- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Hi

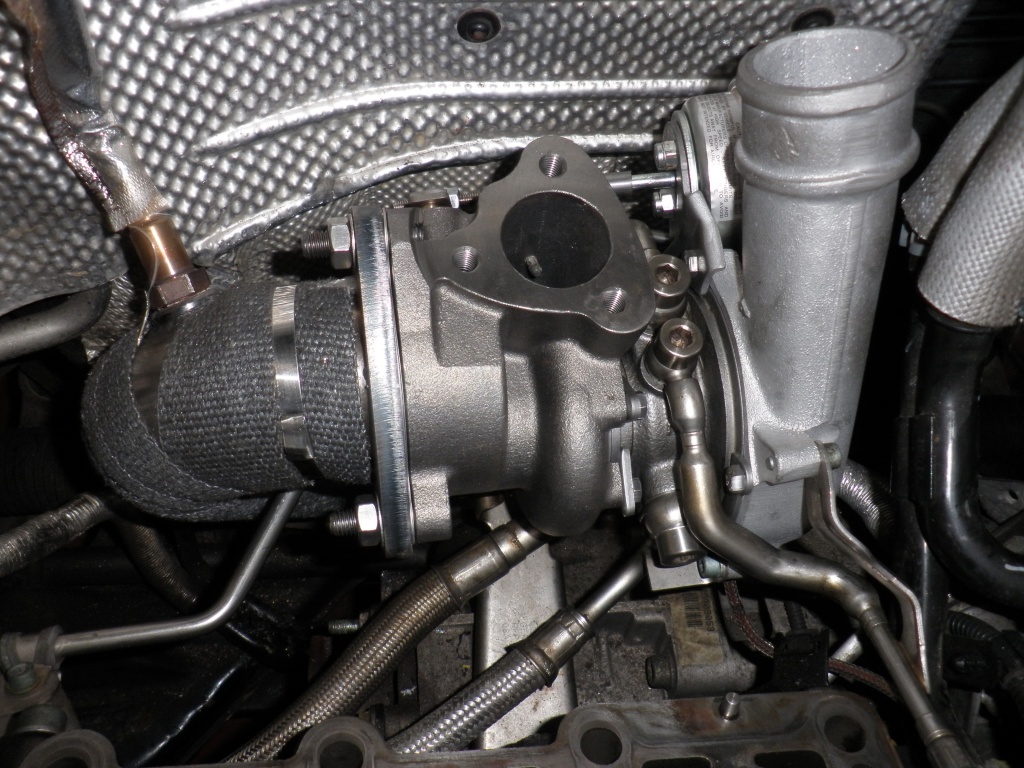

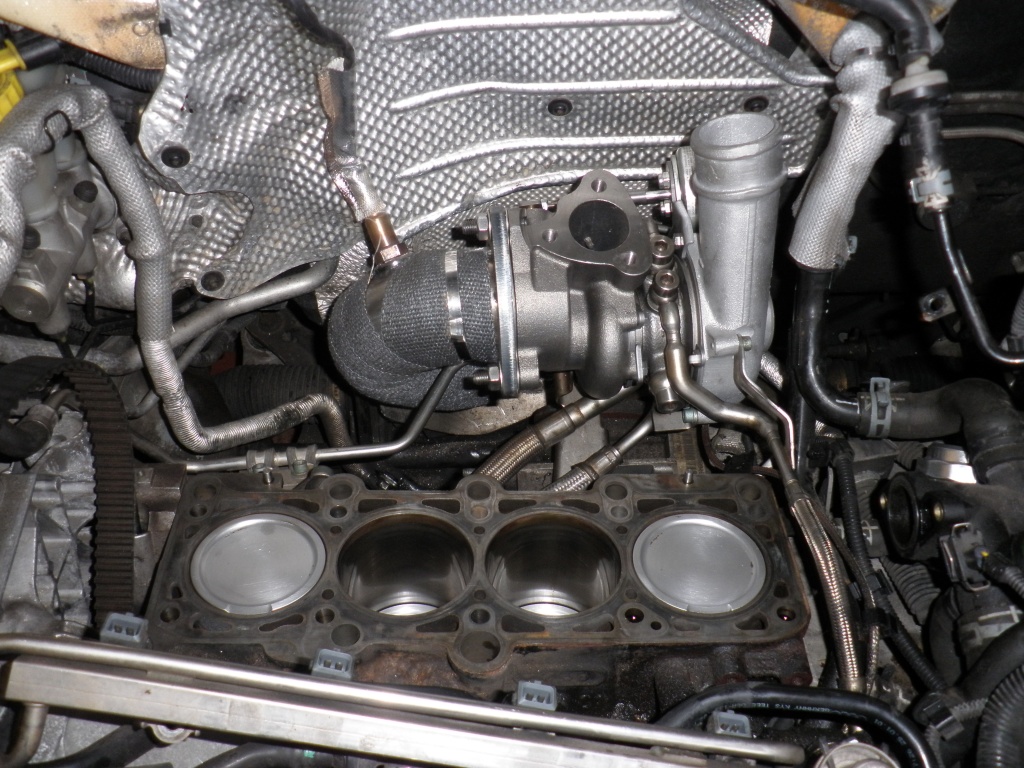

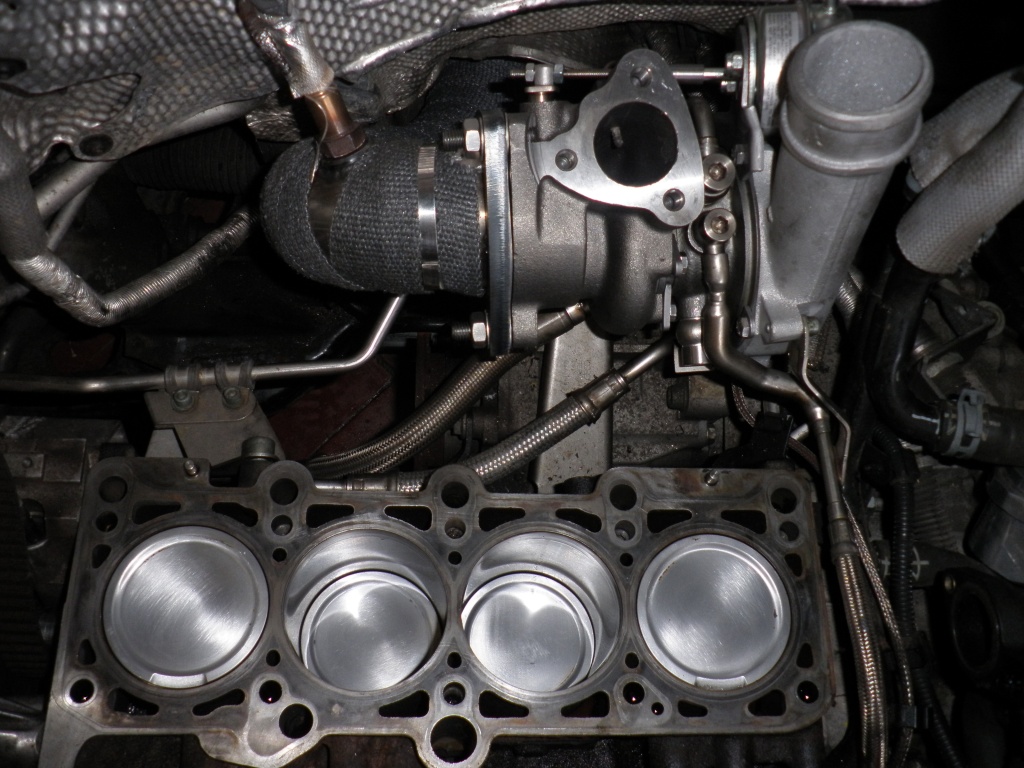

there's a lot of interest in these k04 hybrids.. so to help people visualise whats being talked about I have taken some time to take pictures of on install going on for speedy_steve's S3 which is with me for this upgrade

First of all comparison side by side showing different compressor wheels.. k04 vs billet k06 wheel

k04's std comp wheel

Hybrids billet k06 comp wheel

hot sides comparison

turbine size comparison, rs6 wheel vs k04 wheel

std k04 turbine wheel

hybrids larger turbine wheel (RS6)

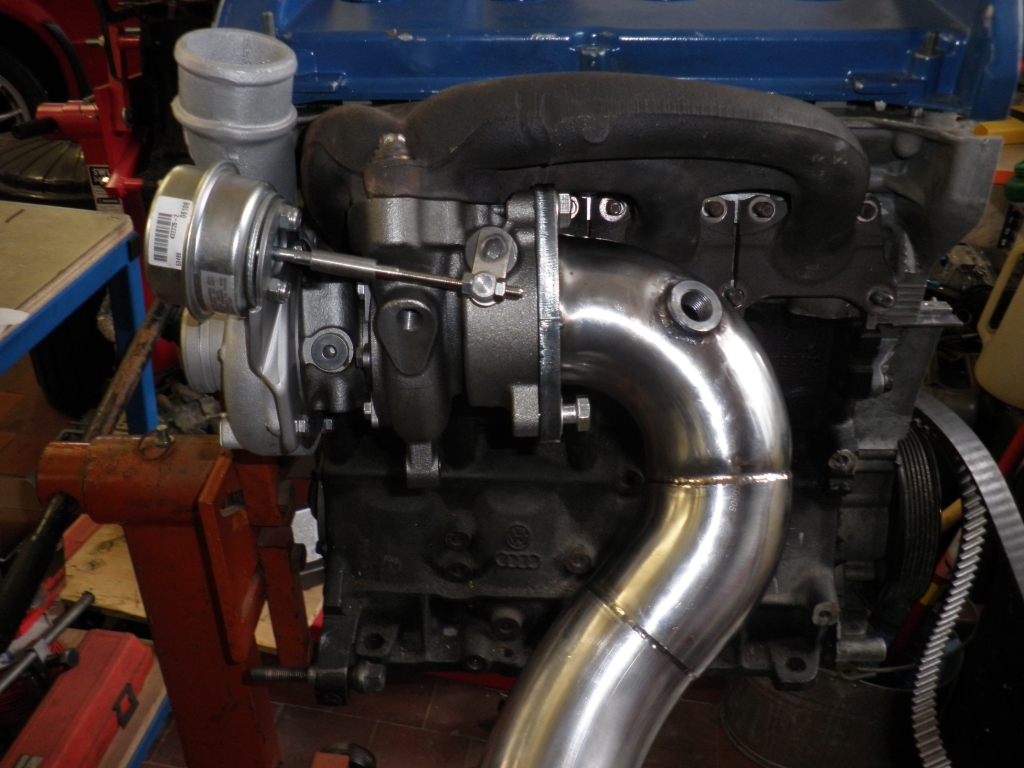

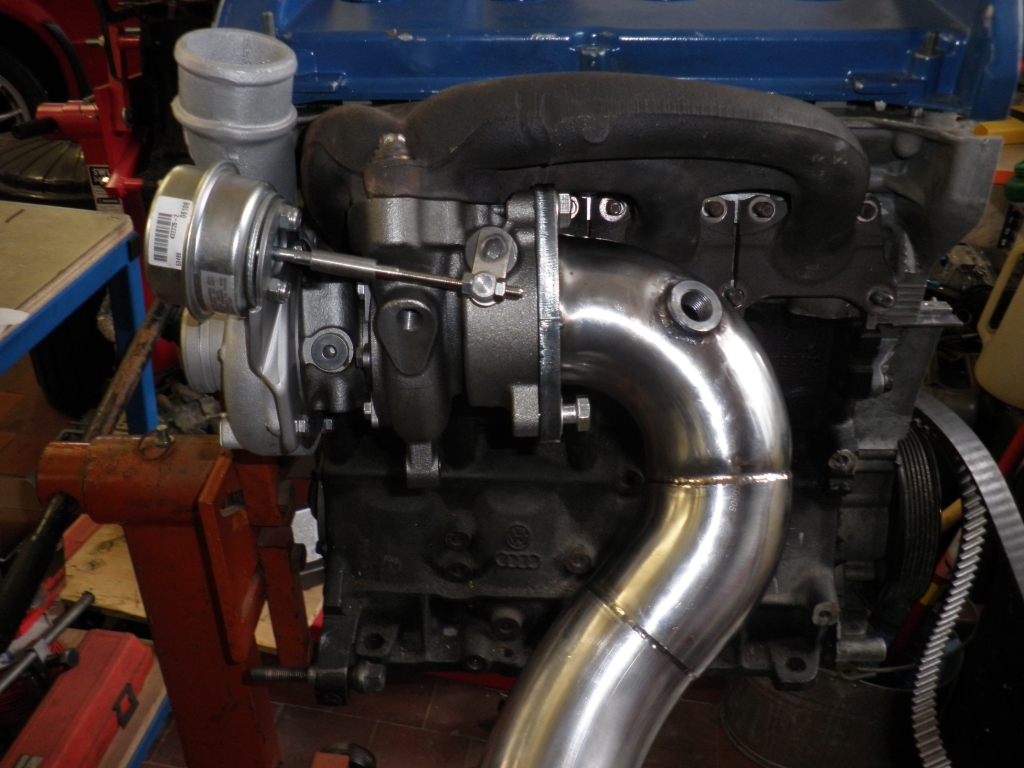

Mocked up with PiperWerx 3" downpipe on engine and stock manifold

Essential mods imho are going to include rods, downpipe, fmic, intake to support what this thing is potentially capable of.

Steve's gone for rods which we have fitted (IE rods), FMIC will be required, and mapping to suit to realise its potential.

more when we have buttoned it back together and test driven it and logged what it does

watch this space folks

regards

bill

there's a lot of interest in these k04 hybrids.. so to help people visualise whats being talked about I have taken some time to take pictures of on install going on for speedy_steve's S3 which is with me for this upgrade

First of all comparison side by side showing different compressor wheels.. k04 vs billet k06 wheel

k04's std comp wheel

Hybrids billet k06 comp wheel

hot sides comparison

turbine size comparison, rs6 wheel vs k04 wheel

std k04 turbine wheel

hybrids larger turbine wheel (RS6)

Mocked up with PiperWerx 3" downpipe on engine and stock manifold

Essential mods imho are going to include rods, downpipe, fmic, intake to support what this thing is potentially capable of.

Steve's gone for rods which we have fitted (IE rods), FMIC will be required, and mapping to suit to realise its potential.

more when we have buttoned it back together and test driven it and logged what it does

watch this space folks

regards

bill