BUL Engine Removal

- Thread starter RichMk3

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I've progressed into my first beer mate  Got the engine all out and into the garage for tomorrow...

Got the engine all out and into the garage for tomorrow...

The clutch was definitely on its last legs, being worn completlco smooth, and the flywheel has lots of play in it and rattles like a plumbers toolbox. So hopefully the new kit will fix it.

To be fair, it was not a difficult job at all taking the engine out, much less hassle than I was expecting.

The clutch was definitely on its last legs, being worn completlco smooth, and the flywheel has lots of play in it and rattles like a plumbers toolbox. So hopefully the new kit will fix it.

To be fair, it was not a difficult job at all taking the engine out, much less hassle than I was expecting.

Well that's looks like a very straight forward job chap, how long has it taken thus far to get the lump into the garage and any tricky bits that I should be aware of.

I need to do a cambelt and water pump change in the next few weeks , also need to replace the cam tensioner and variator , clutch is also on my need to do list so it makes sense to remove the lump and do all at the same time.....well that would be my plan .

I need to do a cambelt and water pump change in the next few weeks , also need to replace the cam tensioner and variator , clutch is also on my need to do list so it makes sense to remove the lump and do all at the same time.....well that would be my plan .

just a thought chap, maybe a good time to remove both intercoolers and give them a darn good cleanout with degreaser and let them fully dry out, you wont get a better opportunity , that's also on my to do list, which is getting longer daily now..lol

I started at 8am and just plodded through to be fair. Engine was in the garage just before 3pm and I did it all on my own. I could definitely do it quicker a second time. Probably the most awkward part is getting access to 3 bolts on the bottom of the gearbox, 11 in total holding the box to the engine, the subframe stops you using a socket so you have to use a ring spanner. It's just difficult to get enough leaverage to crack them off.

Also the sheer amount of hidden electrical connectors that need to come off is a pain and I'd definitely recommend labeling them up!

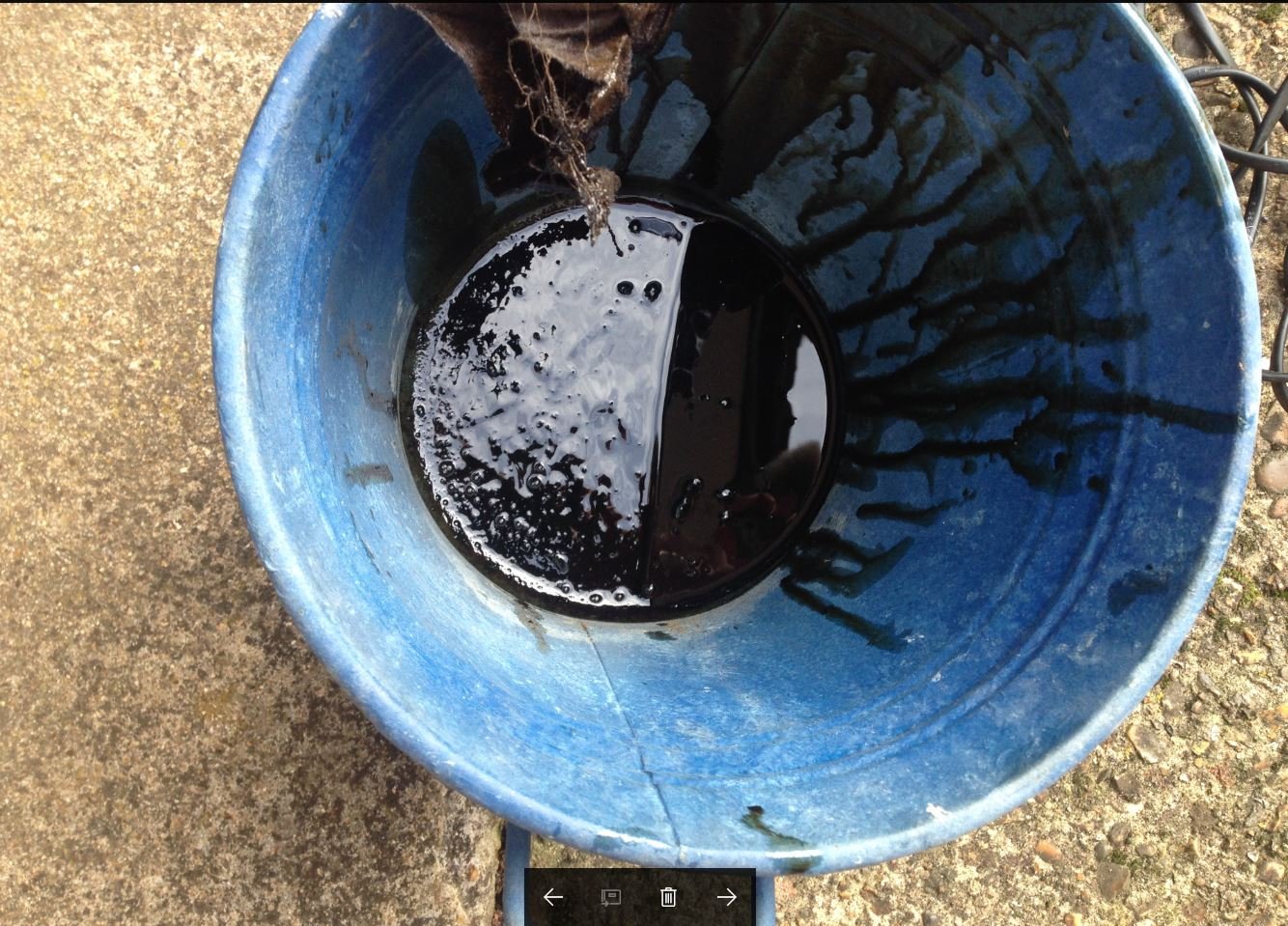

With regard to oil in the intercoolers, my right hand one had virtually a coffee cup worth of oil inside! I couldn't believe just how much had collected. I have a new front mount to fit so thankfully won't have to clean them out.

I've also got a new water pump, thermostat, fuel filter and can belt to fit as well as the dmf and clutch!

Think I'm deffo going to be installing a pcv delete and catch tank after seeing the oil in the IC. How often to you have to empty your tank?

Also the sheer amount of hidden electrical connectors that need to come off is a pain and I'd definitely recommend labeling them up!

With regard to oil in the intercoolers, my right hand one had virtually a coffee cup worth of oil inside! I couldn't believe just how much had collected. I have a new front mount to fit so thankfully won't have to clean them out.

I've also got a new water pump, thermostat, fuel filter and can belt to fit as well as the dmf and clutch!

Think I'm deffo going to be installing a pcv delete and catch tank after seeing the oil in the IC. How often to you have to empty your tank?

Those bellhousing bolts are probably going to be a right pain for me aswell, do they go in from the engine side or from gearbox side ?

The amount of oil that used to be in my IC's was bonkers, don't get a drop now but still need to get them back to spanking clean condition inside, I expect you had this sort of quantity in yours .

I drain my tank fortnightly now and its never full but best to get all that nasty stuff out of the engine full stop....

The amount of oil that used to be in my IC's was bonkers, don't get a drop now but still need to get them back to spanking clean condition inside, I expect you had this sort of quantity in yours .

I drain my tank fortnightly now and its never full but best to get all that nasty stuff out of the engine full stop....

Yeah, same sort of quantity, I couldn't believe it when I pulled the hose off, thought I'd pulled the sump plug!

Those 3 bolts go from the gearbox side into the block, prob about 5" long. A spanner does go on quite easily, it's just difficult to get any force on it while laying on your back with the sump an inch from your nose! If you could do it on a ramp it would be loads easier.

The starter motor also needs to come off, even thou when you look at it it looks like it can stay, but one of the bolts goes into the block.

Just hope I can get the clutch aligned easily with my alignment tool and get it back in as easily as it came out.

If you only need to do cam belt and water pump, access at the front is very good when you remove the rad, condenser and crash bar as a complete assembly, only took me an hour to get to that stage as well.

Those 3 bolts go from the gearbox side into the block, prob about 5" long. A spanner does go on quite easily, it's just difficult to get any force on it while laying on your back with the sump an inch from your nose! If you could do it on a ramp it would be loads easier.

The starter motor also needs to come off, even thou when you look at it it looks like it can stay, but one of the bolts goes into the block.

Just hope I can get the clutch aligned easily with my alignment tool and get it back in as easily as it came out.

If you only need to do cam belt and water pump, access at the front is very good when you remove the rad, condenser and crash bar as a complete assembly, only took me an hour to get to that stage as well.

As I intend on keeping the old bus for a while yet I wanted to get as many of the engine jobs done really , taking the whole lump out would really suit my needs very well to be honest.

The cam tensioner and variator job is a real pain insitu , and the clutch replacement is not much better on the quattro's , I really wanted to do a head decoke, so may aswell go the whole hog and do the cam belt/waterpump too , clean the IC's and fit the newer oil suction pipe .

Seems mad to miss the opportunity to get it all done in one swoop as I wont get the chance again and i'm not paying garage prices either.

I have a weeks hol coming up in july so i'll be aiming to get it done then.

The cam tensioner and variator job is a real pain insitu , and the clutch replacement is not much better on the quattro's , I really wanted to do a head decoke, so may aswell go the whole hog and do the cam belt/waterpump too , clean the IC's and fit the newer oil suction pipe .

Seems mad to miss the opportunity to get it all done in one swoop as I wont get the chance again and i'm not paying garage prices either.

I have a weeks hol coming up in july so i'll be aiming to get it done then.

So I finished early from work for the bank holiday and spent all day today refitting the engine.

Only just knocked it on the head, but managed to get it in and back on the ground. Also fitted the front mount IC and fixed my air con.... Well, ripped the whole lot off to be fair as it was looking like a fairly hefty bill to fix all the knackered bits and it only gets used twice a year anyways.

Not managed to get any pics today cause it lashed it down all day, but I'll update with a few tomorrow for those interested.

Only just knocked it on the head, but managed to get it in and back on the ground. Also fitted the front mount IC and fixed my air con.... Well, ripped the whole lot off to be fair as it was looking like a fairly hefty bill to fix all the knackered bits and it only gets used twice a year anyways.

Not managed to get any pics today cause it lashed it down all day, but I'll update with a few tomorrow for those interested.

Well that's good going chap, pics would be good, any probs getting it back onto the gearbox and shaft...any other odd info that we should know about.

did you get all done yourself or with help in the end and what sort of total time do you estimate it has taken , tea breaks and beer breaks excluded..lol

did you get all done yourself or with help in the end and what sort of total time do you estimate it has taken , tea breaks and beer breaks excluded..lol

I had to enlist the help of my dad (66yo, Mountune ST driving, oldest boyracer in town.. top man!) To help marry the engine back to the gearbox. I would highly recommend using a clutch alignment tool, mine was only cheap but works like a charm.

Thought that the electrical connectors on the back of the engine would be impossible to get to, but turned out to be okay in the end. All in all quite a trouble free job. It took me longer to change a front wheel bearing than remove the engine!

And regard to the FMIC, don't buy a 3" thick one as it's a right pain in the **** to fit.

Thought that the electrical connectors on the back of the engine would be impossible to get to, but turned out to be okay in the end. All in all quite a trouble free job. It took me longer to change a front wheel bearing than remove the engine!

And regard to the FMIC, don't buy a 3" thick one as it's a right pain in the **** to fit.

A few random pics from today, had a productive day and got her running again. Feels like a different car now the dmf and clutch are done.

Forge map sensor adapter...

Intercooler test fit...

Pipework...

Thanks to Derby Performance Hose http://derbyperformancehose.co.uk for supplying the silicone hoses, great price and top quality. Everything made to order and they can make anything custom to your requirement upto 1m in length.

Forge map sensor adapter...

Intercooler test fit...

Pipework...

Thanks to Derby Performance Hose http://derbyperformancehose.co.uk for supplying the silicone hoses, great price and top quality. Everything made to order and they can make anything custom to your requirement upto 1m in length.

Mike Lister

Registered User

Hi, new member here currently wrestling a 2.0 TDI out of a 2010 Q5.

I'm at the splitting stage and even with all the bell housing bolts removed (including the tricky starter motor one) there's something prcenting the motor from sliding out.

It's seperated from the gearbox by about 5mm but it doesn't seem to want to come despite vigorous shuggling.

I take it the DMF comes out with the lump ?

Yours certainly seemed too.

Any help appreciated, thanks

I'm at the splitting stage and even with all the bell housing bolts removed (including the tricky starter motor one) there's something prcenting the motor from sliding out.

It's seperated from the gearbox by about 5mm but it doesn't seem to want to come despite vigorous shuggling.

I take it the DMF comes out with the lump ?

Yours certainly seemed too.

Any help appreciated, thanks