sideways steve

Registered User

I am now fairy happy that we have the map sorted however I think I have worked out why the airflow readings are still so low.

I have also done a log with the N75 disconnected and its pointing to a weak actuator from what I can see.

Have a look at these logs and see what you all think !

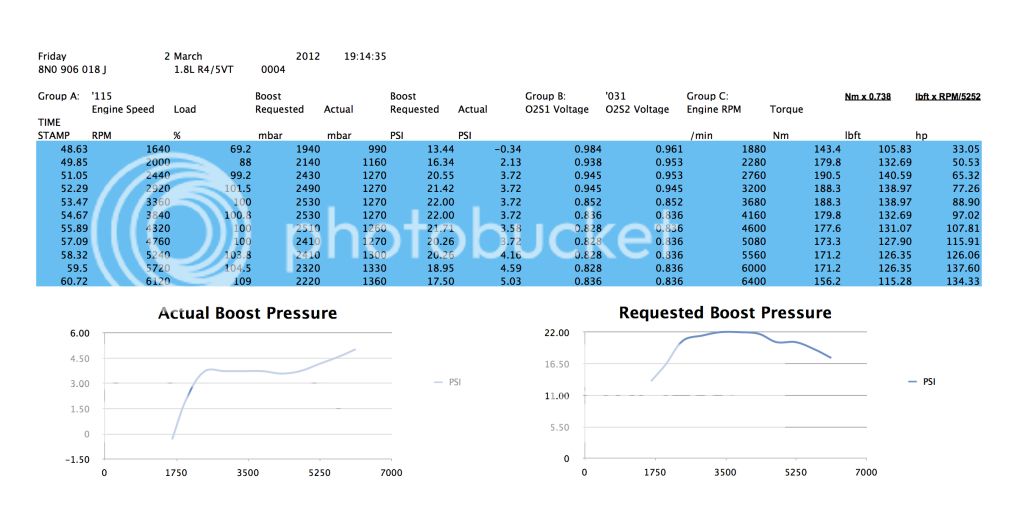

First Log,

Boost and CF's:

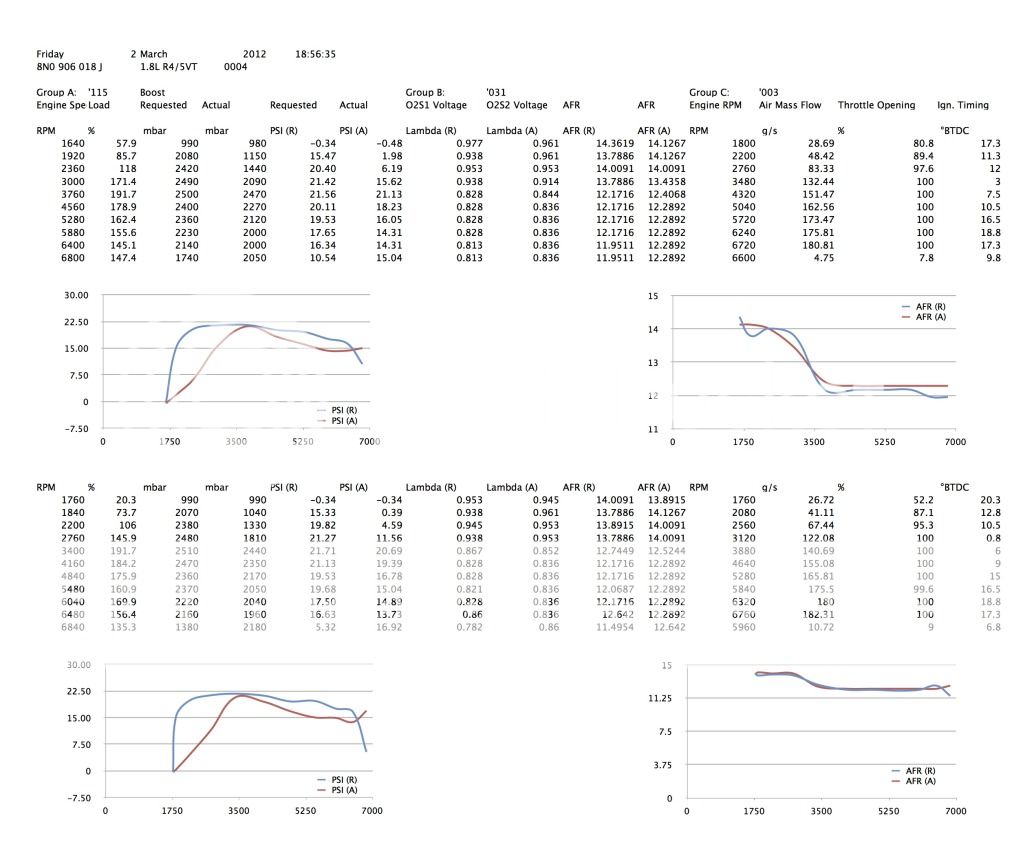

Second Log

Boost & Fuel:

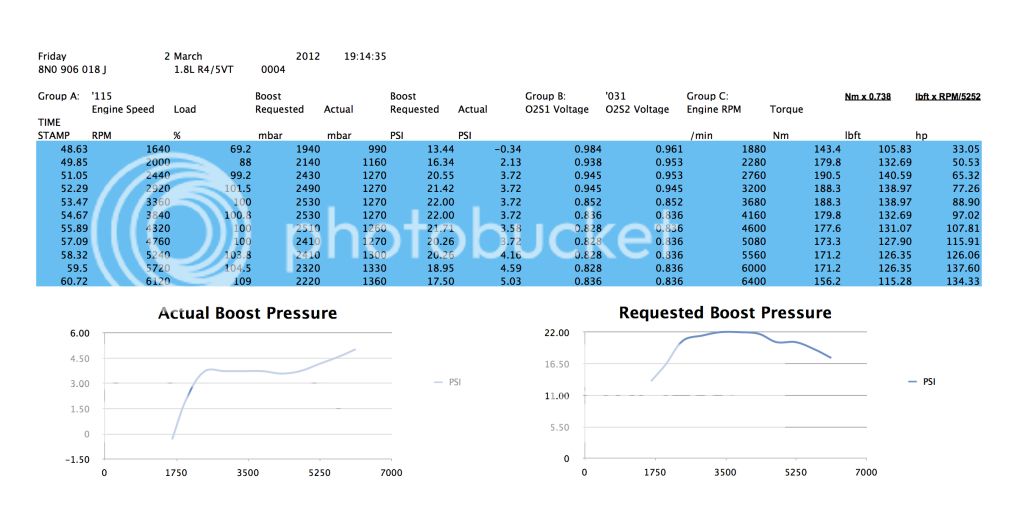

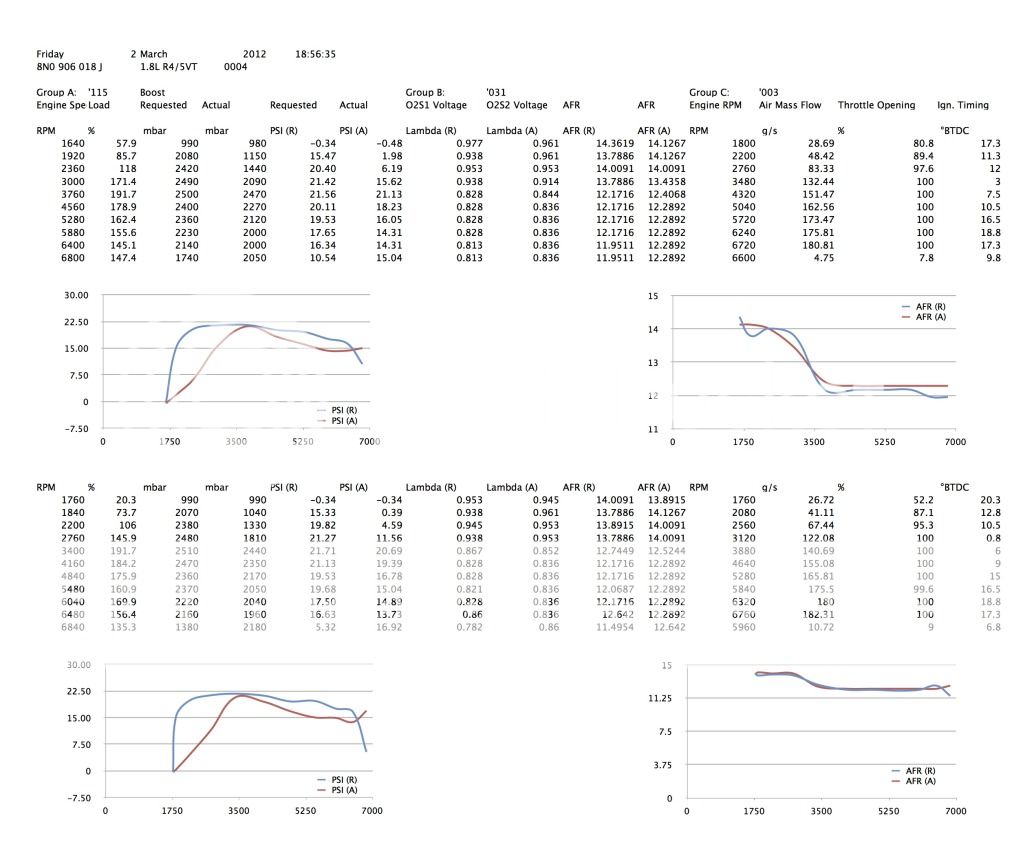

Third Log

Actuator Test:

I have also done a log with the N75 disconnected and its pointing to a weak actuator from what I can see.

Have a look at these logs and see what you all think !

First Log,

Boost and CF's:

Second Log

Boost & Fuel:

Third Log

Actuator Test: