Hello,

Finally got some good news

After the trials & tribulations of the last 10 months, looks like I have finally got to the self set target of 300HP.

After the disappointing dyno run of the 12st September 255.8HP (see here for a report on the dyno run - https://www.ttforum.co.uk/forum/viewtop ... 3&start=45), I came back to the garage mended the exhaust blow, turbo to manifold, only to find that there was also a blow head to manifold. I wasn't surprised as I thought I could hear a blow from infront of the turbo as well as feel the blow at the top of the turbo, this blow was also mended. When I say mended the turbo to manifold had a new Audi gasket fitted but still blew so I used a little exahust paste and finally got it to seal, not wanting to completely remove the exhaust manifold as I have a stainless tubular one which are notoriously difficult to remove & refit, I loosened the nuts around the blow applied a little exhaust paste & retightened which has mended the blow. Not sure how long the fixes will last (hopefully they are the sort of temporary fixes that last forever) but have prepared my self for a weekend of grazed knuckles & swearing at some point.

After "mending" the exhaust blows I tightened the wastegate on the turbo to about 13PSI from 10PSI that it ran for the turbo & added some extra fuel in the mid range on the map after Chris at Surrey Rolling Road commented that the fuel in the mid range was a bit lean.

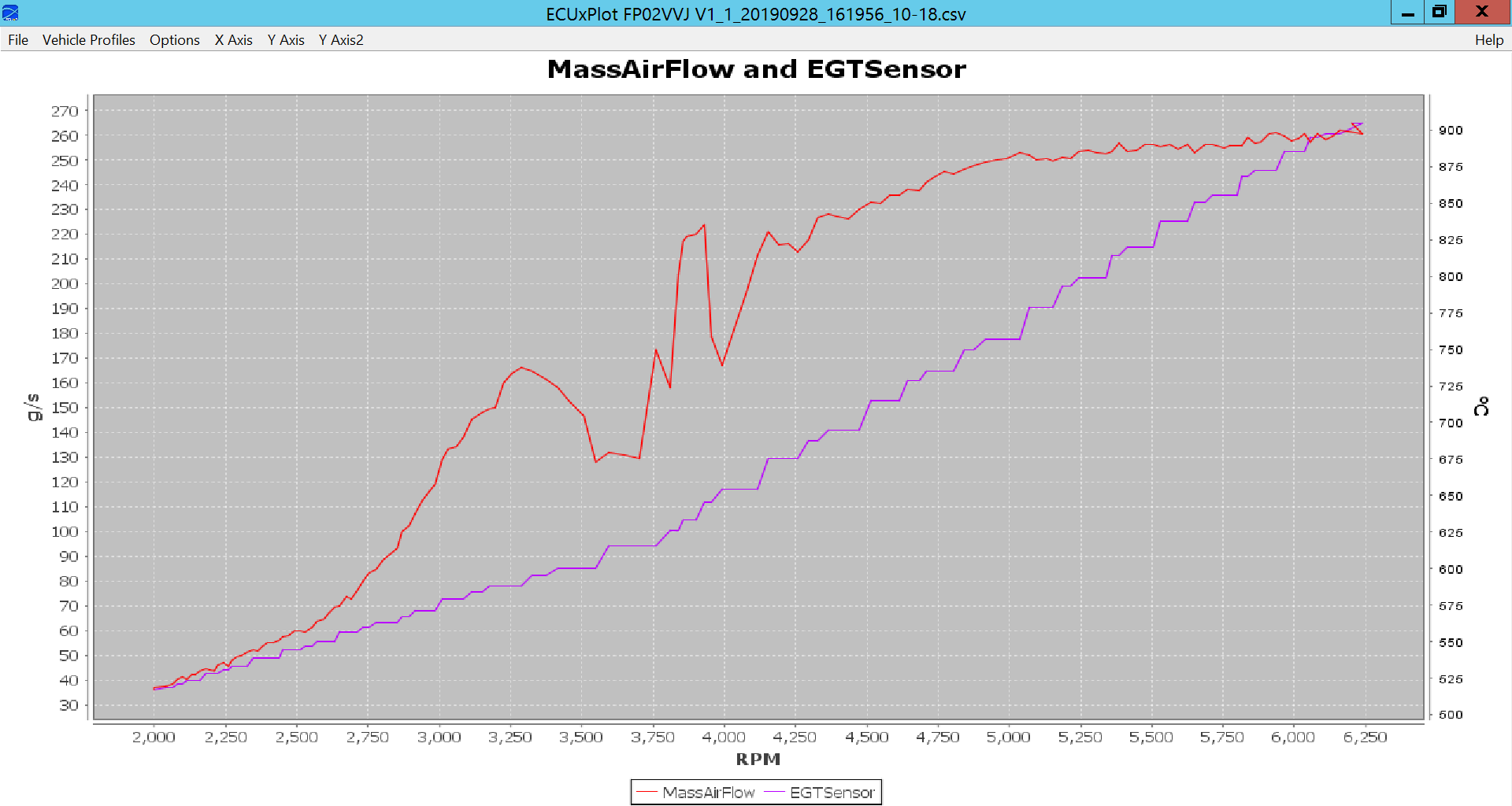

Then out for a couple of 3rd gear drags, it felt faster and I had turbo flutter\over boost on acceleration which hadn’t happened before. So I looked at the log expecting to see 220 - 230 g\s air flow, to my surprise it peaked at over 260 g\s

There is still some work to do as I don't think the engine would last long if I tried to run at full tilt for very long, as you can see from the attached logs;

- The Injectors are maxing out - still need to fit the 440cc injectors & uprated fuel pump I already have.

- The turbo flutter\over boost - I tried to remove this by changing the map which didn't work, I think I'll get a manual boost controller & fit it in parallel with the N75 as this appears to be the best\easiest way to remove the flutter\over boost.

- The EGT's are high over 950c (anybody know what is acceptable?) - hopefully some extra fuel & a FMIC will help this.

- The ESP turns it's self off when you accelerate hard and stays off until the car is restarted - not sure what to do about this (any ideas welcome)

So still a little work to do, but hopefully I should have it back on the dyno in the next couple of months.

Finally got some good news

After the trials & tribulations of the last 10 months, looks like I have finally got to the self set target of 300HP.

After the disappointing dyno run of the 12st September 255.8HP (see here for a report on the dyno run - https://www.ttforum.co.uk/forum/viewtop ... 3&start=45), I came back to the garage mended the exhaust blow, turbo to manifold, only to find that there was also a blow head to manifold. I wasn't surprised as I thought I could hear a blow from infront of the turbo as well as feel the blow at the top of the turbo, this blow was also mended. When I say mended the turbo to manifold had a new Audi gasket fitted but still blew so I used a little exahust paste and finally got it to seal, not wanting to completely remove the exhaust manifold as I have a stainless tubular one which are notoriously difficult to remove & refit, I loosened the nuts around the blow applied a little exhaust paste & retightened which has mended the blow. Not sure how long the fixes will last (hopefully they are the sort of temporary fixes that last forever) but have prepared my self for a weekend of grazed knuckles & swearing at some point.

After "mending" the exhaust blows I tightened the wastegate on the turbo to about 13PSI from 10PSI that it ran for the turbo & added some extra fuel in the mid range on the map after Chris at Surrey Rolling Road commented that the fuel in the mid range was a bit lean.

Then out for a couple of 3rd gear drags, it felt faster and I had turbo flutter\over boost on acceleration which hadn’t happened before. So I looked at the log expecting to see 220 - 230 g\s air flow, to my surprise it peaked at over 260 g\s

There is still some work to do as I don't think the engine would last long if I tried to run at full tilt for very long, as you can see from the attached logs;

- The Injectors are maxing out - still need to fit the 440cc injectors & uprated fuel pump I already have.

- The turbo flutter\over boost - I tried to remove this by changing the map which didn't work, I think I'll get a manual boost controller & fit it in parallel with the N75 as this appears to be the best\easiest way to remove the flutter\over boost.

- The EGT's are high over 950c (anybody know what is acceptable?) - hopefully some extra fuel & a FMIC will help this.

- The ESP turns it's self off when you accelerate hard and stays off until the car is restarted - not sure what to do about this (any ideas welcome)

So still a little work to do, but hopefully I should have it back on the dyno in the next couple of months.