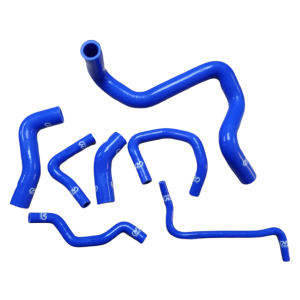

Just in case you were unsure about how bad the lightweight alloy crank dampers are.

Light weight crank pulley for a mk3 golf gti 8v gd or bd?

Hi can anyone help on the brain teaser i have come accross, does a light weight crank pulley play any part in the engines performance output, im...www.clubgti.com

View attachment 249534

If you want to reduce the rotating mass of ancilliaries fit a smaller alternator. Or change the alternator clutch pulley to a larger item as the stock alternator reaches it's 18K RPM limit around 7400 rpm.

Mk1 TT 225 track day car, Officially a ten second car 10.8 seconds at 127 mph.

Been preparing a few things for the gearbox install when it gets warmer in a few months. The Steering wheel I bought I made an aluminium plate for the front to mount the race mode / push to pass switches and the horn. Covered it in some Black Sticky back plastic rather than paint it. Looks OK...www.audi-sport.net

Mk1 TT 225 track day car, Officially a ten second car 10.8 seconds at 127 mph.

Shopping on Ebay again. Decided that the Michelin Pilot Supersports were great and really gave the car loads of grip but on a hot day like Sunday and on a faster track they would probably get ripped up quite quickly. So decided to get some proper track day tyres and put the Michelins on another...www.audi-sport.net

That’s quite an impressive fail! Don’t think I’ve ever seen one as bad.

Sent from my iPhone using Tapatalk