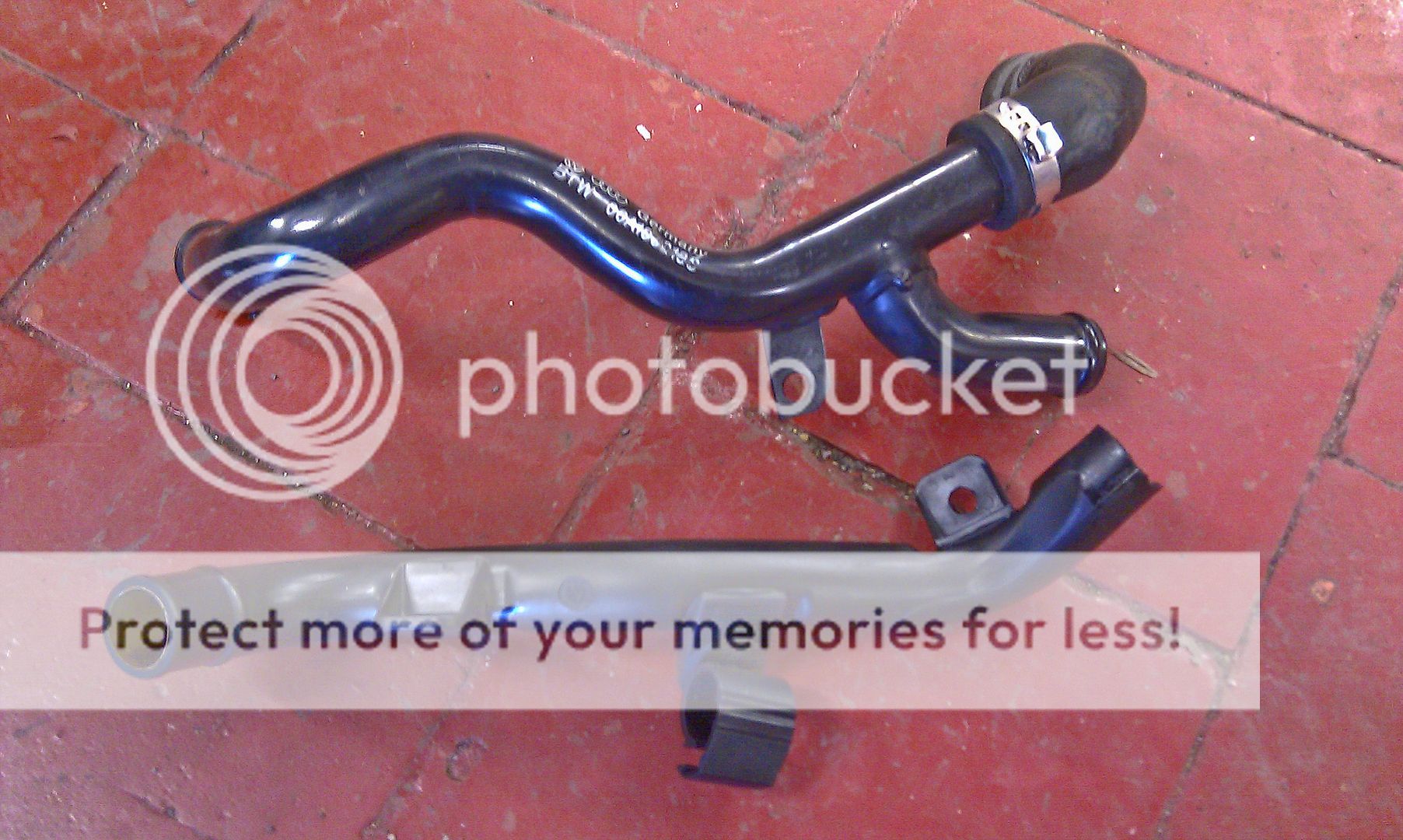

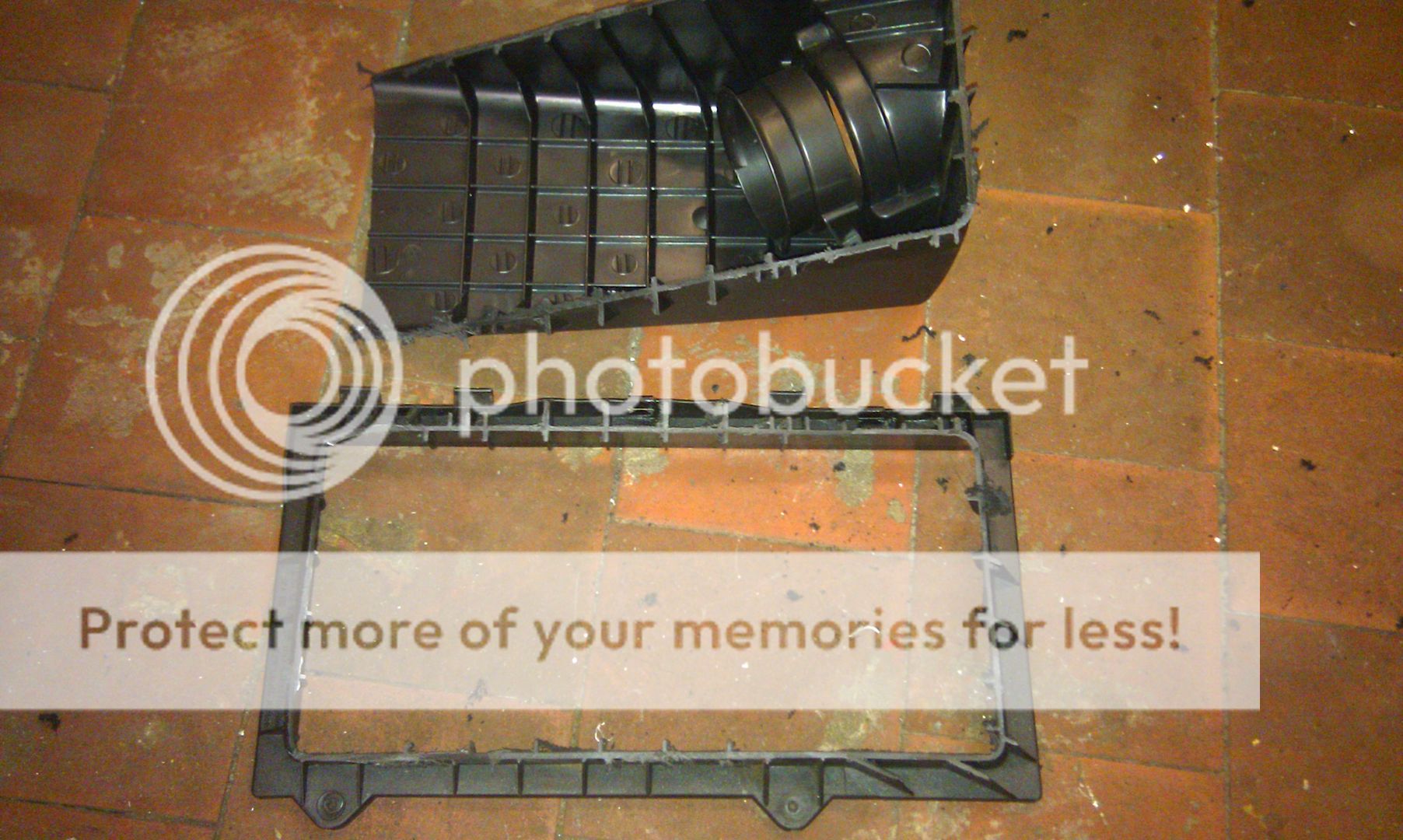

The PCV pipe bodge (sorry... temporary fix) decided to give up the ghost today so needed to get something sorted on that really... I noticed that the non VVT 20v engines on Ibiza's have a pipe thats metal rather than plastic and appear simplier in design so dug one out of the bits box to have a look...

Looking at them side by side the Ibiza (maybe the same as early A3's too) pipe is 'Y' shaped and metal while mine is plastic and crap... and broken of course...

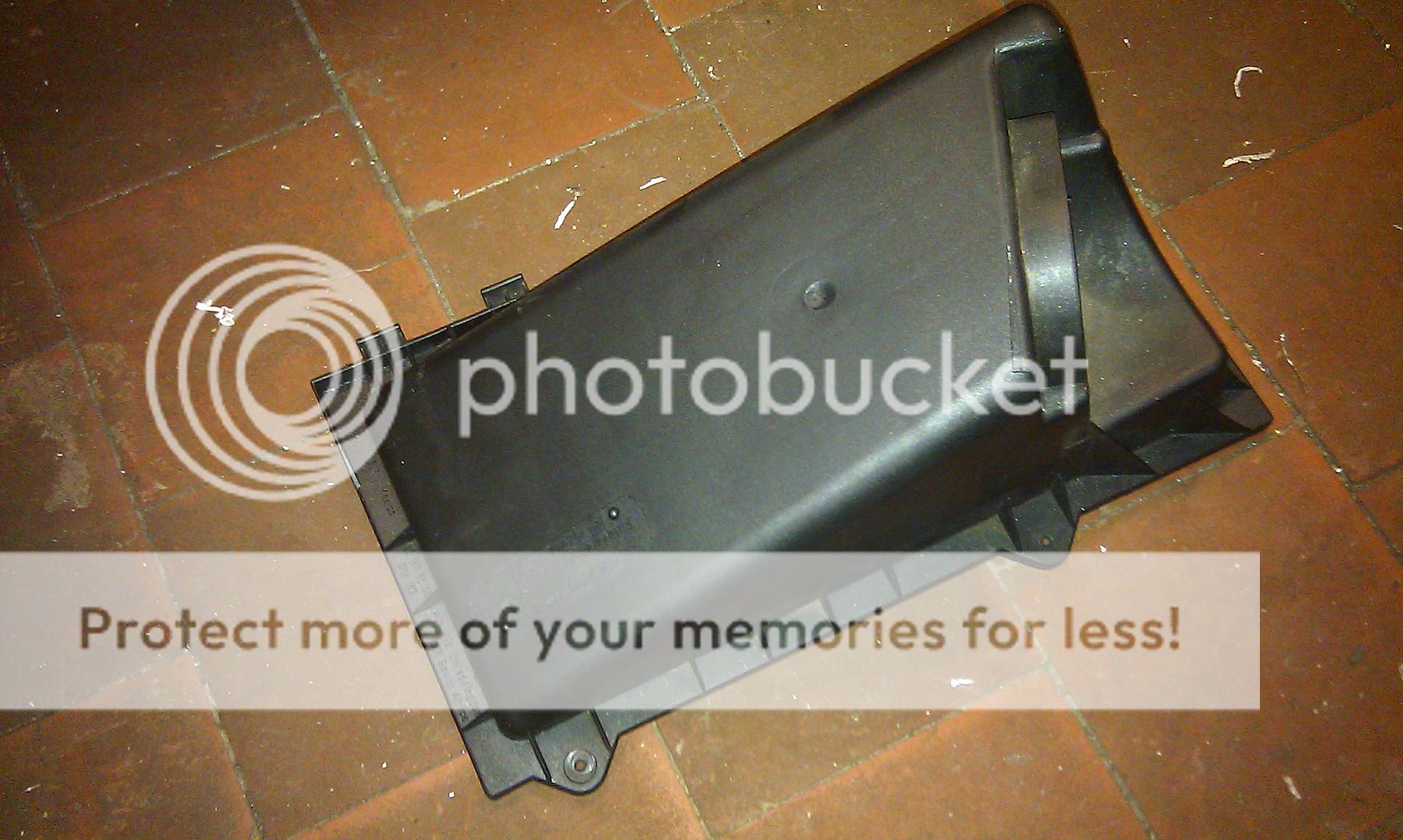

The problem with this pipe of course is that it isn't a direct replacement... nowt will line up right for a start on a std engine layout and as can be seen in the following pic of the pipe in its rightful place on an actual Ibiza its designed to fit with no VVT actuator in the way which sticks out the side a bit further...

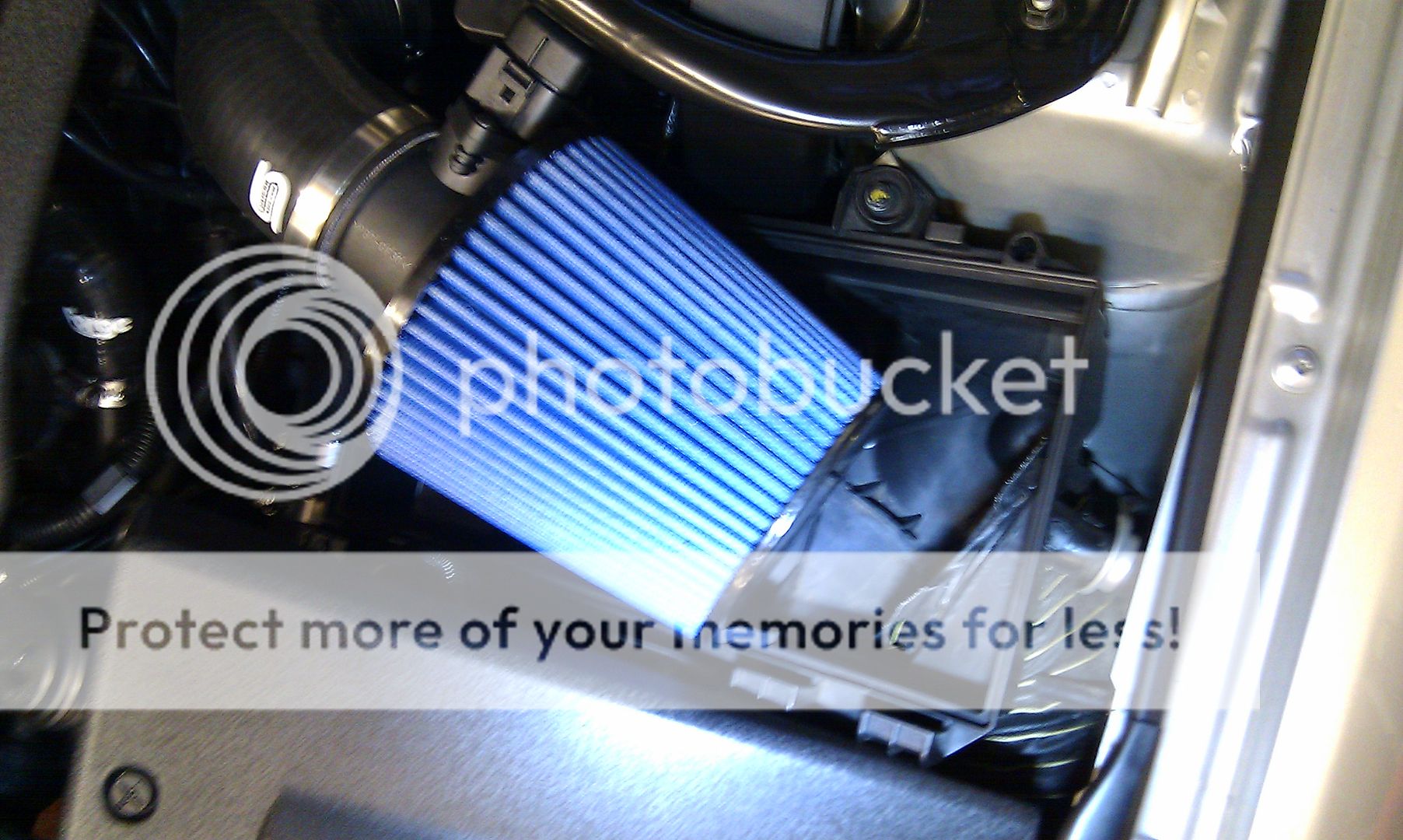

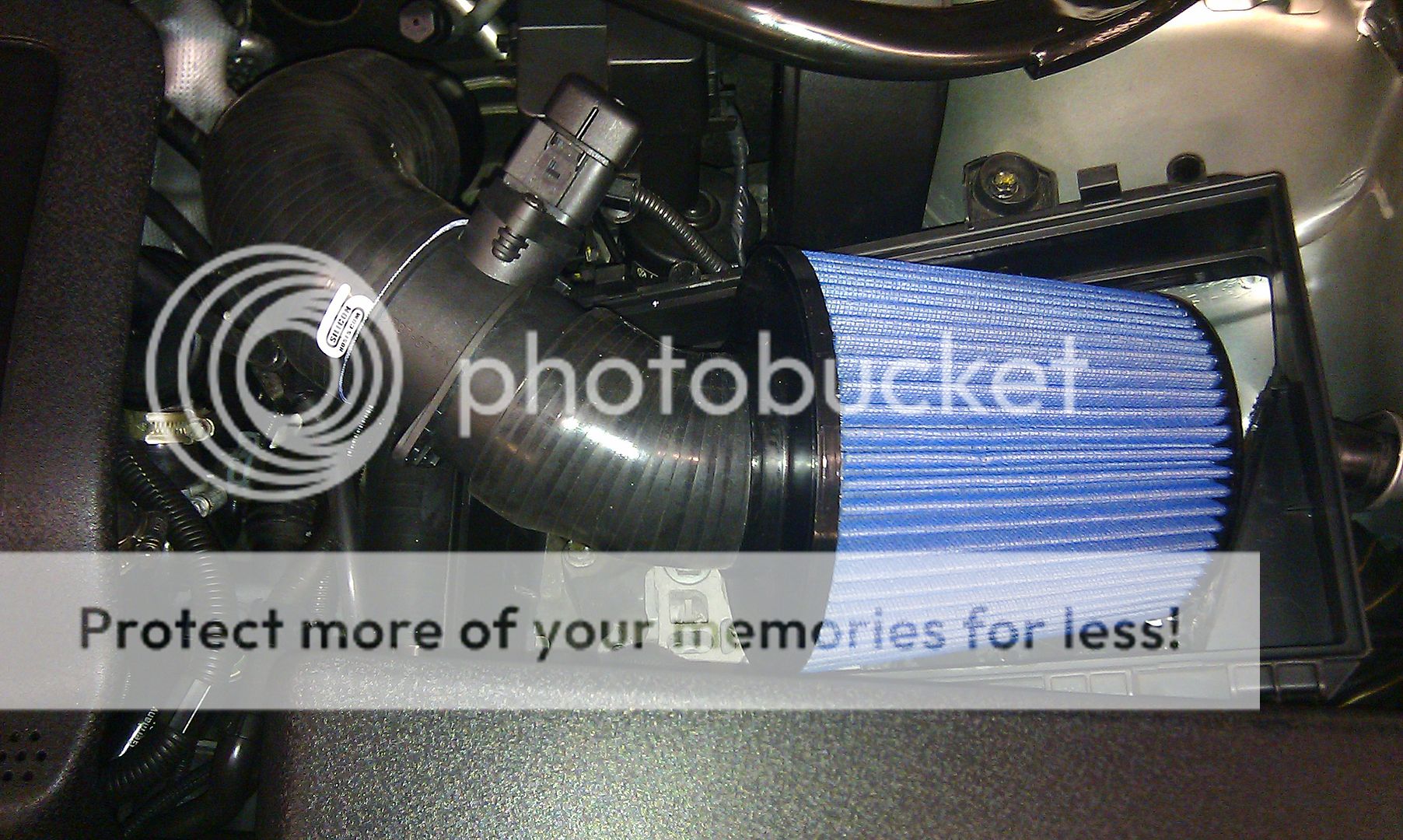

My current setup uses a Forge replacement hose for the crappy rubber ***** coupling the PCV together to the 'hocky puck' from the cam cover and crank breather...

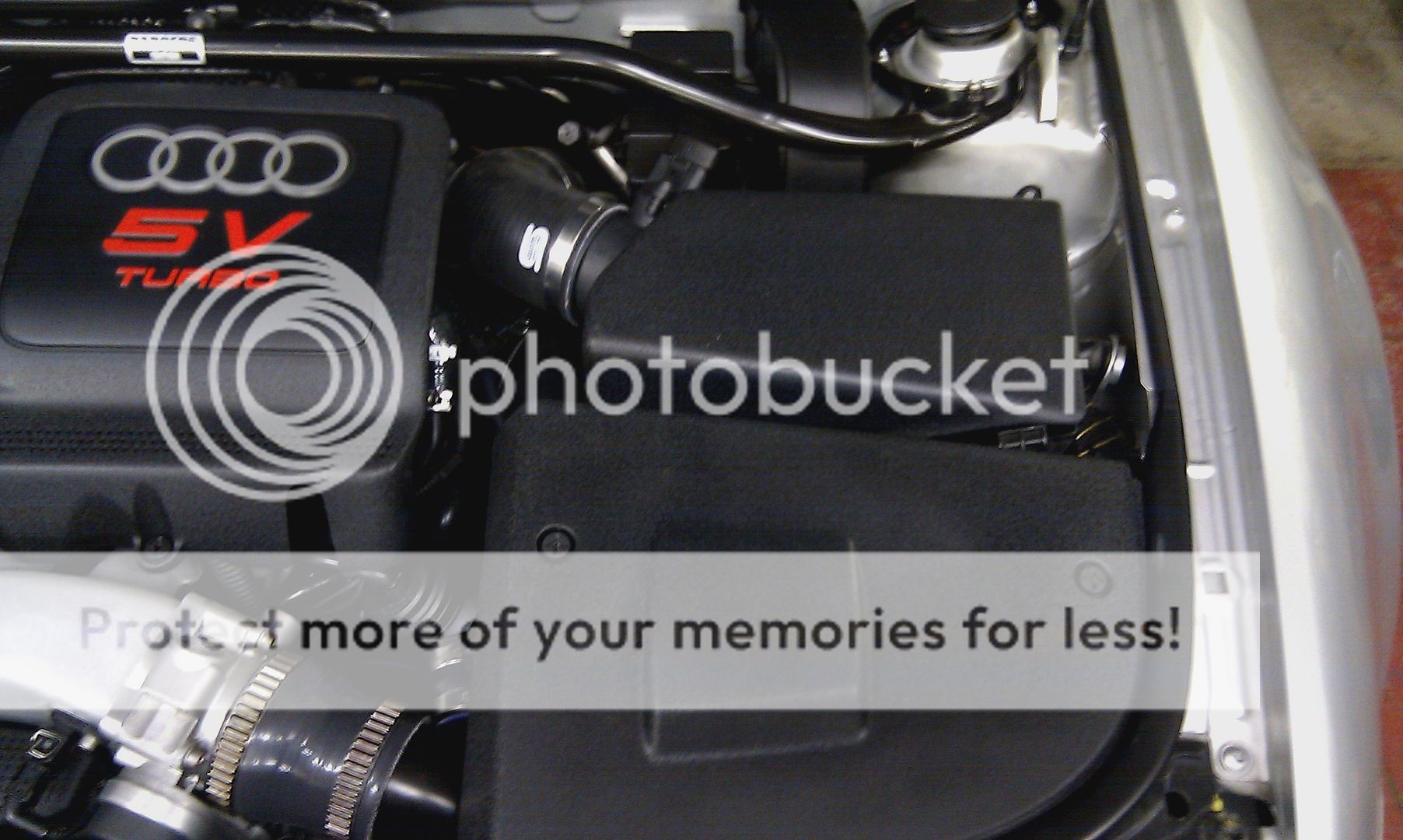

...the Forge pipe that will be coming off

Early AMK engines are different to this setup (Danes car being the one that springs to mind), mine being a later AMK shares more with BAM engine codes and Forge list this part as BAM only but it will fit later AMK engined S3's (and possibly LCR/TT's too)

As I still need to fabricate the catch tank I have set this up pretty much how I had it before venting down to the deck for now... I need to make some adjustments as its touching the VVT unit so really need to stand it off a bit to stop engine vibrations wearing through the VVT actuator and/or the PCV pipe...

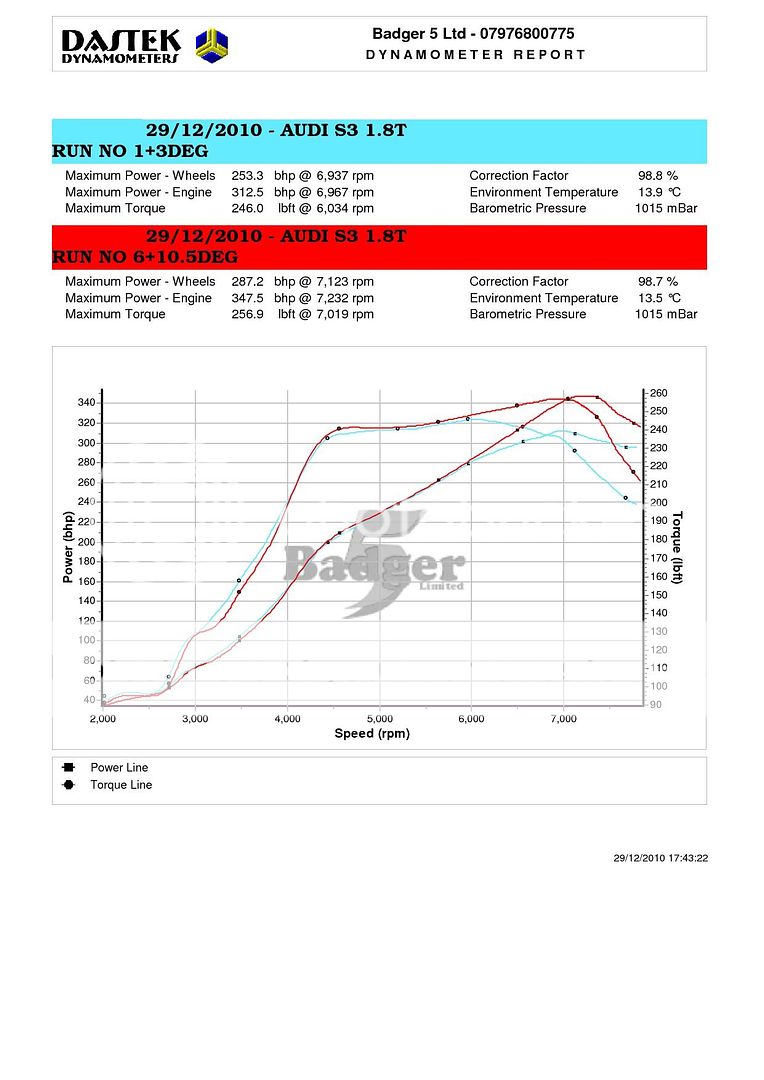

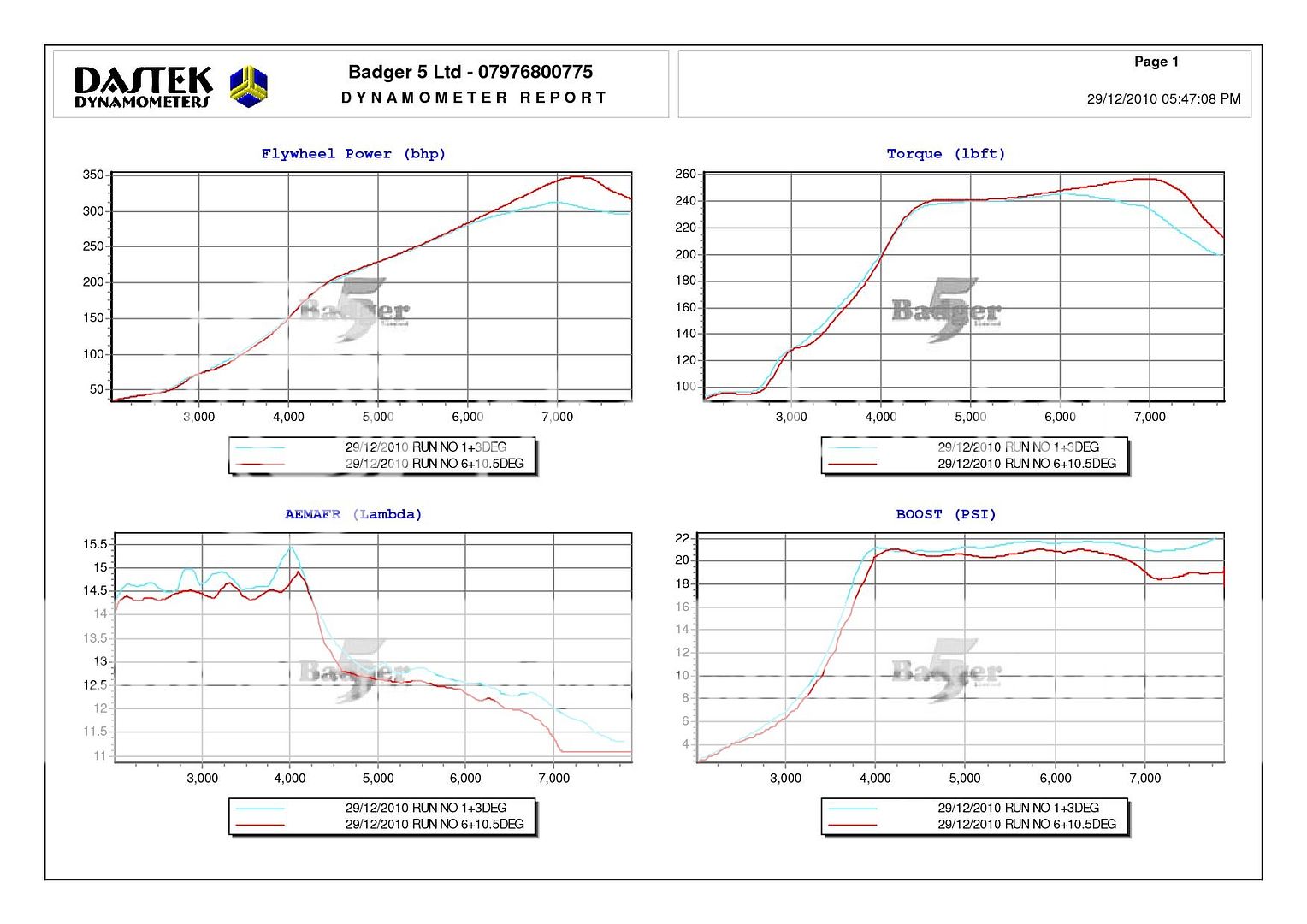

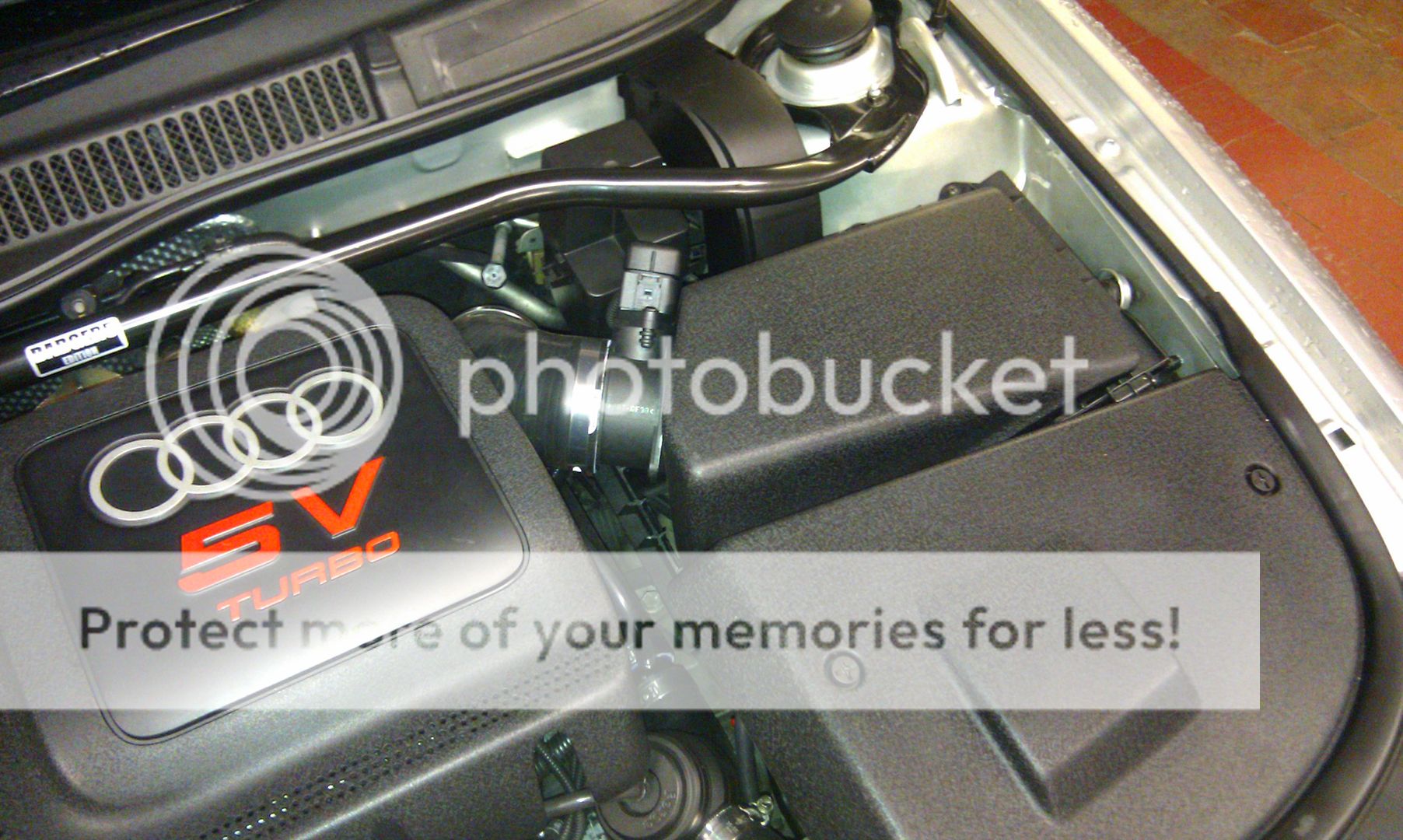

Bill had a new new file for me to try and see if we could get the AFR sorted from 5.5k as it was going very rich and killing power...

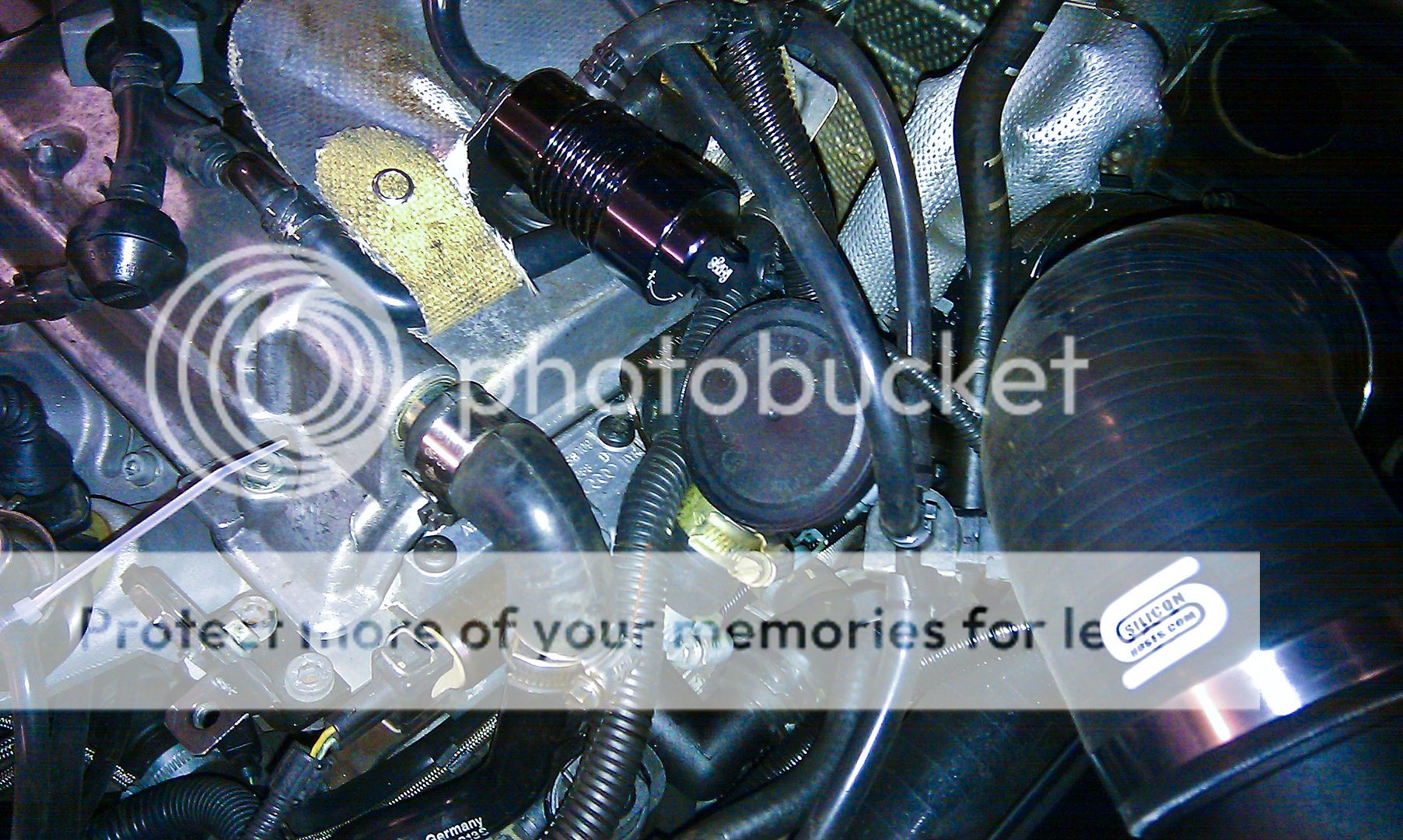

Before running the car on the dyno though I wanted to check the oil pressure as since fitting the AEB large port head I have developed a rattle on idle that I am pretty sure is the VVT unit but to be sure I wanted to check the oil pressure as the oil pump is cheaper and easier to replace if it turned out to be that... hooked up an oil pressure gauge and got the car strapped to the dyno...

warmed her up and checked idle pressure... around 22psi... loaded the car up and this went up to over 80psi (all checked at 90 degrees engine temp)... not the pump then...

Looks like I will need to get a new VVT tensioner unit then.. rubbarsh

Oh well, next Bill ran the car up on the dyno and we managed to get 'a run' before the dyno decided to not record coast down losses... not that there was much point as the AFR went lean after 6k rpm so did some logging runs and left it at that as time was pressing on... the car did manage 354bhp though on the same boost which goes to show the rich AFR was killing the power at the top end... Bill didn't rag the engine too hard though as while it wasn't dangerously lean its better to be safe than sorry... ran out of time so will tweak the map again and try another day...

Quite productive so happy :thumbsup:

<tuffty/>