You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The main issue is I do have a little creep... not sure exactly what the cause is but crack pressure is some 8-9psi rising to 12-14psi ish... a stiffer spring may exacerbate the issue which is a concern.

<tuffty/>

You’re a victim of your own success at this point!

A nice free flowing system wants to spool up and the the Wastegate can’t dump enough gases to to fight it.

Used to make me laugh when the the BMW guys woulthe best flowing exhaust manifold they could and a full 4” exhaust and wonder why they they couldn’t make less uthan 17-18psi of boost due to boost creep. Build it make 700hp and it wants to make it. Twinscrool with duel Wastegates with the Wastegates tied back into the exhaust at as shallow an angle as possible is about as good as it gets. The shallow angle of the Wastegates tie helps create a scavenging effect to let them dump more exhaust gasses

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

no.You’re a victim of your own success at this point!

A nice free flowing system wants to spool up and the the Wastegate can’t dump enough gases to to fight it.

Used to make me laugh when the the BMW guys woulthe best flowing exhaust manifold they could and a full 4” exhaust and wonder why they they couldn’t make less uthan 17-18psi of boost due to boost creep. Build it make 700hp and it wants to make it. Twinscrool with duel Wastegates with the Wastegates tied back into the exhaust at as shallow an angle as possible is about as good as it gets. The shallow angle of the Wastegates tie helps create a scavenging effect to let them dump more exhaust gasses

more a case of n75 cant flow sufficient to feed a tial external gate. they are a restricted solenoid. external gates like tial are "leaky" inherantly, not sealed diaphragm (on lower port)

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Gets hotter than that when ragged but I had been cruising up to the point I did the run...How do you get 527 degree c EGT that's idling temperature

Measured in the downpipe mind... in the 3.5" section... EGT's have always been low on my setup... but have seen 700+ in the past... egt protection is adjusted to suit the lowered measured temps

Hit nearly 700 on the dyno run the other day...

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

But how? A k04 at 19psi after about 5 seconds is 890-900 with IAT ~33? Is it to do with the hot side, fueling, downpipe valves etc? You are 30psi aren't you? Our does a big turbo setup cancel pout everything else?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

You lose 100-150 deg across the turbine, I have a free flowing setup, 1.5" nominal bore manifold, large turbine and hot side, 3" exhaust, decent amount of ignition timing, fattened AFR... it works... what can I say... its built to perform...

On a 'track' I have no doubt EGT's would easily rise to mid 700's and have seen it before on longer dyno sessions and after a bit of spirited driving... but on the road where its used the most its running nice and cool

<tuffty/>

On a 'track' I have no doubt EGT's would easily rise to mid 700's and have seen it before on longer dyno sessions and after a bit of spirited driving... but on the road where its used the most its running nice and cool

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

...k04's and their manifolds are waaaaaay more restrictive than my setup btw... mine running 30psi is also largely irrelevant

<tuffty/>

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Thanks tuffty, so essentially the heat is not generated from the explosion but instead from the gases exit restriction. In stock manifold, hotside and downpipe.

A ported free flowing manifold and 3inch downpipe should help move it out the way quicker?

A ported free flowing manifold and 3inch downpipe should help move it out the way quicker?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Thanks tuffty, so essentially the heat is not generated from the explosion but instead from the gases exit restriction. In stock manifold, hotside and downpipe.

EGTs are an indication of state of combustion but also restriction... my EGT's from restriction (a turbo by design is itself a big restriction) rise more slowly than a K04 as my overall VE is better...

K04 with its small hotside and compromised manifold design will always run hotter under normal conditions

On the drive to work this morning a steady drive at motorway speeds resulted in measured EGT's of around 650deg... rising to 680deg on an light accelerated overtake and down to mid 500's letting off the throttle... higher EGTs are to be expected as I am cruising at 'high' speed at lambda 1

A ported free flowing manifold and 3inch downpipe should help move it out the way quicker?

Yes.... My setup flows well and as Bill always says its all about the flow... less scope for heat build up and retention... get it in and get it out efficiently...

<tuffty/>

Yes.... My setup flows well and as Bill always says its all about the flow... less scope for heat build up and retention... get it in and get it out efficiently...

<tuffty/>

This is what I was alluding too regarding the Wastegate control.

Due to packaging constraints the Nortech Wastegate placement isn’t theoretically optimal for low boost control. It’s set back in the other direction away from the flow and fluid dynamics 101, the gases will take the path of least resistance. Which is the bigger v-band pipe into the turbo, through the big turbine and into the big low pressure 3.5” downpipe which is perfect for high boost but less so for low boost.

I’m not knocking the manifold by any means just observing what had to be done to fit in the space between the block and firewall.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I hear yah... I did attempt to hook the wastegate outlet upward out the collector as best I could to help it catch the gas as it passed by before dipping it under the comp housing...did think using a larger bore might have helped but space was at a premium and at the time I didn't know if it would creep or not...This is what I was alluding too regarding the Wastegate control.

Due to packaging constraints the Nortech Wastegate placement isn’t theoretically optimal for low boost control. It’s set back in the other direction away from the flow and fluid dynamics 101, the gases will take the path of least resistance. Which is the bigger v-band pipe into the turbo, through the big turbine and into the big low pressure 3.5” downpipe which is perfect for high boost but less so for low boost.

I’m not knocking the manifold by any means just observing what had to be done to fit in the space between the block and firewall.

Once I have sorted a ported housing I may look at dual porting the wastegate and maybe consider a MAC valve but the priority for me is to deal with the surge which isn't actually that big an issue unless I am in a high gear at low revs...

Had a little run in with an Edition 30 the other day.... ALS was switched on (no launch though children... launching is bad mmmmkay...)

ALS held a bar of boost between gearchanges without using combustion so no engine damaging pops and bangs...

Keeping the engine buzzing in the right gear is key to extracting the performance but I do want to sort the surge area out as this messes with the fuelling

<tuffty/>

Jealous, GT3582R with ALS that reliable (as long as you don’t launch it).

Yeah you can probably configure any EBC in the ignitron software

Yeah you can probably configure any EBC in the ignitron software

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

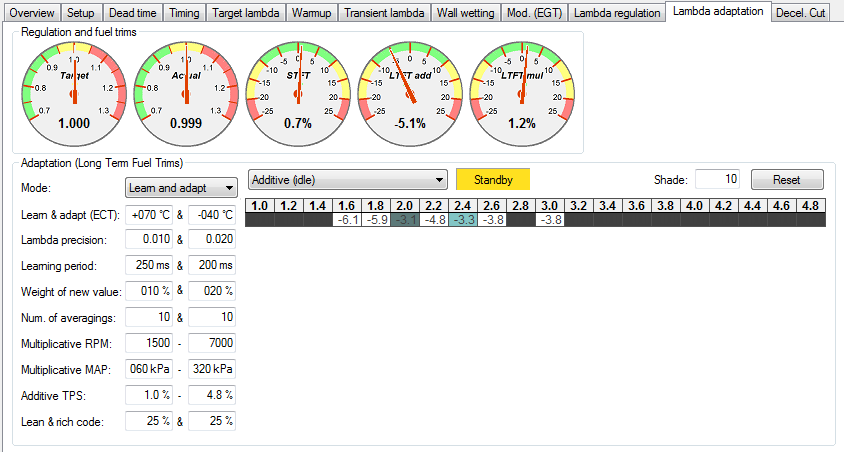

Been spending time sorting the fuel trims since fitting the 4bar FPR... seems the dead time info available for my injectors might be a little off causing my additive trims to be a little sporadic so I have been driving the car to work to allow the adaptions to do their thing...

Bit more driving to do and a few tweaks to go but its getting better and managed an average of 24mpg on the last tank which included a mix of motorway driving, coldstart tuning (two or three static engines starts a day over a week) and the odd bit of spirited driving..

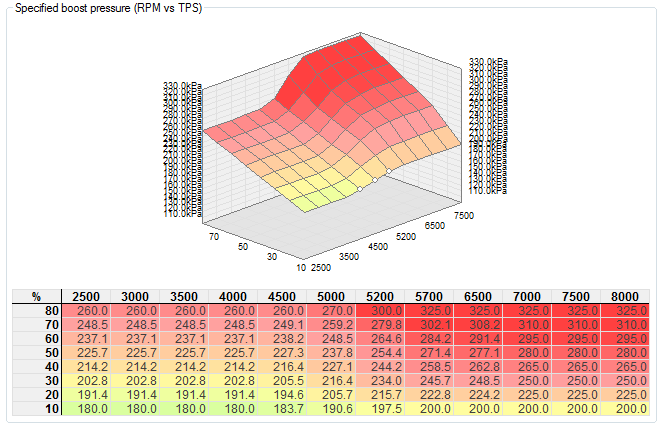

With me driving the car so much recently I started to get a feel for the drivability which most of the time is great but the low % part throttle stuff still feels a little too lively in traffic...

I tend to ride the revs a bit while driving the S3 and the map gets quite lively from 5k on... 220kpa (1.2bar) is typical peak boost for a stage 1 K04 and on a GT3582 at very little throttle makes it a little lively to say the least.... so the plan once the trims are sorted is to play in the 30% TPS and below areas above 5k to tame her down a bit and make things a little more progressive...

Something like this as a start point...

WOT will always be all of it of course but would be nice to have her behave a little better in traffic... I could of course short shift earlier but its how I drive the car so I am tuning to the way I drive

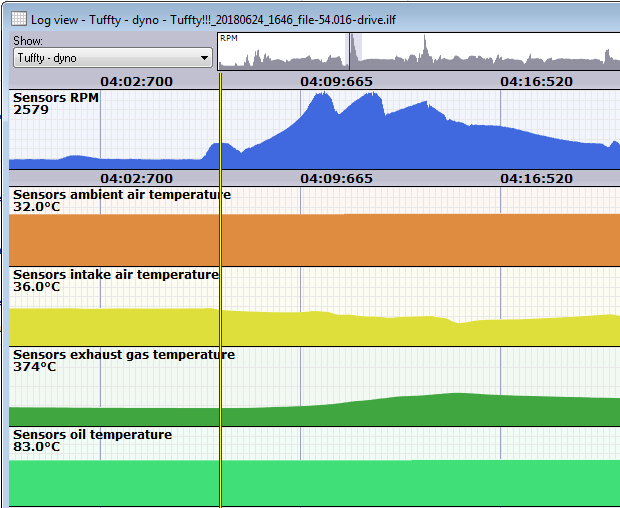

With the weather being as warm as it is at the moment and to continue on a previous discussion about temperatures I thought I would check how well my WMI is working... especially as I have seen ambient temps above 35 degrees recently...

Looking at a recent log (the one I used to demonstrate the ALS in a previous post) I took a series of screen shots to show the affect of WMI on my IAT's

First reference point was IAT's of 37.5deg from heat soak while idling at the lights in Mexico... ambient temp is 32degrees...

Next reference point was pulling off... intake temps will naturally drop as the cooler air drawn through will help drop the IAT's a bit...

Next reference point is the top of first gear... my WMI switches on at 18psi....

1st gear is over quite quickly so the affect of the WMI is a little delayed in context of this... this means the IAT drop is not that significant initially..

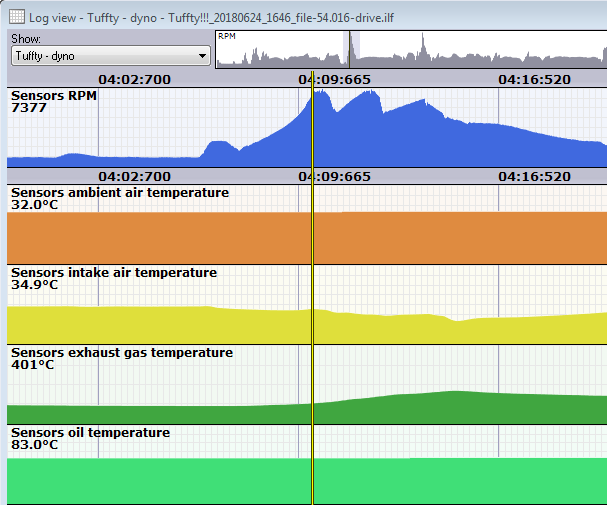

Next reference point is where I lifted off in third...

As you can see the IAT's are now below ambient temps... not sure how much further they would have dropped if I had revved out 3rd gear but you get the idea...

I use WMI to provide consistency... without it I have seen temps rise to 10-15deg above ambient which in itself is actually pretty good...

My initial tuning was done with meth off to make sure the timing was safe... I haven't added much in once meth was on though as I want the safety margin there

<tuffty/>

Bit more driving to do and a few tweaks to go but its getting better and managed an average of 24mpg on the last tank which included a mix of motorway driving, coldstart tuning (two or three static engines starts a day over a week) and the odd bit of spirited driving..

With me driving the car so much recently I started to get a feel for the drivability which most of the time is great but the low % part throttle stuff still feels a little too lively in traffic...

I tend to ride the revs a bit while driving the S3 and the map gets quite lively from 5k on... 220kpa (1.2bar) is typical peak boost for a stage 1 K04 and on a GT3582 at very little throttle makes it a little lively to say the least.... so the plan once the trims are sorted is to play in the 30% TPS and below areas above 5k to tame her down a bit and make things a little more progressive...

Something like this as a start point...

WOT will always be all of it of course but would be nice to have her behave a little better in traffic... I could of course short shift earlier but its how I drive the car so I am tuning to the way I drive

With the weather being as warm as it is at the moment and to continue on a previous discussion about temperatures I thought I would check how well my WMI is working... especially as I have seen ambient temps above 35 degrees recently...

Looking at a recent log (the one I used to demonstrate the ALS in a previous post) I took a series of screen shots to show the affect of WMI on my IAT's

First reference point was IAT's of 37.5deg from heat soak while idling at the lights in Mexico... ambient temp is 32degrees...

Next reference point was pulling off... intake temps will naturally drop as the cooler air drawn through will help drop the IAT's a bit...

Next reference point is the top of first gear... my WMI switches on at 18psi....

1st gear is over quite quickly so the affect of the WMI is a little delayed in context of this... this means the IAT drop is not that significant initially..

Next reference point is where I lifted off in third...

As you can see the IAT's are now below ambient temps... not sure how much further they would have dropped if I had revved out 3rd gear but you get the idea...

I use WMI to provide consistency... without it I have seen temps rise to 10-15deg above ambient which in itself is actually pretty good...

My initial tuning was done with meth off to make sure the timing was safe... I haven't added much in once meth was on though as I want the safety margin there

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

"Had a little run in with an Edition 30 the other day.... ALS was switched on (no launch though children... launching is bad mmmmkay...)

ALS held a bar of boost between gearchanges without using combustion so no engine damaging pops and bangs..."

is that "sort of" how the N249 is supposed to behave?

ALS held a bar of boost between gearchanges without using combustion so no engine damaging pops and bangs..."

is that "sort of" how the N249 is supposed to behave?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Nope..."Had a little run in with an Edition 30 the other day.... ALS was switched on (no launch though children... launching is bad mmmmkay...)

ALS held a bar of boost between gearchanges without using combustion so no engine damaging pops and bangs..."

is that "sort of" how the N249 is supposed to behave?

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

you dont have als"Had a little run in with an Edition 30 the other day.... ALS was switched on (no launch though children... launching is bad mmmmkay...)

ALS held a bar of boost between gearchanges without using combustion so no engine damaging pops and bangs..."

is that "sort of" how the N249 is supposed to behave?

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Lol, I know... I know...

Firstly, I have deleted the n249 but...

it is supposed to hold boost between 1st and 2nd gear changes. Isn't it?

How does the ALS work in Tuffty's set-up?

Isn't this essentially a 'spin the turbo without any exhaust pressure' like the f1 power units using an electric motor or some newer designed engines using compressed air? Isn't that what the n249 does?

https://www.audizine.com/forum/showthread.php/554859-N249-delete-Why-you-should-not-do-it

https://www.homemadeturbo.com/forced-induction-7/compressed-air-anti-lag-turbo-spool-659/

It's not like I will ever do it but its interesting to know this type of technical solutions.

Firstly, I have deleted the n249 but...

it is supposed to hold boost between 1st and 2nd gear changes. Isn't it?

How does the ALS work in Tuffty's set-up?

Isn't this essentially a 'spin the turbo without any exhaust pressure' like the f1 power units using an electric motor or some newer designed engines using compressed air? Isn't that what the n249 does?

https://www.audizine.com/forum/showthread.php/554859-N249-delete-Why-you-should-not-do-it

https://www.homemadeturbo.com/forced-induction-7/compressed-air-anti-lag-turbo-spool-659/

It's not like I will ever do it but its interesting to know this type of technical solutions.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

It essentially works through maintaining the inertia of the turbo by holding the throttle plate partially open (preventing the turbo from stalling) and raising N75 duty to keep the wastegate shut to help keep the turbo spinning...How does the ALS work in Tuffty's set-up?

Settings are on the screen shot I posted previously... TB is only open for a second (configurable) so boost will drop if you are sloppy with the gear changes

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

So even though you said 'no combustion' there still is something to make the turbo spin, but without firing with the valves open or timing retarded or something?

Have you stolen red bulls "blown defuser" map

Jokes aside does Garrett make a compressed air turbo for anti-lag? I read an article where someone was trying to create this.

Have you stolen red bulls "blown defuser" map

Jokes aside does Garrett make a compressed air turbo for anti-lag? I read an article where someone was trying to create this.

So even though you said 'no combustion' there still is something to make the turbo spin, but without firing with the valves open or timing retarded or something?.

It essentially works through maintaining the inertia of the turbo

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Hi Alex, I still don't understand - all you have done is take my question and repeated tuffty's remark, I responded to.

Is the boost pressure maintained for one second by delaying the waste gate or is the turbo spool kept running and the pressure still vented on gear change, as if idle is 3.5k for one second after waste gate operation.

Is the boost pressure maintained for one second by delaying the waste gate or is the turbo spool kept running and the pressure still vented on gear change, as if idle is 3.5k for one second after waste gate operation.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Pressure is maintained by providing a method to keep the turbo spinning...

Normally if you close the throttle the airflow has no where to go and will stall the turbo... this is why valves (DV/BOV) are used to release the pressure to prevent damage to the turbo from stalling...

An engine is essentially an air pump... once rotating it will pump 'air' through the cylinders regardless of a combustion event... combustion just provides impetus for this to happen...

When changing gear using this ALS functionality all you are doing is allowing flow through the engine which provides potential to keep the turbo spinning... granted the airflow out the engine doesn't have the energy of a combustion event but in the short time between gears its normally 'enough' to maintain a degree of turbine speed to maintain a degree of boost... the amount of boost is not a given value though... in this particular case it managed to hold on to 1bar of boost but have seen less before now...

The one second thing is a failsafe to ensure the throttle isn't left open for longer than it needs to be... the basic operation is to keep the throttle partially open allow flow through the engine, injectors/ignition is off so no combustion event (like letting off the throttle when injectors turn off), N75 nails wastegate shut to maintain as much turbine energy as possible during the ALS event...

<tuffty/>

Normally if you close the throttle the airflow has no where to go and will stall the turbo... this is why valves (DV/BOV) are used to release the pressure to prevent damage to the turbo from stalling...

An engine is essentially an air pump... once rotating it will pump 'air' through the cylinders regardless of a combustion event... combustion just provides impetus for this to happen...

When changing gear using this ALS functionality all you are doing is allowing flow through the engine which provides potential to keep the turbo spinning... granted the airflow out the engine doesn't have the energy of a combustion event but in the short time between gears its normally 'enough' to maintain a degree of turbine speed to maintain a degree of boost... the amount of boost is not a given value though... in this particular case it managed to hold on to 1bar of boost but have seen less before now...

The one second thing is a failsafe to ensure the throttle isn't left open for longer than it needs to be... the basic operation is to keep the throttle partially open allow flow through the engine, injectors/ignition is off so no combustion event (like letting off the throttle when injectors turn off), N75 nails wastegate shut to maintain as much turbine energy as possible during the ALS event...

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Lol, I know... I know...

Firstly, I have deleted the n249 but...

it is supposed to hold boost between 1st and 2nd gear changes. Isn't it?

How does the ALS work in Tuffty's set-up?

Isn't this essentially a 'spin the turbo without any exhaust pressure' like the f1 power units using an electric motor or some newer designed engines using compressed air? Isn't that what the n249 does?

https://www.audizine.com/forum/showthread.php/554859-N249-delete-Why-you-should-not-do-it

https://www.homemadeturbo.com/forced-induction-7/compressed-air-anti-lag-turbo-spool-659/

It's not like I will ever do it but its interesting to know this type of technical solutions.

whats n249 (dv actuator solenoid) going to have anything to do with als?

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Thanks Tuffty, so I understand that a bit better now.

Essentially...

for 1 second of engine run down during a gear change "air only" helped by some remaining positive pressure with no fuel to ignite will simply pass through the engine and turbo keeping the turbo essentially primed. This is only really used for between gears whilst the car is moving rather than from a standing start.

Badger, I read somewhere that the N249 cylinder is for storing charge to keep the circuit under positive pressure between gear 1 and gear 2 only so essentially when you are in gear 2 the system is still under pressure built from gear 1 even though the turbo isn't spooling, then that pressure will keep the power on until the turbo is up and running again, I thought it essentially stopped the DV from immediately opening when changing from 1 to 2.

Essentially...

for 1 second of engine run down during a gear change "air only" helped by some remaining positive pressure with no fuel to ignite will simply pass through the engine and turbo keeping the turbo essentially primed. This is only really used for between gears whilst the car is moving rather than from a standing start.

Badger, I read somewhere that the N249 cylinder is for storing charge to keep the circuit under positive pressure between gear 1 and gear 2 only so essentially when you are in gear 2 the system is still under pressure built from gear 1 even though the turbo isn't spooling, then that pressure will keep the power on until the turbo is up and running again, I thought it essentially stopped the DV from immediately opening when changing from 1 to 2.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Badger, I read somewhere that the N249 cylinder is for storing charge to keep the circuit under positive pressure between gear 1 and gear 2 only so essentially when you are in gear 2 the system is still under pressure built from gear 1 even though the turbo isn't spooling, then that pressure will keep the power on until the turbo is up and running again, I thought it essentially stopped the DV from immediately opening when changing from 1 to 2.

The vacuum store you refer to, stores.............. wait for it..................... Vacuum.. so allows ecu to intervene when it needs to even if under boost at the time.

gears are irrelevant sfaik

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

So have spent the last few weeks driving the car, making tweaks and driving the car more... she does quite well MPG wise on the commute to work all things considered... 30+ indicated on the DIS but reality being a couple of MPG less... did a 24mpg average on a tank the other week (couple of days commute plus road map tweaks and a dyno run) which is pretty good as she has been sub 20's of late...

Anyhoo... enough about the 'economy' as thats not what she is about... a couple of the areas I wanted to tweak was midrange and peak boost... I still get surge on a high gear/low RPM run (like a dyno run) but if driven properly its not an issue so tweaked the spool delivery around that...

I am not running as much boost in this area as I did on ME7 as surge really plays silly b*ggers with the fuelling with speed density tuning so had to be mindful of that... next planned mod will be to replace the coldside with a ported housing to help with surge control...

On the road she feels very quick (obvs) but did need to get her on the dyno to see what progress was made... today I had a chance to do that...

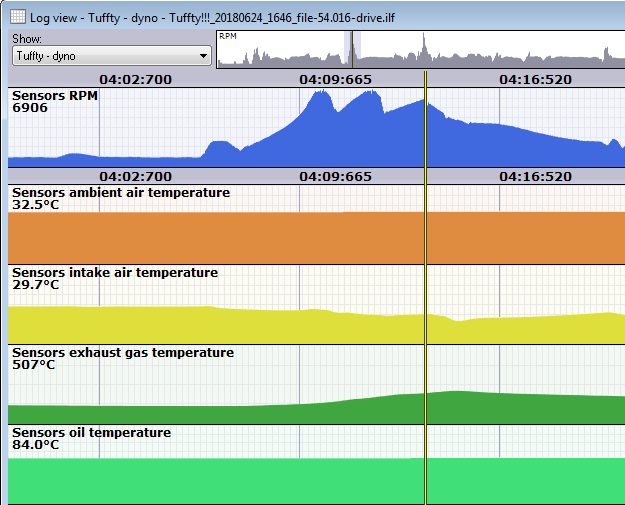

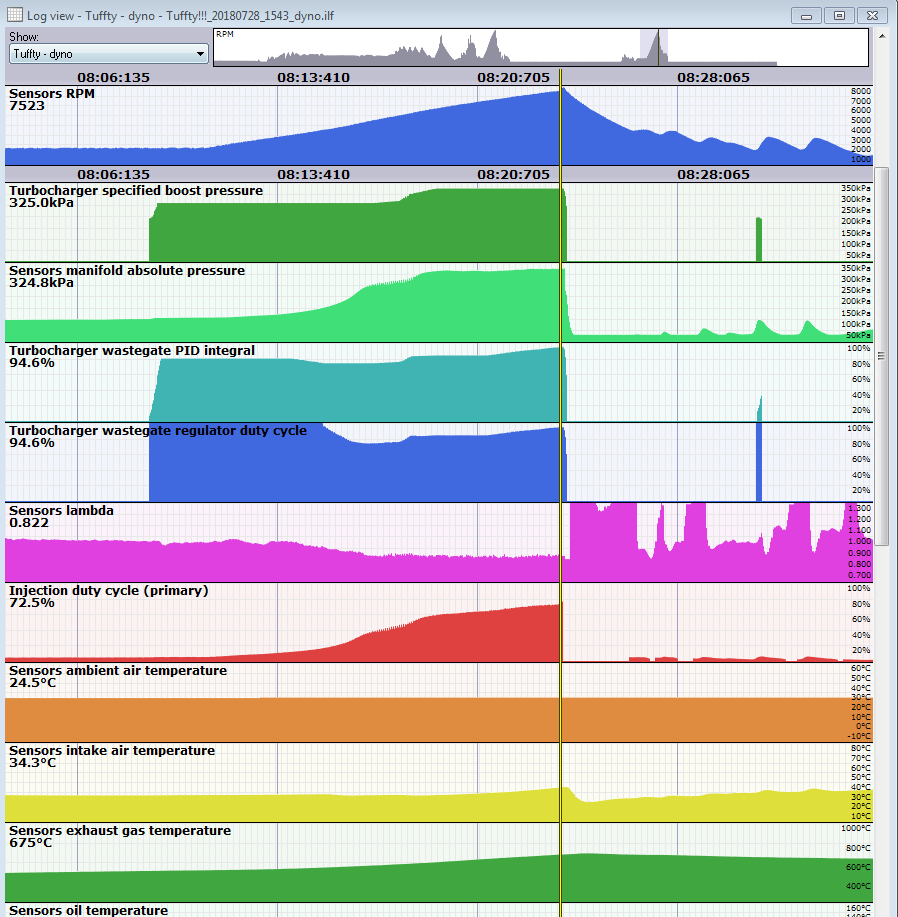

Obviously logged the runs to be sure....

Nothing out of the ordinary there... next to no timing pull which is always a nice place to be...

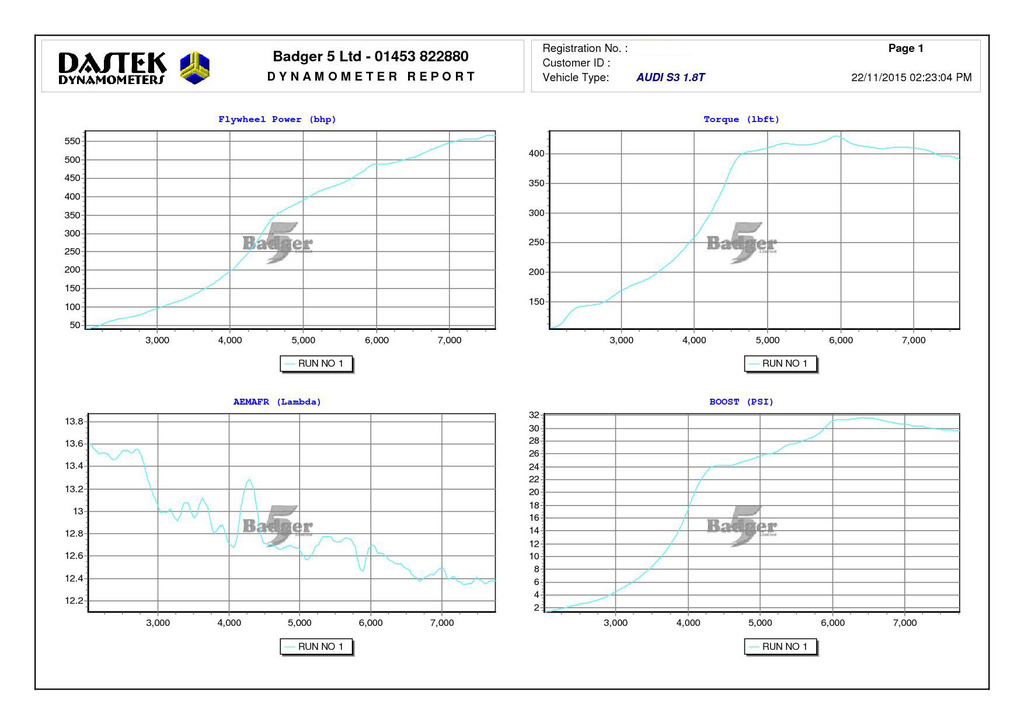

...and of course the scores on the doors

Happy enough with that

<tuffty/>

Anyhoo... enough about the 'economy' as thats not what she is about... a couple of the areas I wanted to tweak was midrange and peak boost... I still get surge on a high gear/low RPM run (like a dyno run) but if driven properly its not an issue so tweaked the spool delivery around that...

I am not running as much boost in this area as I did on ME7 as surge really plays silly b*ggers with the fuelling with speed density tuning so had to be mindful of that... next planned mod will be to replace the coldside with a ported housing to help with surge control...

On the road she feels very quick (obvs) but did need to get her on the dyno to see what progress was made... today I had a chance to do that...

Obviously logged the runs to be sure....

Nothing out of the ordinary there... next to no timing pull which is always a nice place to be...

...and of course the scores on the doors

Happy enough with that

<tuffty/>

Warsuperior

Registered User

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

At this level of power yes...Amazing numbers! Awesome job

almost 100hp of drivetrain loss, is that the normal for s3?

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

nice moody camera work as usual Tuffty, what's Bills thoughts to the setup? - it's making about the same power as before (which you said it would as the hardware is unchanged) but with more sensor control - are the package estimates similar to the real world dyno, not just top figures but graduation?

you had essentially mapped this based entirely on logs hadn't you? are you planning on any further tweaks?

you had essentially mapped this based entirely on logs hadn't you? are you planning on any further tweaks?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Bill seems quite impressed with the ECU... its realistically a no brainer for VAG cars with ME7 management...nice moody camera work as usual Tuffty, what's Bills thoughts to the setup? - it's making about the same power as before (which you said it would as the hardware is unchanged) but with more sensor control - are the package estimates similar to the real world dyno, not just top figures but graduation?

you had essentially mapped this based entirely on logs hadn't you? are you planning on any further tweaks?

Power wise I am making more top end but less mid range... the ME7 on a MAF was less concerned about surge so got away with having more boost through the surge line... using speed density with the MAP sensor makes the turbulance more of an issue as the MAP sensor picks the fluctuation up and this throws the fuelling out... been a great learning experience with this but I am by no means an expert...

ECU power and torque does generally match but as per the normal MAF calc is subject to various influence... I am chatting to Brian at the moment to understand this a little more but trims can affect the calculated value to a degree along with some other stuff... this can be recalibrated though to get it closer to what the dyno is showing but at the end of the day dyno lottery applies so I can only take it relative to previous logs

Tuning has been primarily from logging and driving... the beauty of the IECU is the base files are pretty good as a start point and the ECU learns adaptations quickly... this one of the few ECU's that has a built in wideband controller and its very fast... the logging on it is epic and makes tuning very easy (in relative terms)...

The car has been on the dyno twice since I have had this ECU... mainly because I wanted to do this in my own time rather than encroach on Bills...

Tweaks wise as mentioned before I want to fit a ported housing... this should help me lift midrange boost and therefor get the torque heading in the direction it was before... thats not without risk as its possible bringing the boost in sooner will up the heat generated and cause timing pull top end so top end power will be lost...

We shall see... I think there is room for improvement in the spool range (which is also the surge area) so will see how it goes

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Sadly the British weather beat me on that particular subject... Massive layer of cloud hid the old girl from sightNever mind all those graphs and figures,you know what we really want...where's your gallery of 'Red Moon' photo's,that's what we're all waiting for

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

yes, coastdowns measured and at high power levels + soft sticky tyres, and very high roller speeds (maxed dyno) the losses are always going to be higher with more power. thats how it works.Amazing numbers! Awesome job

almost 100hp of drivetrain loss, is that the normal for s3?

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Is this change in increase for a 10th of a second by design or a symptom of something else?

I'm obviously a total beginner but the progression in everything in line with the revs, make it look really drivable, if you want more power put you foot down more etc where lots of dynos make it appear like they get to 4k and then see how long they can hold that torque for. What would happen if you tried to give it everything like that? Broken transfer box? Driveshafts etc?

I'm obviously a total beginner but the progression in everything in line with the revs, make it look really drivable, if you want more power put you foot down more etc where lots of dynos make it appear like they get to 4k and then see how long they can hold that torque for. What would happen if you tried to give it everything like that? Broken transfer box? Driveshafts etc?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

The boost curve is that shape to deal with surge line of the turbo... if I had no surge I could raise boost request to 30psi at that point and boost would follow... I deliberately hold boost request back because of surge...

Ported housing will potentially increase boost at that point (boost is the result of restriction don't forget) but should also increase torque a bit there too going off previous results

<tuffty/>

Ported housing will potentially increase boost at that point (boost is the result of restriction don't forget) but should also increase torque a bit there too going off previous results

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Not necessarily but obviously I am already putting more torque through the drive train than it was designed for so its largely academic...What would happen if you tried to give it everything like that? Broken transfer box? Driveshafts etc?

I have had this type of delivery before on ME7..

...compared to my current tune...

Spool is a little lazier currently... not sure exactly why as not really spent anytime looking at it closely... previously I am making 18psi at 4k rpm... I am 4psi down currently... this could be a number of reasons but realistically I would need to play on the dyno to see if AFR/timing/N75 duty can be played with to try and get it all going if at all... could also just be mechanical wear... who knows at this time but its certainly something I can look at playing with later...

Something for when I have fitted the ported housing

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Okay so when a car hits it's top torque figure eg 400lb/ft and carries it on is that still increased energy. Say for example a fair ground ride or plane taking off once it reaches its optimum speed there is no more acceleration is there so no more torque. So from 3-4.5 there is an increase in torque so from 0-2g very quickly but then does it continue at 2g until 7500rpm or feel like 1g? ( the g's are figurative for illustration purposes)

Im just trying to understand the physics, example prawn goes to 350lb/ft or whatever from 4k -8k but is that still a constant kick in the back rather than a kick from 3-4 then relative.

In my relatively stock TT when the torque dies off the revs continue but the driver (me) actually leans on the steering as I am continuing to go forward but the car had stopped.

It's a long question, that requires a short answer.

Im just trying to understand the physics, example prawn goes to 350lb/ft or whatever from 4k -8k but is that still a constant kick in the back rather than a kick from 3-4 then relative.

In my relatively stock TT when the torque dies off the revs continue but the driver (me) actually leans on the steering as I am continuing to go forward but the car had stopped.

It's a long question, that requires a short answer.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Torque is force, power is work... rpm factors in to this so if you can maintain torque over rpm then more work can be done... (power = (torque*rpm/5252)

In this case keeping a flat or increasing torque line as rpm increases allows you maintain acceleration... if torque drops off (like your K04) then work will drop off and acceleration will slow...

You need increasing power to maintain acceleration... as you can see from my graph power is still increasing at the top end of the rev range... on a K04 where peak power is lower down the rev range you will see the power curve start to decrease... this is where acceleration will feel like its dropping off...

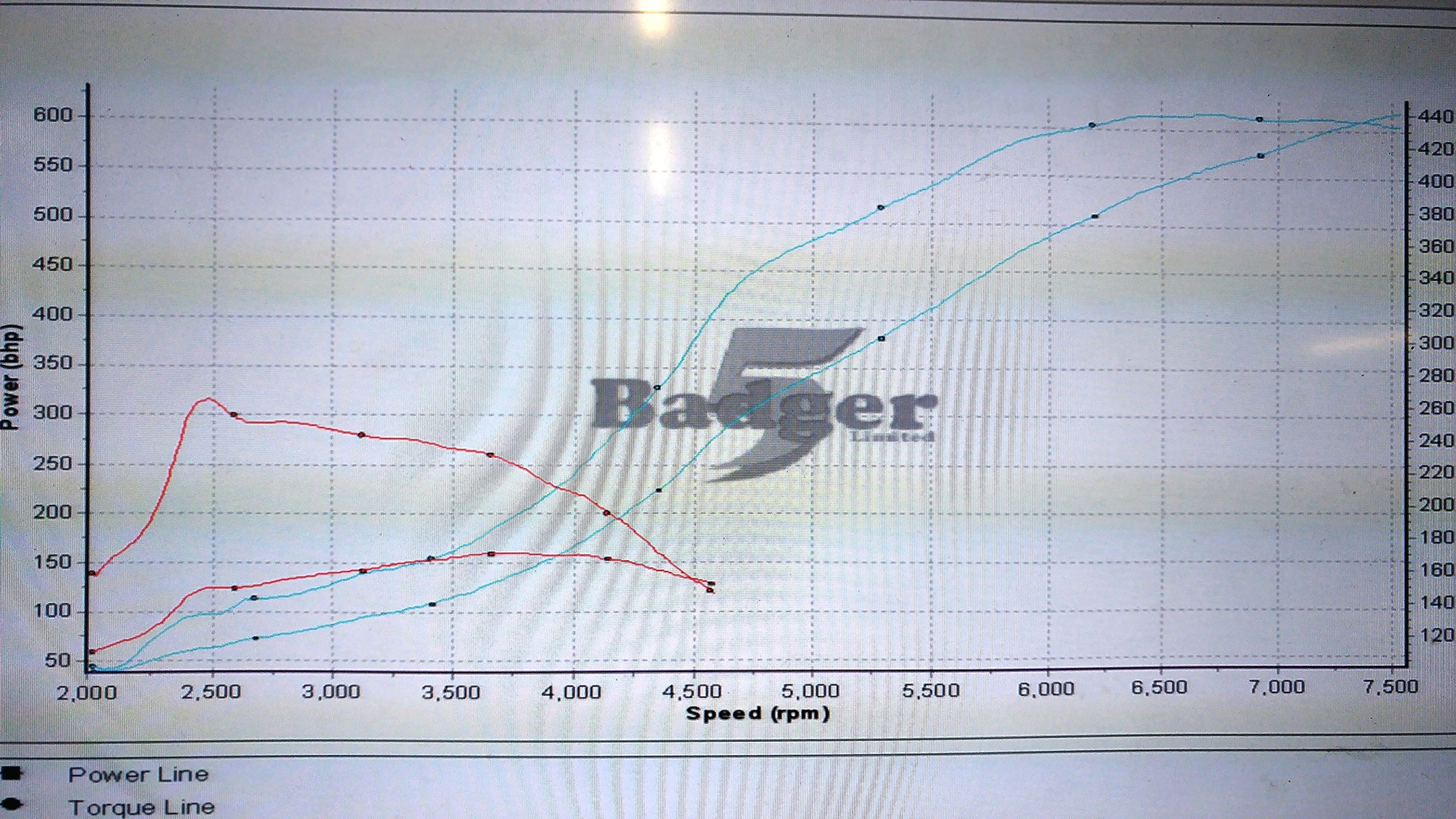

Here is an interesting plot from the same day I ran mine... my mates 2ltr TDi VW over laid with mine...

As you can see the torque fall off on the red plot, there is a point where the falling torque vs increasing rpm equates to falling power... this is the point where the feeling of acceleration will also drop off...

<tuffty/>

In this case keeping a flat or increasing torque line as rpm increases allows you maintain acceleration... if torque drops off (like your K04) then work will drop off and acceleration will slow...

You need increasing power to maintain acceleration... as you can see from my graph power is still increasing at the top end of the rev range... on a K04 where peak power is lower down the rev range you will see the power curve start to decrease... this is where acceleration will feel like its dropping off...

Here is an interesting plot from the same day I ran mine... my mates 2ltr TDi VW over laid with mine...

As you can see the torque fall off on the red plot, there is a point where the falling torque vs increasing rpm equates to falling power... this is the point where the feeling of acceleration will also drop off...

<tuffty/>