- Joined

- Jul 11, 2011

- Messages

- 1,860

- Reaction score

- 443

- Points

- 83

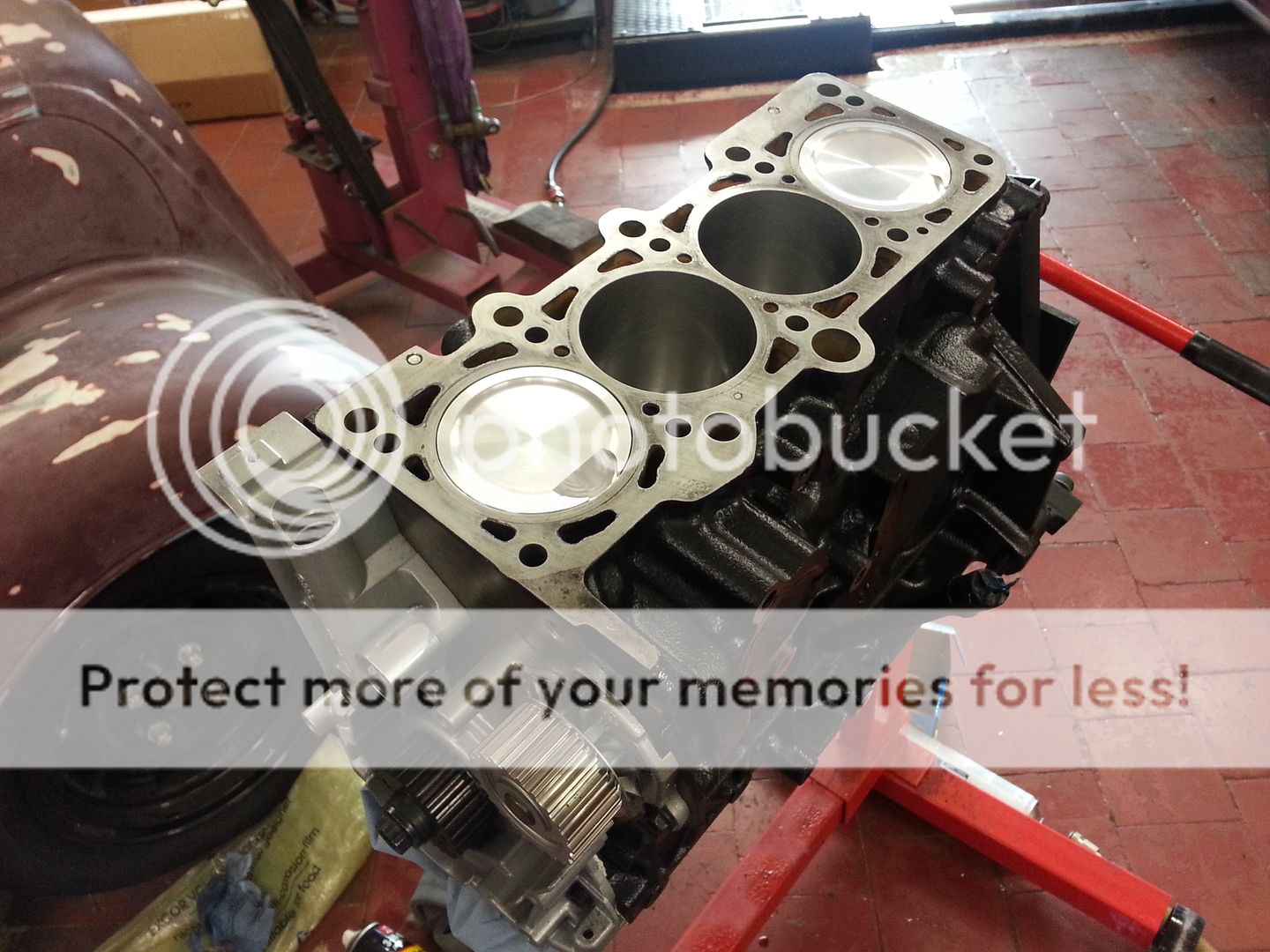

I'm hoping to get my block back from the engineers soon to I can get cracking with this ****** build!

The guy doing the honing phoned me today and said that there's already a lip of AT LEAST (hasn't actually measured it accurately yet) a thou on the bore from wear and even a light hone will take off about 8/10 of a thou... The rings they've ordered me are pre-gapped (mahle), and by the time he's honed the bores he rekons ring gap will be about 27 thou, which he says will lead to leaky bores, high crank case pressures, smokey running and all that lovely stuff

He rekons my best option (and i know he's right) would be to go for an over sized piston and over bore... Which I REALLLLLY don't want to do!!! Mainly cos of the monies $$$'s

So I'm thinking of using a ring that isn't pre-gapped, gapping them my self and still using the AGU pistons I have here...

So as the title suggests, my real question here is what is the maximum acceptable bore size/piston-wall clearance for a hybrid build like this. And what would the ring gap ideally be?

I know I've asked a similar question before but didn't really get the answer I was looking for... I also appreciate that there's loads of information on tolerances on elsawin/internet but as I understand they don't really apply when running high boost and getting the most out of an engine. . .

Brains really in a bit of a pickle over this one, if anyone in the know has some input that'd be very helpful!

thanks in advance guys

The guy doing the honing phoned me today and said that there's already a lip of AT LEAST (hasn't actually measured it accurately yet) a thou on the bore from wear and even a light hone will take off about 8/10 of a thou... The rings they've ordered me are pre-gapped (mahle), and by the time he's honed the bores he rekons ring gap will be about 27 thou, which he says will lead to leaky bores, high crank case pressures, smokey running and all that lovely stuff

He rekons my best option (and i know he's right) would be to go for an over sized piston and over bore... Which I REALLLLLY don't want to do!!! Mainly cos of the monies $$$'s

So I'm thinking of using a ring that isn't pre-gapped, gapping them my self and still using the AGU pistons I have here...

So as the title suggests, my real question here is what is the maximum acceptable bore size/piston-wall clearance for a hybrid build like this. And what would the ring gap ideally be?

I know I've asked a similar question before but didn't really get the answer I was looking for... I also appreciate that there's loads of information on tolerances on elsawin/internet but as I understand they don't really apply when running high boost and getting the most out of an engine. . .

Brains really in a bit of a pickle over this one, if anyone in the know has some input that'd be very helpful!

thanks in advance guys