Dane's Hybrid Conversion Thread

- Thread starter Dane

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Morgan-VAGCHECK

Foot to the floor

- Joined

- Jan 31, 2007

- Messages

- 103

- Reaction score

- 2

- Points

- 16

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

This AM at cold startup, our tester tried feeling around the flange for leaks. Nothing. We're looking into seafoaming it. Yeesh.

I got the PM, Bill.

I got the PM, Bill.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Do you have a 118 log you can share Bill ?

hi morgan

from yesterdays running, on CR's actuator with preload etc

Code:

Group C: '118

RPM Temperature Load Absolute Pres.

TIME

STAMP /min °C % mbar

29.97 1600 33 70.2 1020

31.17 1600 30 94.5 1100

32.27 2000 27 94.5 1170

33.49 2520 26 94.5 1360

34.72 3080 26 77.3 1680

35.92 3600 25 72.5 1950

37.13 4120 25 73.7 1980

38.34 4600 26 79.2 2030

39.52 5080 27 80.8 2050

40.74 5560 29 89.8 2170

41.96 6040 30 94.5 2150

43.06 6440 32 94.5 2070

44.26 6880 34 94.5 1990

45.46 7320 36 94.5 2000to put the above into context.. CR actuator, same setup as above just different logs

Code:

'115

RPM Load Absolute Pres. Absolute Pres.

/min % mbar mbar

1560 34.6 1010 1020

1600 68.4 1540 1010

1720 79.7 1720 1100

2240 93.2 2010 1230

2760 112 2020 1450

3320 160.9 2000 1980

3920 173.7 2000 2110

4440 176.7 2200 2140

5080 183.5 2370 2180

5720 191.7 2550 2260

6240 186.5 2550 2260

6640 175.9 2550 2190

7040 172.2 2550 2170

7360 164.7 2540 2140

Last edited:

- Joined

- Dec 2, 2008

- Messages

- 17,400

- Reaction score

- 1,104

- Points

- 113

That is the weirdest thing I have seen in a while.... :-/

What are we looking at, the boost fluctuating up and down?

What are we looking at, the boost fluctuating up and down?

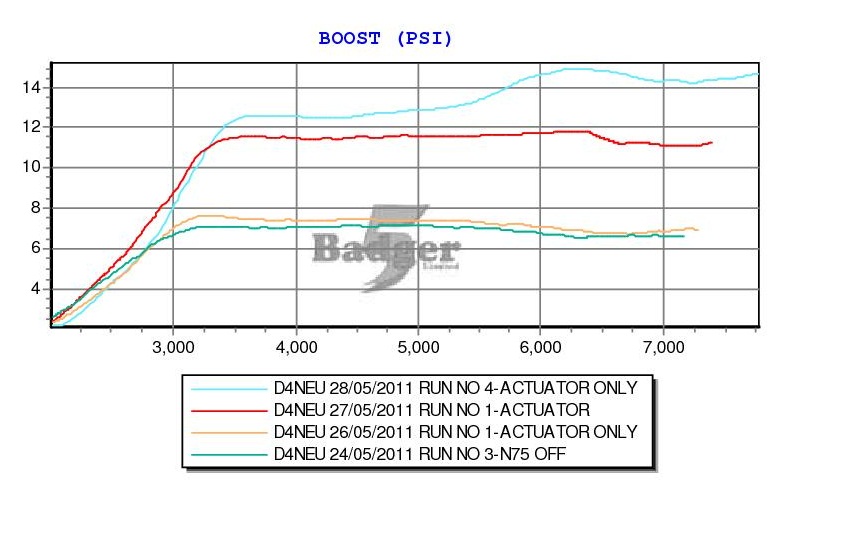

I just meant the situation in general. If the actuator cracks open at 14 PSI when pressure tested, and then the car is run with N75 electrically disconnected (meaning actuator pressure), it should see that pressure as tested manually (14 PSI).

However, the turbo on actuator pressure during load is only making 7.5 PSI.

Makes no sense AT ALL.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

What are we looking at, the boost fluctuating up and down?

no.. the map I have started with is speedysteves... which was always bring in boost slowly setup.

Whats odd on Danes is actuator pressure bares no resemblance to what its set to.. and way too low. (such that I think wastegate is being pushed open by the manifold pressure)

Wellys ran 12psi actuator pressure, but, true to form the actuator which was sent on Wellys turbo, when it was refurbished, did'nt return with the unit, and some "other" one came back. A 10psi one.. which wont hold more than 8.5psi with a lot of preload added. I have changed it out to forge one which starts to open, hooked onto the turbo in situ @ 14psi.. but when you run the car up it only ran 7.5psi boost..

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

- Joined

- Dec 2, 2008

- Messages

- 17,400

- Reaction score

- 1,104

- Points

- 113

Has anyone complained to CR about them swapping over perfectly decent actuators for gash weak ones?

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

I will check forge have fitted the spring I asked for... and if its not what I said I wanted I have some on the shelf to swap out..

its now cold again, so when I swap back of the LCR I am also doing @ same time, I will remove the actuator "again"

its now cold again, so when I swap back of the LCR I am also doing @ same time, I will remove the actuator "again"

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

Morgan-VAGCHECK

Foot to the floor

- Joined

- Jan 31, 2007

- Messages

- 103

- Reaction score

- 2

- Points

- 16

hi morgan

from yesterdays running, on CR's actuator with preload etc

Code:Group C: '118 RPM Temperature Load Absolute Pres. TIME STAMP /min °C % mbar 29.97 1600 33 70.2 1020 31.17 1600 30 94.5 1100 32.27 2000 27 94.5 1170 33.49 2520 26 94.5 1360 34.72 3080 26 77.3 1680 35.92 3600 25 72.5 1950 37.13 4120 25 73.7 1980 38.34 4600 26 79.2 2030 39.52 5080 27 80.8 2050 40.74 5560 29 89.8 2170 41.96 6040 30 94.5 2150 43.06 6440 32 94.5 2070 44.26 6880 34 94.5 1990 45.46 7320 36 94.5 2000

Hi Bill,

Hmm you would certainly kinda expect more boost than is being seen with that N75 DC even with the oddly behaving actuator.

I think you might have hit the nail on the head that the wastegate flapper is being forced open by the exhaust gasses.

In fact I did experience something similar myself although nowhere near to such a large degree.. at the time I put it down to the tubular manifolds better flow, & also the fact the wastegate had been quiet heavily ported (since previous testing)

Funnily enough we also had some issues with the CR supplied actuator that was fitted when the thrust bearing was replaced, & I ended up having to get another one from them. Albeit what happened in our case was we would set our desired crack pressure do a couple of runs on the dyno with each run making a little less boost than the previous.

On checking the actuator the crack pressure had dropped, we added some more pre-load to get back to where we wanted it only for it to drop off again within a few more runs.

Whether the radiant heat being generated from the sustained tests was having an affect on the spring, or the spring itself wasn't up to much I dunno.. but once swapped for the replacement actuator together with a small heat shield made for it we didn't experience any more more probs.

For reference with the replacement actuator set to crack at 0.75bar, 1.75bar+ boost was possible at the top end without the N75 DC being anywhere near maxed out.

Anyway good luck with it, I am sure you will get to the bottom of it.

Regards

Morgan

Last edited:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Hi Bill,

Hmm you would certainly kinda expect more boost than is being seen with that N75 DC even with the oddly behaving actuator.

I think you might have hit the nail on the head that the wastegate flapper is being forced open by the exhaust gasses.

In fact I did experience something similar myself although nowhere near to such a large degree.. at the time I put it down to the tubular manifolds better flow, & also the fact the wastegate had been quiet heavily ported (since previous testing)

Funnily enough we also had some issues with the CR supplied actuator that was fitted when the thrust bearing was replaced, & I ended up having to get another one from them. Albeit what happened in our case was we would set our desired crack pressure do a couple of runs on the dyno with each run making a little less boost than the previous.

On checking the actuator the crack pressure had dropped, we added some more pre-load to get back to where we wanted it only for it to drop off again within a few more runs.

Whether the radiant heat being generated from the sustained tests was having an affect on the spring, or the spring itself wasn't up to much I dunno.. but once swapped for the replacement actuator together with a small heat shield made for it we didn't experience any more more probs.

For reference with the replacement actuator set to crack at 0.75bar, 1.75bar+ boost was possible at the top end without the N75 DC being anywhere near maxed out.

Anyway good luck with it, I am sure you will get to the bottom of it.

Regards

Morgan

thanks morgan..

I am hoping I am not going mad..

actuator was removed and refitted yet again.. oh joys... (the CR one behaved exactly as you describe.. it would be set, and then run less and less......)

I removed the red spring out of the forge one, which cracked open off the car at 13psi. I have fitted a white spring now, which is beefy, and checked back on the turbo again with preload its cracking open at 18psi... which is way higher than I would ever choose, BUT given the experience up to now that actual boost runs some several psi less than this static test I am hedging my bets.

Gods knows.

back on the dyno in a short while.

cars eh!

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

...the CR one behaved exactly as you describe.. it would be set, and then run less and less......

?

How is such behavior possible? It seems almost diabolical of a parts maker to do such a thing.

- Joined

- Dec 18, 2005

- Messages

- 16,775

- Reaction score

- 2,628

- Points

- 113

?

How is such behavior possible? It seems almost diabolical of a parts maker to do such a thing.

It does need mentioning to them,someone has gained a decent one along the way

Morgan-VAGCHECK

Foot to the floor

- Joined

- Jan 31, 2007

- Messages

- 103

- Reaction score

- 2

- Points

- 16

Hi,

I think the actuators CR use "might" be Garret ones, although I am not 100% certain on this.

When I discussed the actuator behaviour with CR they said it was not an issue any other K04.2x hybrid user had previously reported.

Regards

Morgan

I think the actuators CR use "might" be Garret ones, although I am not 100% certain on this.

When I discussed the actuator behaviour with CR they said it was not an issue any other K04.2x hybrid user had previously reported.

Regards

Morgan

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

Well my thoughts are, I've had to buy a forge actuator, not something I would of had to do if the one supplied was working properly

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Hi,

I think the actuators CR use "might" be Garret ones, although I am not 100% certain on this.

When I discussed the actuator behaviour with CR they said it was not an issue any other K04.2x hybrid user had previously reported.

Regards

Morgan

I have had this "line" from them also.. Reality is somewhat different to what you get told.

My Patience has run out.

Last edited:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

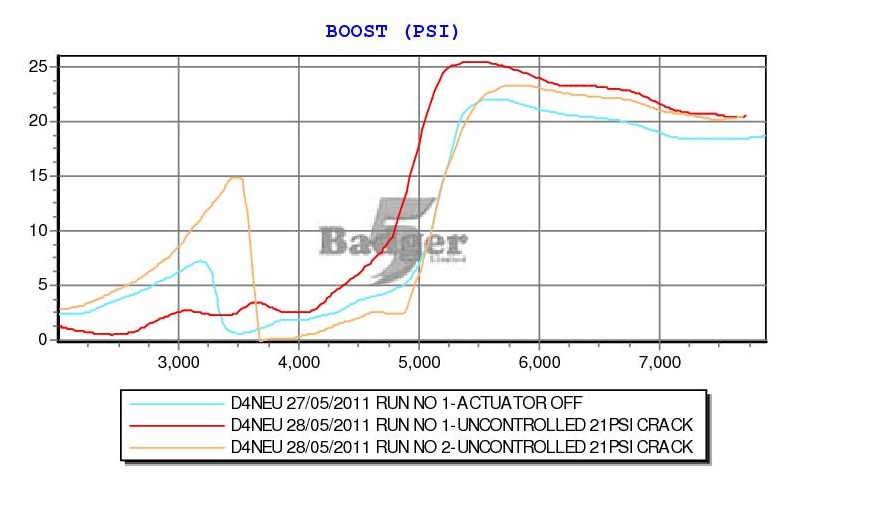

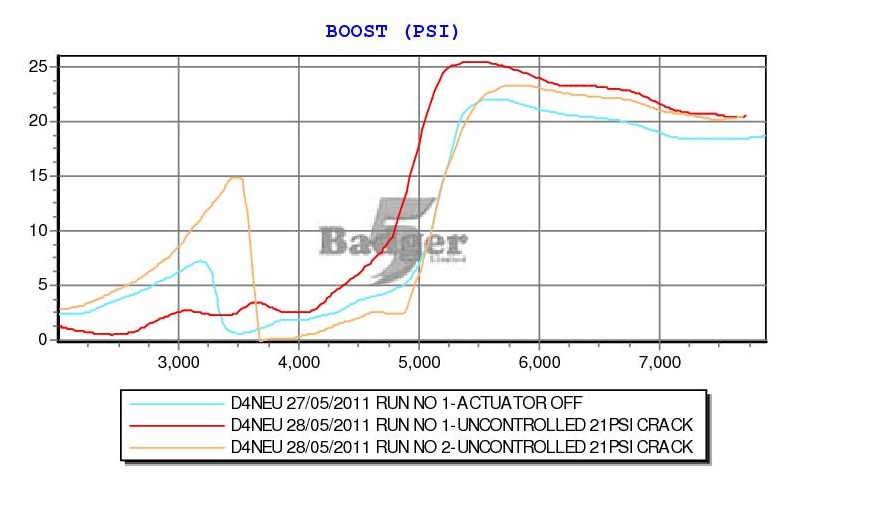

an interesting comparison of Wellys when it ran its best power, vs danes on n75/ecu control, vs actuator disconnected (careful) run.

wot only applied on the disconnected run at just before 5krpm - note the boost is the same as wellys

wot only applied on the disconnected run at just before 5krpm - note the boost is the same as wellys

Last edited:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

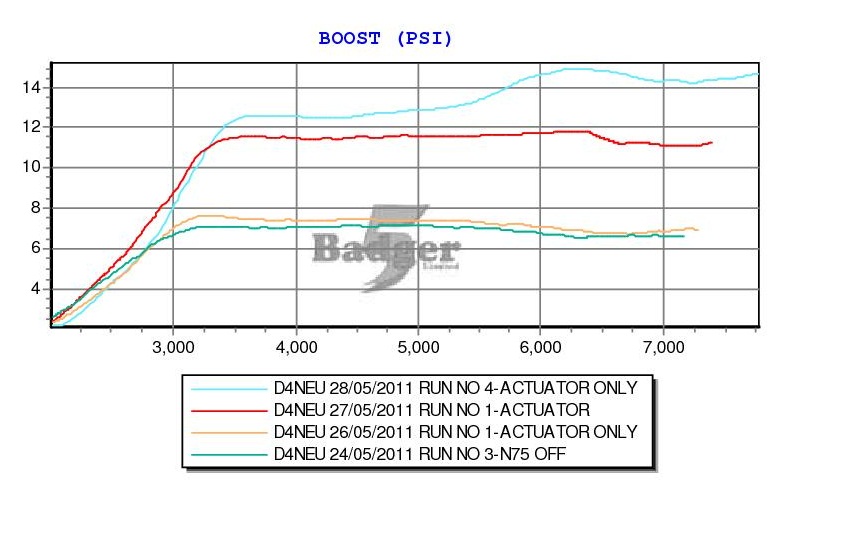

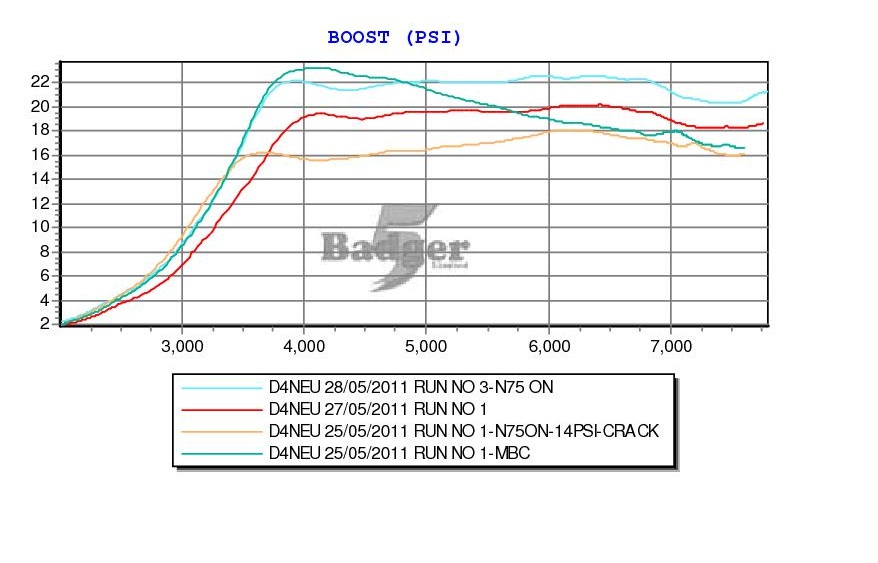

interesting stuff ahead (for some)

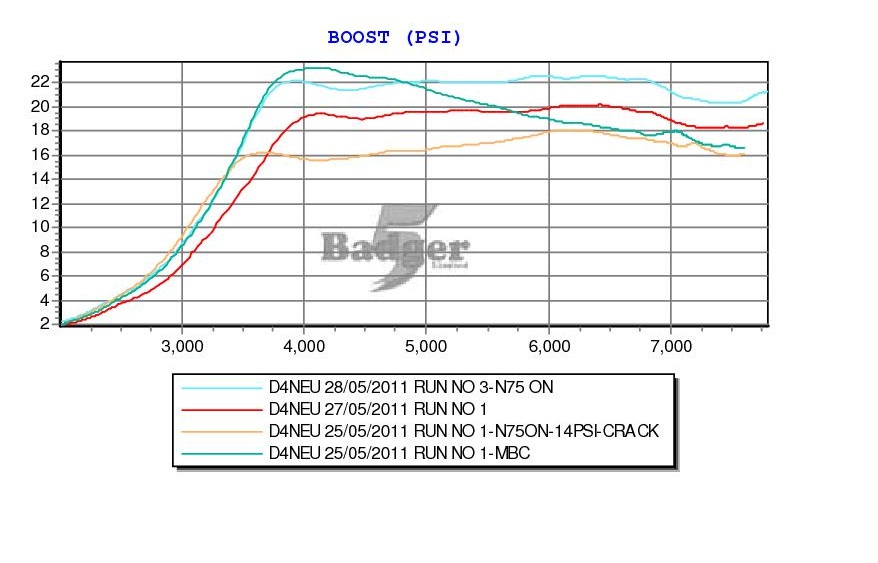

comparison of a very tweaked forge actuator, white spring, which cracks open at 21psi, vs the previous setting of 18psi (I have added as much preload as it has travel for... and slightly too much - see further)

We have held an additional 1-2psi, now holding 20-21psi where 18psi was what it held earlier. (wastegate is being pushed open is my thought-must be quite some manifold pressure there, acting on the larger surface area of the wastegate penny.. 660mm^2 now from 452mm^2 of a stock exhaust housing)

Actuator (n75 electrically off) comparisons, with these differing preloads..

note the blue trace has "creep", which is I think because I have used up almost all the forge actuators travel (which is'nt enough imho anyhows compared to other actuators) - Artificially made the effective wastegate hole smaller again, recovered some boost by this also... Hmmmm

Comparison of earlier in the week MBC on much lower actuator pressure vs the higher pressure its holding of current.

comparison of a very tweaked forge actuator, white spring, which cracks open at 21psi, vs the previous setting of 18psi (I have added as much preload as it has travel for... and slightly too much - see further)

We have held an additional 1-2psi, now holding 20-21psi where 18psi was what it held earlier. (wastegate is being pushed open is my thought-must be quite some manifold pressure there, acting on the larger surface area of the wastegate penny.. 660mm^2 now from 452mm^2 of a stock exhaust housing)

Actuator (n75 electrically off) comparisons, with these differing preloads..

note the blue trace has "creep", which is I think because I have used up almost all the forge actuators travel (which is'nt enough imho anyhows compared to other actuators) - Artificially made the effective wastegate hole smaller again, recovered some boost by this also... Hmmmm

Comparison of earlier in the week MBC on much lower actuator pressure vs the higher pressure its holding of current.

Morgan-VAGCHECK

Foot to the floor

- Joined

- Jan 31, 2007

- Messages

- 103

- Reaction score

- 2

- Points

- 16

Hi Bill,

I would have personally thought with pressure reference/regulation removed from the actuator, & the white Forge spring boost would be a lot more in that first plot !

I guess the flapper must be being blown open as you suspect..

What will be your next steps ?

Regards

Morgan

I would have personally thought with pressure reference/regulation removed from the actuator, & the white Forge spring boost would be a lot more in that first plot !

I guess the flapper must be being blown open as you suspect..

What will be your next steps ?

Regards

Morgan

Last edited:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Hi Bill,

I would have personally thought with pressure reference/regulation removed from the actuator, & the white Forge spring boost would be a lot more in that first plot !

I guess the flapper must be being blown open as you suspect..

What will be your next steps ?

Regards

Morgan

well, some more, lot more runs, done during this afternoon.

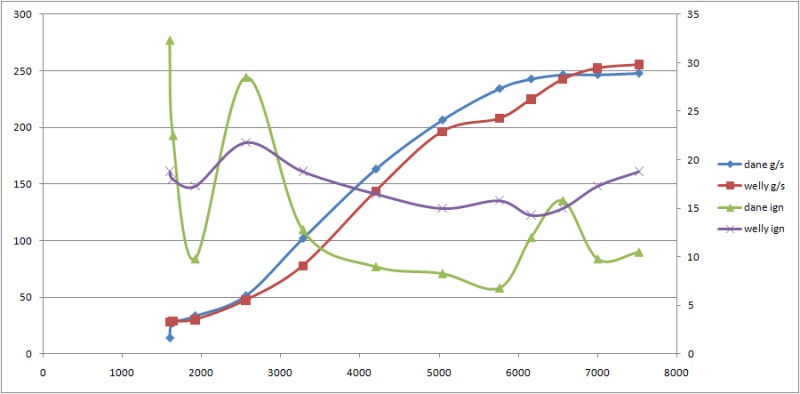

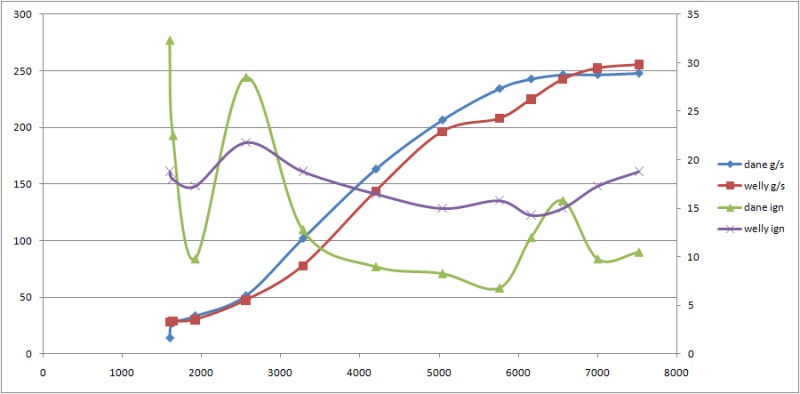

my theory: (oh no another one) - backpressure in hotside/manifold is significant, and proportional to the total boost being run... more boost more backpressure, which is why increase preload to a v.high level, and the uncontrolled boost level rises. I did'nt go wot until 5krpm during that run and was trying to just ease some throttle without the turbo letting loose to crazy boost..

I think the 29mm bored out wastegate is too large also now.. the clip, i am still 50/50 on being the right thing to do. zero surge which was its objective, and only 200rpm slower spool than wellys was.. As to what other side effects its had, I'm not sure. airflow for airflow its pretty close wellys vs danes. One big difference between them is timing. wellys ran a lot more than danes wants to. From car i have seen, largeports always soak up additional timing without cf's going mad over smallports... to the tune of 10 degree difference. 1.5deg added and 5bhp gained on what was a hot run.. as a guide of the margin it makes. (i dont have to tell you this obviously, but for others reading this its maybe of interest)

ignition and airflow comparisons-water/meth on wellys largeport, none yet on danes smallport-food for thought

more tomorrow.. when wmi is finished & running

upside, egt's are lovely - nice and low for the power/boost

Last edited:

Feeling for yous on this project, who would have thought a k04 would bring so many issues. Testiment to the train of thought that the hybrid k04 is definately a stage 3 setup and just as much if not more of an **** to sort out as a BIG turbo.

Liking all the info your sharing Bill keep it up and good luck with it all!!

Liking all the info your sharing Bill keep it up and good luck with it all!!

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

once sorted, and a lot learnt along the way, their will be a decent place for hybrids.... but they are not simple to extract power of without some side effects. I am sharing this openly so peeps can see the good the bad and the ugly. Some myths and industry turbo supplier BS uncovered along the way.

Last edited:

Morgan-VAGCHECK

Foot to the floor

- Joined

- Jan 31, 2007

- Messages

- 103

- Reaction score

- 2

- Points

- 16

well, some more, lot more runs, done during this afternoon.

my theory: (oh no another one) - backpressure in hotside/manifold is significant, and proportional to the total boost being run... more boost more backpressure, which is why increase preload to a v.high level, and the uncontrolled boost level rises. I did'nt go wot until 5krpm during that run and was trying to just ease some throttle without the turbo letting loose to crazy boost..

I think the 29mm bored out wastegate is too large also now.. the clip, i am still 50/50 on being the right thing to do. zero surge which was its objective, and only 200rpm slower spool than wellys was.. As to what other side effects its had, I'm not sure. airflow for airflow its pretty close wellys vs danes. One big difference between them is timing. wellys ran a lot more than danes wants to. From car i have seen, largeports always soak up additional timing without cf's going mad over smallports... to the tune of 10 degree difference. 1.5deg added and 5bhp gained on what was a hot run.. as a guide of the margin it makes. (i dont have to tell you this obviously, but for others reading this its maybe of interest)

ignition and airflow comparisons-water/meth on wellys largeport, none yet on danes smallport-food for thought

more tomorrow.. when wmi is finished & running

upside, egt's are lovely - nice and low for the power/boost

Hi Bill,

Thanks for your update, interesting stuff indeed.

Excellent news the turbine clipping appears to have eliminated any surge occuring, air flow looks very stable in your plot.

Best of luck with it for todays tweaks.

Regards

Morgan

Last edited:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

So the water meths on. Some excellent workmanship from Tuffty!

And I can still get to the cd changer

The nozzle in place

The supply from the tank runs down the passenger side of the car underneath all of the trim panels so it's totally hidden

And the wiring runs from underneath the steering wheel, along underneath trim again, behind the seat and then across behind the carpet underneath the rear bench and into the boot.

Currently using the medium size nozzle.

And I can still get to the cd changer

The nozzle in place

The supply from the tank runs down the passenger side of the car underneath all of the trim panels so it's totally hidden

And the wiring runs from underneath the steering wheel, along underneath trim again, behind the seat and then across behind the carpet underneath the rear bench and into the boot.

Currently using the medium size nozzle.

Take it you get lots of pipe with these kits?

How much are they going for?

Think if (most probably WHEN) i get a WMI kit ill endeavour to keep it to the confines of my bay. Probably put the battery in the boot, as a nice battery box looks better than the tank ans pump etc.

However it does look good though. Has Tufty chopped the lhs trim panel in half? I wouldnt even know as even though ive got an S3, ive only looked in the boot about 3 times!! lol

Good to see such a good mod though mate keep it up

How much are they going for?

Think if (most probably WHEN) i get a WMI kit ill endeavour to keep it to the confines of my bay. Probably put the battery in the boot, as a nice battery box looks better than the tank ans pump etc.

However it does look good though. Has Tufty chopped the lhs trim panel in half? I wouldnt even know as even though ive got an S3, ive only looked in the boot about 3 times!! lol

Good to see such a good mod though mate keep it up

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

I think it was £300 ish for the kit including the wiring and pipe work.

Bill and Tuffty did a WMI setup in a TT from the boot before so they knew it would work well.

The left hand side panel has been carefully cut in half to make the install easier and easy to live with.

Bill and Tuffty did a WMI setup in a TT from the boot before so they knew it would work well.

The left hand side panel has been carefully cut in half to make the install easier and easy to live with.

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

Is it possible that the wastegate penny simply isnt sealing properly/well enough, so rather than being blown open its just leaking?

Would explain why with no N75 your only making 7psi when the actuator visibly doesnt crack open until 14?

Would explain why with no N75 your only making 7psi when the actuator visibly doesnt crack open until 14?

So the water meths on. Some excellent workmanship from Tuffty!

And I can still get to the cd changer

The nozzle in place

The supply from the tank runs down the passenger side of the car underneath all of the trim panels so it's totally hidden

And the wiring runs from underneath the steering wheel, along underneath trim again, behind the seat and then across behind the carpet underneath the rear bench and into the boot.

Currently using the medium size nozzle.

Love the mod to the CD access panel.... Got a lot of time for that.

Glad it's installed and sorted now - good work :thumbsup:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

righto....... after several very frustrating days...

a Conclusion, not the conclusion.

I have just had the car run uncontrolled boost, on its forge actuator on n75 on and n75 off... Removed it and the things sticking!

youtube sticking video..

YouTube - ‪sticking-actuator.3gp‬‏

Whilst flapping the wastegate penny open and shut repeatedly, it became apparent in a "double take" kind of way... that the thing sometimes did'nt close. The Penny is hanging up on the edge of the wastegate hole. The wastegate hole, bored as it is is causing most of the issues we have been suffering, I am convinced of it. The wastegate penny hanging up on the hole is the final ****** straw!

Sticking penny (sticking slightly open) combined with a now sticking actuator, this things doomed to never work. days of work completely wasted. It has to come off and start over. not a happy bunny with the turbo one bit! CR will have an irate badger on the phone tomorrow, this is beyond a joke.

a Conclusion, not the conclusion.

I have just had the car run uncontrolled boost, on its forge actuator on n75 on and n75 off... Removed it and the things sticking!

youtube sticking video..

YouTube - ‪sticking-actuator.3gp‬‏

Whilst flapping the wastegate penny open and shut repeatedly, it became apparent in a "double take" kind of way... that the thing sometimes did'nt close. The Penny is hanging up on the edge of the wastegate hole. The wastegate hole, bored as it is is causing most of the issues we have been suffering, I am convinced of it. The wastegate penny hanging up on the hole is the final ****** straw!

Sticking penny (sticking slightly open) combined with a now sticking actuator, this things doomed to never work. days of work completely wasted. It has to come off and start over. not a happy bunny with the turbo one bit! CR will have an irate badger on the phone tomorrow, this is beyond a joke.

Sorry to hear the trouble you're having Bill, makes it worse when you spend time on doing things properly to ensure all the work's been done right, only to find that the parts aren't up to scratch!

Time to make your own Badger5 Actuator??

Time to make your own Badger5 Actuator??

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

CARS in danes hands again.. so hoping he's enjoying it and rid of the micra for a while

too add to the rest of the hassles, the n75 seems to have packed in tonight, giving full on boost no matter whether its connected or not.. joys of vag cars.

sticking actuator, sticking wastegate, expired n75.......... what else eh?

too add to the rest of the hassles, the n75 seems to have packed in tonight, giving full on boost no matter whether its connected or not.. joys of vag cars.

sticking actuator, sticking wastegate, expired n75.......... what else eh?