I don't think 8 Bar would make as much difference, to sound like that i reckon they are popping much, much higher. Remember dieselbob only sets the pilot injection, these injectors are dual stage and the pop pressure is adjusted by installing longer or shorter pins which no many places have- it's very expensive.

Correct part number for AFB injectors

- Thread starter two left feet

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think that either the injector pump is tired, pop pressures are way too high and/or SOI maps are still off ! I am too busy but i will try and work on a map just for you however i need logs to see what the car does really- might be time you invest in a vag-com/vcds lead !

two left feet

Registered User

I will get the pump done this week. Then at least we have only a few more variables to work on. I have also thought about getting the vcds leads. Regarding the injectors, does it make any sense at all to put the original AKE injectors back in with the race nozzles ? even though it will give a rough idle.

Nope, they will drive you crazy if you swap nozzles to AKE holders, them race nozzles are designed for AFB injectors and will shudder like mad !

I wish you had a spare pump to rebuild so you know you had a spare working and minimize downtime...

I wish you had a spare pump to rebuild so you know you had a spare working and minimize downtime...

two left feet

Registered User

two left feet

Registered User

Just got the bad news on the pump. According to the local experts it is non repairable. Will get a newly reconditioned one next week. Let's see if this was the problem with the tuning....

What ? They get repaired in uk and rest of the world...

Some pump casings wear where the timing is but engineering shops do press a new sleeve from hardened steel so it's as good as new...Only time it cannot be repaired is when the casing is cracked...

Some pump casings wear where the timing is but engineering shops do press a new sleeve from hardened steel so it's as good as new...Only time it cannot be repaired is when the casing is cracked...

two left feet

Registered User

It's got me guessing also, as to why it can not be repaired. Considering it was still functional before they sent it off for assessment and repair. However, they have me over a barrel now that the car is off the road in the garage. I will get the original one back. Hopefully the EGT / turbo pressure gauge will arrive next week ( McNally ).

Chorus, any ideas when you will be traveling through Germany next?

Chorus, any ideas when you will be traveling through Germany next?

ben parris

Registered User

- Joined

- Sep 10, 2014

- Messages

- 29

- Reaction score

- 0

- Points

- 1

two left feet

Registered User

Hi Ben, according to Chris the 2260 will get to 35psi (ca 2.5 bar), so I went for the 40 psi model. Will hide it in the drivers side air vent..

ben parris

Registered User

- Joined

- Sep 10, 2014

- Messages

- 29

- Reaction score

- 0

- Points

- 1

Tidy, I think I'm on about 27 psi so a 30psi might be a bit close to the limit... suppose I should get it running again first....

two left feet

Registered User

I should be running by Wednesday, so I will see if the pump or the injectors were causing the timing issues. Chris still seems to think the injectors with the the race 683 nozzles are the problem. I will check in again on Wednesday. Cheers from Heidelberg.

Good luck ! Keep us updated please... I should be travelling trough Europe in a few weeks, going back to do some work in my house so will have my hands pretty busy ! Don't have much time left for myself and still need to do a timing belt change to the van i am travelling with...talk about mechanic's cars !

two left feet

Registered User

Chris, will keep you posted. I bought a VCDS in the meantime, so once I get the car back I can collect some information. The EGT / boost gauge will get installed this week too. Fingers crossed!

two left feet

Registered User

two left feet

Registered User

of course it will go in 180 degrees on my car

The new pump is now installed, and once you hit boost (>2000 rpm) you really have to hold onto your hat.

Still got a some injector noise at start of boost though.

Will now start to read the instruction manual for the VCDS.....

The new pump is now installed, and once you hit boost (>2000 rpm) you really have to hold onto your hat.

Still got a some injector noise at start of boost though.

Will now start to read the instruction manual for the VCDS.....

two left feet

Registered User

Hi Chris, I sill take the car for a longer drive to Tomorrowand jet you know..

In the meantime, I have to drill and tap for the McNally sensors (1/8 27 NPT) to get the gauge working...

Getting really close now..

In the meantime, I have to drill and tap for the McNally sensors (1/8 27 NPT) to get the gauge working...

Getting really close now..

two left feet

Registered User

update:

Verdict, new pump did not make and difference. Still have the injector clatter as boost starts...

At full throttle, maxed boost at ca 2.5 bar. EGT maxed at 800°C. at normal driving (cursing) the boost was between 0.5 and 1.

Installed the sensors into the blocking plates for the EGR, one at the exhaust side, one at the inlet side. See the picture below.

Regarding logs, i guess i am looking to log block 011, which shows the time/rpm/boost request/boost actual/N75%. (between 1500 - 4000 rpm). That does that sound right ? (very new at VCDS)

Verdict, new pump did not make and difference. Still have the injector clatter as boost starts...

At full throttle, maxed boost at ca 2.5 bar. EGT maxed at 800°C. at normal driving (cursing) the boost was between 0.5 and 1.

Installed the sensors into the blocking plates for the EGR, one at the exhaust side, one at the inlet side. See the picture below.

Regarding logs, i guess i am looking to log block 011, which shows the time/rpm/boost request/boost actual/N75%. (between 1500 - 4000 rpm). That does that sound right ? (very new at VCDS)

Hi Andrew, boost levels are as requested by the tune so the turbo gauge is accurate, i am glad that egt does not go over 800 degrees, i would not want it to go more than 900-950 celsius, the vnt tips start to melt at about that ! Can you send me your original map so i could try and do a map from scratch for you, we really need to get to the bottom of that issue with your car...

Looking at your boost log Andrew the turbo is building boost quite well, N75 duty cycle is not getting below 37% which means that the ECU still have some control over the actuator/vanes ! Also it does 2.5 Bar of boost at 3000 rpm's which is right there on the money ! Give me a few days and i will send you another file then you let me know how it feels !

two left feet

Registered User

All good Chris, cant wait to try the new map. Thanks for all your help!

Cheers from Heidberg

Andrew

Cheers from Heidberg

Andrew

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

Just wondering why are you using so low opening pressure on your injectors? With nozzles that big you should use at least 260bar or even higher.

Race nozzles do knock when pop pressures are too high and you loose torque low down and you need to slip the clutch a little. Best to just make sure they pop at the same sort of pressures and spray evenly !Just wondering why are you using so low opening pressure on your injectors? With nozzles that big you should use at least 260bar or even higher.

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

I'm not saying that you need to set them too high. Just for example race683 work just perfect in every rev area with 280bar opening pressure. Slightly increased injector opening pressure has a significant effect on the performance and emissions of diesel engines. Increase in injection pressure gives you better atomisation at the nozzle outlet, resulting in a more distributed vapour, hence better mixing. Useful when using larger hole nozzles.

Last edited:

Agree with you diffas, higher pop pressures are beneficial when you have the 3 plunger pump to drive them however most later v6 tdi's have the 2 plunger pumps and they struggle to feed them under 2000 rpm's. Stock pop pressures just work well on 2 plunger pumps even on the power plus 683 nozzles which are a lot smaller.

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

Well but this car in this topic has high pressure AKE pump. Even at smallest 2plunger pump available in V6:s from AKN has no problem with 280bar. I think its more about ecu-tuning than problem with nozzles on lower revs. These pumps use so high pressures that they just dont have any issues with high opening pressures. Not sure if mine (300bar) is near the limit but atleast it works fine.

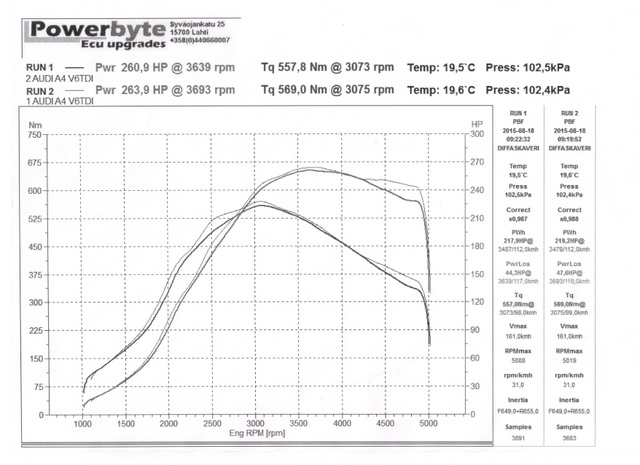

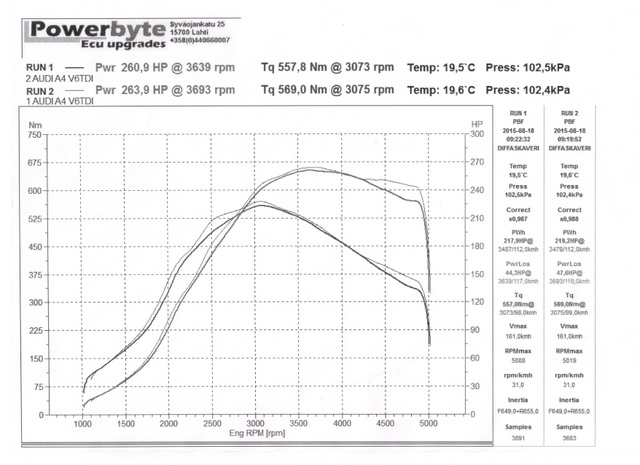

Here is my friends car that we just dynoed with 42mg/str and race683, A4Q with AKN.

Not that smokey under 3000rpm, mostly light haze. Thats with only 1.65bar, I'll try 1.8b next time.

Here is my friends car that we just dynoed with 42mg/str and race683, A4Q with AKN.

Not that smokey under 3000rpm, mostly light haze. Thats with only 1.65bar, I'll try 1.8b next time.

The issue is diffas that these nozzles were set by dieselbob and every set he done were noisy. Now I do not set them myself, I just take AFB injectors, put race nozzles In then I take them to the shop for pop pressure testing and even spray. They work fine. In Andrew's car he got the injectors balanced himself, everything else works on other a6 Tdi with same pump and mods and the tune/hardware is good for 300 Bhp... He needs to take it on a dyno to see what it puts out, I will be very surprised If it doesn't do 300Bhp...

Here's my old a6 with BDH engine, ported heads, hybrid gt20 turbo and solid intercooler from early Allroad -basically same setup as Andrew's. I am using same SOI/EOI and same IQ values under 2000 rpm's so the car should perform well. There are few variables in his car: pump has been changed- part number is unknown and timing was set by 3rd party garage.

two left feet

Registered User

The injectors are noisy on boost ( surge?) but not noisy before or after start of boost. Idle is a little lumpy, but not really that anoying. If the noise is a function of the injectors (and doesnt improve with the next map) then i might look for other options. In the meantime, i will get on the expensive Dyno (in Switzerland) and post the results..diffas, thanks for weighing in

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

two left feet

Registered User

I made a quick recording using the phone. its not as loud as it was originally, occurs between 2000 - 2500 rpm. Just need to find a way to share it now......

Last edited:

two left feet

Registered User

OK, i have officially given up. How do i upload / share the audio file ? (I'm surely having a stupid moment)

two left feet

Registered User

two left feet

Registered User

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

Hmm didn't found any odd sound there. Sounds like normal combustion knock. Seems that there might pre-injection turns off and combustion noise is getting louder, which happens with bigger nozzles and short duration.

None of my cars did that noise with nozzles calibrated by me in uk, only time friend of mine fitted some power plus 683 nozzles which were set by dieselbob at about 260bar and they knocked with his 2 plunger pump but did not on my Allroad with 3 plunger pump.

- Joined

- Jan 19, 2010

- Messages

- 156

- Reaction score

- 24

- Points

- 28

- Location

- Lahti, Finland

- Website

- www.facebook.com

Sure, thats why you have over fueling issues on low revs. Fuel is getting sprayed on wrong pressure - sure it does not have louder combustion noise due low injection pressure and over fuel. Have you ever heard how hard CR engines knock without pre and after injections ?