- Joined

- Jul 11, 2011

- Messages

- 1,860

- Reaction score

- 443

- Points

- 83

Just finished putting the Auuuuuds back together  finally! . . So pleased to have her back after almost three months

finally! . . So pleased to have her back after almost three months

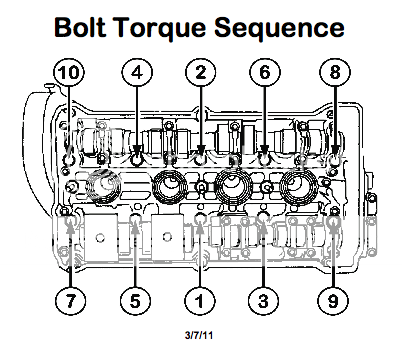

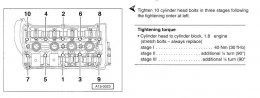

When I torqued up the head bolts I swear auto-data said 40nm, 90deg + 90deg... Now I'm home I've noticed a bit of paper that came with the head kit that says 40nm, 60nm, 90 + 90.

Car's driving fine, just wondering if this is anything I should be worrying about or am I good to go for a proper drive tomo!?

Lewis

finally! . . So pleased to have her back after almost three months

finally! . . So pleased to have her back after almost three months

When I torqued up the head bolts I swear auto-data said 40nm, 90deg + 90deg... Now I'm home I've noticed a bit of paper that came with the head kit that says 40nm, 60nm, 90 + 90.

Car's driving fine, just wondering if this is anything I should be worrying about or am I good to go for a proper drive tomo!?

Lewis