Into the space where the SMI were as there should be some air flow here and maybe vent the wheel arch liner to aid in air flow or stick a magic tree at the end of your current outlet

S3 PE1820 big turbo build

- Thread starter Welly

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Into the space where the SMI were as there should be some air flow here and maybe vent the wheel arch liner to aid in air flow

I agree with you on that one, down in the front bumper/wheel arch area looks to be the winner in all honesty. That is most likely where I will be looking to put it.

The problem with the smell of crankcase vent fumes is that they really are putrid. Horrible ++

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

...The problem with the smell of crankcase vent fumes is that they really are putrid. Horrible ++

You need some of Bill's (slightly) expensive Motul race oil... smells like sweets

<tuffty/>

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

With a healthy engine, how much of an issue will it really make having the fumes vented back into the intake?

Have you tried comparing figures on the dyno with and without it?

Have you tried comparing figures on the dyno with and without it?

Speedy Steve

Registered User

Know if it was bubble gum smell id vent it into the cabin lolYou need some of Bill's (slightly) expensive Motul race oil... smells like sweets

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

With a healthy engine, how much of an issue will it really make having the fumes vented back into the intake?

Have you tried comparing figures on the dyno with and without it?

depending how "fumey"/worn the engine is will depend on the oil fume oil content and ability to degrade the effective octane

shagged engines, which injest their own oils and fumes pull a lot of timing...

case by case

on one not smoking like a trooper, I cant say I notice any more timing pull or dyno difference, but over time those which do rebreath their fumes will gather oil in the charge pipes more.

Well, did several things when I got home from work.

Firstly, installed a nice new pipe for the breather. Sits way back from where it did before, and is definitely much much better. Good start.

Secondly, took plugs out and checked them for colour. A lovely golden biscuit brown. Just the job.

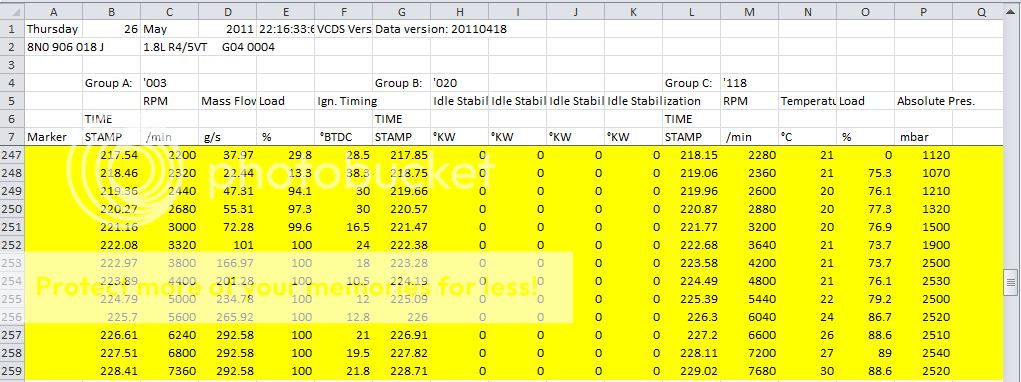

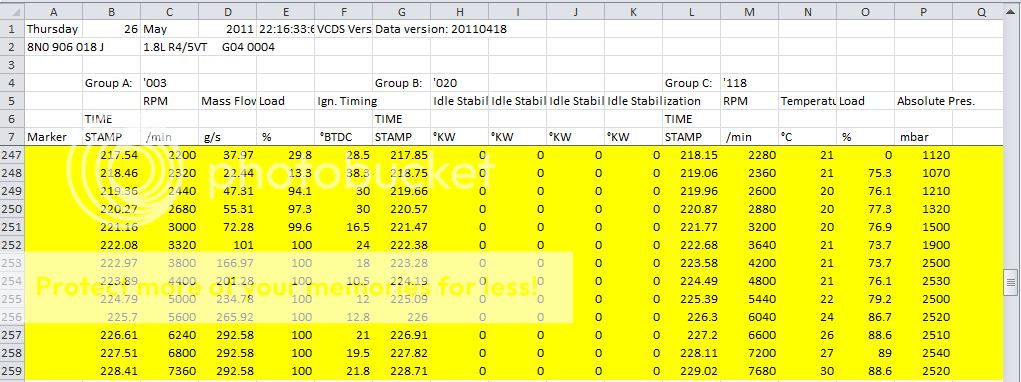

Lastly, installed D07 nozzle and took out for some logs. Still getting more timing pull than ideal seeing up to and including 6s, but nothing to write home about. My inlet temps aren't as low as I was expecting either. I will need to compare today's log with the ones bill has from dyno runs, as well as manually test the WMI setup.

It seems that my MAF is incapable of reading anything higher than 280.33. I have NEVER seen the figure get above that, and these logs today demonstrate that, despite it hitting 280.33 at 7K RPM with another 800+ RPM to go... and then it just repeating that figure. Seems a bit strange.

Anyway, all is well, however I suspect that my WMI pump my be on the way out.... Boooo. Oh well, time for a new 120 PSI one me thinks...

A quick extract from the D07 log:

Firstly, installed a nice new pipe for the breather. Sits way back from where it did before, and is definitely much much better. Good start.

Secondly, took plugs out and checked them for colour. A lovely golden biscuit brown. Just the job.

Lastly, installed D07 nozzle and took out for some logs. Still getting more timing pull than ideal seeing up to and including 6s, but nothing to write home about. My inlet temps aren't as low as I was expecting either. I will need to compare today's log with the ones bill has from dyno runs, as well as manually test the WMI setup.

It seems that my MAF is incapable of reading anything higher than 280.33. I have NEVER seen the figure get above that, and these logs today demonstrate that, despite it hitting 280.33 at 7K RPM with another 800+ RPM to go... and then it just repeating that figure. Seems a bit strange.

Anyway, all is well, however I suspect that my WMI pump my be on the way out.... Boooo. Oh well, time for a new 120 PSI one me thinks...

A quick extract from the D07 log:

Code:

Group A: '002 Group B: '011 Group C: '020

RPM Load Inj. On Time Mass Flow RPM Temperature Temperature Ign. Timing TIME TIME TIME

Marker STAMP /min % ms g/s STAMP /min °C °C °BTDC STAMP CF CF CF CF

2nd 379.62 2560 19.5 1.23 10.75 380.02 2600 89 20 36.8 380.51 0 0 0 0

381.01 2600 24.8 1.64 12.25 381.5 2600 89 20 36.8 381.9 0 0 0 0

382.3 2640 25.6 1.64 12.44 382.7 2640 89 20 36.8 383.1 0 0 0 0

383.5 2720 32.3 2.05 17.19 383.9 2800 89 20 36 384.3 0 0 0 0

384.7 3040 58.6 3.28 35.14 385.1 3200 89 21 33 385.51 0 0 0 0

385.9 3760 112 6.15 84.44 386.3 4160 89 21 24 386.7 0 0 0 0

387.1 5440 191.7 14.35 250.75 387.5 6120 89 21 19.5 387.9 0 3 5.3 1.5

388.3 7320 191.7 12.71 280.33 388.7 7800 88 21 8.3 389.1 0 0 0 0

3rd 389.5 5520 175.2 11.89 196.61 389.9 5800 88 20 16.5 390.3 3 5.3 0.8 6

390.7 6440 191.7 14.35 276.53 391.1 6720 88 23 15.8 391.6 3 5.3 0.8 5.3

392 7320 191.7 12.71 280.33 392.51 7560 87 24 18.8 392.91 3 3.8 0.8 3.8

393.31 7240 27.8 2.87 63.31 393.71 6040 87 21 15.8 394.09 0 5.3 0.8 6

4th 394.49 6360 191.7 13.94 272.67 394.89 6480 86 26 15.8 395.29 0 5.3 0.8 6

395.69 6760 191.7 13.94 279.72 396.09 6880 86 27 16.5 396.49 0 5.3 0.8 6

396.89 7120 191.7 13.12 280.33 397.29 7200 86 27 17.3 397.69 0 3 0.8 3.8

398.09 7440 191.7 12.71 280.33 398.49 7520 86 28 19.5 398.89 0 1.5 0.8 1.5

399.29 7680 191 12.3 280.33 399.69 7720 86 29 6 400.09 0 6 0.8 6- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

The MAF thing seems the same sorta thing as mine hitting 292.58 and going no further... not seen Bill's logs on your car so maybe its always been there...

<tuffty/>

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Doesn't always track mate... EGT's at high RPM can still be reasonable and defo lower than a K04 flat out... IAT's on the log aren't too bad either so not silly at all... my logs as a comparison...

Similar IAT's and I am not running WMI...

<tuffty/>

Similar IAT's and I am not running WMI...

<tuffty/>

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

The MAF thing is seen on S4's as well, Vagcom maxes out at some value around 300, the exact value depending on the exact ECU revision, even though the MAF itself isnt maxed out as far as the ECU is concerned, its just the vagcom output that pegs.

The Absolute max for the S4 MAF is apparently 364g/sec however Vagcom can peak at anything between 310 and 330 depending on which ECU the car has.

The Absolute max for the S4 MAF is apparently 364g/sec however Vagcom can peak at anything between 310 and 330 depending on which ECU the car has.

Similar IAT's and I am not running WMI...

<tuffty/>

Exactly, I used to see IATs drop down to ambient temp when WMI was running. I will have to whip the bumper off and bench test the WMI I think.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

On tufftys S3 maf, it is pegged at 4.98v for its 292g/s figure

S4 maf may be required on tufftys.

will have to check wellys ecu code for its current maf scaling. Its stock as it tufftys currently.

you can scale in software the g/s against voltage, but the maf sensor voltage being max'd is the issue on Tufftys, and *might* be the case on Wellys also.. Might need to physically hang the dvm off the sensor output again to confirm voltage. (like I did on tufftys way way back)

S4 maf may be required on tufftys.

will have to check wellys ecu code for its current maf scaling. Its stock as it tufftys currently.

you can scale in software the g/s against voltage, but the maf sensor voltage being max'd is the issue on Tufftys, and *might* be the case on Wellys also.. Might need to physically hang the dvm off the sensor output again to confirm voltage. (like I did on tufftys way way back)

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Exactly, I used to see IATs drop down to ambient temp when WMI was running. I will have to whip the bumper off and bench test the WMI I think.

from the logs I would think its no workie mate

from the logs I would think its no workie mate

It's certainly looking that way. However, on the plus side, I now know that I can run out of WMI without any bad side effects.... Timing pull is within tolerance.... Mwhahaha (Rub hand with glee).

I thought I wasn't using much meth lately....

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

I thought that meth consumption was just much better than the hybrid, due to being off the boost more.

Turns out the WMI is just shagged. Booooo.

Talk about a let down....

However, as I said, a successful test. Glad to know that if this were to happen again, the thing won't blow up from massive CFs.

Turns out the WMI is just shagged. Booooo.

Talk about a let down....

However, as I said, a successful test. Glad to know that if this were to happen again, the thing won't blow up from massive CFs.

Speedy Steve

Registered User

I need WMI in my life Bill you have a PM!

So do I it would seem..... lol

You still after a manifold matey...

http://www.edition38.com/forums/index.php?showtopic=386718&pid=3693766&st=0&#entry3693766

hope that works, its off me iphone...

http://www.edition38.com/forums/index.php?showtopic=386718&pid=3693766&st=0&#entry3693766

hope that works, its off me iphone...

You still after a manifold matey...

http://www.edition38.com/forums/index.php?showtopic=386718&pid=3693766&st=0&#entry3693766

hope that works, its off me iphone...

I can't open the link bud annoyingly. What is it?

The problem wasn't that the meth wasn't working, it appears that it was just set to fir up too late.

The meth was originally set up to come on at 12 PSI, however when tested, it didn't switch on until 18 PSI. The issue there is that it is trying to cool something that is already very hot, as opposed to stopping it getting so hot in the first place.

Timing CF is back down to 3's where it belongs which is nice. I still think I need a new pump as mine is leaking. I may well get one which is a slightly higher pressure this time...

The meth was originally set up to come on at 12 PSI, however when tested, it didn't switch on until 18 PSI. The issue there is that it is trying to cool something that is already very hot, as opposed to stopping it getting so hot in the first place.

Timing CF is back down to 3's where it belongs which is nice. I still think I need a new pump as mine is leaking. I may well get one which is a slightly higher pressure this time...

Looking at these as they seem very good (I know someone who is using one) and have a 1 year guarantee...

The 160 PSI: 160psi Automatic High Pressure Pump 12v Methanol Water | eBay UK

The 120 PSI: 120psi Automatic High Pressure Pump 12v Methanol Water | eBay UK

The 160 PSI: 160psi Automatic High Pressure Pump 12v Methanol Water | eBay UK

The 120 PSI: 120psi Automatic High Pressure Pump 12v Methanol Water | eBay UK

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Mine says 200 psi on it... whether that actually means what you mean I dont know lol.

Yeah, the AEM ones are 200 PSI which gives a really nice fine mist. My current one is only 100 PSI, and it leaks, so probably isn't 100 PSI anyway....

nice find on pumps welly

Yeah, I thought they were a bargain. Same design as the Sureflo ones, but just nowhere near the money.

Well, over two months have been and gone now since completion.

I've done a great many miles as well since.

Nothing to report really. Still goes really well which is good!

I did bend scared2: ) the bolt that holds the dog bone mount to the gearbox, which was a bit of an issue... Not really sure how, but I guess it must be the savage beatings she gets.

scared2: ) the bolt that holds the dog bone mount to the gearbox, which was a bit of an issue... Not really sure how, but I guess it must be the savage beatings she gets.

Also, on the way back from Kettering yesterday, I did snap one of the engine mount bolts cam belt side which is a bit of a pain! New ones sorted though, got to collect them in an hour.

Nothing else to report though, apart from the biblically bad fuel economy....

I've done a great many miles as well since.

Nothing to report really. Still goes really well which is good!

I did bend

Also, on the way back from Kettering yesterday, I did snap one of the engine mount bolts cam belt side which is a bit of a pain! New ones sorted though, got to collect them in an hour.

Nothing else to report though, apart from the biblically bad fuel economy....

Speedy Steve

Registered User

Good to hear she's running well mate. Shame the weather turned crap yesterday or i'd have stayed around longer

- Joined

- Dec 2, 2008

- Messages

- 17,400

- Reaction score

- 1,104

- Points

- 113

Welly I would love to do the engine build you have, I was mighty impressed when you took me out for a spin.

That's some savage torque to bend and snap mounting bolts!!!

That's some savage torque to bend and snap mounting bolts!!!

Welly I would love to do the engine build you have, I was mighty impressed when you took me out for a spin.

That's some savage torque to bend and snap mounting bolts!!!

Its all well and good doing this sort of thing, but it's the lack of longevity in the supporting parts that you don't think about at the time.

For example, the rear doughnut on the prop had some bolts go snapola due to torque delivery to the rear end, it also mashed the doughnut out of shape.

Engine mounts the same, they have to cope with, and retain all the engine movement under load which is a hard job I guess.

I love it don't get me wrong, but it's the little things like this that you don't think about at the point of build.

Good to hear she's running well mate. Shame the weather turned crap yesterday or i'd have stayed around longer

Thats cool mate, no probs. I wasn't hanging about in an empty field in the rain either believe me.

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

Good to hear the car's running well bud! I caught a glimpse of it yesterday, i was leaving Wicksteed Park as you were driving in, car looks mean!!

- Joined

- Dec 2, 2008

- Messages

- 17,400

- Reaction score

- 1,104

- Points

- 113

My engine mounts themselves are fine.

It's the ****** bolts between them = fail.

SEM is some thing I really want too mate I must admit.... It's the last thing I feel I actually need.

It's the ****** bolts between them = fail.

SEM is some thing I really want too mate I must admit.... It's the last thing I feel I actually need.

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

Having spoken to Bill about it the other day I'm going to use a SEM as a continuation of the project in an attempt to keep the initial cost down.

Is it worth getting a SEM if you're moving on?

Is it worth getting a SEM if you're moving on?

Also, on the way back from Kettering yesterday, I did snap one of the engine mount bolts cam belt side which is a bit of a pain! New ones sorted though, got to collect them in an hour.

Nothing else to report though, apart from the biblically bad fuel economy....

I would hazard a gues that these are causing that nice characteristic clunk you have mate.

TT ok now?

- Joined

- Dec 2, 2008

- Messages

- 17,400

- Reaction score

- 1,104

- Points

- 113

Stop it with all the mods boys pleas! I've just got my list of things to do right down and my eBay watch list only has 1 thing left. It's time to buy a house for me.

Stop it with all the mods boys pleas! I've just got my list of things to do right down and my eBay watch list only has 1 thing left. It's time to buy a house for me.

Quit your moaning, you can do that as well....

IbanezDan51

Registered User

Hey Welly looks like this is producing some nice results now! Bet you are glad to be rid of the hybrid ko4....

You are running a similar RPM to me but a bit less torque - I was near 350lbft with a 7900 RPM limit before I killed the head and gave up. If/When I build another 1.8t I would do the valves and springs - suprised you haven't been a bit on edge running that sort of RPM range and those levels of boost at such high rpm.

Hope everything continues succesfully! OW and I was using one of those OBX manifolds - but a large port one which I found in this country. I lost mid range torque but it did help develop a few more horses top end for those willy waving rights lol.

Dan

You are running a similar RPM to me but a bit less torque - I was near 350lbft with a 7900 RPM limit before I killed the head and gave up. If/When I build another 1.8t I would do the valves and springs - suprised you haven't been a bit on edge running that sort of RPM range and those levels of boost at such high rpm.

Hope everything continues succesfully! OW and I was using one of those OBX manifolds - but a large port one which I found in this country. I lost mid range torque but it did help develop a few more horses top end for those willy waving rights lol.

Dan