How to: N249 Bypass - AMK/BAM Engine

- Thread starter BenJee_S3

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Where does everyone put the valve that's left over? Got all the bits ready to do it just not sure on where to put the valve after

I wrapped the valve in the heat wrap that's no longer used once the n249 is removed and cable tied it up out the way.

Once you've started doing the mod it'll become more apparent, but you can see on the picture the heat wrap and cable ties. Hope that helps

The only difference I noticed from it was the DV seemed...... A little louder and a bit more responsive. Other than that a tidier engine bay that about it I think

MSTRKRFTSMN

Registered User

How do you get the bracket off the cam cover once you've removed the pipework and the mystery black plastic box (whatever that is).

I can't even get close to getting the bolts out with an Allen key.

I can't even get close to getting the bolts out with an Allen key.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Leave it plugged in... If not adaptions don't work... Don't link it either... Needs to be a resistanceDone mine today >.<

Can you just link out the N249 valve? I've left mine plugged in as suggested, I was just wondering if it could be linked out?

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

How do you get the bracket off the cam cover once you've removed the pipework and the mystery black plastic box (whatever that is).

I can't even get close to getting the bolts out with an Allen key.

Longer Allen key

<tuffty/>

i did the bypass today, i've read a few posts about the car becoming sluggish...i disagree. What i did find was the DV noise did change depending on where you let off the throttle in the rev range, at peak spool the noise was different & it seemed like the system struggled to deposit the dump hence why the blackbox is part of the original system it's hesitant for a second, quite hard to describe. Defo worth doing if you know your N249 system is leaking.

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

A point to note is that this device isn't just for cutting out the turbo in the case of an accident as I assumed, it is supposed to hold the turbo between 1st and 2nd gear change too, maybe not an issue for mapped cars or quick changes?

TurboLover

Registered User

- Joined

- Jul 23, 2016

- Messages

- 25

- Reaction score

- 1

- Points

- 3

Hi. I did the bypass on AMK 30 minutes ago just as shown on the first page. I removed everything from the dv to n249 and inlet mani. Then i put direct 4mm pipe from dv to under inlet mani and left n249 electrically connected with no pipes on it. And now i have error on vcds :

17608 - Boost Pressure Control Valve (N249)

P1200 - 35-00 - Mechanical Malfunction

Am i doing something wrong?

17608 - Boost Pressure Control Valve (N249)

P1200 - 35-00 - Mechanical Malfunction

Am i doing something wrong?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

This code pops up if the ECU tries to use the DV to dump boost because its not happy about something...Hi. I did the bypass on AMK 30 minutes ago just as shown on the first page. I removed everything from the dv to n249 and inlet mani. Then i put direct 4mm pipe from dv to under inlet mani and left n249 electrically connected with no pipes on it. And now i have error on vcds :

17608 - Boost Pressure Control Valve (N249)

P1200 - 35-00 - Mechanical Malfunction

Am i doing something wrong?

The ECU uses the N249 to operate the DV under boost using the vacuum store to open it... if it doesn't see boost drop off in the timescale it expects then it assumes there is a mechanical problem (which is why it normally says check DV) as it knows the N249 is connected so suggests an issue with the DV which of course isn't the problem unless the DV is actually faulty of course

Clear the code and see if it comes back... if it does you need to log boost request vs actual and see if there is an appreciable difference as its normally an over boost issue that leads to the ECU feeling it needs to intervene

<tuffty/>

TurboLover

Registered User

- Joined

- Jul 23, 2016

- Messages

- 25

- Reaction score

- 1

- Points

- 3

I cleared it 3 times and after 3-4 min it came back again. The dv is working properly.

I will log 115 channel right now.

I will log 115 channel right now.

David Rowntree

Registered User

- Joined

- Jul 11, 2017

- Messages

- 1

- Reaction score

- 0

- Points

- 1

You won't get to see the photos unless the person who originally uploaded them pays photbucket to upgrade their account so they will host the pictures for third parties. This has wrecked a lot of potentially useful threads as the pictures are now no longer available.

- Joined

- Sep 18, 2012

- Messages

- 514

- Reaction score

- 323

- Points

- 63

That said, there are a handful of browser extensions that help act as a temporary workaround which mean not all forum content online is lost. Doesn't work for all though, with typically older images being harder to view (this thread being one of those, sadly).

Tedious, but if there are a couple of images you particularly need to view you can often follow the trail back onto the PB site and get to them, so if there's a certain how-to you could do with some extra detail on it's always worth hunting.

For this n249 guide, for example, you can follow the seemingly dead links back to the original account and with some tedium hunt down the images you need:

Tedious, but if there are a couple of images you particularly need to view you can often follow the trail back onto the PB site and get to them, so if there's a certain how-to you could do with some extra detail on it's always worth hunting.

For this n249 guide, for example, you can follow the seemingly dead links back to the original account and with some tedium hunt down the images you need:

It would be very useful to have the pics re-uploaded, but very nice tip from Rainbird there.

I haven't done it yet, will probably do it by the end of this month and see how it goes.

Thanks for the efforts.

I haven't done it yet, will probably do it by the end of this month and see how it goes.

Thanks for the efforts.

- Joined

- Sep 18, 2012

- Messages

- 514

- Reaction score

- 323

- Points

- 63

Here we go. With the exception of the first image which didn't want to play ball, here's the original guide in all its former glory:

I Thought I'd do a little guide on the N249 bypass for the AMK and BAM engine which is different (and more simple) than the bypass on other engine codes.

The AMK/BAM engines dont have an N112 valve, which means there's no need to cut and t-piece anything. It's as simple as putting silicon vacuum hose from the DV to the inlet.

All that's needed is some 4mm internal diameter vacuum hose and new hose clips. I bought 2 meters on eBay for about 4 quid all in.

So remove engine cover to expose the mess that is this:

Vac chamber and N249 spaghetti junction...

This is what we will be removing:

So undo the bolts which attach the vac chamber to the metal bracket and release the valve from the catch.

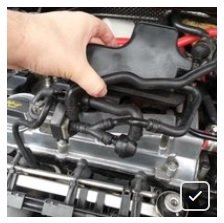

Follow the pipe to the dump valve and disconnect:

Now remove the plastic cover down near the dipstick which is secured with 2 Phillips screws.

This reveals a metal plate underneath which is removed with 2 Allen key bolts.

Follow the vac pipe from the N249 down to the inlet and disconnect. This can be found on the left of the inlet manifold on the underside:

Here:

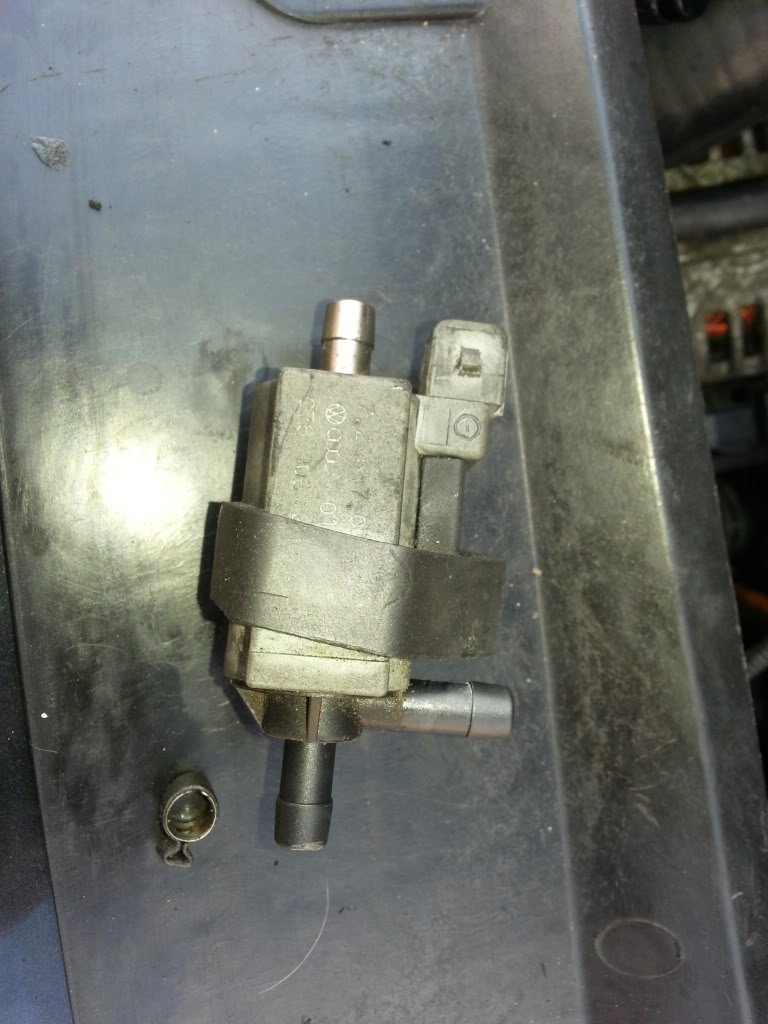

Dont forget to disconnect the electrical valve. Once disconnected pull out and keep aside:

Once out the car, disconnect the piping to salvage the valve:

Despite bypassing this valve, we still need to keep it electrically connect otherwise the ecu will throw up an error code.

I re connected the valve and tucked it away behind some heat proof to hide it.

Now disconnect the metal bracket which is bolted to the cam cover

The bay should now look like this (ignore the fact my coils are out, I changed my plugs whilst I was at it)

Now all that's left is to connect the dump valve to the inlet with the 4mm Vac hose. I used small cable ties to run the hose the route I wanted:

And that's it! Re assemble the bracket near the inlet and the plastic cover and it should look like this:

Since doing this my DV seems a bit more responsive, makes a slightly different noise and keeps the bay nice and neat!

Hopefully this will help some fellow AMK/BAM owners as this was a lot easier than first thought.

I Thought I'd do a little guide on the N249 bypass for the AMK and BAM engine which is different (and more simple) than the bypass on other engine codes.

The AMK/BAM engines dont have an N112 valve, which means there's no need to cut and t-piece anything. It's as simple as putting silicon vacuum hose from the DV to the inlet.

All that's needed is some 4mm internal diameter vacuum hose and new hose clips. I bought 2 meters on eBay for about 4 quid all in.

So remove engine cover to expose the mess that is this:

Vac chamber and N249 spaghetti junction...

This is what we will be removing:

So undo the bolts which attach the vac chamber to the metal bracket and release the valve from the catch.

Follow the pipe to the dump valve and disconnect:

Now remove the plastic cover down near the dipstick which is secured with 2 Phillips screws.

This reveals a metal plate underneath which is removed with 2 Allen key bolts.

Follow the vac pipe from the N249 down to the inlet and disconnect. This can be found on the left of the inlet manifold on the underside:

Here:

Dont forget to disconnect the electrical valve. Once disconnected pull out and keep aside:

Once out the car, disconnect the piping to salvage the valve:

Despite bypassing this valve, we still need to keep it electrically connect otherwise the ecu will throw up an error code.

I re connected the valve and tucked it away behind some heat proof to hide it.

Now disconnect the metal bracket which is bolted to the cam cover

The bay should now look like this (ignore the fact my coils are out, I changed my plugs whilst I was at it)

Now all that's left is to connect the dump valve to the inlet with the 4mm Vac hose. I used small cable ties to run the hose the route I wanted:

And that's it! Re assemble the bracket near the inlet and the plastic cover and it should look like this:

Since doing this my DV seems a bit more responsive, makes a slightly different noise and keeps the bay nice and neat!

Hopefully this will help some fellow AMK/BAM owners as this was a lot easier than first thought.

Very much appreciated rainbird for taking the time to sort this out. I'm debating whether to do this or not but having the pictures will make it easier if i decide to.

It says bout using 4mm hose. I have 3mm would that do or should i get 4mm?

It says bout using 4mm hose. I have 3mm would that do or should i get 4mm?

- Joined

- Sep 18, 2012

- Messages

- 514

- Reaction score

- 323

- Points

- 63

No worries. Given how many threads on assorted forums are dead it'll likely come in handy to someone in the future, regardless of whether you end up using it yourself. Pics now hosted on ASN so hopefully last a while longer.

3mm should be fine

3mm should be fine

S

[ sam ]

Guest

Hi all I after driving for about two weeks now since delete my blow off sounds a bit chirpy

more instant but nothing like before is this normal or is my diaphragm shot standard dv as per suggestions my forge 007 is going on ebay ?

more instant but nothing like before is this normal or is my diaphragm shot standard dv as per suggestions my forge 007 is going on ebay ?