Hi all,

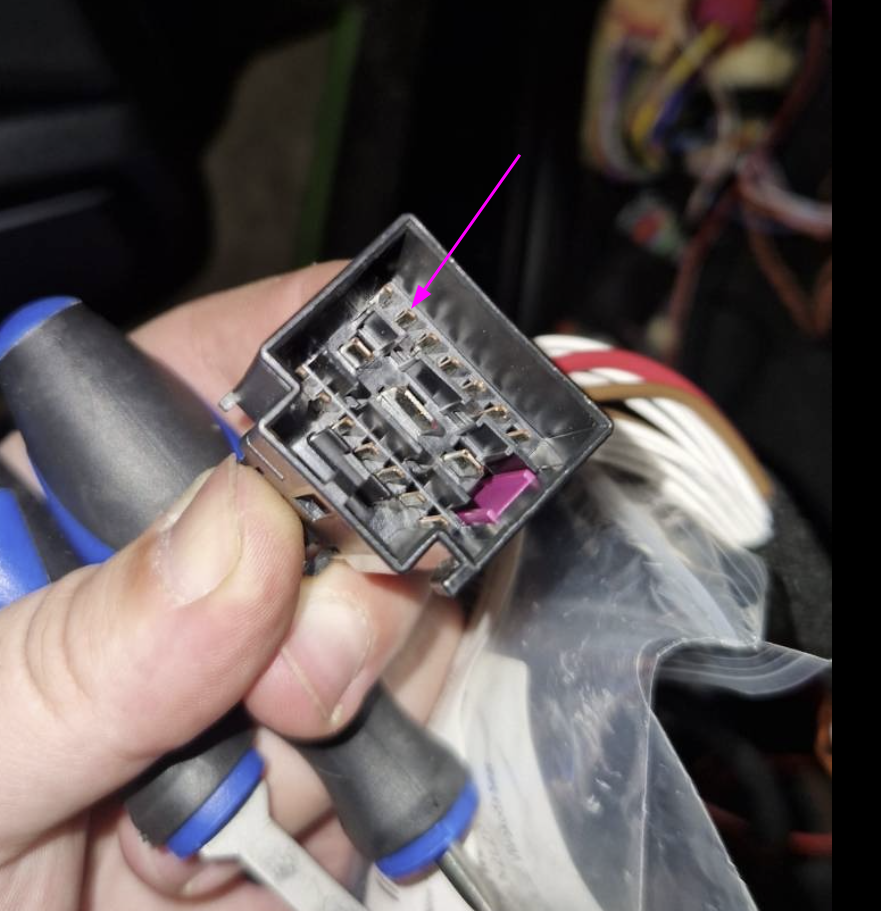

I am trying to identify the pin type in the square black connector in the LHS A-pillar. Specifically the extended CAN pins. Both male and female, and what to search for to buy some.

I ordered every set of VAG loom connection termination types I could find on Amazon and none of them are correct.

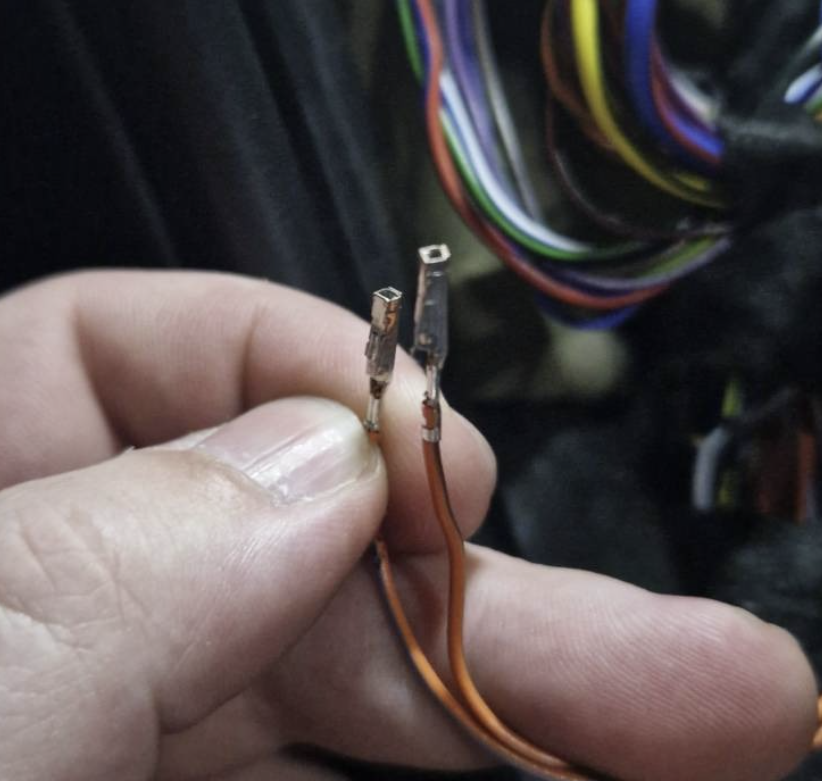

I ordered a direct TPMS kit from eBay and the tap for the extended CAN came with female terminations to re-pin the socket, but the terminations were not right. They fit the socket, but are for round thin pins. The plug's male pins are wider and crush the female pins on the loom (or push them out).

I need to re-terminate the tap of the TPMS loom with the correct female termination so it isn't a bodge job with crushed terminations and fouled male pins.

Annoyingly the range of terminations I ordered came with 20 of these female terminations that fit the socket, but accept thinner pins.

Is there a PN for these?

Summoning using a magic incantation @DJAlix before I absolutely give up. I've not even got to the "No communication" errors in VCDS yet (despite testing continuity to the module via the backside of the socket).

I am trying to identify the pin type in the square black connector in the LHS A-pillar. Specifically the extended CAN pins. Both male and female, and what to search for to buy some.

I ordered every set of VAG loom connection termination types I could find on Amazon and none of them are correct.

I ordered a direct TPMS kit from eBay and the tap for the extended CAN came with female terminations to re-pin the socket, but the terminations were not right. They fit the socket, but are for round thin pins. The plug's male pins are wider and crush the female pins on the loom (or push them out).

I need to re-terminate the tap of the TPMS loom with the correct female termination so it isn't a bodge job with crushed terminations and fouled male pins.

Annoyingly the range of terminations I ordered came with 20 of these female terminations that fit the socket, but accept thinner pins.

Is there a PN for these?

Summoning using a magic incantation @DJAlix before I absolutely give up. I've not even got to the "No communication" errors in VCDS yet (despite testing continuity to the module via the backside of the socket).