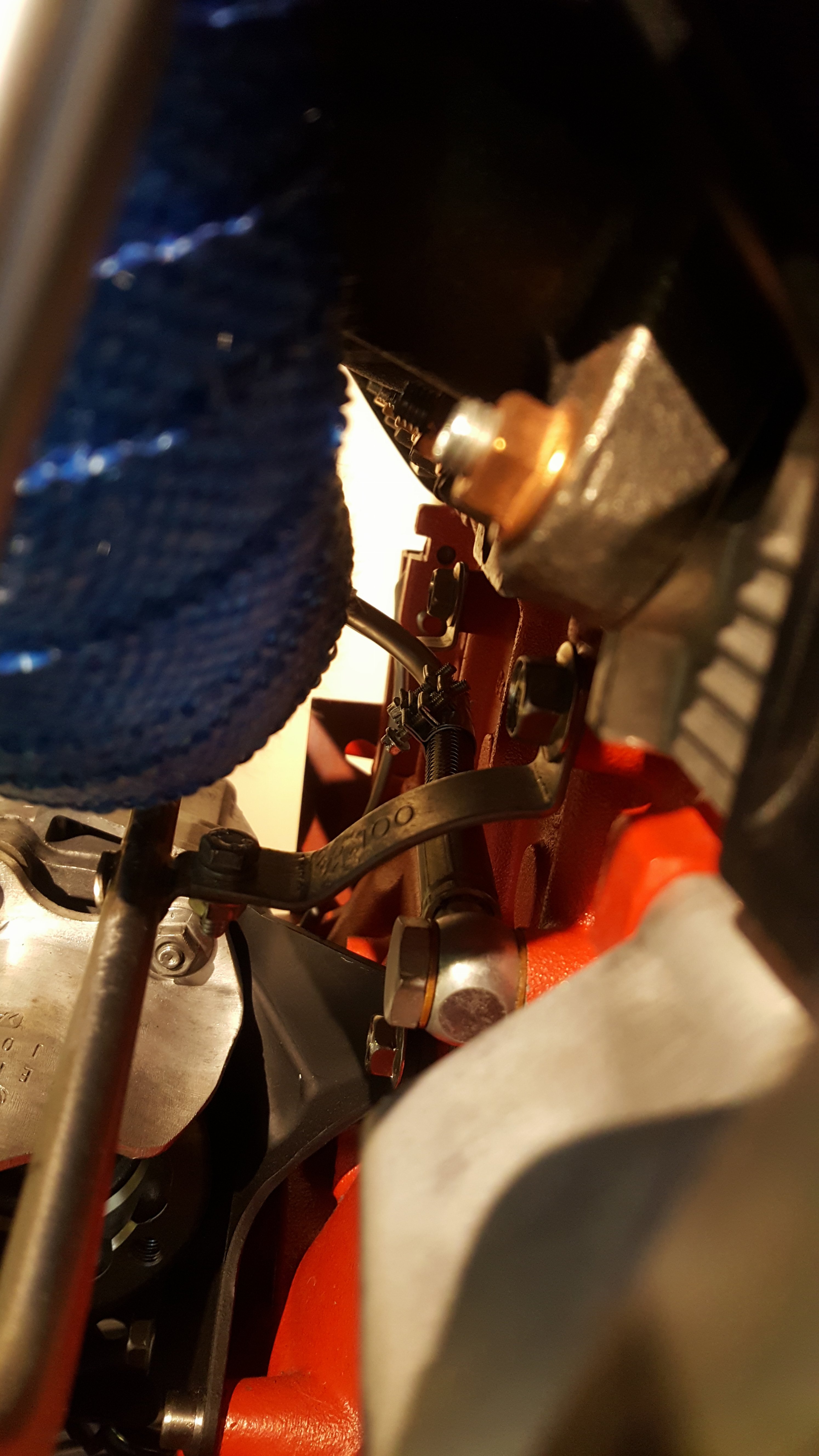

After test fitting everything I got the downpipe all wrapped up to try and keep the Temps down a bit. Got the engine mount fitted along with cover ect and oil feed and return installed however I am yet to make my mind up on the oil return as to weather it will be ok but will get the trasfer box on and decide then. Coolant lines will be finished off this week and put on then it's pretty much ready to go. Everything else has arrived like intercooler.. oil cooler and new rad. All engine mounts have been uprated. Will try and get on here a bit more to update but will get some more pics up when coolant lines are made up and mani is all on with transfer box.

First of is the head come back and after sitting it on top of the block and checking everything I noticed that the wrong head gasket had been sent to me so more waiting around for correct one

While waiting around I got the old engine out the car and split the box off along with painting on the rocker cover and other bits and bobs.

Will be getting the box all cleaned up this weekend hopefully as can't have a dirty box with a fresh engine

Head gasket come along with a load of other bits I was waiting for like head bolts and few bits off badger.

It soon went from this

To this over a weekend

The uprated coil packs were also fitted along with the plate. I'm not sure tho if the hard boost pipe has been made correctly as I don't see any way of joining to the pipes on the underside so will prob make something up unless anyone has any advise..

After test fitting everything I got the downpipe all wrapped up to try and keep the Temps down a bit. Got the engine mount fitted along with cover ect and oil feed and return installed however I am yet to make my mind up on the oil return as to weather it will be ok but will get the trasfer box on and decide then. Coolant lines will be finished off this week and put on then it's pretty much ready to go. Everything else has arrived like intercooler.. oil cooler and new rad. All engine mounts have been uprated. Will try and get on here a bit more to update but will get some more pics up when coolant lines are made up and mani is all on with transfer box.

JonBoi25

Registered User

Great progress so far mate!.

I'm in the process of removing my turbo very soon to do the same.

Engine colour scheme looks very cool!.

I see you kept the gates belt though after recommendations to use oem.

It's a bit catch 22 really but I went with oem after discussion with Bill and tufty.

Keep up the good work mate!.

I'm in the process of removing my turbo very soon to do the same.

Engine colour scheme looks very cool!.

I see you kept the gates belt though after recommendations to use oem.

It's a bit catch 22 really but I went with oem after discussion with Bill and tufty.

Keep up the good work mate!.

Great progress so far mate!.

I'm in the process of removing my turbo very soon to do the same.

Engine colour scheme looks very cool!.

I see you kept the gates belt though after recommendations to use oem.

It's a bit catch 22 really but I went with oem after discussion with Bill and tufty.

Keep up the good work mate!.

Cheers mate.. yer I kind of just was making the colour's up as I was going but I am very pleased with how it's all looking now. I know I was recommended to use OEM but I have always used gates and have yet to experience a problem so fingers crossed it won't let me down again. One recommendation I would say to you that was said to me is stay away from CTS turbo kits.. alot of fitment problems and just a general ball ache. Good luck tho mate

Managed to crack on a bit this weekend so few more pics. Got the trasfer box split and all cleaned up along with the coolant turbo lines all fitted (just needs bracing now) also inlet manifold is all made up and installed to head. Still not 100% sure on how it looks so comments would be appreciated. Hopefully won't be on there for too long as when money has built up again will be looking to treat her to SEM mani

Turned out to be a proper bedroom build my Mrs has been very tolerant having this sexy lady share the bedroom with her

Turned out to be a proper bedroom build my Mrs has been very tolerant having this sexy lady share the bedroom with her

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,077

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

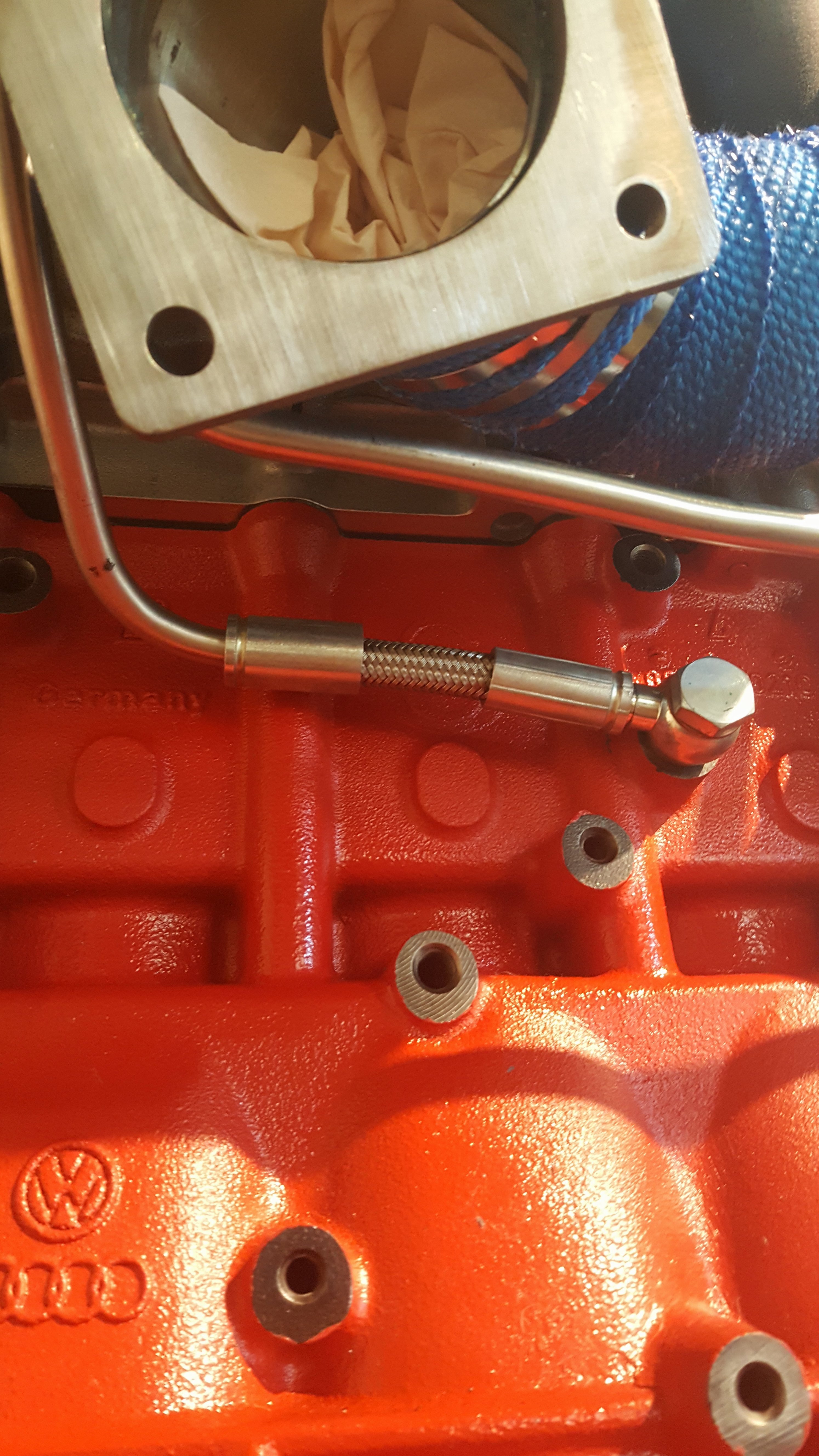

I would suggest putting some sort of bead/swage or similar on the end of the coolant pipe thats in front of the cam belt cover... hoses have a habit of sliding off no matter how tight you think the clip is

<tuffty/>

<tuffty/>

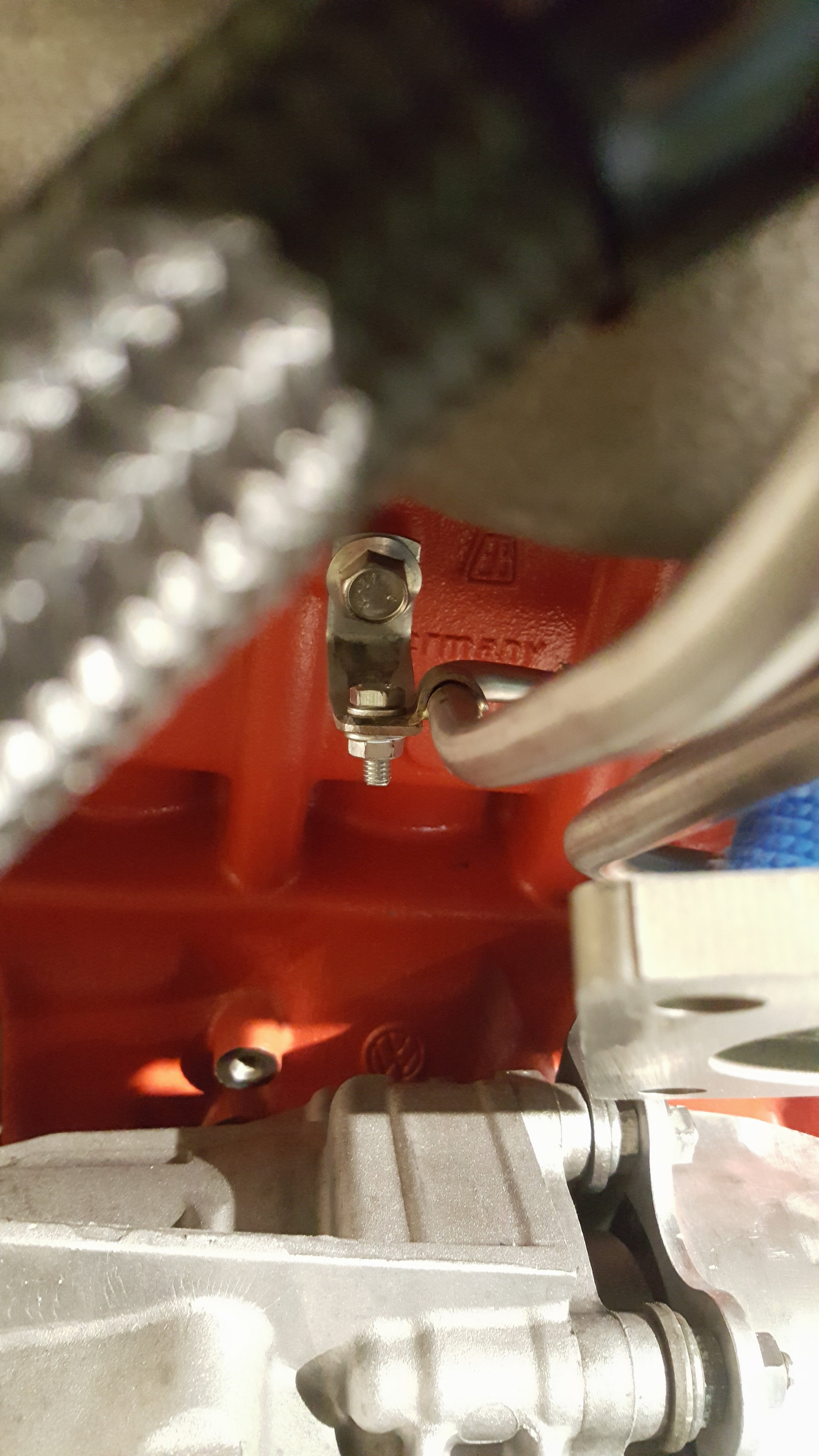

Little update. Both coolant lines have now been braced to the block and a compression fitting has been installed on the end of the coolant feed pipe as suggested by tuffty so cheers for the heads up. Booked some time of work at the end of the month to get it in with hopefully minimal problems. Will update when it's in.

Similar threads

- Replies

- 3

- Views

- 1K