Anybody wanting to fit HID's may want to consider the newer Digital Slimline Ballasts that "quattroJames" put me onto in his thread -

quattrojames thread

The Slimline HID kit used was off Ebay -

LINK

Before with standard size Ballasts I had.....

And now I have everything self-contained within the Headlight assembly - with nothing hanging out!

What I did...........

1. New Slimline Ballast on a custom mounting plate I made - primed and painted:

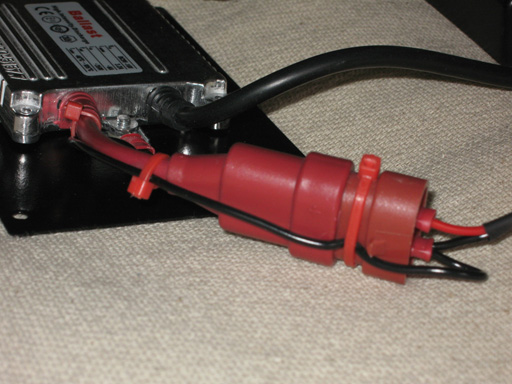

2. Did not use the waterproof connector for 12v connection as this will be in the headlight assembly - made up a custom connection using standard mini-crimp connectors. Also earthed the Ballast casing with an additional earth wire as it seems to be floating.

3. This was the hardest part - getting the cables from the Ballast into the light assembly. I assume this part is normally cut out for factory fit OEM Ballasts. Anyway decided on a 40mm hole cutter located as shown. (Be careful as drill center will hit the back of the light reflector - but disconnect the motor actuator under the other access panel and this gives more internal clearance for the drill with the reflectors moved out the way.

Also place a plastic bag inside the headlight assembly to catch any plastic swarf from hole cutting. Have a vacuum cleaner hose to hand to remove any stray swarf as you cut the 40mm hole - it's a pain to remove if it falls into the headlight assembly owing to static from the various internal plastic parts!!

4. Hole from inside.....

5. Put two layers of bathroom silicon sealant around the rim of the plate recess and let it set for 24 hours. This acts as a waterproof seal between the plate and the light assembly.

6. Passed the HV unit and 12v connector through the 40 mm hole and mounted the Ballast plate with self tapping screws.

7. Stuck the HV unit down with a couple of double sided sticky pads and made 12v connections with standard male flat spade connectors into Audi connector. HID bulb mounted and HT connections made.

Repeated for other light and remounted to car - That's It All Done