- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

whats the wheel spec's on that baby? (and price?)Get my Xona turbo, and you will have all that

whats the wheel spec's on that baby? (and price?)Get my Xona turbo, and you will have all that

There was some silicon grease supplied with the DW65 that I used for the o-ringsDid you use any lubricant when install fuel pump?

64/88mm Compressor Wheel inducer/exducer diameter.whats the wheel spec's on that baby? (and price?)

wow, thats a phat old hotside. ideal for a 3.2 engine or something.64/88mm Compressor Wheel inducer/exducer diameter.

Turbine Outlet - 67mm diameter.

82lb/min max compressor mass flow.

600-850 horsepower applications

Has the Tial 1.03 Vband housing(thermal coated)

Price: 2400

LOL... Nah... Wouldn't touch a GTX with a barge pole...Whats next? A nice compact submerged dual pump surge tank in the boot?

Then 1300cc injectors and the GTX3584rs

Laggy for starters... Never seen a GTX perform on a 20v very well unless you turn the boost right up and that's not what I want on a road car... Can see where it would potentially work on an engine destined for the drag strip but not a road carWhat is wrong with a GTX model? Are they not better than the GT models?

all of this technical stuff is brill Tuffty, but does it do this?

Whats next? A nice compact submerged dual pump surge tank in the boot?

all of this technical stuff is brill Tuffty, but does it do this?

Love to know what’s that’s guys running I’m sure it has a v6 in it

lol... 2.5bar isn't quite possible on my current setup mainly due to me running quite a soft spring on the wastegate... this was by design as I wanted a fairly low base pressure for drivability... it was a bit of a gamble as at the time I wasn't sure what the top end boost would do as traditionally you would go for at least a 1bar spring setup... mines around 0.6bar crack pressure creeping to about 0.8bar... this means that the engines not trying to launch me into space at part throttle and gives me a better range of control...Since you have one DA-31 its less than £300 for a dual submerged tank, another DA-31 and lines.

I was joking on the GTX, you’re half a litre short on displacement for even mediocre spool up.

The current turbo is barely moving with the boost it’s running, I’m surprised Bill hasn’t cranked it up to 2.5 bar when you’re not looking

Hi Tuffty, can I ask the purpose of exposing the oil pressure to the ECU? I understand you want to see this in log files etc but can you program in a trigger based on oil pressure @ 80-90 degree c @ 3875 rpm @ 4 gear etc

You know what I mean, can you alert or 'All stop' if the pressure is low?

Knowing what the oil pressure is doing is always a nice place to be... but this is generally done using gauges which are simply a ballache to keep track of... I have a boost gauge but rarely look at it as I kinda feel that knowing what I need to avoid hitting on the road takes precedence

The limp mode on the IECU can react to various inputs and conditions (as per the pic in my previous post)... oil pressure is just one of them and limp mode will be triggered based on engine temp vs a minimum expected oil pressure for a certain duration... limp mode will limit you to 20% throttle and N75 will be switched off (actuator pressure)

This may or may not 'save' an engine of course depending on circumstances but its better than trying to watch half a dozen gauges while driving as the ECU will certainly react more quickly than I would in the event of oil pressure failure or any of the other configurable monitoring conditions..

The ECU has other protection mechanisms too... for starters it will limit boost based on engine coolant temp... it can prevent you running 2.2bar from cold for example...

<tuffty/>

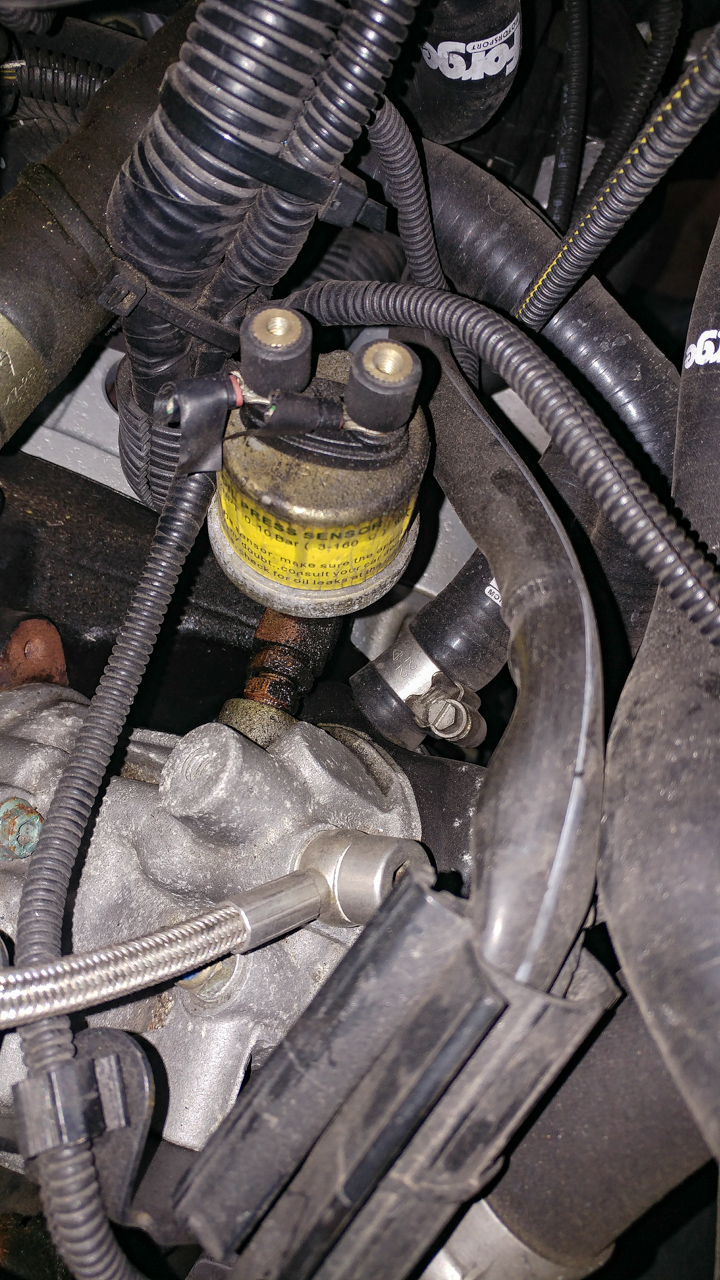

Done some spannering today...

Been meaning to fit a new oil pressure sensor for a while.. I had already sorted the wiring to the ECU when I did the fuel pressure sender...

Manifold off to get to it...

Old one was leaking a little...

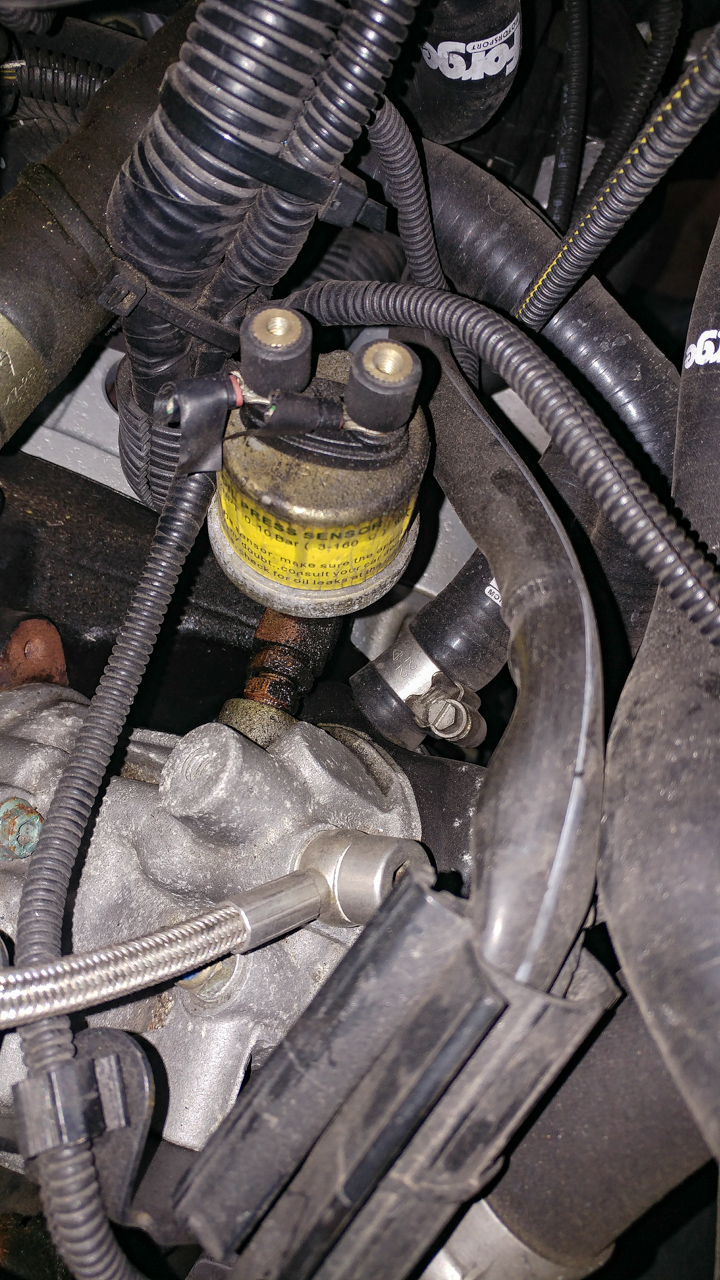

New one in...

Next I had to add the sensor to the map so the ECU could see it...

View attachment 157670

...and tell the ECU what the input was...

View attachment 157671

Fired up the engine....

Looking good... I also added the sensor to the autolog so I can continually monitor the oil pressure when I haven't got the laptop connected...

I checked the log when I got home and pressure is looking ok...

View attachment 157673

Only issue I seem to have though is the oil pressure when 'hot' gets a little below a bar on idle... I know for a fact the engine is sound and tbh the oil pressure is no different to when the engine was first built... its always been like this... I fitted a Topran pump when I first built the engine then changed it some miles in to an OE one that improved it a bit but it is what it is... I have also plastigauged the crank and all is in spec...

Pressure only seems to get low on idle when hot... once up in the revs its all good so not overly bothered... I will however consider changing to 10w50 on the next oil change as lets face it its an engine producing nearly 300hp per litre...

Will be checking the logs over the next few weeks to see where the oil pressure is... I can then build the limp mode table for oil pressure as an extra safety feature..

View attachment 157675

Happy with that

Some of you may recall a little while back I mentioned I was going to resurrect my camber plates and look at using a larger spherical bearing as the standard one supplied by Silver Project is woefully small... I had already popped two of them which prompted me to swap back to LCR rubber tops...

Finally got around to making a start on these...

First job was to cut the weld for the original bearing holder to look at reusing the plate for the new bearing...

The larger bearing holder is quite a lot larger but just needed a little turning in the lathe to get it where it needed to be...

Just the other one to do and then weld it in...

A reminder of the bearing difference... Silver Project on the left, larger one to fit on the right...

<tuffty/>

Tease....

all of this technical stuff is brill Tuffty, but does it do this?

With WMI... without they are typically substantially higher especially on the dyno...the 7 degr. over ambient is with or without WMI, Paul?? Either way, that's nice and low, and it does seem like you're getting there!!

eat sleep launch repeat

This car is essentially madness Tuffty I love the smooth controlled look in the graphs , can I ask how the power and torque "estimates" from the map and logs alone compared to Bill's dyno ? what might you consider regarding modifications for more power? without turbo charging a 3.2?

Errrrmm... what?That's actually amazing, what weight did you put into you vehicle profile 1500kg?

Lol.... no!You need to do the boost tables again anyway but you know that..... you know when you put the proper spring in the Wastegate

Nope... weight has no influence on an engines ability to produce power... only how quick it gets up the road...Don't you have to tell the program the weight of the vehicle including fluids and people to help it calculate power and torque? Ecu plot and Android torque for example changes the values based on the weight of the thing that's being measured. A stock 225 TT weighs about 50kg more than an S3. At about 1450kg if I recall plus oil, fuel, coolant, luggage and driver etc all needs to be added to the dry weight?

What can I tell yah... its working so far...Considering you use such a low Wastegate spring I’d expect you to have more issues trying to get it to hold over 3x its set pressure.

Since 2x is the recommended