Hi,

I've recently been prepping for MOT, front discs/pads, front drop links have been changed, I definitely have some NS bearing noise at about 30mph so I know the bearing will need to be replaced at some point but Im not sure its so bad.

The wheel rocks about 1mm from left to right on the wheel test, but not top to bottom, so Im going to try just replacing the track rod ends this sunday and see if it improves.

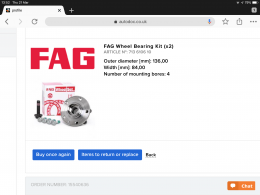

That aside I will replace the bearing hub.

Things I know that obviously need removing off the top of my head: Caliper, caliper carrier, disc (may have forgotten some)

In one video they removed the bottom ball joint and the track rod end, then knocked the driveshaft back. In another video he managed just to remove the 4 spline bolts without doing the rest and had the hub off very quickly, is this possible of does the CV gaitor get in the way?

Thanks.

I've recently been prepping for MOT, front discs/pads, front drop links have been changed, I definitely have some NS bearing noise at about 30mph so I know the bearing will need to be replaced at some point but Im not sure its so bad.

The wheel rocks about 1mm from left to right on the wheel test, but not top to bottom, so Im going to try just replacing the track rod ends this sunday and see if it improves.

That aside I will replace the bearing hub.

Things I know that obviously need removing off the top of my head: Caliper, caliper carrier, disc (may have forgotten some)

In one video they removed the bottom ball joint and the track rod end, then knocked the driveshaft back. In another video he managed just to remove the 4 spline bolts without doing the rest and had the hub off very quickly, is this possible of does the CV gaitor get in the way?

Thanks.