Excellent work mate. Does it matter that the bearings yous had weren't the same was it just a OCD moment?Will these one your helping to build be like your own? Ur running a gt3076 aren't you? As a turbo how would you rate it power wise top end and what is it like at normal town driving. I'm asking cause I've been offered a gtx3076 and was just looking some info.

My S3 Addiction

- Thread starter S3 Hilife

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Excellent work mate. Does it matter that the bearings yous had weren't the same was it just a OCD moment?Will these one your helping to build be like your own? Ur running a gt3076 aren't you? As a turbo how would you rate it power wise top end and what is it like at normal town driving. I'm asking cause I've been offered a gtx3076 and was just looking some info.

No it wouldn’t have mattered mate, just Sams OCD kicking in haha. Build wise it’s going quite a way beyond mine (for now lol) but I’ve still got to strengthen and rebore my bottom end. Personally I love love the billet 3076, it’s perfect mate. Nice and responsive, rapid spool and plenty of power

I had a parcel arrive from the states today. I’ve been quite excited about trying this out lol, sad I know but it should save time diagnosing faults in the future

Anyone know what it is? I’m guessing most of you do

Steve

Anyone know what it is? I’m guessing most of you do

Steve

Something I think every Audi A3/S3 8L owner should have in there inventory  I like the style, very militarised Steve

I like the style, very militarised Steve

Sent from my iPhone using Tapatalk

I like the style, very militarised Steve

I like the style, very militarised Steve Sent from my iPhone using Tapatalk

Haha yes, it’s full of ammo really for venting anger when the car breaks down

Haha yes, it’s full of ammo really for venting anger when the car breaks down

Haha a bit more expensive than my lump hammer then! How much was it if you don’t mind me asking mate?

Sent from my iPhone using Tapatalk

I think it worked out around £110 after import fees. You could make one for around half that tbh with a bit of 20awg Nichrome wire making sure the resistance is correct, a sealable metal container plus a few other little bits lol

That’s not too bad really! I was expecting more. Does look the part

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

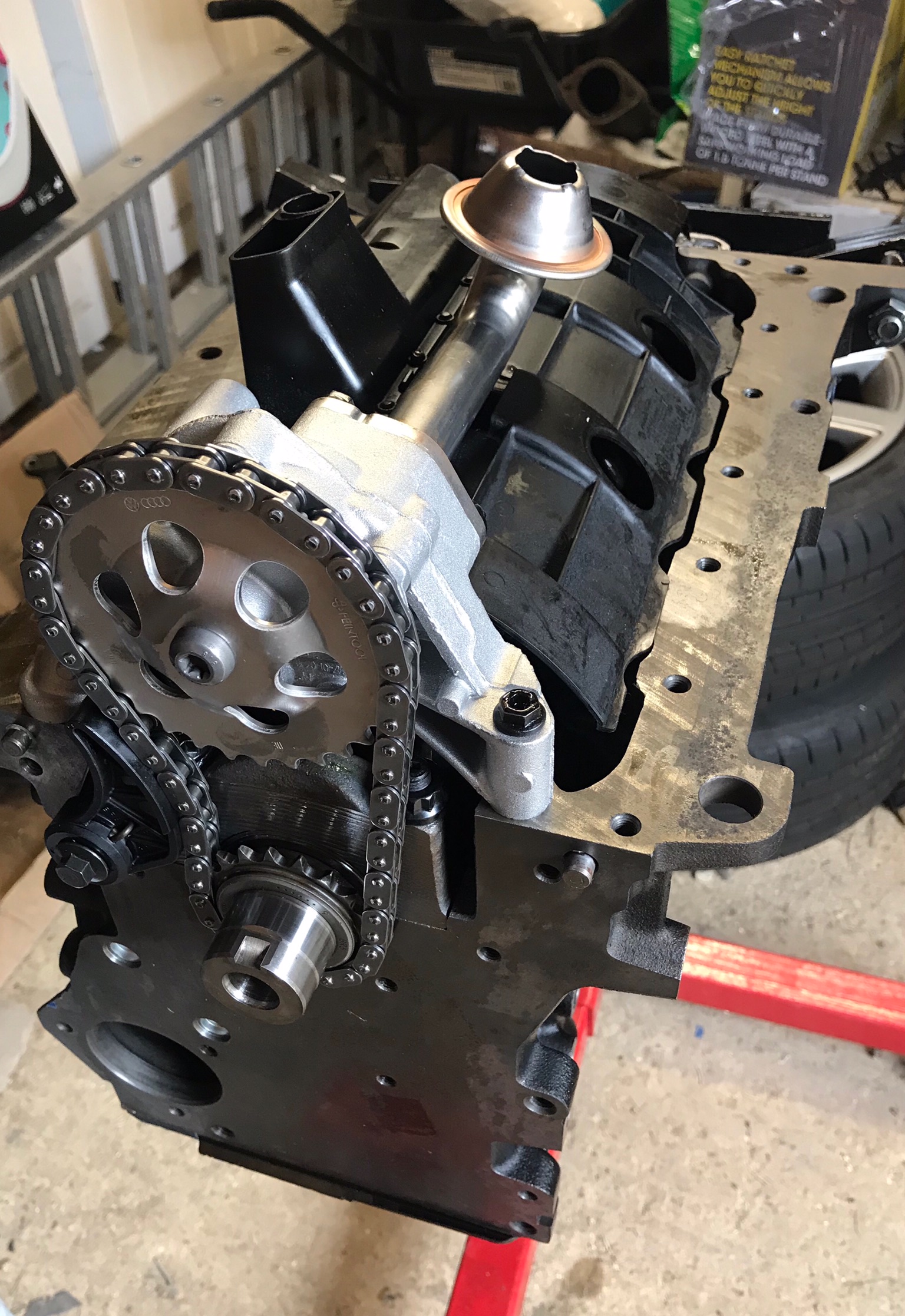

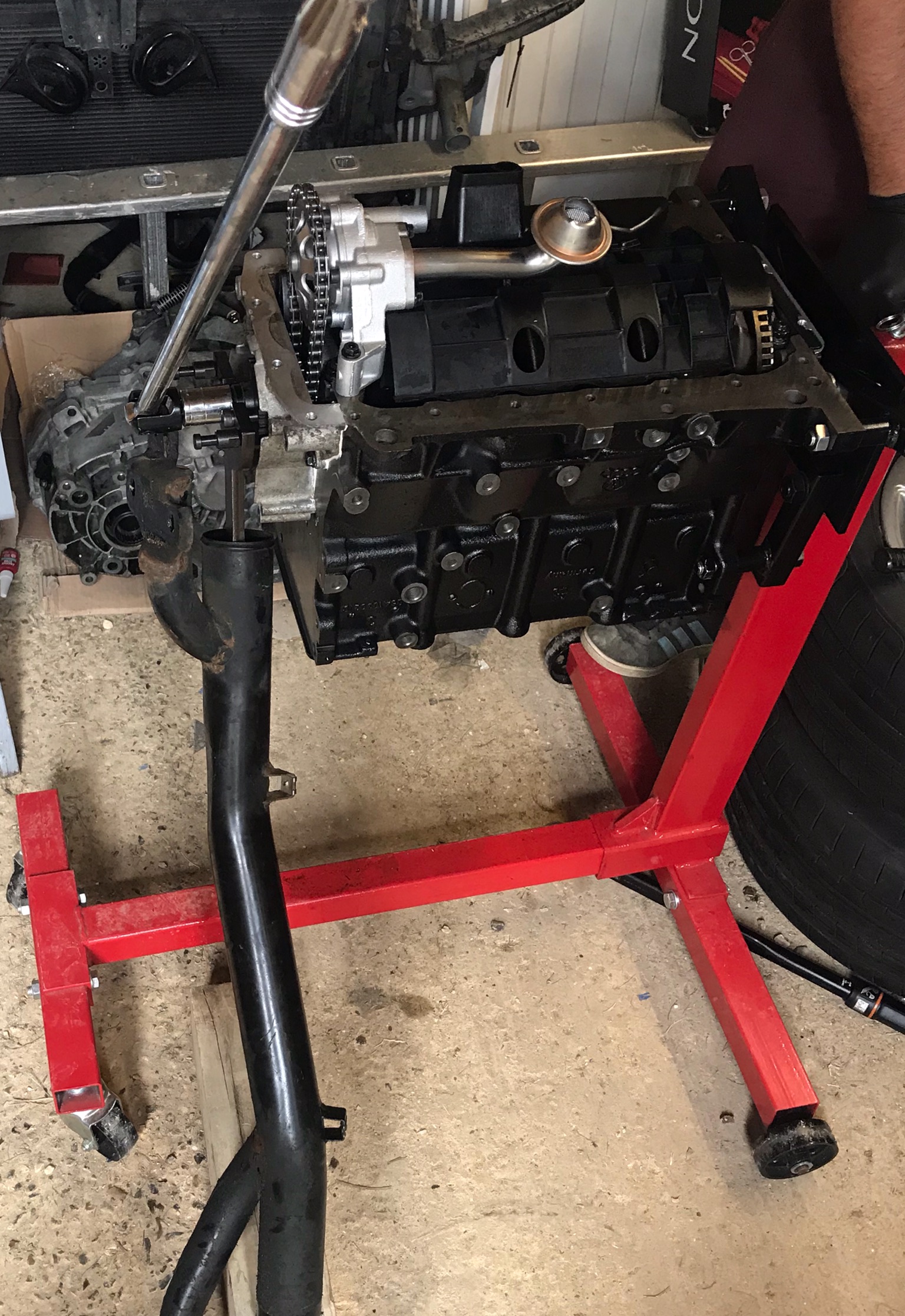

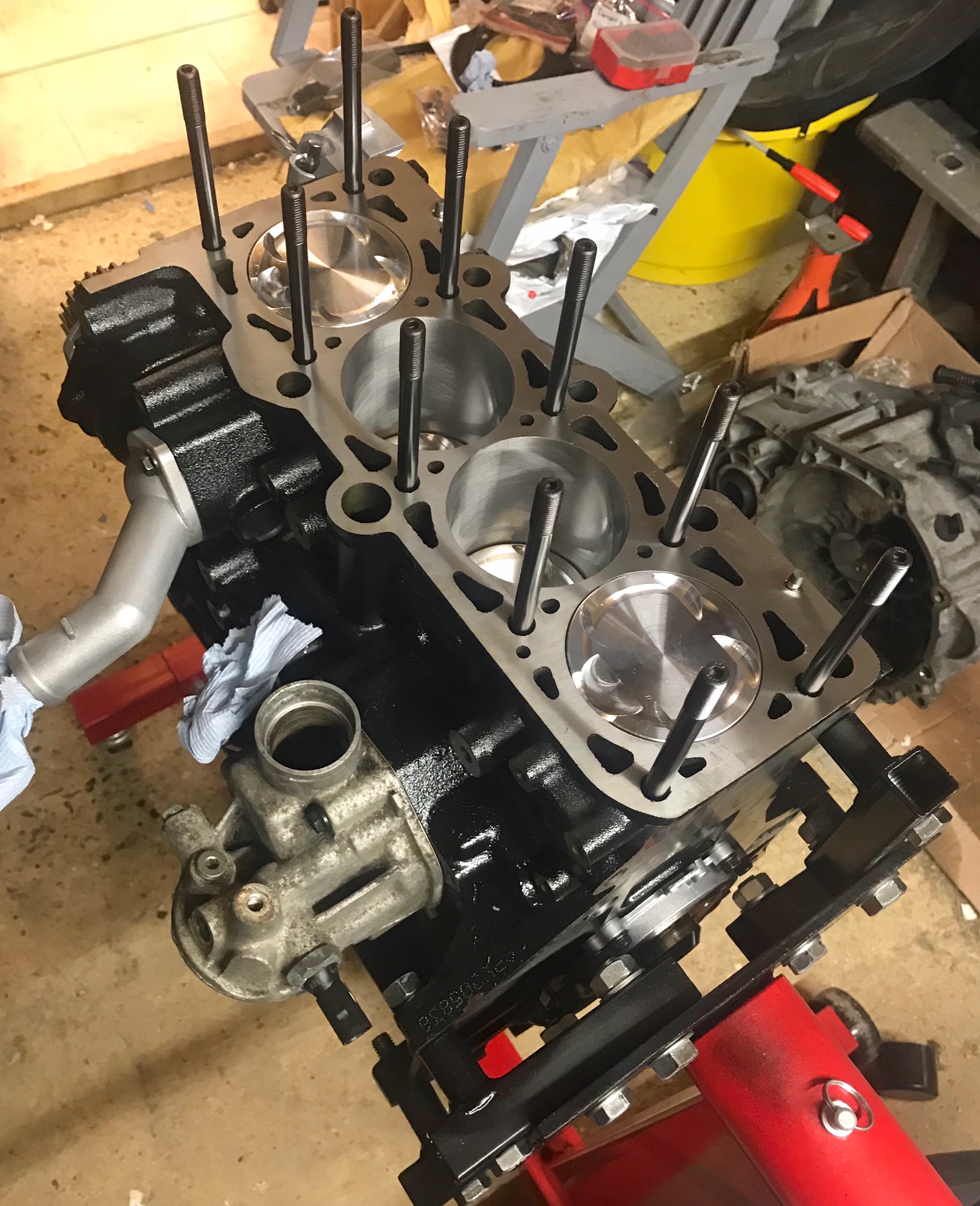

We made a little bit more progress on Sams engine today, that’s the bottom end complete now and looking great

After fitting all the rings in the correct orientations on the pistons and the new ACL race rod bearings in place we carefully slid each one into the bores and added the plastigauge under the rod bearings as we’d previously done with the crank mains, torqued the bolts down on the rod caps and then removed again to measure the clearances. Getting the caps off proved challenging as they’re an extremely tight fit but eventually got them all seperated to find all are within spec, phew

So after a good clean up and lube the caps were refitted and torqued down again for the final time

Next up we fitted the new OE oil pump, chain and tensioner, along with new pickup pipe, and then tapped in the new crank seal and fitted the front main seal using a little sump sealer

Then the not so fun bit, IE crank gear and ARP bolt. That thing is seemed impossible to get the full 1/4 turn. We ended up bending the breaker bar and crank holding tool lol. Tried everything but couldn’t quite get that full 1/4 turn so I think we need to get some thicker steel tube to use as an extension for leverage and one for the holding tool so we’ll have to try again next time

Lastly we bolted on the sump which needed a little bit of grinding on one edge to clear the ARP studs, this is normal. Thankfully it all moves nice and smoothly which was a relief

Next job is to finish the head and get it fitted and timed up

Steve

After fitting all the rings in the correct orientations on the pistons and the new ACL race rod bearings in place we carefully slid each one into the bores and added the plastigauge under the rod bearings as we’d previously done with the crank mains, torqued the bolts down on the rod caps and then removed again to measure the clearances. Getting the caps off proved challenging as they’re an extremely tight fit but eventually got them all seperated to find all are within spec, phew

So after a good clean up and lube the caps were refitted and torqued down again for the final time

Next up we fitted the new OE oil pump, chain and tensioner, along with new pickup pipe, and then tapped in the new crank seal and fitted the front main seal using a little sump sealer

Then the not so fun bit, IE crank gear and ARP bolt. That thing is seemed impossible to get the full 1/4 turn. We ended up bending the breaker bar and crank holding tool lol. Tried everything but couldn’t quite get that full 1/4 turn so I think we need to get some thicker steel tube to use as an extension for leverage and one for the holding tool so we’ll have to try again next time

Lastly we bolted on the sump which needed a little bit of grinding on one edge to clear the ARP studs, this is normal. Thankfully it all moves nice and smoothly which was a relief

Next job is to finish the head and get it fitted and timed up

Steve

Last edited:

M

Michael O'Connor

Guest

Fancied a change so swapped out the black Audi rings on the front grill for a nice new chrome one, the old chrome one was looking a little tatty. It’s amazing how different the car looks just by changing the colour of the rings. Not sure which I prefer tbh but I do like the all black grill look personally

View attachment 161459

There’s one thing that’s been bugging me

since I fitted the Zinram cat back. The only thing I think let’s it down is the tail pipes look a bit lost in the bumper recess. From a distance it doesn’t look like there’s an exhaust fitted lol

See what I mean

View attachment 161460

I dropped the tail pipe off at the fabrication shop I use along with a pair of 3” polished stainless trims that I’d cut down to size and had them welded on

View attachment 161461

View attachment 161462

I think it looks much better now and you can actually tell there’s something in the recess

View attachment 161463

I need to put the chrome rings back on the tailgate aswell now as it looks a bit odd lol

Steve

Looks lovely now with the bigger, longer tailpipes. I thought the exact same thing, would be nice for them to colour code with the chrome rings at the back. The noticed you'd said just that!

Looks lovely now with the bigger, longer tailpipes. I thought the exact same thing, would be nice for them to colour code with the chrome rings at the back. The noticed you'd said just that!

Thanks Michael

Steve

Next weekends job has arrived

I’m not really looking forward to doing this job and I’m still trying to find out how to get the clearance on the exhaust cam to replace the chain but I’ll muddle through it somehow hopefully without damaging anything lol

hopefully without damaging anything lol

I’m helping my mate Sam today finish putting his head together and fit it to the block and try and get it all timed up. The valve train is already assembled so it should hopefully be straight forward. I’m hoping it might give me an idea of how to replace my cam chain too

I’m not really looking forward to doing this job and I’m still trying to find out how to get the clearance on the exhaust cam to replace the chain but I’ll muddle through it somehow

I’m helping my mate Sam today finish putting his head together and fit it to the block and try and get it all timed up. The valve train is already assembled so it should hopefully be straight forward. I’m hoping it might give me an idea of how to replace my cam chain too

I contacted a supplier at Listers Stuart, I’ll PM you details mateDid you order the parts online? There's bits and bobs of gaskets i need.

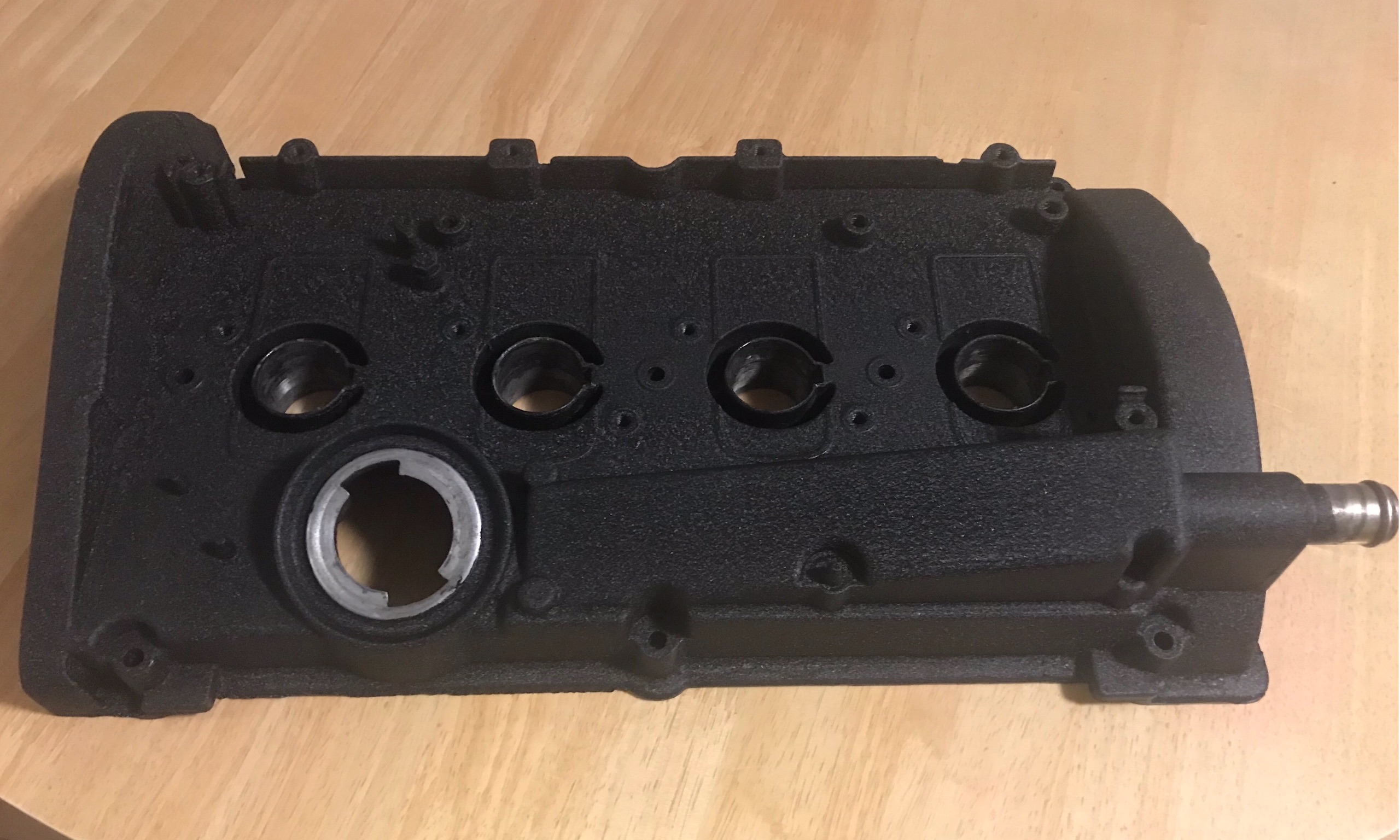

As usual things didn’t go to plan today lol. I was hoping to get a good start on some jobs today but the weather had other ideas. My plan was to replace my VVT tensioner and hopefully replace the chain too. Removed all the upper boost pipes and intake, removed the oil feed to the turbo and loosened the bolts on the compressor cover to get clearance to remove the cam cover. I’d only managed to get the cam cover removed and set cylinder #1 to physical TDC which lines up with the cam marker.

Is this normal for the belt to sit so far over? It is flush with the outer edge of the pulley but just thought I’d ask

It started chucking it down so I didn’t get chance to visually check the crank pully mark but the flywheel mark wasn’t visible so I’ll have to leave it now until next weekend and check it again then

Plugs don’t look too good

Looks like oil fouling but I also suspect the recent boost leaks might have had some influence too as it must have been running rich for a while. The middle cam cover gasket has been leaking into all four plugs so the top of the threads and porcelain is wet. These BKR9EIX plugs were fitted beginning of July so around 3.5 months old and not done many miles at all, the BKR8EIX that came out looked quite normal to me and had been in there around 8 months or so

(BKR8EIX removed 1st July)

Not wanting it to have been a wasted day and as the cover was off and looking very tatty I decided to give it a quick coat of paint. I’d recently done one in wrinkle black which looked really good so I slapped some of that on. Just needed a good clean and a quick prep and prime as the thick wrinkle paint hides most defects

Before:

Looks muck better now

Is this normal for the belt to sit so far over? It is flush with the outer edge of the pulley but just thought I’d ask

It started chucking it down so I didn’t get chance to visually check the crank pully mark but the flywheel mark wasn’t visible so I’ll have to leave it now until next weekend and check it again then

Plugs don’t look too good

Looks like oil fouling but I also suspect the recent boost leaks might have had some influence too as it must have been running rich for a while. The middle cam cover gasket has been leaking into all four plugs so the top of the threads and porcelain is wet. These BKR9EIX plugs were fitted beginning of July so around 3.5 months old and not done many miles at all, the BKR8EIX that came out looked quite normal to me and had been in there around 8 months or so

(BKR8EIX removed 1st July)

Not wanting it to have been a wasted day and as the cover was off and looking very tatty I decided to give it a quick coat of paint. I’d recently done one in wrinkle black which looked really good so I slapped some of that on. Just needed a good clean and a quick prep and prime as the thick wrinkle paint hides most defects

Before:

Looks muck better now

Last edited:

Rocker cover looks good mate. What is the red plate on top.of ur rocker cover? Is it a plate so you can use different coil packs. Will u just go back to a new set of BKR81EX or go for a new set of the BKR9E1X?

Thanks mate, should neaten it up a littleRocker cover looks good mate. What is the red plate on top.of ur rocker cover? Is it a plate so you can use different coil packs. Will u just go back to a new set of BKR81EX or go for a new set of the BKR9E1X?

Not sure on the plugs yet tbh, I think I’ll probably order some 8’s as it ran fine with those, saying that though it ran perfectly well with 9’s in. I always thought it seemed to prefere the 9’s lol

Last edited:

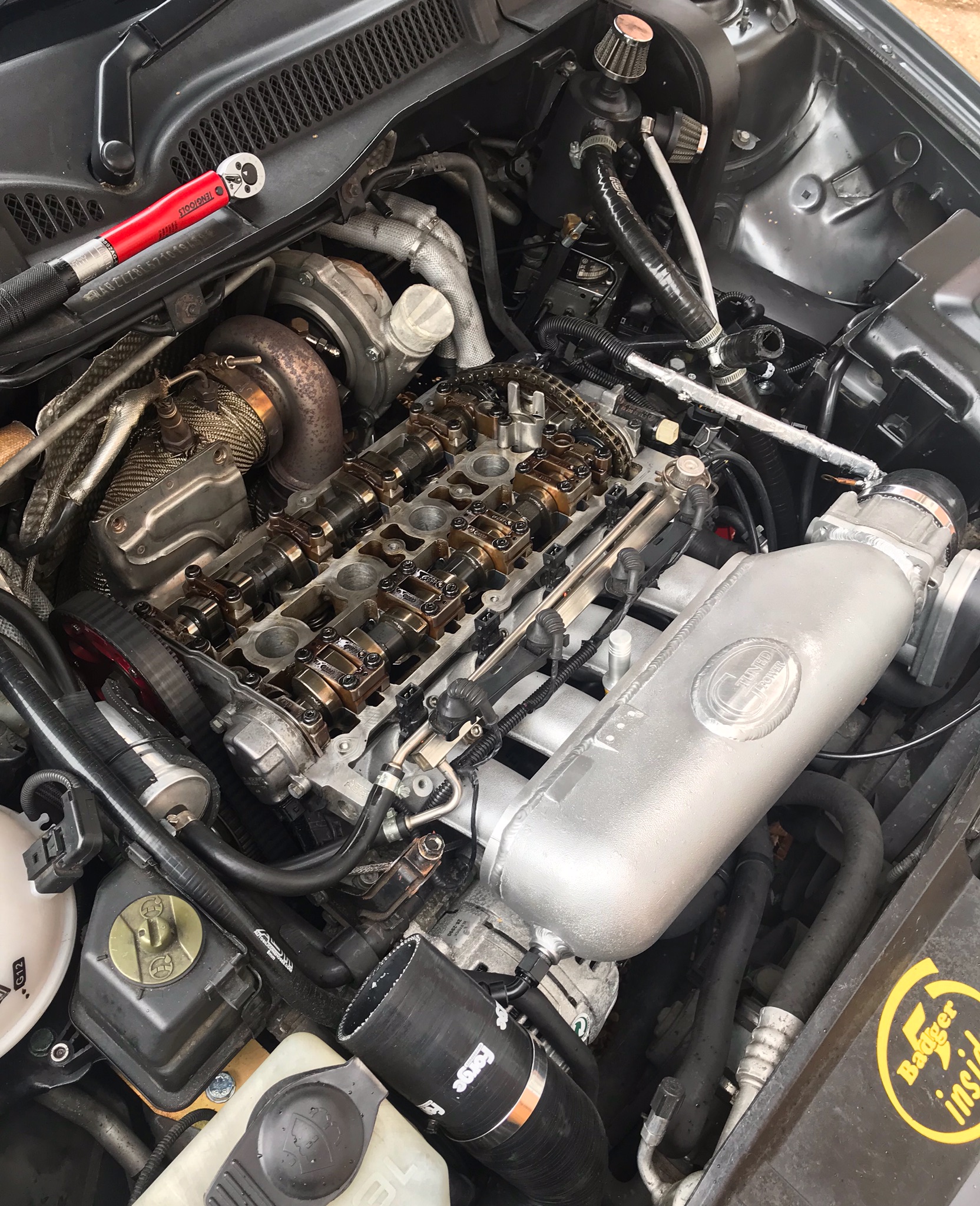

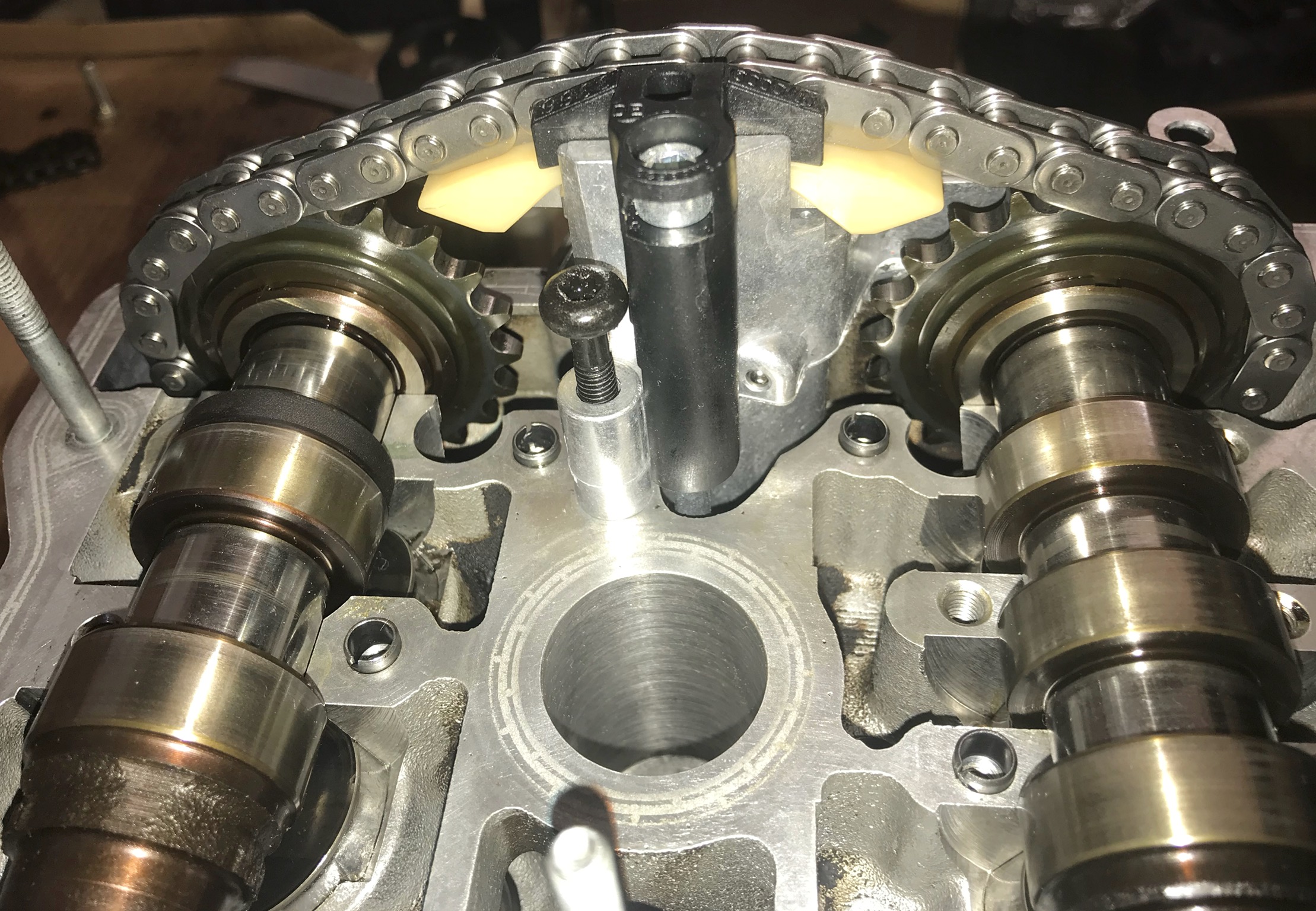

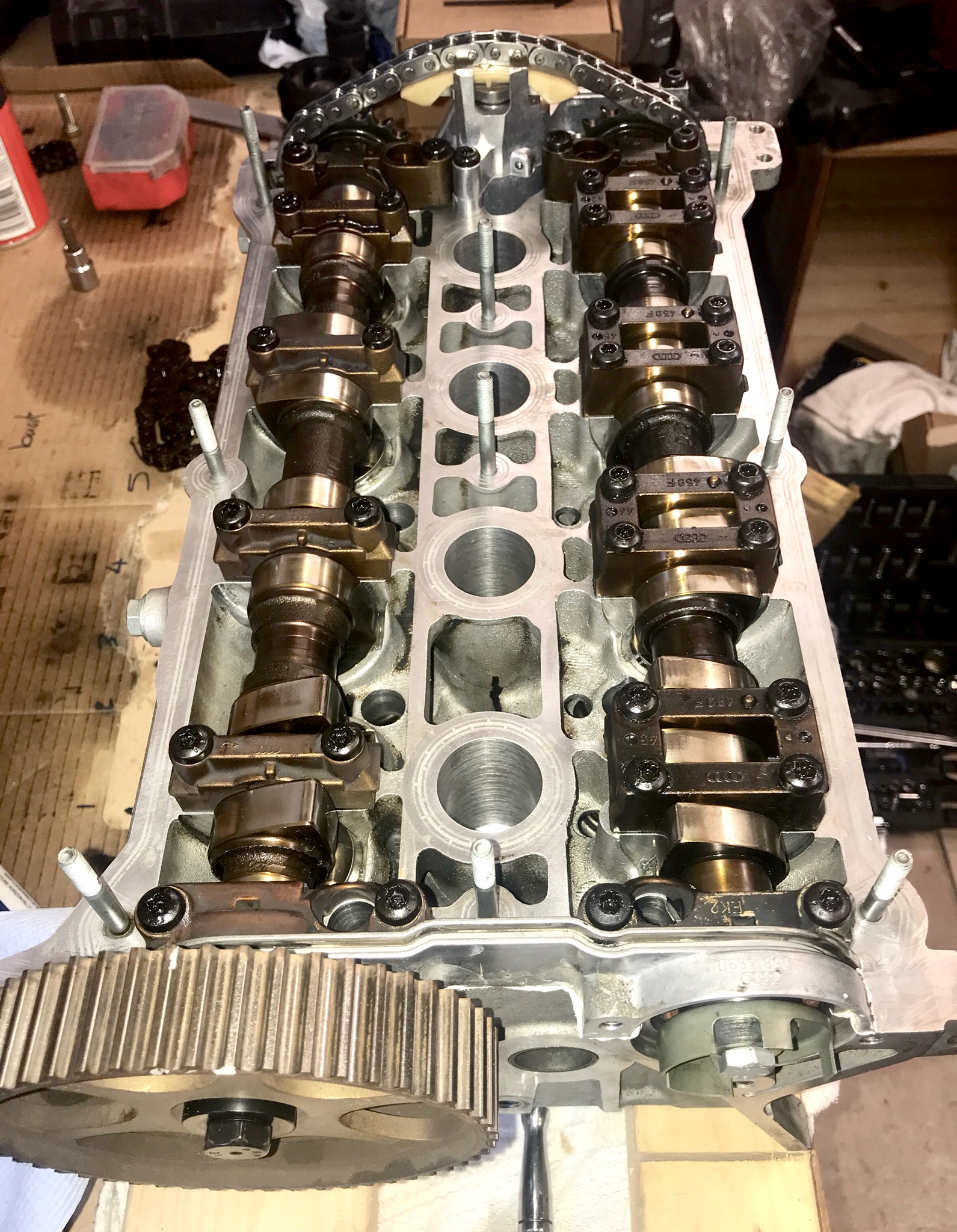

Made some really good progress with @Grundy on his engine this morning. Started off with new cam seals and put the cams in the vice to torque the new bolts and laid them in position along with the new cam tensioner and gaskets

ARP exhaust cam bolt (55ft/lb with red locktite) Inlet cam needs new bolt and torqued to 24Nm

Lubed the important bits where the cams sit in the head, we’d already lubed the valve lifters last week

Cams in position with the alignment notches facing upwards. Set the cam gears in the chain with 16 rollers between the marks

Refitted the cam caps and gradually worked all the bolts down then followed the torque sequence starting with caps 3, 4, 2, 5 working outwards and then 1 and finally the long end cover which needs a little gasket sealer underneath. Torqued the bolts down to 10Nm tightening in a opposite cross pattern

ARP head studs fitted using ARP lube on threads

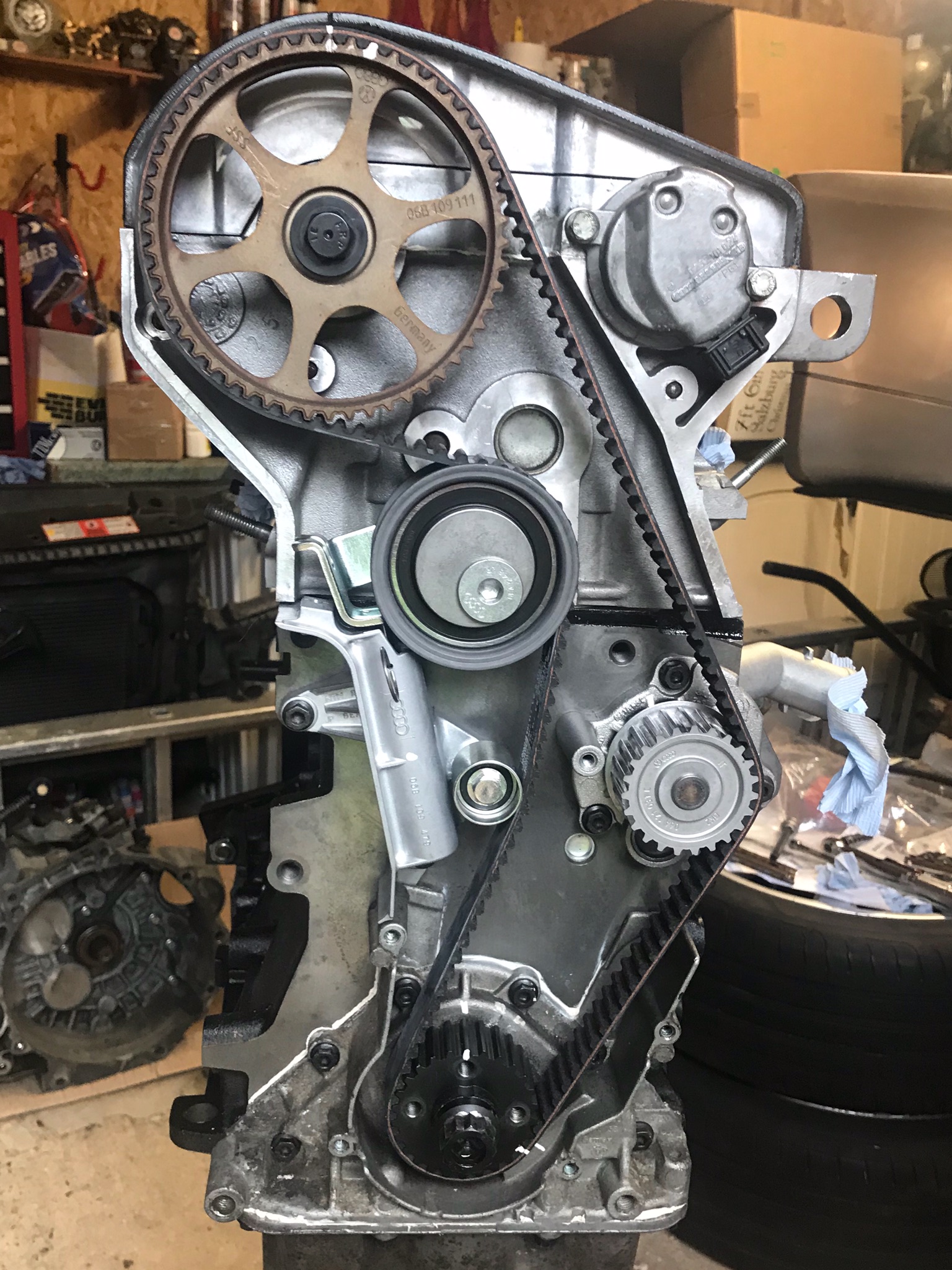

That’s the head fitted Made sure cylinder #1 was at TDC and cams aligned before mating. The ARP stud kit needs torquing to 80ft/lb in three equal steps using the ARP lube

Made sure cylinder #1 was at TDC and cams aligned before mating. The ARP stud kit needs torquing to 80ft/lb in three equal steps using the ARP lube

Timing belt fitted, timing marks checked. All looks good

Test fitted the exhaust manifold, inlet and wastegate

1.5” runners, it’s huge

Precision Turbo wastegate

Awesome looking turbo oil and water lines arrived from Badger5

I know it’s not my engine build but I think I’m more exited about this than Sam is, haha. I’m just glad I’m not the one footing the bill Next is the turbo purchase, this will be coming from AET Turbos and the manifold is now going away for ceramic coating before it’s all fitted. We still need to install the meth kit, fuel pumps, AEM wideband gauge and a few other things before it goes away for exhaust fabrication and then it’s running in time and then down to Badger5 for mapping

Next is the turbo purchase, this will be coming from AET Turbos and the manifold is now going away for ceramic coating before it’s all fitted. We still need to install the meth kit, fuel pumps, AEM wideband gauge and a few other things before it goes away for exhaust fabrication and then it’s running in time and then down to Badger5 for mapping  I think I should drive it back Sam @Grundy

I think I should drive it back Sam @Grundy

ARP exhaust cam bolt (55ft/lb with red locktite) Inlet cam needs new bolt and torqued to 24Nm

Lubed the important bits where the cams sit in the head, we’d already lubed the valve lifters last week

Cams in position with the alignment notches facing upwards. Set the cam gears in the chain with 16 rollers between the marks

Refitted the cam caps and gradually worked all the bolts down then followed the torque sequence starting with caps 3, 4, 2, 5 working outwards and then 1 and finally the long end cover which needs a little gasket sealer underneath. Torqued the bolts down to 10Nm tightening in a opposite cross pattern

ARP head studs fitted using ARP lube on threads

That’s the head fitted

Timing belt fitted, timing marks checked. All looks good

Test fitted the exhaust manifold, inlet and wastegate

1.5” runners, it’s huge

Precision Turbo wastegate

Awesome looking turbo oil and water lines arrived from Badger5

I know it’s not my engine build but I think I’m more exited about this than Sam is, haha. I’m just glad I’m not the one footing the bill

Last edited:

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

cool write - up - how on earth do you manage to keep track on working on 2 builds at the same time? I struggle to spend more than a couple of hours on mine without have to buy another tool

what is the purpose of the adjustable cam pully? have you ever adjusted it?

what is the purpose of the adjustable cam pully? have you ever adjusted it?

cool write - up - how on earth do you manage to keep track on working on 2 builds at the same time? I struggle to spend more than a couple of hours on mine without have to buy another tool

what is the purpose of the adjustable cam pully? have you ever adjusted it?

Haha, mines not in the build phase atm. It’s just ongoing maintenance so far

yeah it’s quite difficult split between working on mine, helping Sam and also spending time with the family so I don’t always get chance to do as much I’d like but we’re getting there

The vernier pulley allows for small adjustment in cam timing so the cams can be fine tuned and no that job’s entrusted to Bill, haha

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Vernier is more to compensate for the height lost from decking the block and skimming the head in this case... Bills cams are designed to be drop in...Oh I see, so Bill's racing cams are slightly offset or similar - amazing.

<tuffty/>

Vernier is more to compensate for the height lost from decking the block and skimming the head in this case... Bills cams are designed to be drop in...

<tuffty/>

Ahh, I see thanks for clearing that up

@<tuffty/> what would you recommend as the ideal compression ratio for a stroker piston on my setup, baring in mind my block’s been decked and head’s skimmed? I think I’m keeping the AET3076 (for a while at least lol) I love the rapid spool and it’s capable of producing around 560bhp. I’m going to start collecting parts and this will be the first purchase so I can source a block to have rebored (and probably decked if needed)

Thanks

Thanks

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I run 9.5:1... not sure what Bill's preference is these days but 9.5:1 works for me

<tuffty/>

<tuffty/>

I run 9.5:1... not sure what Bill's preference is these days but 9.5:1 works for me

<tuffty/>

Thank you

I did do quite an in depth write up (with plenty of images) of how I stripped and cleaned both the controller internals and pump, if it’s of any interest to anyone I’ll make a post when I get a few minutes

Great car and the best colour

Is the offer of putting your write up still open? I'm sure it would be be beneficial to others.

Thank youGreat car and the best colour

Is the offer of putting your write up still open? I'm sure it would be be beneficial to others.

Yes I can do that, I’ll get it put together as soon as I’ve got the car sorted and get a little free time

Steve

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Hi so here you said you put the camshaft into a vice to undo / do-up cam pulley bolt, my neighbour suggested the same. Did you just protect the cam lobes with card board?

The head is last on my list so I Just want to do it right. Did you actually need to change the inlet can bolt as there is no load on it?

The head is last on my list so I Just want to do it right. Did you actually need to change the inlet can bolt as there is no load on it?

Hi so here you said you put the camshaft into a vice to undo / do-up cam pulley bolt, my neighbour suggested the same. Did you just protect the cam lobes with card board?

The head is last on my list so I Just want to do it right. Did you actually need to change the inlet can bolt as there is no load on it?

View attachment 166411

Hi Stuart, yeah we wrapped the cams with rags and then covered with cardboard placed in a vice with wood over the clamping pieces.

I read somewhere (maybe Elsawin) that the inlet cam bolt must be replaced so we just replaced for piece of mind

Could someone please have a look at these pictures and tell me if they look right. With the crank in line at TDC, the flywheel notch is visible but the cam marker isn’t quite aligned somehow. With the cam aligned correctly the crank and fly are out. I’m a bit puzzled and don’t want to proceed until I know it’s okay

Thanks

Thanks