Changed the intake cam several weeks ago now. Fairly easy job to do as you don't have to retime the engine. The cam belt connecting to the exhaust cam.

Just get a new gasket for the VVT tensioner and I reused the rocker cover gaskets as they are fairly recent.

I bought a complete cylinder head for £80 from a scrap yard off a 1.8 NA A3 with an APG engine.

This is the later engine with VVT . I only wanted an intake cam as I am not sure an exhaust cam change as well would make that much difference. And not changing the exhaust cam means an easier swap.

From Cat Cams site both fast road and ultra fast road have same exhaust cam 217 degree 9.95mm standard turbo exhaust 210 degree 9.3mm NA exhaust cam 210 degree 10.4mm . The CAT cam exhaust cam has only 7 degrees more duration and 0.7mm more lift than a BAM exhaust cam.

The AGP NA cam actually has more lift again than the CAT cam item with only 7 degrees less opening.

There are several threads around with the details of various cams and the timing of them .

inlet:

058109021 = ADR und AFY 8,78mm, 210°, 4° n.OT

058109021.B = APX, ANB, AEB,APU, AJL, AGU, AQA, ARZ, AJQ, APP, APY, AUL 7,67mm, 190°, 18° n.OT

058109021.K = ADR, APT, ARG, AVV 8,41mm, 202°, 16° n.OT

058109021.M = AWT, AUM, ARX, ARY, AUQ, AMK, BAM, AUL, APP 7,67mm, 190°, 18° n.OT

058109021.F = AGN, APG 8,41mm, 202°, 18° n. OT

058109021.E = AWB 8,6mm, 207°, 9° n.OT

058109021.D = ADR, AGN 8,41mm, 202°, 12° n. OT

esxaust:

058109022.B = AQA, ARZ, AJQ, APP, APY, AEB, APU, ANB, AJL, AWT, AGU, AUM, ARX, ARY, AUQ, AMK, BAM 9,3mm, 210°, 10° v.OT

058109022.C = ADR, AFY, APT, ARG, AVV 10,25mm, 210°, 8° v.OT

058109022.D = AGN, APG 10,4mm, 210°, 8° v.OT

v.OT = vor dem Oberen Totpunkt = before Top Dead Centre

n.OT = nach dem oberen Totpunkt = after Top Dead Centre

Had to undo the V bands on the turbo and swing the compressor back a little as the outlet was stopping the rocker cover coming off. Got to love these V-Band turbos so easy to work on.

Set the cam timing marks to the correct place and marked the chain links with the 16 link spacing .

Remove all the cam caps carefully noting location, they are all marked anyway, and remove original cam.

Looking at the cams you cannot see any difference. The original BAM cam marked with an L the new APG cam marked AC .

I did take some measurements with a vernier on the cam lobe maximum height and the base circle diameter.

Measured height of lobes on both cams.

BAM original cam marked with an L

Maximum height lobe width

43.62 36 outer lobes of each threesome

35.4 centre lobe

APG cam marked ac

Maximum height lobe width

44.35 36 outer lobes of each threesome

35.4 centre lobe

Calculated extra lift 44.35 - 43.62 = 0.73mm from specs above 8.41-7.67 = 0.74mm

So seems to me specs above seem correct as regards the extra lift.

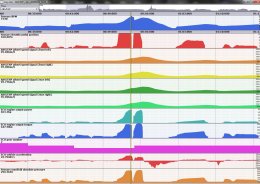

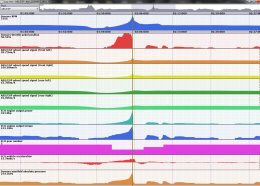

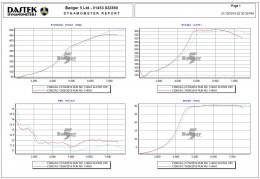

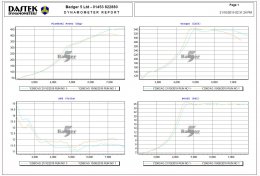

Engine definitely pulls stronger at the top end and is keener to rev than it was before. Virtual dyno third gear pulls seem to show 30-40bhp more at the top end so hopefully this will show up on the dyno next time it runs.

]

]