- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

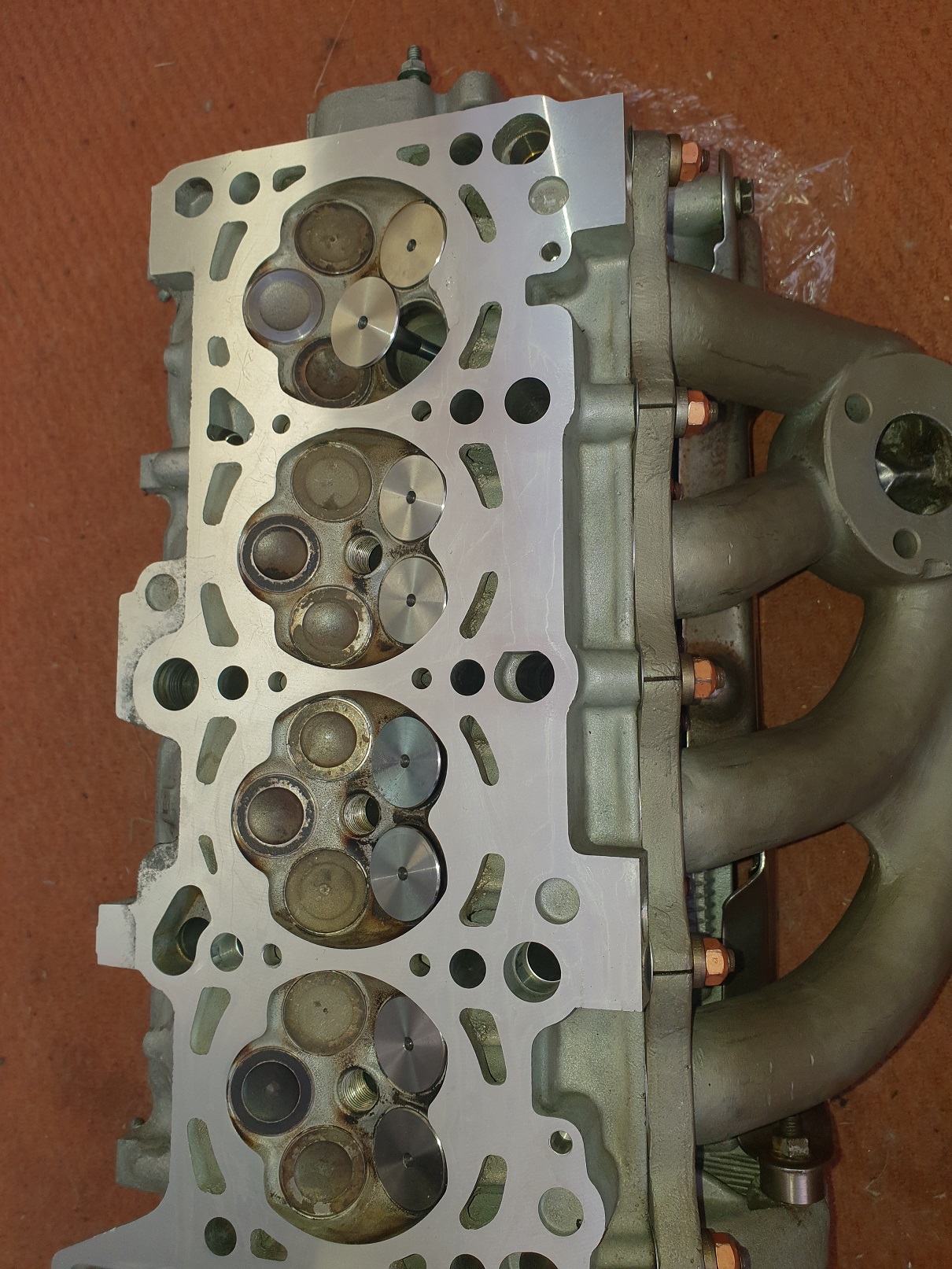

well I checked the head and this happened, hmmm....tut..

I have been concerned over how much of the collector to remove the triangle is created to stop the exhaust from 4 travelling down to 1 and 2 isn't it

hmmm I think I have run out of picture space? do I go through my previous threads and delete them? even though the file is only 174k it's saying the server cannot upload it.

I have been concerned over how much of the collector to remove the triangle is created to stop the exhaust from 4 travelling down to 1 and 2 isn't it

hmmm I think I have run out of picture space? do I go through my previous threads and delete them? even though the file is only 174k it's saying the server cannot upload it.

keep up the good work though! Your still ahead of me

keep up the good work though! Your still ahead of me