Safety Device

- Thread starter Drue1

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Sep 12, 2010

- Messages

- 34,884

- Reaction score

- 15,949

- Points

- 113

Stewart, send a private message to nick (user prawn) he be able to advise you.  x

x

View Profile: Prawn - Audi-Sport.net

View Profile: Prawn - Audi-Sport.net

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

The best cage fitment I've found so far is the OMP ab105 -202 for the mk4 golf.

The safety devices cages seem a bit hit and miss in the golfs. Let alone the a3 it's not designed for.

Details of my cage install are around August 2011, linked in my build thread in my sig.

The safety devices cages seem a bit hit and miss in the golfs. Let alone the a3 it's not designed for.

Details of my cage install are around August 2011, linked in my build thread in my sig.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

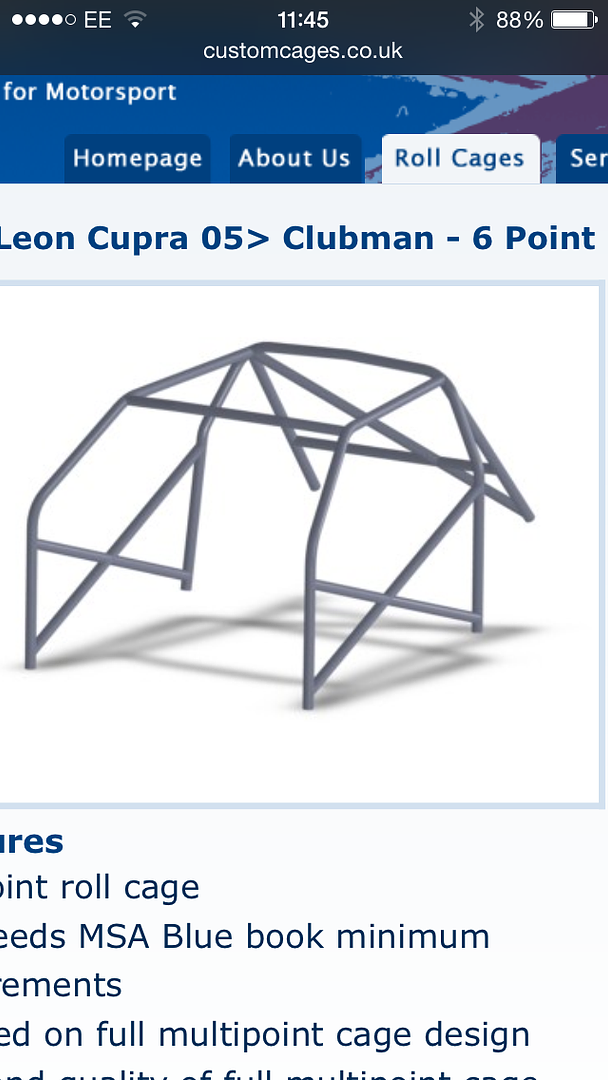

Custom cages want £1800-£2200 to develop a 6 point clubman for the A3/S3.....if you take the plunge it will make it cheaper for the rest of us

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

the OMP multi point is a far more comprehensive cage than the basic clubman 6 point from Custom Cages though, the additional roof crosses and main hoop diagonals were what swung it for me.

Also, Custom Cages won't do the fitted price advertised to put the mk4 cage into an A/S3, because it's not designed for it and would perhaps need alternations. they want the full whack £1800+ to put one in an A3.

At least with the OMP mk4 golf Bolt in we KNOW it'll fit an A3 nicely.

Don't ever be fooled into thinking 'bolt in' means 'easy to install' though. it's still a monumental amount of work!

Also, Custom Cages won't do the fitted price advertised to put the mk4 cage into an A/S3, because it's not designed for it and would perhaps need alternations. they want the full whack £1800+ to put one in an A3.

At least with the OMP mk4 golf Bolt in we KNOW it'll fit an A3 nicely.

Don't ever be fooled into thinking 'bolt in' means 'easy to install' though. it's still a monumental amount of work!

Also, Custom Cages won't do the fitted price advertised to put the mk4 cage into an A/S3, because it's not designed for it and would perhaps need alternations. they want the full whack £1800+ to put one in an A3.

very true

Did you get the cross welded into yours as I don't like just the one bar across ?

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Sadly the pic on the DT website is an utter joke and doesn't represent the cage you get at all.

the cage as supplied has a full X in the main B hoop, a single diagonal in the rear stays, and a full X above the drivers head.

For me, the Main hoop Cross and the cross above the drivers head add WAY more rigidity than an unbraced standard clubman 6 point.

This is the cage as supplied, the only addition being the door bars:

And the certificate that came with it, mine is an AB105-202H, which I BELIEVE is a little cheaper than the full multipoint shown above, as I paid around £650 + VAT at the time.

the cage as supplied has a full X in the main B hoop, a single diagonal in the rear stays, and a full X above the drivers head.

For me, the Main hoop Cross and the cross above the drivers head add WAY more rigidity than an unbraced standard clubman 6 point.

This is the cage as supplied, the only addition being the door bars:

And the certificate that came with it, mine is an AB105-202H, which I BELIEVE is a little cheaper than the full multipoint shown above, as I paid around £650 + VAT at the time.

i understand more bars mean a stiffer cage, but surely a weld in cage with gussets to the car would be stiffer than a bolt in cage with more bars?

Not sure if what I've been told is true but someone said to me that a bolt in cage is a 'semi floating' cage to protect the occupants and clearly offers chassis stiffness by the very nature of the fact its bolted to the car, and a weld in cage becomes almost part of the chassis as much as a safety cell, the guy that told me works for Jaguar land rover and tests the cars, they use bolt in cages to test the chassis structure in rollovers but won't want a weld in cage as they need to test the actual cars integrity

Not sure if what I've been told is true but someone said to me that a bolt in cage is a 'semi floating' cage to protect the occupants and clearly offers chassis stiffness by the very nature of the fact its bolted to the car, and a weld in cage becomes almost part of the chassis as much as a safety cell, the guy that told me works for Jaguar land rover and tests the cars, they use bolt in cages to test the chassis structure in rollovers but won't want a weld in cage as they need to test the actual cars integrity

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

i understand more bars mean a stiffer cage, but surely a weld in cage with gussets to the car would be stiffer than a bolt in cage with more bars?

yep

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Worth remembering that a 'weld in' cage is equally open to interpretation as a 'bolt in'. there are good and bad of each. A good bolt in can be far superior to a bad weld in, but the ultimate of of course a full weld in multi point.

The basic Custom Cages 6 point clubman is just that, 6 points of contact, 2 front legs, 2 main legs, and 2 rears stays, and not otherwise tied to the shell without additional cost and labour.

I can't see that, anchored at those 6 points only , being stiffer than a more comprehensive bolt in cage anchored at the same points.

it's the ties into the shell that add the stiffness, and the triangulation, whether bolted or welded in.

mine is technically a bolt in, as at the 6 feet of the legs it bolts to boxes welded into the car, but it's also tied into the shell via 6 welded gussets at high level to eliminate all of the creaking and flexing usually associated with bolt in cages. This flexing isn't limited to bolt in cages only though, as you get exactly the same creaking with very simple 6 point weld in's.

In short - do it as properly as you possibly can, and tie it into the shell at each and every given opportunity regardless of which route you take.

The basic Custom Cages 6 point clubman is just that, 6 points of contact, 2 front legs, 2 main legs, and 2 rears stays, and not otherwise tied to the shell without additional cost and labour.

I can't see that, anchored at those 6 points only , being stiffer than a more comprehensive bolt in cage anchored at the same points.

it's the ties into the shell that add the stiffness, and the triangulation, whether bolted or welded in.

mine is technically a bolt in, as at the 6 feet of the legs it bolts to boxes welded into the car, but it's also tied into the shell via 6 welded gussets at high level to eliminate all of the creaking and flexing usually associated with bolt in cages. This flexing isn't limited to bolt in cages only though, as you get exactly the same creaking with very simple 6 point weld in's.

In short - do it as properly as you possibly can, and tie it into the shell at each and every given opportunity regardless of which route you take.

yup, gussetted are clearly stronger, one thing that test guy that i spoke too once said is you shouldn't gusset a bolt in cage to the shell, no idea if thats the case, simply repeating what i have been told, he said they are designed to be bolted in at the points designated, also that they are fine to add bars in within themselves as long as they dont fix to the car other than where they should - again though just repeating what i was told.

From a totally uneducated on the subject point of view i cannot see whether the whole cage is welded in at those 6 points or just the foot plates are and then the cage bolted to them makes any difference with respect to them being tied into the shell at further points, only thing that then differs is the rest of the cage thats bolted together rather than welded, I'm sure lots of people have differing opinions on it too.

From a totally uneducated on the subject point of view i cannot see whether the whole cage is welded in at those 6 points or just the foot plates are and then the cage bolted to them makes any difference with respect to them being tied into the shell at further points, only thing that then differs is the rest of the cage thats bolted together rather than welded, I'm sure lots of people have differing opinions on it too.

From the pic you can't see the cross but yours is perfect.I take it the one that goes to each strut sets it off nicely but thanks very much for the pics.How was it like spraying the cage inside the car ?

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

one thing that test guy that i spoke too once said is you shouldn't gusset a bolt in cage to the shell

I'd definitely disagree on that one.

The box feet on mine at the sills are identical to those you'd install a weld in cage on, simply the legs have plates on the ends, and those plates bolt to the feet.

If I ran a mig welder around the feet of mine (Which I intend to do at some point), then I can't see how it becomes any different to a weld in cage at all really.

Obviously we'd all like a full weld in multi point if we won the lottery though

I'd definitely disagree on that one.

The box feet on mine at the sills are identical to those you'd install a weld in cage on, simply the legs have plates on the ends, and those plates bolt to the feet.

If I ran a mig welder around the feet of mine (Which I intend to do at some point), then I can't see how it becomes any different to a weld in cage at all really.

Obviously we'd all like a full weld in multi point if we won the lottery though

So would welding the feet to the box plates be ok for MSA rules as from next year I will doing hill climbs in my s3

Sam_

Down under

If you're going to the effort, would it not be wise to do it properly and add points to brace the front turrets?

Unrelated but I was building a 306 track car before I left the UK back in 06 and used the BTCC design as a guide (cage wasn't built by me):

Unrelated but I was building a 306 track car before I left the UK back in 06 and used the BTCC design as a guide (cage wasn't built by me):

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

So would welding the feet to the box plates be ok for MSA rules as from next year I will doing hill climbs in my s3

I guess it depends on what rules you're working to.

Mine is FIA compliant as per this cert:

But not MSA compliant being bolt in I believe. I've been told that to be MSA compliant I'd have to weld my harness bar into place not on the 12.9 grade bolts it's on currently) and weld the feet in permanently.

How true this is I'm not sure as I have no need to look into it further, but I have no reason to doubt it.

Sam, the cage you posted is gorgeous, but you're looking at an easy £2k+ to buy and install, vs under 1k for a good bolt in.

It depends what you're after, roll over protection with some increased chassis stiffness, or the last line in top level race car chassis prep. One costs double the other, pick which one best suits your requirements

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

unless its changed bolt in cages are allowed... plenty of them in combe saloons

bolt down straps also ok, where appropriate spreader plates being used.

lap belts are thru eyelets into floor with reinforcing plates under them on many.

Consult the msa blue book for 100% rule of course

bolt down straps also ok, where appropriate spreader plates being used.

lap belts are thru eyelets into floor with reinforcing plates under them on many.

Consult the msa blue book for 100% rule of course

Ahh that all makes sense now as really couldn't get my head round why the OMP looked dearer than other simular cages but as you have pointed out the pic is far from the reality of what you get

I'm leaning towards the CC clubman and adding extra supports in to keep the costs down and quite fancy doing it myself

I was really keen on the multipoint due to the beam behind the dash to stop unwanted items from the bay entering the cabin should the worse happen, but don't think i can bring myself to hack the dash apart and cut through to get to the front turrets

I'm leaning towards the CC clubman and adding extra supports in to keep the costs down and quite fancy doing it myself

I was really keen on the multipoint due to the beam behind the dash to stop unwanted items from the bay entering the cabin should the worse happen, but don't think i can bring myself to hack the dash apart and cut through to get to the front turrets

So if you welded in a Fia bolt in cage would it it be ok for MSA or is that a grey area ? Not that I'm going to do time attack only sprinting and hill climbs but yet to do a hill climb as I broke my evo for sparesI guess it depends on what rules you're working to.Mine is FIA compliant as per this cert:But not MSA compliant being bolt in I believe. I've been told that to be MSA compliant I'd have to weld my harness bar into place not on the 12.9 grade bolts it's on currently) and weld the feet in permanently.How true this is I'm not sure as I have no need to look into it further, but I have no reason to doubt it.Sam, the cage you posted is gorgeous, but you're looking at an easy £2k+ to buy and install, vs under 1k for a good bolt in.It depends what you're after, roll over protection with some increased chassis stiffness, or the last line in top level race car chassis prep. One costs double the other, pick which one best suits your requirements

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 1

- Views

- 650