- Joined

- Dec 2, 2008

- Messages

- 17,400

- Reaction score

- 1,104

- Points

- 113

I've created this thread to try and put together a definitive guide that cuts out all the crap from this thread:

http://www.audi-sport.net/vb/a3-s3-...yone-including-pcv-system-simplification.html

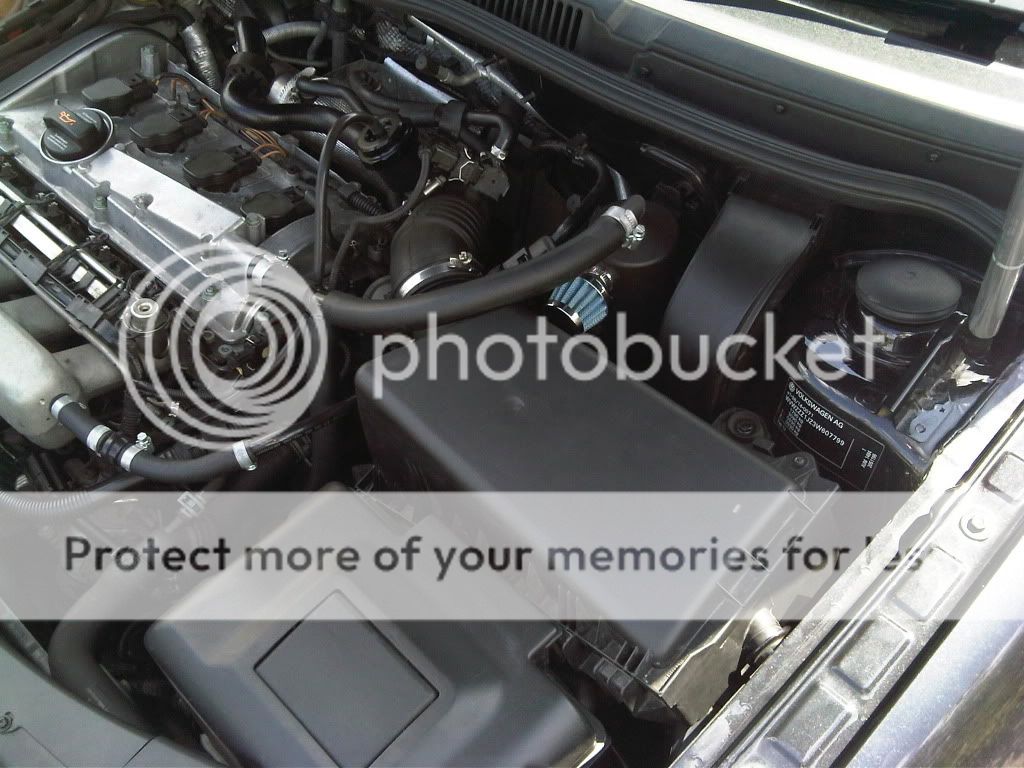

PLEASE NOTE THAT SOME OF MY PICS ARE OF THE S3 BAY AND SOME OF A GOLF BAY SO SOME VALVES/PIPES MIGHT NOT BE ON ALL MODELS OF 1.8T ENGINE

Ok so firstly a little back ground into the PCV (positive crankcase ventilation) system and how it works in stock form:

With the stock PCV system oil vapour burnt by the engine is vented from the rocker cover and is introduced to the TIP (Turbo Intake Pipe) on boost so that it is burnt in the combustion chamber with fuel and air. This design was due to the strict emissions rules that are in place when designing a car.

The problem with introducing oil vapour into the TIP is that oil gats into the boost system, intercooler(s), and throttle body. When burnt in the combustion chamber with fuel and air can reduce the octane level of the fuel and therefore effect performance.

Another problem with the PCV system is that over time the rubber hoses become clogged with oil and start to perrish which leads to splits and more issues.

The whole idea behind the catch can is to catch the vapour, remove the oil and return cleaner vapour into the TIP (when venting back to TIP), or vent to atmosphere for an even cleaner system.

A catch can with baffles works more efficiently at seperating the oil from the vapour but if you're unable to get one with baffles you can use wire brillo pads inside the can.

-------------------------------------------------------------------------------------------------

Right firstly you will need the following bits:

- Catch can. Ideally one with 19mm inlet/outlet

- 2 metres of 19mm oil grade hose

- 1x 19mm plastic t-piece

- 2x 90 19mm plastic joiners

-------------------------------------------------------------------------------------------------

Now it's time to rip out all the old gear:

The whole lot should look like this when out:

INSTRUCTIONS

(Taken from this thread: 1.8t - PCV simplification and catch can installation - uk-mkivs )

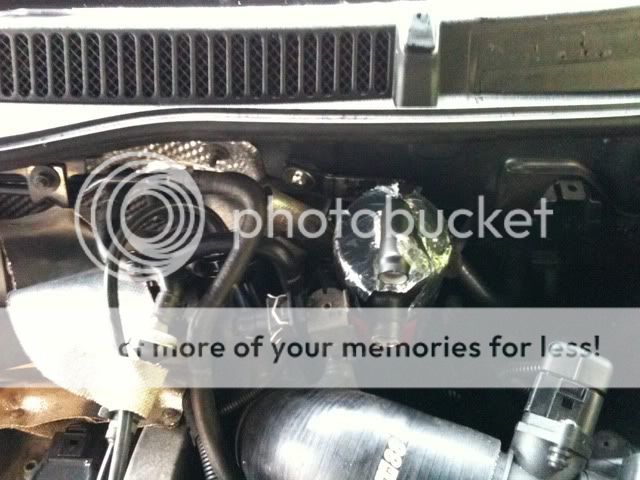

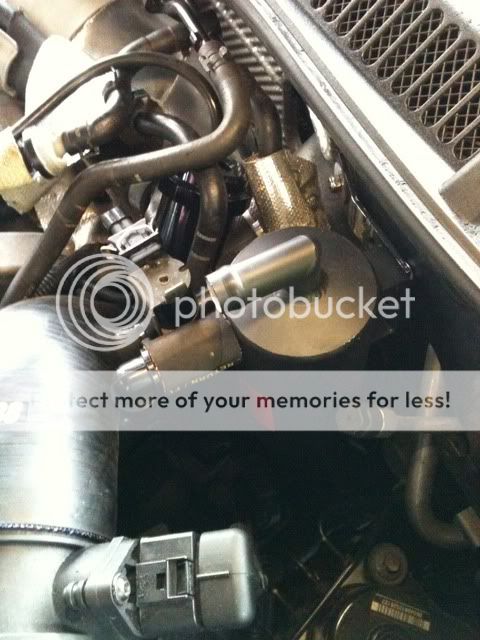

The first thing I did was to remove both engine covers. Under the lower cover I loosened the metal plate which houses the N112, the N249, a checkvalve and a small maze of vac pipes

2 x 10mm bolts holding the SAI (secondary air injection) pump inlet pipe

then 2 x hex bolts holding the plate to the manifold

Carefully lift the plate from out of the clip on the side of the dipstick holder. If your dipstick holder's never been replaced it'll be very fragile and it'd be a good idea to replace it now for what it costs (about £5-6)

Now I started removing all the stock pipework from the top

See right behind the dipstick, there's the first small L section of pipe that leads to the suction jet pump Y piece. This is the pipe in which I've previously inserted a checkvalve, to stop boost before it hits the suction pump

I removed that, leaving the suction pump end exposed

Next was the infamous for splitting upper breather, on the passenger side of the rocker cover

It attaches to the TIP via the 'hockey puck' accumulator valve

Removed

Then I disconnected the brake booster line, leading from the suction pump

and finally I took out the lower breather pipe which is located right on the oil filter housing

You can see it on this picture from above, but unfortunately it's not in focus

I used a long shafted flathead screwdriver to prise off the C clip that holds it in position

There's an O ring in there too, careful not to lose it!

Removed

Now I managed to shimmy all the pipework clear and took this photo. The Upper breather Y pipe and the L piece leading to under the manifold are not attached, as mentioned above, I disconnected before removal

Yeggers! Look at that sludge that's accumulated

Stuff like this clogs the PCV valve, the suction pump and will make it into your TIP..

Stuff like this clogs the PCV valve, the suction pump and will make it into your TIP..

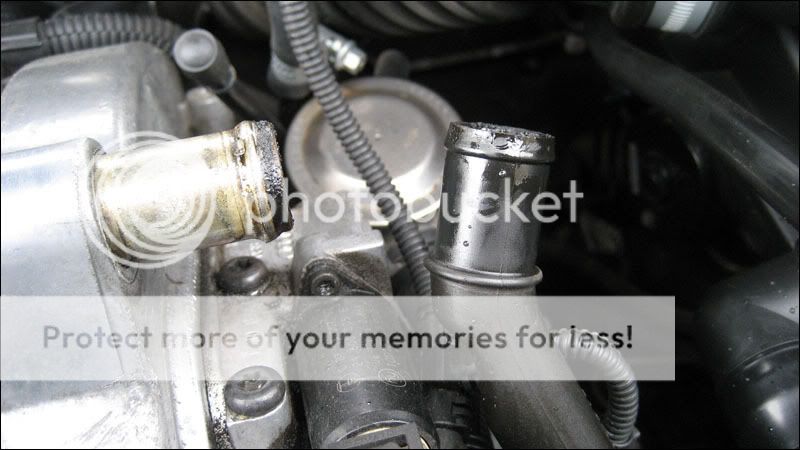

Keep these 2 parts for the new installation

Now I want to cap the vacuum source under the manifold. It's not going to be used, all the pressure is positive coming from the crankcase and upper breather anyway and it'll be caught in the can. The fumes will also pull via the TIP connection when under acceleration. I used a small length of 3/8" ID pipe with a bolt screwed tightly into it

This then fits to the nipple under the inlet manifold like so:

I'm also wanting to cap the brake booster line and just use the 1 vac source for brakes. It works on the AGU and ARZ so no reason it shouldn't work on an AUM right? I used a 1/2" piece of nylon rod and a jubilee clip but have since replaced this section of the brake booster line. Picture of revised piece to be edited in later

Or alternatively use another screw:

http://www.audi-sport.net/vb/a3-s3-...yone-including-pcv-system-simplification.html

PLEASE NOTE THAT SOME OF MY PICS ARE OF THE S3 BAY AND SOME OF A GOLF BAY SO SOME VALVES/PIPES MIGHT NOT BE ON ALL MODELS OF 1.8T ENGINE

Ok so firstly a little back ground into the PCV (positive crankcase ventilation) system and how it works in stock form:

With the stock PCV system oil vapour burnt by the engine is vented from the rocker cover and is introduced to the TIP (Turbo Intake Pipe) on boost so that it is burnt in the combustion chamber with fuel and air. This design was due to the strict emissions rules that are in place when designing a car.

The problem with introducing oil vapour into the TIP is that oil gats into the boost system, intercooler(s), and throttle body. When burnt in the combustion chamber with fuel and air can reduce the octane level of the fuel and therefore effect performance.

Another problem with the PCV system is that over time the rubber hoses become clogged with oil and start to perrish which leads to splits and more issues.

The whole idea behind the catch can is to catch the vapour, remove the oil and return cleaner vapour into the TIP (when venting back to TIP), or vent to atmosphere for an even cleaner system.

A catch can with baffles works more efficiently at seperating the oil from the vapour but if you're unable to get one with baffles you can use wire brillo pads inside the can.

-------------------------------------------------------------------------------------------------

Right firstly you will need the following bits:

- Catch can. Ideally one with 19mm inlet/outlet

- 2 metres of 19mm oil grade hose

- 1x 19mm plastic t-piece

- 2x 90 19mm plastic joiners

-------------------------------------------------------------------------------------------------

Now it's time to rip out all the old gear:

The whole lot should look like this when out:

INSTRUCTIONS

(Taken from this thread: 1.8t - PCV simplification and catch can installation - uk-mkivs )

The first thing I did was to remove both engine covers. Under the lower cover I loosened the metal plate which houses the N112, the N249, a checkvalve and a small maze of vac pipes

2 x 10mm bolts holding the SAI (secondary air injection) pump inlet pipe

then 2 x hex bolts holding the plate to the manifold

Carefully lift the plate from out of the clip on the side of the dipstick holder. If your dipstick holder's never been replaced it'll be very fragile and it'd be a good idea to replace it now for what it costs (about £5-6)

Now I started removing all the stock pipework from the top

See right behind the dipstick, there's the first small L section of pipe that leads to the suction jet pump Y piece. This is the pipe in which I've previously inserted a checkvalve, to stop boost before it hits the suction pump

I removed that, leaving the suction pump end exposed

Next was the infamous for splitting upper breather, on the passenger side of the rocker cover

It attaches to the TIP via the 'hockey puck' accumulator valve

Removed

Then I disconnected the brake booster line, leading from the suction pump

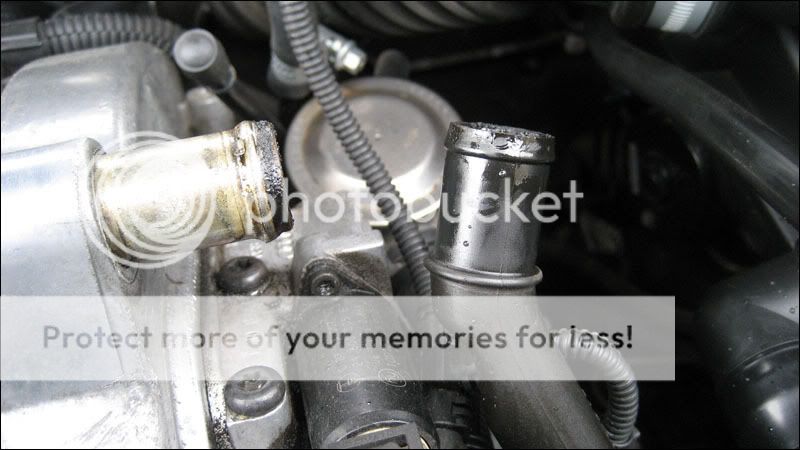

and finally I took out the lower breather pipe which is located right on the oil filter housing

You can see it on this picture from above, but unfortunately it's not in focus

I used a long shafted flathead screwdriver to prise off the C clip that holds it in position

There's an O ring in there too, careful not to lose it!

Removed

Now I managed to shimmy all the pipework clear and took this photo. The Upper breather Y pipe and the L piece leading to under the manifold are not attached, as mentioned above, I disconnected before removal

Yeggers! Look at that sludge that's accumulated

Keep these 2 parts for the new installation

Now I want to cap the vacuum source under the manifold. It's not going to be used, all the pressure is positive coming from the crankcase and upper breather anyway and it'll be caught in the can. The fumes will also pull via the TIP connection when under acceleration. I used a small length of 3/8" ID pipe with a bolt screwed tightly into it

This then fits to the nipple under the inlet manifold like so:

I'm also wanting to cap the brake booster line and just use the 1 vac source for brakes. It works on the AGU and ARZ so no reason it shouldn't work on an AUM right? I used a 1/2" piece of nylon rod and a jubilee clip but have since replaced this section of the brake booster line. Picture of revised piece to be edited in later

Or alternatively use another screw: