finally pulled my finger out and started putting bits together!

thought I would run a build thread for those interested.

plan was to build a torquey but high revving engine that was bullet proof that would give around 200bhp/200+ftlbs at 4000rpm and max out somewhere above 350bhp.

will be in a A4 tqs (5 spd box, my biggest issue is the lack of torque available between 2500-4000 rpm when in 2nd gear, hate going in to first when pulling away from really slow corners!). car will be running KW v3 coilovers and B7 rs4 brakes on hybrid struts and driveshafts.

never done a full engine build before and have spent about two years collecting parts and researching. sourced most stuff from the US for both cost and product choice.

Spec as follows:

Block

AJL code engine block bored to 83mm (will be just over 2l 83mmx92.9mm borexstroke)

92.8mm forged crank from a 2l VW (dowelled to strengthen timing sprocket)

Raceware Main studs

Eurospec main bearings

144mm Forged Scat rods

Calico Rod bearings

83mm Forged Supertech pistons

New water pump with metal impeller

New Oil pump

New IM shaft bearings

New seals/gaskets throughout

stock sump

Head

Ported and port matched big port head

supertech inconel/nitrided valves

Supertech titanium springs and seats

new valve guides

stock cams

Turbo/manifold/exhaust

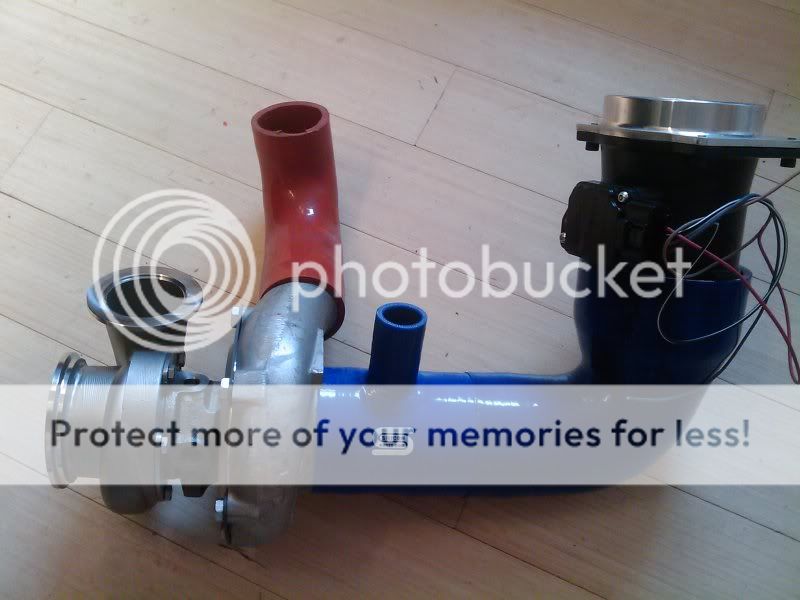

GT2871 with vband stainless turbine housing, custom integral 44mm Tial external wastegate vband mounting on turbine housing

custom tubular equal length runner 316 Stainless exhaust manifold with "Burns Stainless" merge collector

3" stainless downpipe

2.75" Milltek exhaust

Fuel/Intake

90mm Ford Lightning MAF

630cc injectors

Bosch motorsport inline high flow fuel pump

stock FPR

Tapp Auto software on new ECU

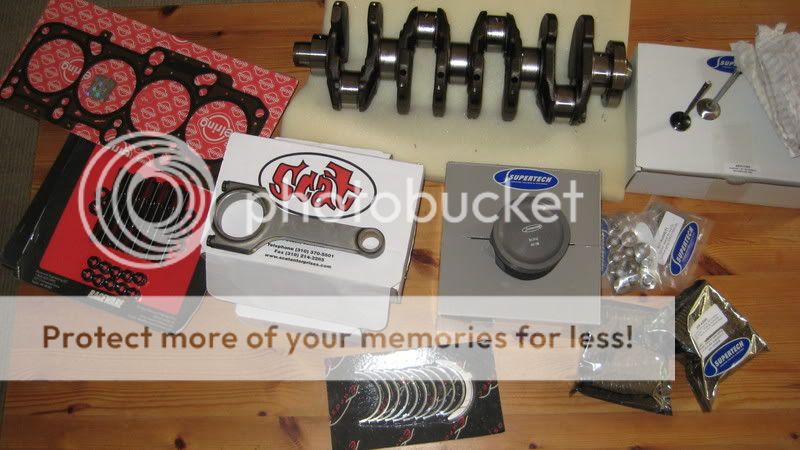

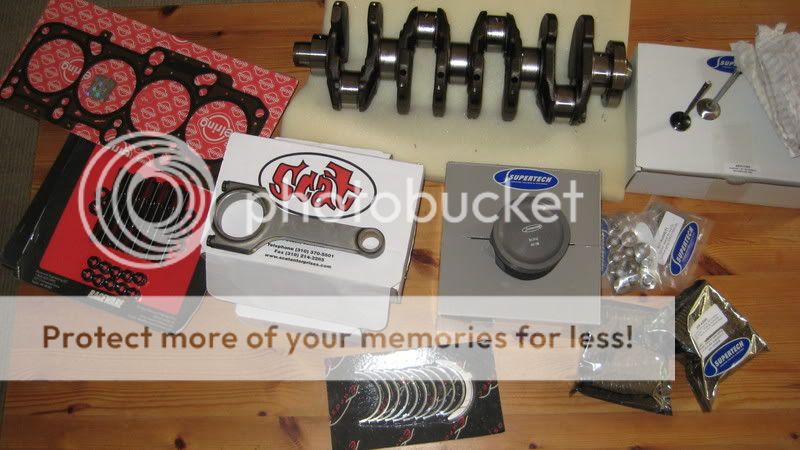

parts porn

block prepared

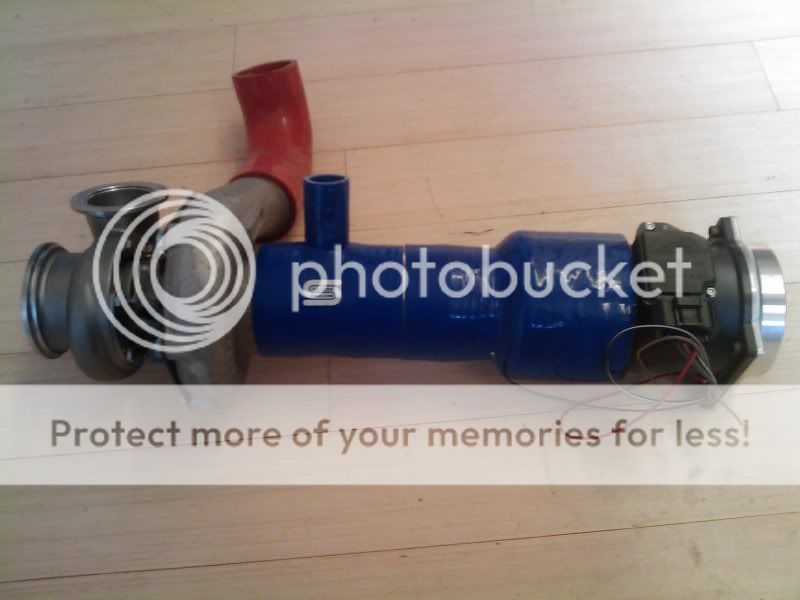

GT2871 with vband turbine housing

Block was prepped and painted and all bolt holes were cleaned up with an appropriate tap, you would be amazed how much crud came out of the holes!

bearing clearances have all bean checked with plastigage and micrometer measurements.

bearing surfaces were cleaned , top bearings fitted, lubed, crank fitted, studs fitted finger tight till they bottomed out, bottom shells/c bearings fitted to caps, lubed, tapped into place with wooden mallet and all torqued up.

crank is in place ready for run out check with dial guage (forgot my small crowbar so had to stop there!)

you can just see behind the dial guage one of the dowel pins fitted to the end of the crank for the timing pully to fit onto. the pulley has two holes right through it and fits into the dowels and keyway on the crank. It is a design fault that has failed numerous times on BT engined cars I am not having that come off when I have spent so long building up this list!

more pics to follow

thought I would run a build thread for those interested.

plan was to build a torquey but high revving engine that was bullet proof that would give around 200bhp/200+ftlbs at 4000rpm and max out somewhere above 350bhp.

will be in a A4 tqs (5 spd box, my biggest issue is the lack of torque available between 2500-4000 rpm when in 2nd gear, hate going in to first when pulling away from really slow corners!). car will be running KW v3 coilovers and B7 rs4 brakes on hybrid struts and driveshafts.

never done a full engine build before and have spent about two years collecting parts and researching. sourced most stuff from the US for both cost and product choice.

Spec as follows:

Block

AJL code engine block bored to 83mm (will be just over 2l 83mmx92.9mm borexstroke)

92.8mm forged crank from a 2l VW (dowelled to strengthen timing sprocket)

Raceware Main studs

Eurospec main bearings

144mm Forged Scat rods

Calico Rod bearings

83mm Forged Supertech pistons

New water pump with metal impeller

New Oil pump

New IM shaft bearings

New seals/gaskets throughout

stock sump

Head

Ported and port matched big port head

supertech inconel/nitrided valves

Supertech titanium springs and seats

new valve guides

stock cams

Turbo/manifold/exhaust

GT2871 with vband stainless turbine housing, custom integral 44mm Tial external wastegate vband mounting on turbine housing

custom tubular equal length runner 316 Stainless exhaust manifold with "Burns Stainless" merge collector

3" stainless downpipe

2.75" Milltek exhaust

Fuel/Intake

90mm Ford Lightning MAF

630cc injectors

Bosch motorsport inline high flow fuel pump

stock FPR

Tapp Auto software on new ECU

parts porn

block prepared

GT2871 with vband turbine housing

Block was prepped and painted and all bolt holes were cleaned up with an appropriate tap, you would be amazed how much crud came out of the holes!

bearing clearances have all bean checked with plastigage and micrometer measurements.

bearing surfaces were cleaned , top bearings fitted, lubed, crank fitted, studs fitted finger tight till they bottomed out, bottom shells/c bearings fitted to caps, lubed, tapped into place with wooden mallet and all torqued up.

crank is in place ready for run out check with dial guage (forgot my small crowbar so had to stop there!)

you can just see behind the dial guage one of the dowel pins fitted to the end of the crank for the timing pully to fit onto. the pulley has two holes right through it and fits into the dowels and keyway on the crank. It is a design fault that has failed numerous times on BT engined cars I am not having that come off when I have spent so long building up this list!

more pics to follow