Next one planned for me once the wing is on is some form of side skirts.

Not so much to have any huge effect, but the car is looking pretty aero heavy front and rear now, and in the middle it’s very bare indeed and looks a bit out of proportion.

I was looking at it the other day, and realised that this is largely down to how the sides of the car sweep in from the door line, so by the time you get down to floorpan height it’s ‘waisted’ in by a good 6’’ per side already. This not only looks a bit daft, but it gives a very clear and easy path for air to sweep in under the car, partially undoing the good work of the splitter.

If I could just have an extension downwards, vertically from the bottom of the doors. It wouldn’t even need to go lower than floorpan height to have a huge visual impact, as well as genuine aero merit too.

Idea stolen 100% from RobT and his (former) lovely Ibiza Sprint car:

I believe Rob just used some form of roofing sheets and attached them to the vertical seam under the sills. It was apparently quite effective increasing the efficiency of his splitter by stopping air getting back in under the car, so the splitters gains are felt futher along the underside of the car as I understand it.

My plan would be to mount them slightly further outboard for a greater visual impact.

Excusing my awful sketch, this is how I interpret the current stock arrangement:

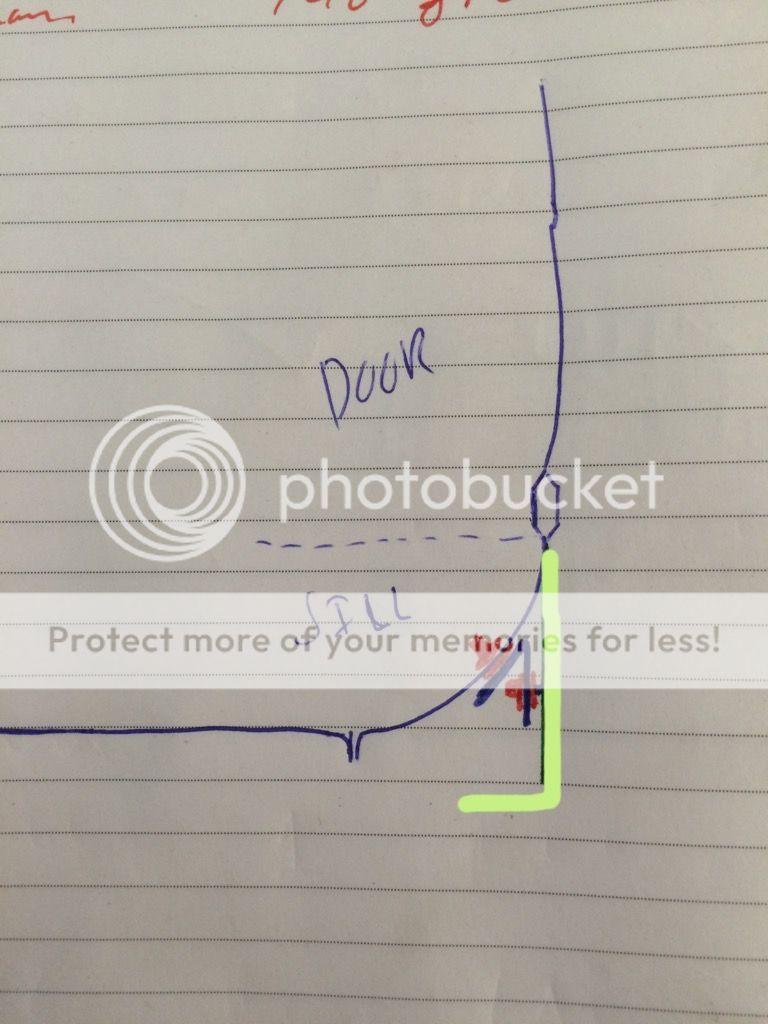

And this would be my intended plan:

The red indicates a Riv nut in the sill, and again in an inverted V shaped steel bracket. The green then indicates some form of sheet material, most probably using some Mini wheel arch trim along the top edge to give a smart seam / joint to the bodywork.

These could be made and tested at varying depths to see if the gains were felt at all.

Nige at one point ran his just 30mm off the ground and made from rubber strips, and literally let them find their own height be wearing down until they stopped wearing.

In theory, once the brackets are made I could experiement with a few different materials too and see what works best.