Been preparing a few things for the gearbox install when it gets warmer in a few months. The Steering wheel I bought I made an aluminium plate for the front to mount the race mode / push to pass switches and the horn. Covered it in some Black Sticky back plastic rather than paint it.

Looks OK and is functional, My Aliexpress stick on paddle extensions arrived from China, So fitted them.

Had to do some fiddling with the paddles to get them working with Ignitron as the paddles aren't just a switch they have resistors built into them . Not easy to get them apart and I didn't want to break them so made up a small PCB with a 5v regulator and some resistors /capacitors to do some level shifting. This works fine now and the ECU sees both Paddles will generate the CAN messages to the gearbox. The paddle switches have LED's in that I have powered up when ever the ignition is on.

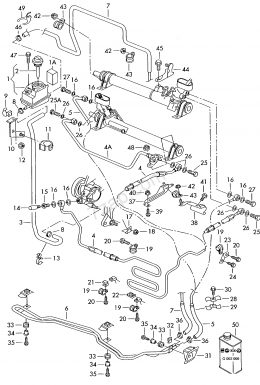

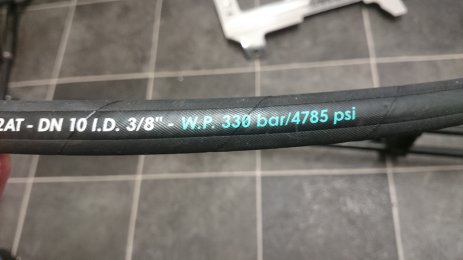

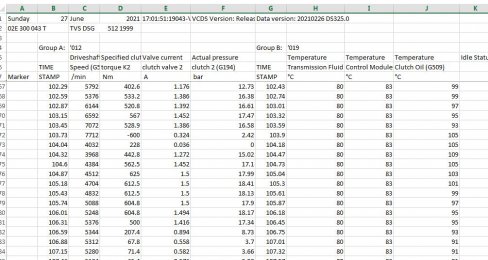

The gearbox doesn't put out oil temp on the CAN bus for the ECU to read and as I would like to keep an eye on this added a cheap 150 degree oil temp sensor to the alloy filter housing. This has an 1/8 NPT thread but M10X1 is very close and fits fine, so fitted the sensor.

Temp sensor is a VAG item for 150 degree oil temperature gauges. Found the calibration data and then using this site

calculated the values outside the normal 50-150 degree range.

1H0919563

https://daycounter.com/.../Steinhart-Hart-Thermistor...

Temp resistance (ohms)

0 - 3061

10 - 1832

20 - 1135

30 - 726

40- 478

50 - 323

60 -223

70- 158

80 -113

90- 83

100- 62

110- 48

120 - 37

130- 30

140 - 23

150- 18

Used the spare resistance input on pin 26 and connected the sensor there. With the wire earthed on the engine it was measuring 4 ohms. As the sensor resistance is pretty low at high temperatures this would make a big difference in the calculated value. So added 4 ohms to all the values to take this into account.

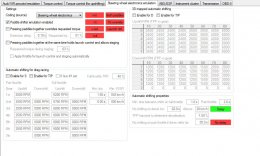

Easily created a new sensor input in Ignitron and added the sensor calibration.

Looks OK and is functional, My Aliexpress stick on paddle extensions arrived from China, So fitted them.

Had to do some fiddling with the paddles to get them working with Ignitron as the paddles aren't just a switch they have resistors built into them . Not easy to get them apart and I didn't want to break them so made up a small PCB with a 5v regulator and some resistors /capacitors to do some level shifting. This works fine now and the ECU sees both Paddles will generate the CAN messages to the gearbox. The paddle switches have LED's in that I have powered up when ever the ignition is on.

The gearbox doesn't put out oil temp on the CAN bus for the ECU to read and as I would like to keep an eye on this added a cheap 150 degree oil temp sensor to the alloy filter housing. This has an 1/8 NPT thread but M10X1 is very close and fits fine, so fitted the sensor.

Temp sensor is a VAG item for 150 degree oil temperature gauges. Found the calibration data and then using this site

calculated the values outside the normal 50-150 degree range.

1H0919563

https://daycounter.com/.../Steinhart-Hart-Thermistor...

Temp resistance (ohms)

0 - 3061

10 - 1832

20 - 1135

30 - 726

40- 478

50 - 323

60 -223

70- 158

80 -113

90- 83

100- 62

110- 48

120 - 37

130- 30

140 - 23

150- 18

Used the spare resistance input on pin 26 and connected the sensor there. With the wire earthed on the engine it was measuring 4 ohms. As the sensor resistance is pretty low at high temperatures this would make a big difference in the calculated value. So added 4 ohms to all the values to take this into account.

Easily created a new sensor input in Ignitron and added the sensor calibration.