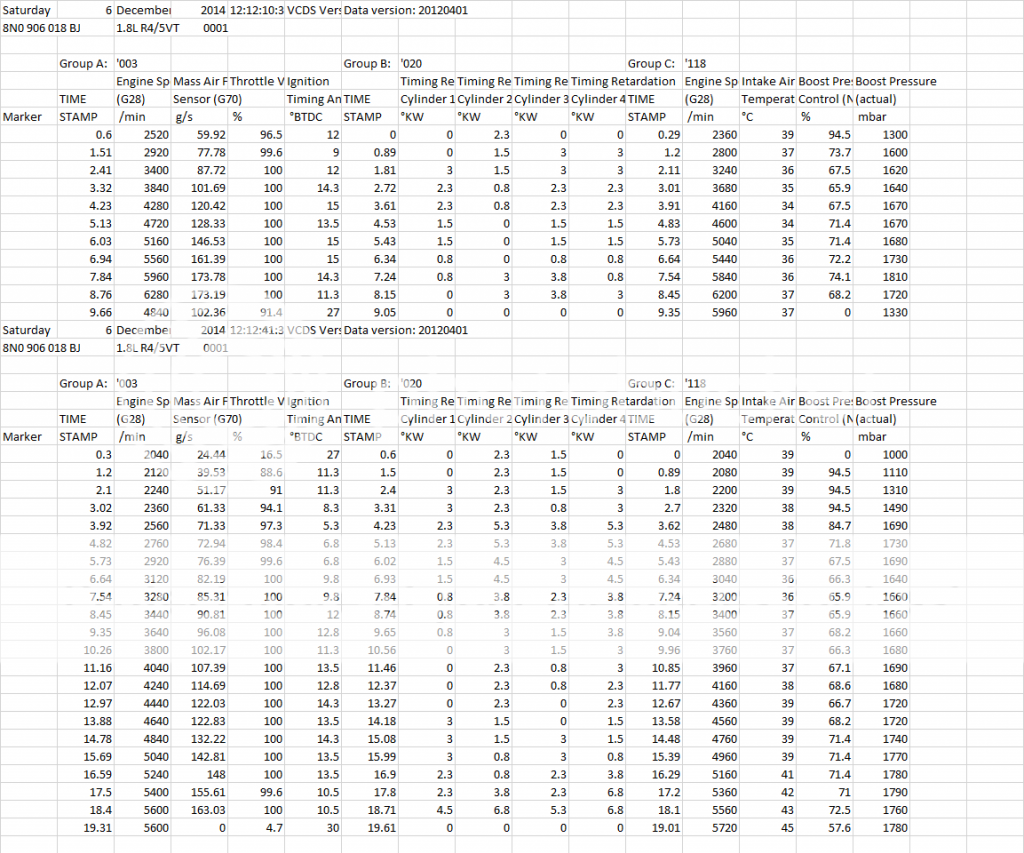

Ok a small update. i have put the car back to stock. it is still pulling timing although not as much but still enough to be a problem. I have done a fuel pressure test and there is no problem there. I was reading up on what could be causing this and came across this

O2 Sensor – Because of strict emissions these 1.8T’s are very sensitive to readings from the O2 sensors. 2001+ have a wideband front O2 sensor with high accuracy and a linear response. The car will adjust the fueling based on the readings from the sensor. If the sensor is over heated, exposed to lead (race gas), flooded with soot (too rich) or is just old, it can provide the car with false readings and the car will not provide the proper fueling. When the O2 sensors go bad and the ECU detects this the car will run on reserve fueling maps and will not be able to adjust for boost leaks, fuel pressure, MAF readings or any other parameter that affects fueling. To check for a bad sensor the first thing to do is run block 032 on the VAG com. If the sensors are bad, the readings will both be 0%, replace the Front O2 sensor. If the sensor is bad, it will also respond slowly, or reach a peak. Logging block 031 will show the lambda reading from the O2 sensor as well as the requested lambda from the ECU. To get air fuel ratio multiply lambda by 14.7. If the lgo shows the lambda jumping wildly when running through a gear, or perhaps it flat lines at an unreasonable level, then the O2 sensor should be replaced. It is a 50$ part. If the o2 sensors get shorted out or the wires get pulled, they will damage the ECU, be careful with the wiring on these sensors. 2000 and older cars do not have a wideband sensor, however they will still perform some adjustment of fueling based on the sensor. .

what i am wanting to know. the Sensor after where the cat would normally be. came loose awhile back, and i took it back to the guys that did the down pipe and they put a copper wahser on it and tightened it. could that sensor be damaged from the rattling, and causing the running lean issue? or can it only be the pre cat wideband sensor?