Afternoon all. So then... today was dyno day.

For openers, this engine is not as powerful as it's predecessor. I'm not sure if this is down to everything still being a bit tight and new, an the fact I'm not running synthetic oil or whatever, but she will not make the same power levels from the same boost as previously.

That said however, whilst it won't make the equivalent peak power, it does produce more power more of the time which is a plus.

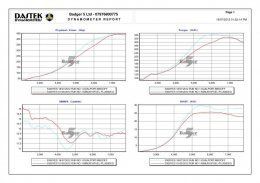

The day opens with the motor first run on the dyno. She made 380 BHP at 1.5 bar actuator pressure. Not bad.

Moving the boost up to around the same as previous dyno took us to around about the 420 mark. 25 BHP down on previous and I was a bit surprised.

Anyway, then came time to up the boosty... and the turbo just didn't want to play. Up 5 clicks on the MBC gave some more, another 5 clicks made little change. There was also some slightly abnormal boost characteristics.

Following this we let the car cool down and regrouped to have a think. Bill worked out from previous experience of about 45 PSI exhaust manifold pressure on the Lupo that my wastegate penny valve is seeing around 49 lbs of pressure, and is only being held shut by a 26 lb spring. Hench the wastegate is cracking and allowing turbine gas to bypass the turbine.

This explained both the boost oddities as well as the fact that it simply wouldn't make more than about 27 PSI peak.

Bill then has a stroke of genius frankly. The problem is the actuator spring not being strong enough to counteract the turbo flow. So why not use what the engine already has? Boost pressure. Create a twin port actuator to help the spring stay shut.

This didn't actually take much to be fair, as the Forge actuator I have already has a plugged port with a thread. It was a case of winding a stub in to allow a boost feed.

Here is the finished product:

First run with 10 clicks on the MBC and the Twin Port actuator working Bill had to back out of the first run as we saw 30 psi and climbing.

Wound the MBC right back down to 0 and ran it, she made 29 PSI peak and held a steady 27 PSI across the rev band.

Perfecto.

It also made 444.7 BHP and 344 Ftlbs. Timing pull was within tolerance as well. Fuelling in thee 12's.

So we left it like that.

No map tweaks today as my new Lambda hasn't arrived annoyingly, job for another day there then.

The end result is good, yet bad. Same peak BHP from more boost, but more of it everywhere.

Torque is up due to increased boost.

Good end result and after a few thousand and with some fully synthetic oil on board it will be interesting to see how that compares.

Fair play though, that old engine did a great job considering.

Hoping Bill will pop some comparison graphs up.

Thanks again for your help today Bill - and great work on the actuator! :thumbsup: