Audi TT 225 - banger project

After reading many threads on various forums about Audi coupe's lack of being water tight. I decided that I was not going to run the S2 over the winter months. I also don't want to chuck a load of miles on the car doing mundane driving and want to avoid the salty winter roads. So over the past months I'm been looking around for options. It had to be Audi and cheap. I've had a load of B5 over the years, and did not want another estate car. Was thinking of an 80 but was getting board with NLA part finding.

So for a while now I was thinking about the TT, I kind of like the MK1 and they are cheap enough at the moment. There is a couple of MK1 TT where I live and I walk past one very day when I'm walking the dog, and it's been catching my eye. I've also noticed they are starting to thin out on the UK roads, with a lot of them being broken from what I see on FB market place. Let face it who is going to spend £300-500 on a cambelt change and service on a car worth £1K, unless you can do it yourself. Labour rates are the death of cars.

So my brief on the car I need. It's had to be cheap around £1K, and to be the BAM engine and the body work had to be in good condition. Don't mind if need wings just as longs as the main body was ok. There were plenty of £2.5K-£3K cars around that look very good on the surface and interior but the running gear still needs a lot of work as they are all around 20 years old with 100K miles. So would rather get a £1K car and spend £2K to bring it up to scratch. Also with lots of cars being broken parts are cheap, and everything I've ordered from TPS at the moment has either been in stock or with me next day. Which is a nice change.

When I was searching for a cheap motor I went to see two cars, both were in poor condition. One looked like it had been painted with a rattle can, and the other car the owner had let slip it had been a track car after I asked why the engine had been replaced, and the airbag system had been disabled! On both cars I got out of there quickly and never even bothered with a test drive. Few days ago one lunch time I was searching FB marketplace and one had been posted only an hour before and it was local. So messaged the seller and within 3 hours the car was mine after a bit of haggling.

Issues with the car as follows.

Engine management light on, think a sensor has failed from the VCDS scan.

Needs a new windscreen

Needs a cambelt.

Engine needs servicing, plugs, oil, filters etc.

Sump removed to check the pickup, the 1.8 is know for sludging up.

Haldex needs servicing.

Brake, gearbox and PAS fluid needs changing.

Needs a replacement rear exhaust (Owner gave me a good one for free).

A/C needed fixing loads of gas but does not work.

Drivers side wing has a dent & scrape will either repair or replace.

All the running gear need blasting and powder coating.

New bushes & joints required.

Needs shocks & springs.

Car needs a good clean inside and out..

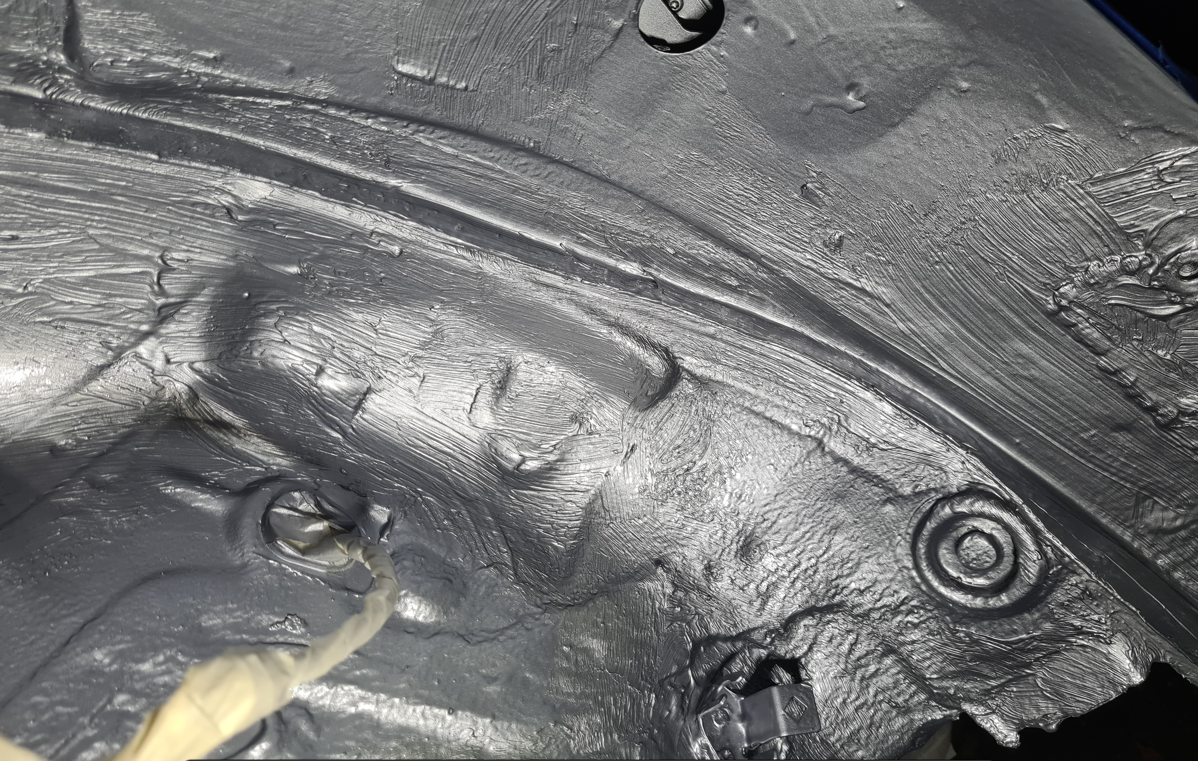

With the car back home the work has begun. Engine bay has never been cleaned.

Looks like the entire scuttle trim needs replacing, just because this VIN window has failed

Started the strip down

Lovely

Rocker cover was leaking, in a few places!

Belt is not in good health

Looks like someone got a job lot on self tapping screws. They were the only thing holding the undertray on

Spark plugs are also well passed their best, gap on the plugs was massive compare to the new ones.

This was about as far as I got on the first day

More to follow