Correct part number for AFB injectors

- Thread starter two left feet

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

two left feet

Registered User

ben parris

Registered User

- Joined

- Sep 10, 2014

- Messages

- 29

- Reaction score

- 0

- Points

- 1

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

two left feet

Registered User

Chris, thanks again to you for all your help! The whole deal about S4 performance at diesel milage really works. I think the overall liters / 100 went down by more than 1 Litre.The guy at the Garage couldnt believe it and was concerned that the drive train may not cope. It may well be a weakness but i will look at this some more at later. The map is probably still a little raw, but thats something i can improve later also. So thats about it for this thread actually, all the improvements are in place, and work like a charm. Might upgrade the Mikalor clamps as they are a little wide, Oil temp hits 120 in spirited driving - so this might need to be upgraded, but again this is something for later. (i need something to do next year - dont i ?) regards to all and thanks for all the great various advice.

I like your thinking ! To be honest the drivetrain can take a lot more abuse than the garage operators might think ! I think the DMF is the weak link in the recipe as torque increasing exponentially with the bhp !

I will work on a remote oil cooler as i have something in mind however i don't have much time on my hands. I have a map ready for you however my laptop has packed up and using the ipad to surf the net and that has no usb port to email you the map.

I will work on a remote oil cooler as i have something in mind however i don't have much time on my hands. I have a map ready for you however my laptop has packed up and using the ipad to surf the net and that has no usb port to email you the map.

two left feet

Registered User

Yeah i hear you Chris. Een though the DMF is a new Sachs one, it may still be part of the weakness. Regarding map, Ipads are great things, but they are not laptops. I email everything and try and avoid USB sticks, but not always possible. In any csae drop me a line when have it ready, and i will flash the ECU and let you know how it goes. and about the 300 bhp.......

to be continued...

to be continued...

two left feet

Registered User

Chris, the handling issue you noticed during your last visit i have traced to a destroyed rear right drop link....

Also, last night i drove from Basel to Heidelberg, basically empty Autobahn, what this car now does between 140 and 210 kmh is unbelievable ...

Also, last night i drove from Basel to Heidelberg, basically empty Autobahn, what this car now does between 140 and 210 kmh is unbelievable ...

two left feet

Registered User

Found the reason for the handling woes, the rear right drop link was destroyed. The last shop used one of those plastic ones! New metal ones are inplace now, with the HR ARB at the toughest setting, completely new car to drive.....

I always had metal droplinks fitted on the car, coupled with genuine rs6 rear antirol bar and stock s6 shocks/ eibach pro springs and it was a very nice car to drive. I really miss my old a6, it was 95% complete...

I am putting together a larger intercooler package, ball bearing water cooled turbocharger and remote oil cooler for these engines. Also i will look into making new exhaust manifolds from stainless steel 316 scheddule 10 pipe, it should flow a lot more up the rev range.

I am also getting a few hybrid gtb2260vk made with larger turbine and billet compressors- good for 350-400 Bhp with supporting mods ! Choice of 6+6 blades for low end response and midrange kick or 11 blades midrange cick and max flow at high speeds. All will feature extended tip technology and stager gap oil seals...

Also looking into newer technology nozzles as the race nozzles are very large but also very potent...coupled with a 3 plunger head, they should make very nice numbers!

I am putting together a larger intercooler package, ball bearing water cooled turbocharger and remote oil cooler for these engines. Also i will look into making new exhaust manifolds from stainless steel 316 scheddule 10 pipe, it should flow a lot more up the rev range.

I am also getting a few hybrid gtb2260vk made with larger turbine and billet compressors- good for 350-400 Bhp with supporting mods ! Choice of 6+6 blades for low end response and midrange kick or 11 blades midrange cick and max flow at high speeds. All will feature extended tip technology and stager gap oil seals...

Also looking into newer technology nozzles as the race nozzles are very large but also very potent...coupled with a 3 plunger head, they should make very nice numbers!

two left feet

Registered User

Car is now nice to drive with the HR RARB and the bilstein/ eibach setup. Could be a little more agressive, but it nice to drive. I will take one of the oil coolers you are making as i hit 120 oil temp on the autobahn and i don't want to fry the turbo. The new map is my next target, so when you get your laptop up and running let me know. S4b6 brakes look to be the way ahead, but i will need 18 inch wheels first.....all good. Cheers from the land of the autobahn....

two left feet

Registered User

On the weekend i noticed some oil on the bottom of the boost pipe on the turbo side of the Intercooler, so replaced the Mikalor clamp with another one, and there is now a noticable improvement (noise etc) between 2000 and 3000 rpm as the Boost starts. So i guess i was loosing some boost there, and must have contrbuted to the noise. Will go through all the connectors (this winter) on the boost side and replace them. The IMHO and you have to tighten the **** out them to get them to work. Any recommendations ? (currently running 2.5 Bar)

regards to all from Germany

regards to all from Germany

two left feet

Registered User

Update Jan 2016.

Just passed 10000 Km of Chris inspired spirited autobahn driving.

However Friday afternoon, on the autobahn, without any notice the car lost power and boost.

Foot on gas led to very slow and smokey performance. I could still cruise at 140 kmh (no smoke) but power was gone, no acceleration.

I made it home, but I'm guessing MAF if stuffed, or I have split a connector and have a boost leak somewhere.

It was a really funny feeling to be driving in the slow lane with the trucks and Opels........

Just passed 10000 Km of Chris inspired spirited autobahn driving.

However Friday afternoon, on the autobahn, without any notice the car lost power and boost.

Foot on gas led to very slow and smokey performance. I could still cruise at 140 kmh (no smoke) but power was gone, no acceleration.

I made it home, but I'm guessing MAF if stuffed, or I have split a connector and have a boost leak somewhere.

It was a really funny feeling to be driving in the slow lane with the trucks and Opels........

two left feet

Registered User

Checked for split connectors and loose clamps, all good.

I Will replace the MAF on the weekend, but i have my suspicions that the vnt mechanism is coked up and not freely moving. Will run through a Mr Muscle treatment on the weekend.

The car is also sounding a little "agricultural" currently, that is - tractor like... Stay tuned.

Regs Andrew

I Will replace the MAF on the weekend, but i have my suspicions that the vnt mechanism is coked up and not freely moving. Will run through a Mr Muscle treatment on the weekend.

The car is also sounding a little "agricultural" currently, that is - tractor like... Stay tuned.

Regs Andrew

Most likely you popped a boost hose, check the vnt mechanism/actuator- disconnect the rubber hose on the actuator and see if the vnt arm goes down under spring resistance. Alternately use a vacuum pump or suck hard on the pipe. With vcds in engine, measuring blocks 11 and pressing basic settings you can cycle on and off the n75. If no movement then either diaphragm has split or n75 is goosed. Also check boost hoses if you heard a loud pop noise...

two left feet

Registered User

Had the same thoughts Chris.

Checked left side connectors - all good. Will have to take the bumper off to check the right side of the intercooler.

I noted also that if you wait longer the boost eventually build, but it takes time.

As i am running in a overfuel mode with thes race nozzles, i am betting the vnt is coked up.

Ran vcds and the arm moves through the range, but the movement seems slow.

Will check the movement tomorrow, and try the mr muscle trick.

Will post the results...

Regards from Germany

Checked left side connectors - all good. Will have to take the bumper off to check the right side of the intercooler.

I noted also that if you wait longer the boost eventually build, but it takes time.

As i am running in a overfuel mode with thes race nozzles, i am betting the vnt is coked up.

Ran vcds and the arm moves through the range, but the movement seems slow.

Will check the movement tomorrow, and try the mr muscle trick.

Will post the results...

Regards from Germany

Andrew, i will try and isolate the N75 off the anti shudder valve by un-plugging the tee piece or blocking the feed from the vacuum pump to the anti shudder valve with a suitable bolt or similar. I had low boost issues in a few occasions when the anti shudder valve control solenoid had stopped working and it was loosing vacuum hence the car was in low power mode ! The solenoid is by the ABS pump and the tee is under the coolant tank...

two left feet

Registered User

So an update..

Checked all clamps and hose connectors - all fine and tight, no sign of oil or anything.

Disconnected the VNT actuator bar, and it was easily moved.

Ran measurement block 11 on the vcds to check the movement, all seemed fine, but i did notice that during the cycle the actuator move to max then slowly returned (not holding the vacuum) but this may be normal..

Used my vacuum gauge and the movement is as normal, diaphragm is OK no leaks.

So bypassed the PSV as Chris suggested, still really slow to build boost still lots of smoke. if you wait long enough (nearly 4500 rpm) it will get to nearly 2 baar, but this is a long long way away from normal performance.

Had a spare MAF and 4 bar MAP, installed these but no change.

faulty n75 solenoid

regards

Andrew

PS. did not go ahead with the Mr Muscle

Checked all clamps and hose connectors - all fine and tight, no sign of oil or anything.

Disconnected the VNT actuator bar, and it was easily moved.

Ran measurement block 11 on the vcds to check the movement, all seemed fine, but i did notice that during the cycle the actuator move to max then slowly returned (not holding the vacuum) but this may be normal..

Used my vacuum gauge and the movement is as normal, diaphragm is OK no leaks.

So bypassed the PSV as Chris suggested, still really slow to build boost still lots of smoke. if you wait long enough (nearly 4500 rpm) it will get to nearly 2 baar, but this is a long long way away from normal performance.

Had a spare MAF and 4 bar MAP, installed these but no change.

faulty n75 solenoid

regards

Andrew

PS. did not go ahead with the Mr Muscle

Andrew, does the turbo sounds a bit higher pitch when the actuator is fully up touching on the stop screw ? Me and others had issues with the exhaust manifolds breaking internally and small bits of metal getting sent into the tubo's VNT mechanism and damaging the turbine/VNT ring...

two left feet

Registered User

just took the down pipe off the turbo, and tried to move the exhaust spindle.

The spindle is not easy to move. Though there is not significant play in the spindle - it will just not rotate easily. This is why the boost is so slow to build.

So I'm thinking now that the bearing is rooted / on the way out.

Will try some Mr Muscle treatments in case is just build up, but i am thinking i will need to get the turbo refurbished.

lets see what tomorrow brings..

The spindle is not easy to move. Though there is not significant play in the spindle - it will just not rotate easily. This is why the boost is so slow to build.

So I'm thinking now that the bearing is rooted / on the way out.

Will try some Mr Muscle treatments in case is just build up, but i am thinking i will need to get the turbo refurbished.

lets see what tomorrow brings..

Most likely the exhaust manifolds are breaking mate and the metal bits are jamming the turbine and keeps the vnt mechanism wide open. The manifolds are made of stainless steel on the outside and cheap steel for the runners inside ! If you take the turbo off put a magnet inside the collector and fish for metal shards...the manifold on passenger side will come off easily, you can try removing that first and look for damage. Diffas makes some solid exhaust manifolds but i am having issues with the ones he supplied to one of my clients as they are blowing all over at the joints ! I will try to make some log style manifolds very, very soon, just need to find time... Some stainless steel 304 bends and a few hours of welding should do it nicely !

two left feet

Registered User

tried and failed to remove the turbo today. My impact driver, (bless its little heart) politely stripped the inside thread of one of the hex bolts. So this is now no-mans land for me now. I really cant rule out that metal pieces from the exhaust manifold haven't taken out the blades in the turbo for the moment. Would explain what is have seen recently.

Not quite sure what to do next...........the car is still somewhat drivable (but with next to no boost , smokey and it sounds like a tractor) so next step is to get it to an Indy to remove and strip the turbo. Would need to find some better manifolds too....

would be great to be located somewhere near London (but sadly not the case)

Andrew

Not quite sure what to do next...........the car is still somewhat drivable (but with next to no boost , smokey and it sounds like a tractor) so next step is to get it to an Indy to remove and strip the turbo. Would need to find some better manifolds too....

would be great to be located somewhere near London (but sadly not the case)

Andrew

Hammer a ribbed bit in them hex bolts and use a ratchet to undo ! If you use a vacuum pump on the actuator do the noise from exhaust changes ? That rules the manifolds breaking and might be just a faulty N75- seen it before ! Also check the stop screw has not fallen out, i had that come off as well in a few instances due to heat !

two left feet

Registered User

Chris, tried the manual application of vacuum directly to the VNT (with vacuum pump). You can hear a difference in the exhaust tone. Not dramatic a difference ,but it is there. Perhaps its just the N75. Will order a replacement one at Audi....

Fingers crossed it's just that. You could also look for vacuum leaks from the vacuum actuator to the servo/one way valve. Another thing to try is to swap the EGR solenoid with the N75 and see if the car pulls any better. They are very, very similar and you can do with simplifying the vacuum system as there is no more EGR system and it's shut close in the map anyway !

two left feet

Registered User

got the new N75 today.

Yee-hah !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Boost is back, f-n happy camper i can tell you...

thanks again Chris, the remote troubleshooting worked again.

i had a few anxious moments though.

i had a few anxious moments though.

So this years plan is back on; S4 brakes, and 18 inch wheels.

I do need to get a new ECU map. Still a bit smoky and noisy on boost. (Chris any chance??)

I can now get on with life.....

hahaha...

regs to all from Germany

Andrew

Yee-hah !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Boost is back, f-n happy camper i can tell you...

thanks again Chris, the remote troubleshooting worked again.

So this years plan is back on; S4 brakes, and 18 inch wheels.

I do need to get a new ECU map. Still a bit smoky and noisy on boost. (Chris any chance??)

I can now get on with life.....

hahaha...

regs to all from Germany

Andrew

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

Diffas makes some solid exhaust manifolds but i am having issues with the ones he supplied to one of my clients as they are blowing all over at the joints !!

What joints are "blowing all over"? You have any pics about?

What joints are "blowing all over"? You have any pics about?

Attachments

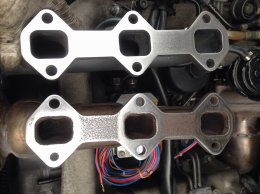

I had to skim the mating faces down but there's still a leak from where it meets the collector manifold ! The car goes in limp mode if you keep it to 2500 rpm's in 4th, 5th or 6th as it's not making the boost required by the file... It started after Ben fitted the manifolds along with rebuilding the engine. The leaks were quite severe as i could hear loud woosh-ing sounds on drivers side... One picture shows a stock manifold next to the solid ones supplied by diffas...

Attachments

Last edited:

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

I can sen you new up-pipes with uncut flange, or is only the drivers side needed? Looks like the flange is cut too much off

To be honest mate i think both sides are required as they both blow - only took pictures of one side as i could not be bothered to take more pictures with dirty gloves, Ben fitted some gaskets at first however it leaks even between the link pipes and manifolds. Do you have suitable new flanges and/or new gaskets to go with them flanges ? I could cut them off the manifolds and weld new ones instead. The flanges are different to what were fitted on original manifolds by audi and the stock gaskets require notching to fit- not an ideal solution in my opinion. Other than that i cannot fault the craftsmanship... Do you want my address details ? Ben's allroad it's at my workshop few hundred miles away from where he leaves ! Sorry for cluttering Andrew's build thread and i am not trying to slag your product in any way...

Last edited:

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

It's good to have feedback and hoping that we can solve the problem. I heard nothing from ben since is send them so didn't know that. Btw No gaskets should be used, only extremely slim layer exhaust paste. But lets continue on private not to continue this offtopik

two left feet

Registered User

no problems to borrow my thread. Now that i have my boost and power back, i am just happy.

Interesting to learn about the header pipes degrading with the increased temp. My EGT is nôrmally constant at 500. Peaks are higher, but seldom for long.

I will stick headers on my list...

greetings to all.

Interesting to learn about the header pipes degrading with the increased temp. My EGT is nôrmally constant at 500. Peaks are higher, but seldom for long.

I will stick headers on my list...

greetings to all.

two left feet

Registered User

After dodging the bullet on the breaking exhaust headers, I went for a spirited drive to Switzerland. All good, power back, lots of fun to drive. However the Oil temp pushes to 120C on prolonged 200+ kmh stretches. How concerned do I need to be? I read that sustained temps will break down the oil, meaning the need life is reduced. So, should I plan for a remote cooler with Mocal thermostatic plate, or carry on and just change the oil more frequently ?

two left feet

Registered User

Well bullet not dodged.

Was driving home, and got power loss and lots of smoke, has to get the "AA" guy and get the car shipped back to my garage.

Originally at the road side, the AA though it was the turbo.

My garage (doesn't really specialize in diesels) noted that when you open the oil filler cap, that there is diesel vapor coming out. You can also see this vapor push past the injector seals.

This happens at idle.

He thinks that it either an injector body leaking diesel, or a mounting plate ( the curved ones) is stuffed.

Tried searching this but got no ideas.....

Has anyone ever seen an injector bottle leak ? I had these injectors serviced by DieselBob about 9 months ago, so i can't imagine the reason...

Was driving home, and got power loss and lots of smoke, has to get the "AA" guy and get the car shipped back to my garage.

Originally at the road side, the AA though it was the turbo.

My garage (doesn't really specialize in diesels) noted that when you open the oil filler cap, that there is diesel vapor coming out. You can also see this vapor push past the injector seals.

This happens at idle.

He thinks that it either an injector body leaking diesel, or a mounting plate ( the curved ones) is stuffed.

Tried searching this but got no ideas.....

Has anyone ever seen an injector bottle leak ? I had these injectors serviced by DieselBob about 9 months ago, so i can't imagine the reason...

two left feet

Registered User

perhaps rings ? Diesel not compressed, blows back past rings, into crankcase, then up through vents into the rocker covers... ? hole in piston...cracked piston ?

Last edited: