Been a long day.... seems like I have removed half the car to get to the gear box but its all ready for removal now (I hope at least) and when great mate Mark pops over to give me a hand...

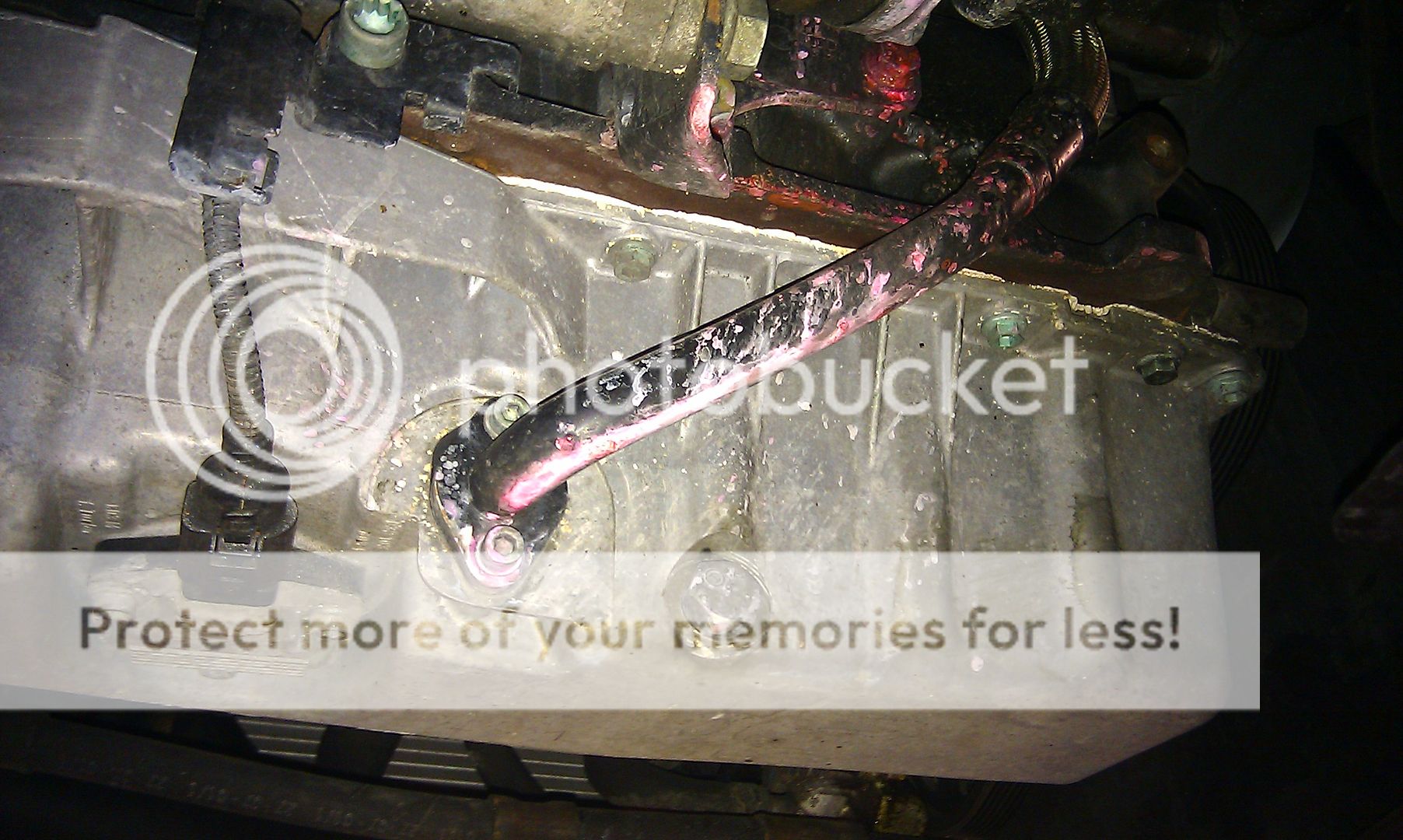

Removed the metal pipe that spanned the front of the car legacy from the old SMIC's... simple enough task once I had removed the plastic trims from underneath the car and undone the bolts holding the power steering pipework to it... I will have to make up some brackets for those later.... the metal pipe is only held on by three 13mm bolts either side of the car and isn't that heavy tbh...

... removed both drive shafts...

...to stop the shaft turning while undoing the bolts...

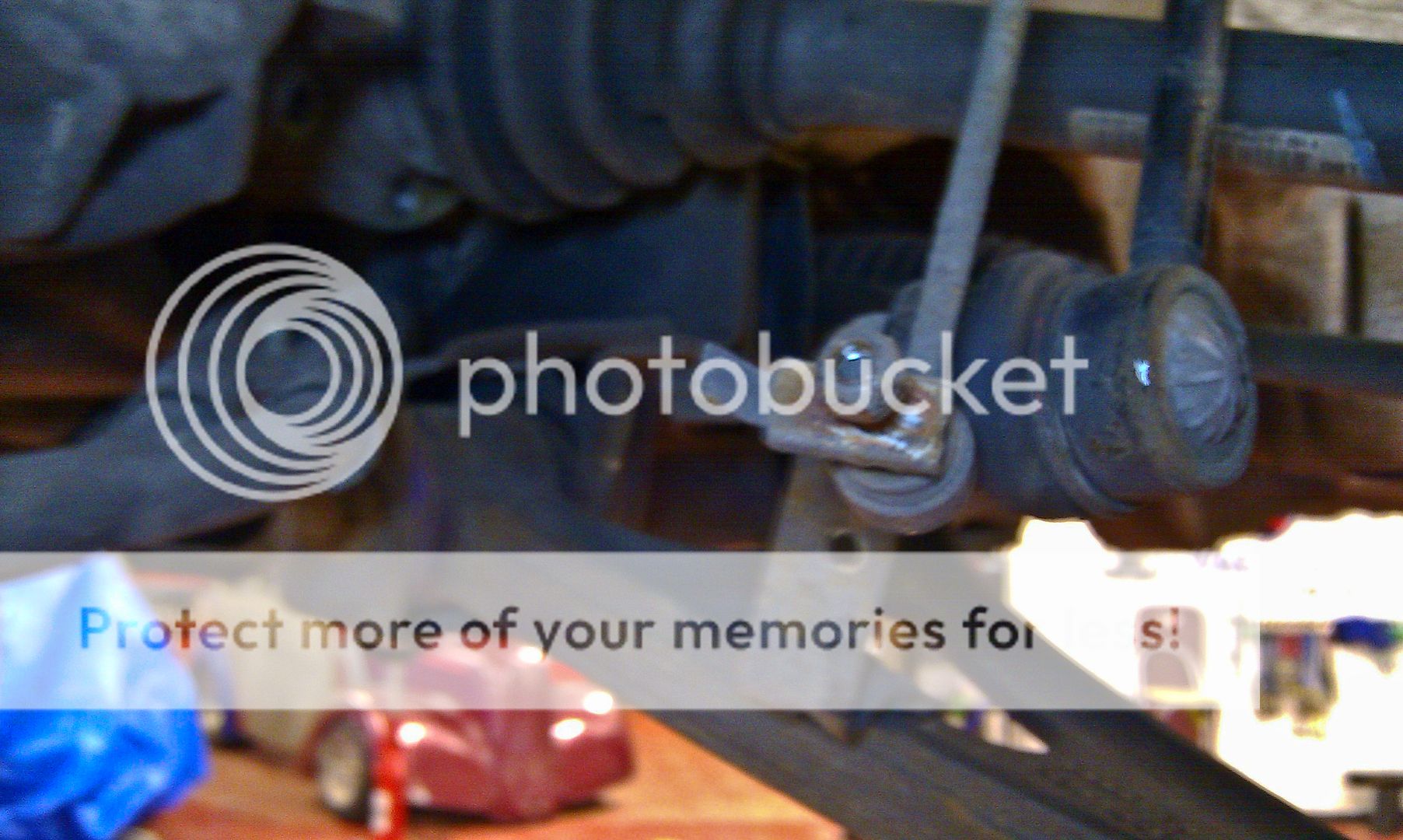

...make sure (on cars with factory Xenon lights) you undo the Xenon level sensor rod from the lower arm before...

...cracking off the ball joint... if the Xenon level sensor rod is left connected you could break the plastic arm off...

...and done...

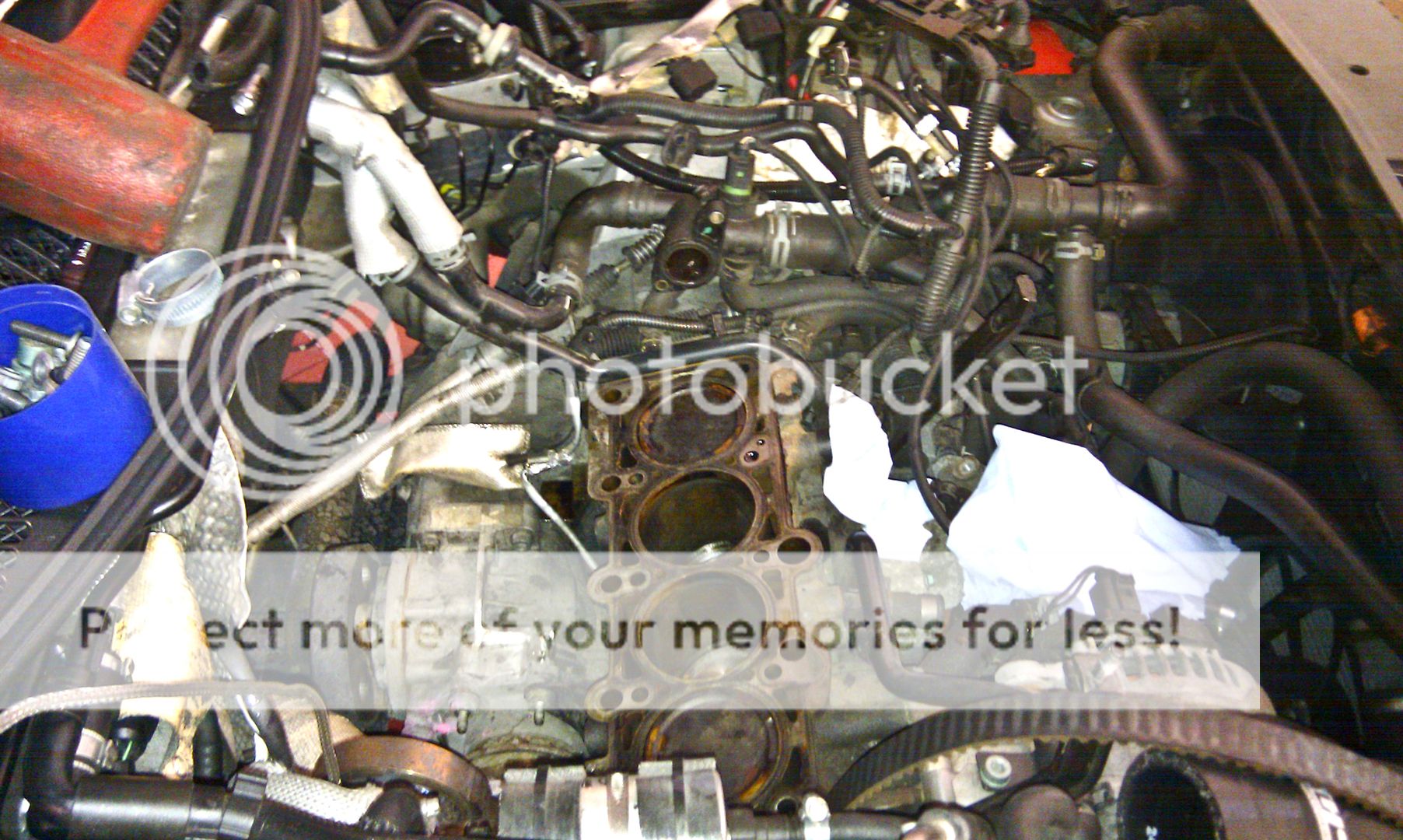

The pile of bits being removed is growing...

Hit a problem with undoing the subframe bolts as they were firkin tight and required the he-man strength of Tony's mate winney (sp) to undo them!!

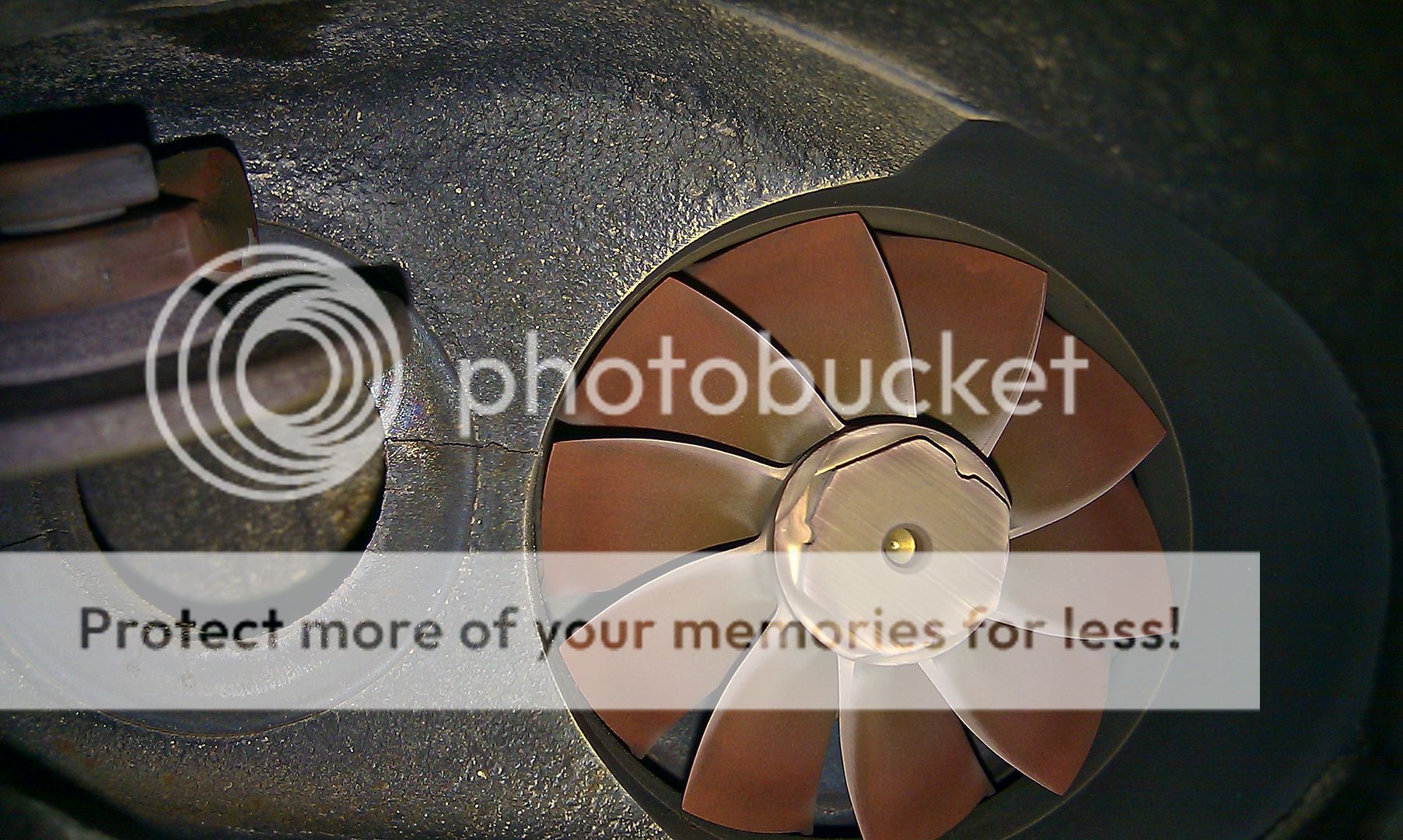

As there wasn't much more I could be bothered to do (been at this most of the day and now into the evening) I decided to take the turbo off the manifold so I could start stripping the head... turned out to be a very disappointing move... checking the comp wheel there was a little frilling of the blades, nowt to worry about I don't think but one of the vanes has a slight bend in it...

...there is also far too much oil in the intake so I am going to simplify the PCV and fit a catch tank somewhere...

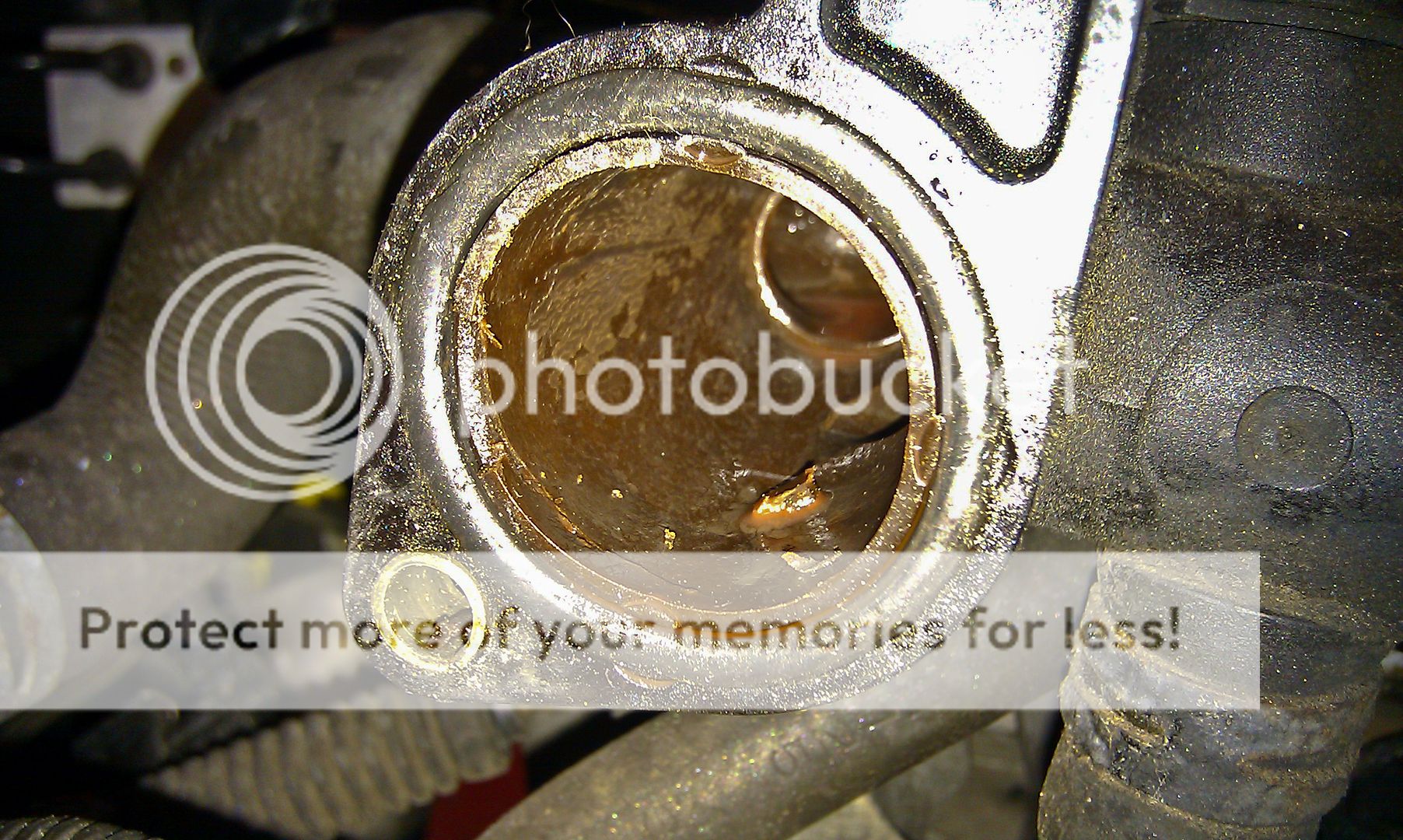

...things got worse when I inspected the turbine housing...

******!!! pretty sure I am going to need a new housing... not really sure how it happened as tbh the most my car gets ragged is when its on the dyno... will see what Bill has to say

Hoping the clutch swap will go a bit smoother but if I need to buy a new housing it will impact my initial plans of getting another FMIC to play 60mm pipework with as I can't afford both... turbo trumps FMIC in this case... rubbarsh...

<tuffty/>