It's been a while.

car doesn't get used much but that doesn't mean things can't go wrong.

it's on 106k km.

Last summer it got new aircon motor and condenser along with a new aircon pipe.

With the addition of the new 65mm drop in intercooler with inlet air guide fins.

Not to long after, in september, car started using more oil, and finally started engine light flashing and running on 3 cylinders.

Spark plug no.1 had oil over it.

Clear indicator that it's not good.

Inspeciton gave 0 compression in cyl. no.1.

After stripping the engine, it was clear that piston has gone. Thankfully walls were good enough and the block could be rebuilt.

So we went for JE ultra series pistons with 9.5 compression with bar-tek riffle drilled xbeam conrods, arp bolts, acl bearings all good for 500+bhp.

Injectors were sent to bar-tek and tested cleaned and rebuilt.

Along with that we changed bunch of sensors and vacuum pipes.

Head was also ispected and rebuilt (no uprated parts).

New chain and tensioner.

We decided to remove balance shafts with vis bsd freewheel.

Lpfp internals were swapped for bar-tek (dw) uprated one (500+bhp capable).

Hpfp had 5mm inled valve mod done to relieve lpfp side (runs on lower duty cycle).

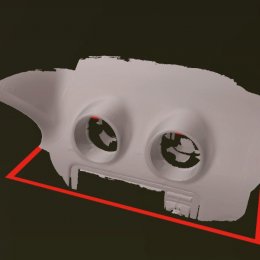

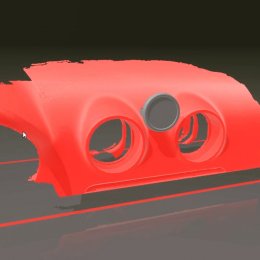

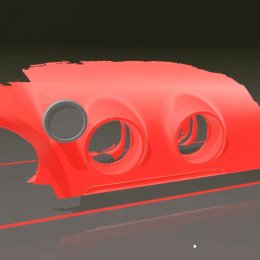

After that smoke test revealed that alu turbo outlet pipe was leaking boost, so decided to ditch that weak part and make it future proof.

After rebuild it had 1200km runing in period with 600ish km below 2500rpm, rest up to 3500rpm.

Recently it had oil change for fuchs titan race pro s 5w40 ester oil.