You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

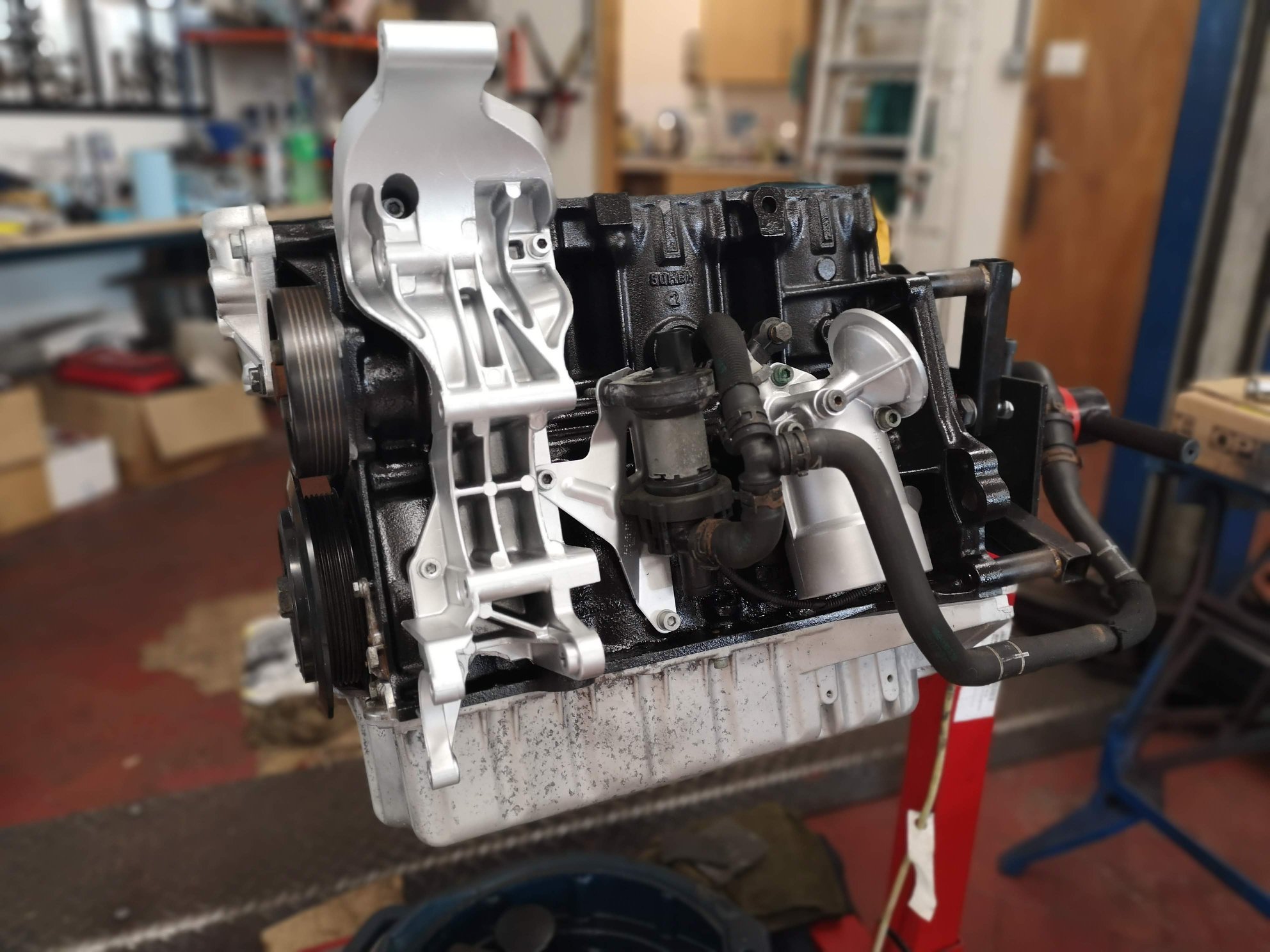

So yesterday I took this off...

View attachment 183620

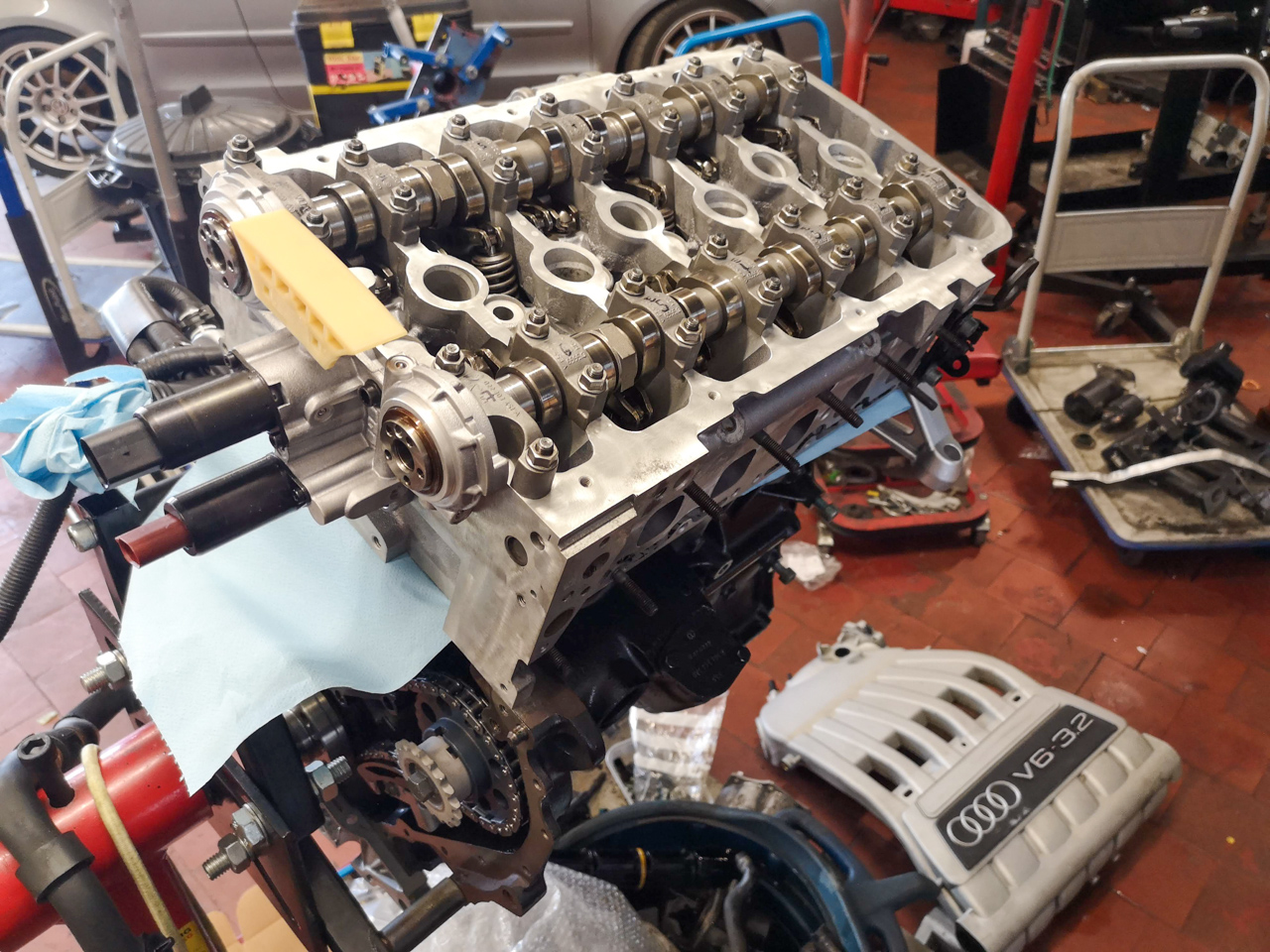

Everything on this engine is either bigger or more... 20 (yes 20!) head bolts... 7 of which are longer!

View attachment 183641

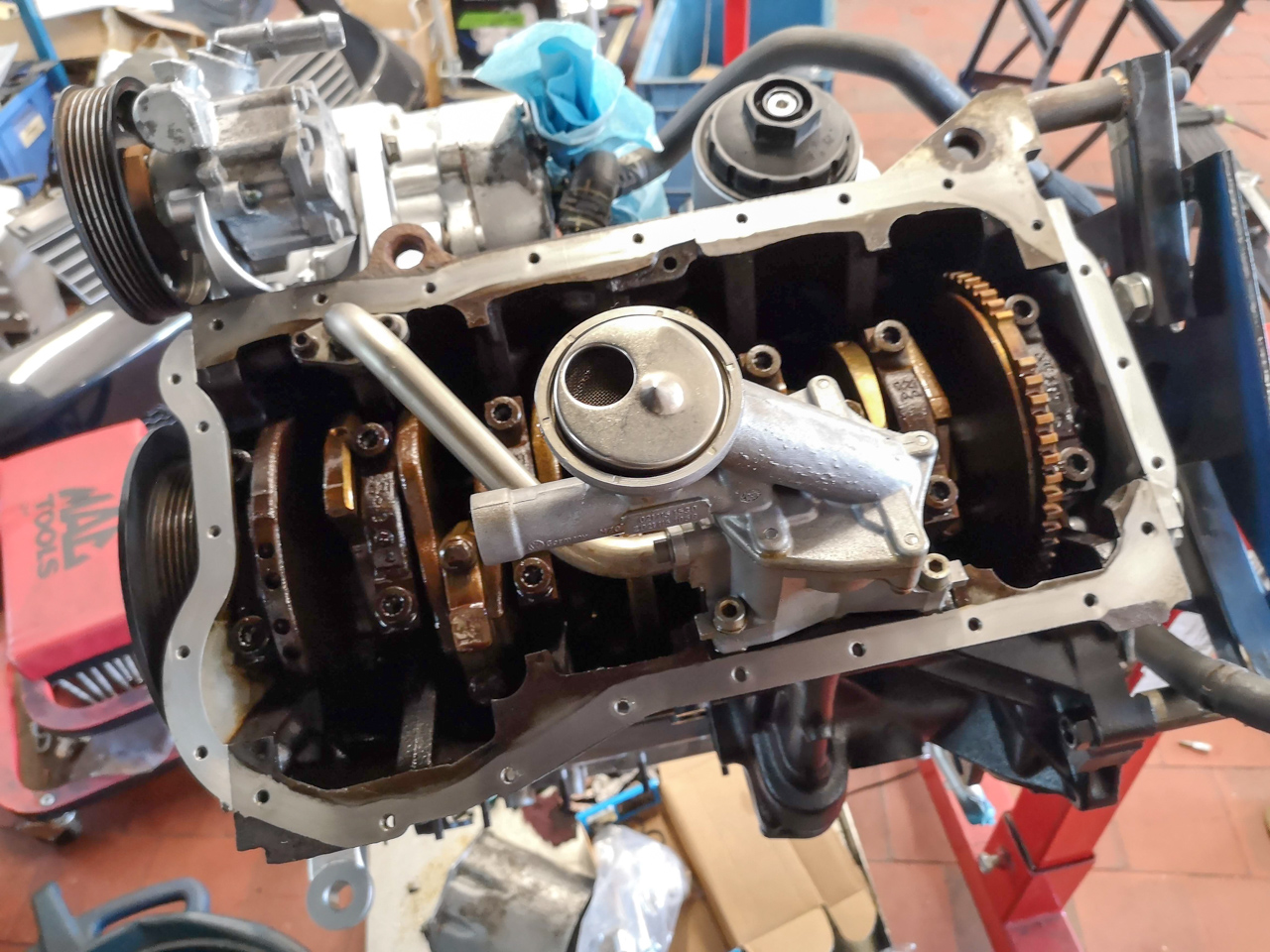

Bottom end looks pretty good considering the engine has done nearly 100k miles..

View attachment 183621

Little bit of carbon build up on the top of the bores but nothing that a little wd40 and a rub wouldn't sort out...

There are no ridges at the top of the bore from the rings and the honing is still very much visible so happy days.... the pistons clean up ok too..

View attachment 183622

The bottom end can wait though as I needed to get the head stripped ready for guides and a skim.. so gave it a clean...

View attachment 183623

View attachment 183624

A bit different to what it looked like earlier...

View attachment 183651

The VVT setup is a little more complex than the 20v but its not too bad once you get into it..

View attachment 183625

View attachment 183626

View attachment 183627

Once all that lot is off the cams are accessible... took the inlet cam off first... M8 studs are a nice touch and a little more sturdy than the 20v's M6 bolts....

View attachment 183629

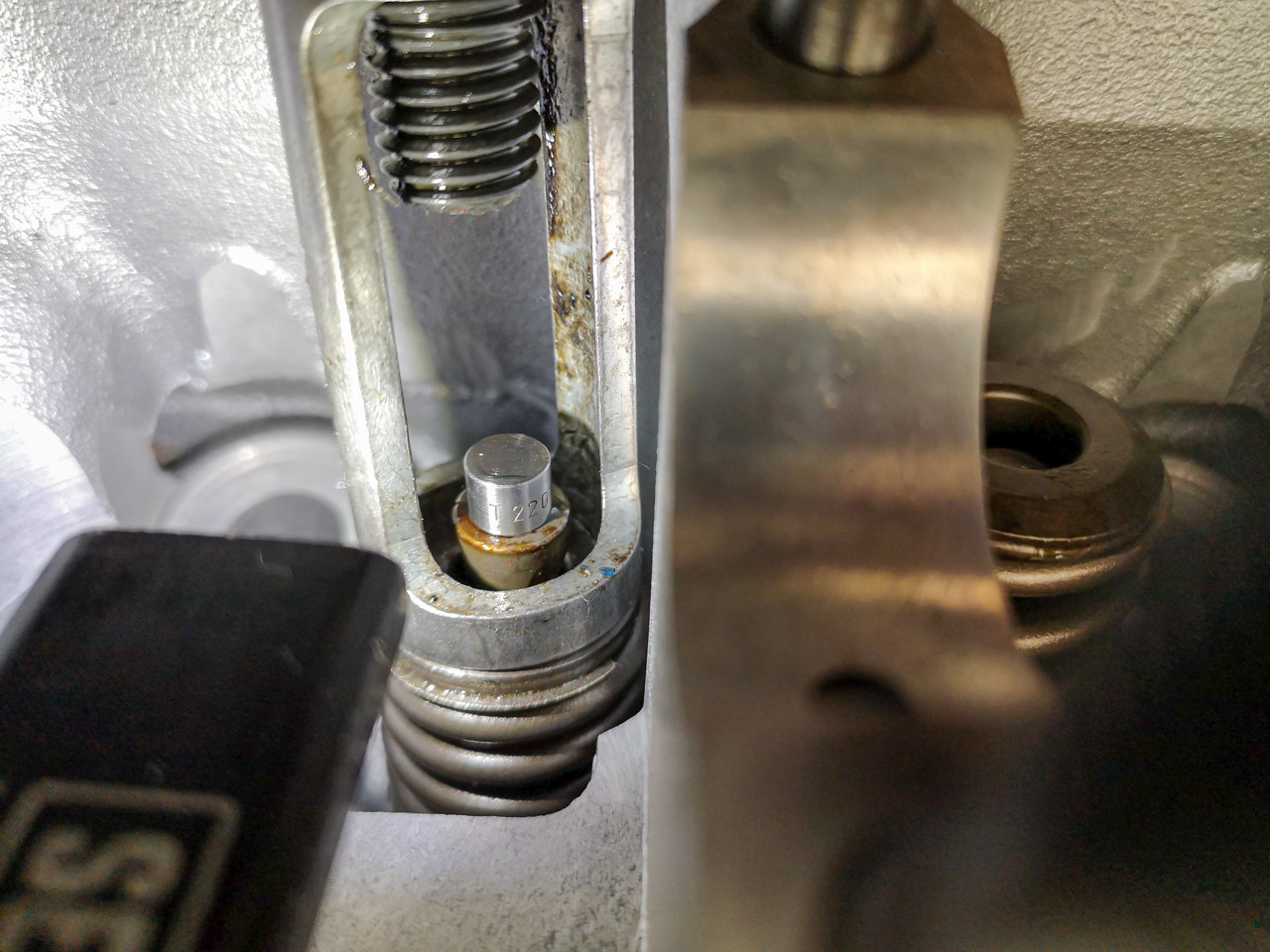

Once the cam is off you can gain access to the rocker gear... solid bit of kit with a hydro lifter...

View attachment 183630

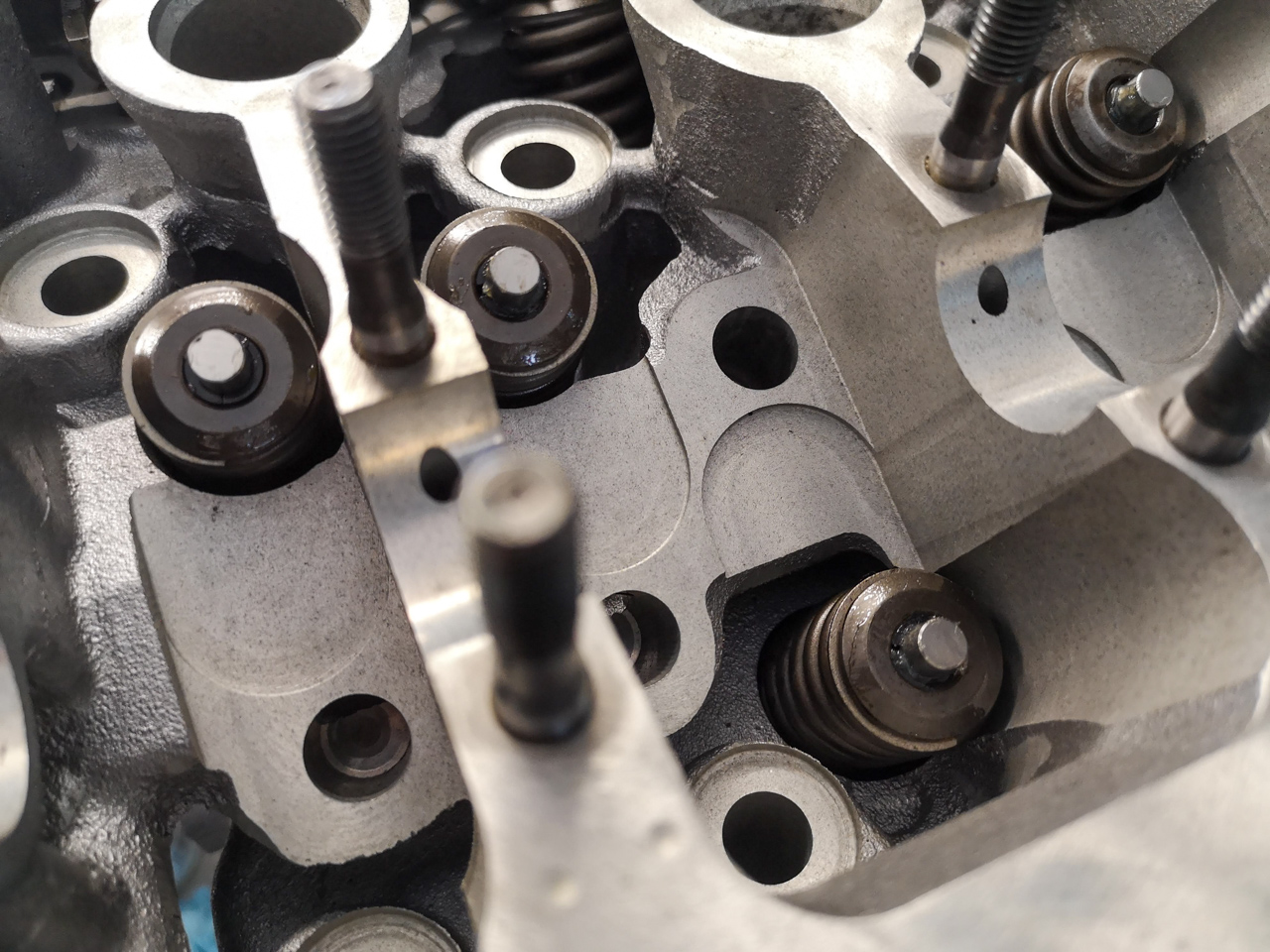

With both cams and all the rockers removed I then removed the valves...

View attachment 183633

AS you may notice on the right I used a bit of card to keep all the rockers in the order they were removed... the rockers would be ok to use in any order but felt with nearly 100k miles it would be better to keep the hydro lifters in their original positions

I will be replacing the exhaust valves with either supertech or OE MK5 items... I am currently sorting prices for the supertechs..

The inlets will be reused... VR6 valves are quite odd... they have a number of normal length valves in the outer rows and the centre rows have longer stems!

View attachment 183634

....so I cleaned them...

View attachment 183635

Next job was to clean the oil pump...

View attachment 183637

While this was off I also replaced the pump's drive shaft from the intermediate shaft... these have on occasion failed from what I have read and was cheap enough not to worry about renewing..

View attachment 183639

It just pulls out and you then just slot the new one back in...

The pump came up nicely and I ran a bit of oil through it to prevent any potential for corrosion while I build the engine...

View attachment 183638

Finished by cleaning the valve springs and tidying up...

View attachment 183640

The head had been dropped off at the head guy in the afternoon and he reported back saying the guides won't need changing which is nice so will just be getting the head lightly skimmed to clean it up...

Busy day but getting lots done

<tuffty/>

Why mk5 exhaust valves if it’s a mk4 based engine are they better?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Today I cleaned some stuff...

...painted some stuff...

...and assembled some stuff

<tuffty/>

...painted some stuff...

...and assembled some stuff

<tuffty/>

Tuffty since you have the same exhaust manifold as me is there any point using a 44/50mm waste gate as it’s only a 38mm flange? Or is the biggest usable the 40mm chandler with the 38mm adapter flange ?

Liking the focus on the bottom end, I see your photography skills are also coming into play mate. Great progress so far. I’ll be popping down Monday with my car to have a gander

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

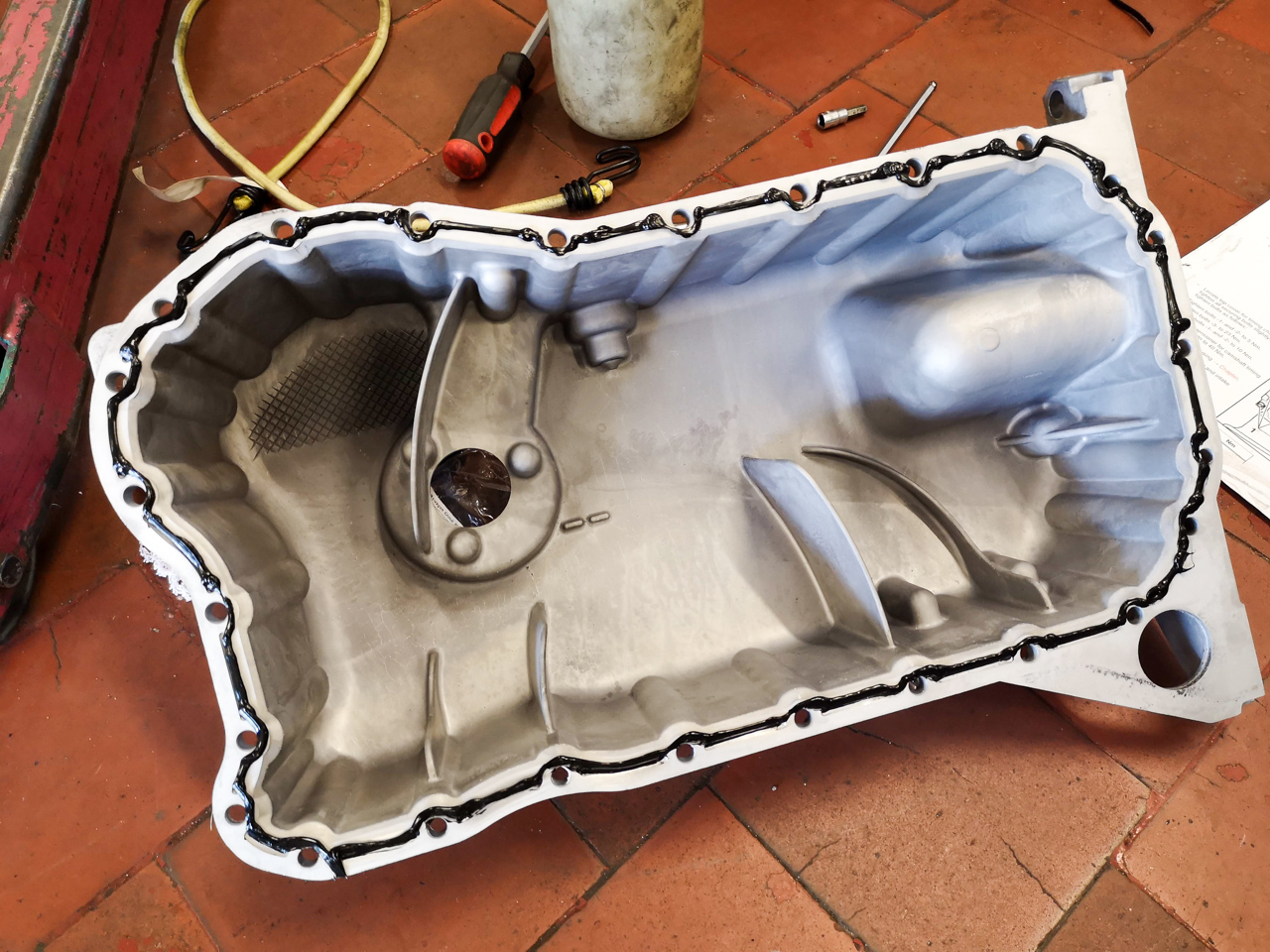

Definitely source yourself the mk5 oil pan/oil pump setup @<tuffty/> !

When you see those built in baffles you will just forget all about the TT empty one.

When you see those built in baffles you will just forget all about the TT empty one.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I'll look into it for the turbo portion of the build mate... this one will go on as is for now...Definitely source yourself the mk5 oil pan/oil pump setup @<tuffty/> !

When you see those built in baffles you will just forget all about the TT empty one.

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Tuffty since you have the same exhaust manifold as me is there any point using a 44/50mm waste gate as it’s only a 38mm flange? Or is the biggest usable the 40mm chandler with the 38mm adapter flange ?

Its only 38mm for now

Not actually looked too much into a solution for this as yet but will involve a bit of machining and welding v-band fittings on...

Turbosmart do a 40mm gate that I am considering but definitely trying to avoid a 38mm if I can help it... larger wastegate makes boost control on a larger turbo much easier

Final choice for me will depend on what I can do to modify it... its a shame that the choices are limited on this platform... most log manifolds are a compromise but I like the 'runner' design on this one... shame mostly all mani's are bolt type flanges not v-bands without paying all the actual money..

This was £71 delivered from Aliexpress so cheap enough to experiment with...

Sorry that I can't help much more on this at the moment but its not my primary focus... once the engine is in and the car back on the road as atmo then I will look into it a bit further

<tuffty/>

My think was machine the flange out as much as possible and I know they do a 38mm - 40mm vband adapter flange might have to see if I can get a 38mm - 44 or even 50mm vband made up

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

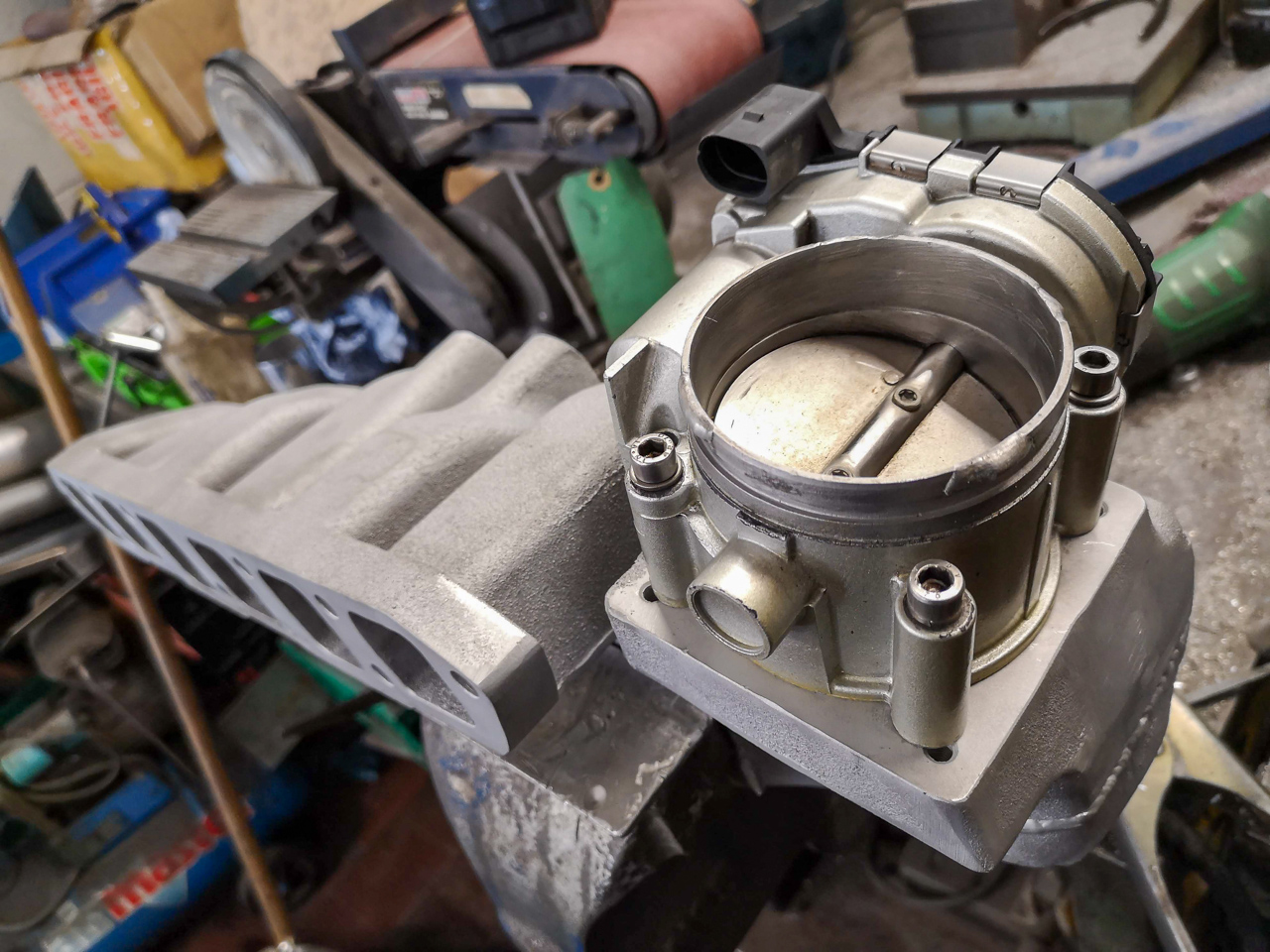

Drilled and tapped the holes for the 70mm TB... just need to get some M6 grub screws to seal into the R32 TB mount holes...

Throttle body fits quite neatly on there and should give a bit more room...

Next job was to sort the SAI delete out... there are various after market solutions available but are fairly pricey plus introduce potential for a coolant leak so.... take one OE SAI fitting...

...add one hacksaw...

....mix it around a bit with a welding rod...

...and finish with a dab of your favourite paint...

Job jobbed!..

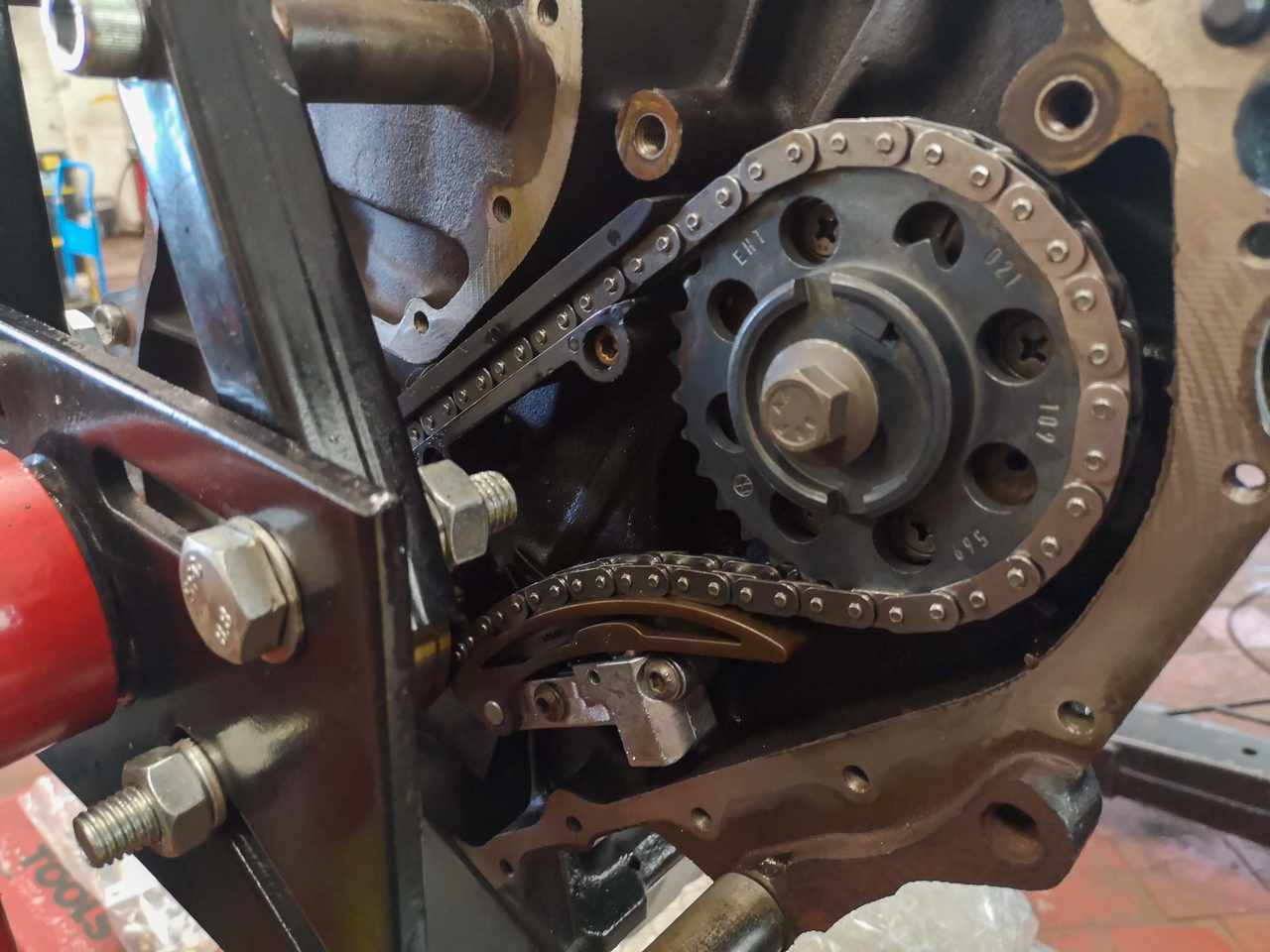

Next was the lower timing chain... this is actually pretty easy (with the engine out).... interestingly the Febi kit I bought appears to use actual OE kit but with the logos ground off...

Lower chain fitted

While cleaning the sprockets I noticed that the smaller one that drives the chain to the cams was a bit worn...

Retail at TPS these are about 17 quid so will add that to the order next week (along with eleventy billion other bits I need too lol)

I finished off fitting ancillaries to the block and thats about it bar a few other parts I need to get... I am leaving the sump until I have put the lower chain cover back on to ensure a good seal...

Head should be back next week and I have gone and ordered Supertech exhaust valves as it kinda makes sense to... I need to put together a longish list of little odds and sods to get from TPS (20 head bolts!!!) and still waiting on a few more bits...

Not too scary this engine swap so far... things might start getting interesting once its in the engine bay though (thats the easy bit)

The inlet mani and cam cover should be off for powder coating soon too...

<tuffty/>

Throttle body fits quite neatly on there and should give a bit more room...

Next job was to sort the SAI delete out... there are various after market solutions available but are fairly pricey plus introduce potential for a coolant leak so.... take one OE SAI fitting...

...add one hacksaw...

....mix it around a bit with a welding rod...

...and finish with a dab of your favourite paint...

Job jobbed!..

Next was the lower timing chain... this is actually pretty easy (with the engine out).... interestingly the Febi kit I bought appears to use actual OE kit but with the logos ground off...

Lower chain fitted

While cleaning the sprockets I noticed that the smaller one that drives the chain to the cams was a bit worn...

Retail at TPS these are about 17 quid so will add that to the order next week (along with eleventy billion other bits I need too lol)

I finished off fitting ancillaries to the block and thats about it bar a few other parts I need to get... I am leaving the sump until I have put the lower chain cover back on to ensure a good seal...

Head should be back next week and I have gone and ordered Supertech exhaust valves as it kinda makes sense to... I need to put together a longish list of little odds and sods to get from TPS (20 head bolts!!!) and still waiting on a few more bits...

Not too scary this engine swap so far... things might start getting interesting once its in the engine bay though (thats the easy bit)

The inlet mani and cam cover should be off for powder coating soon too...

<tuffty/>

While cleaning the sprockets I noticed that the smaller one that drives the chain to the cams was a bit worn...

View attachment 183820

Retail at TPS these are about 17 quid so will add that to the order next week (along with eleventy billion other bits I need too lol)

<tuffty/>

Wouldn’t even think to replace the oil pump drive sprocket! Nice find

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

PT,

whats's the odd looking silver thing sat between your alternator and PAS pump?

Looks uncommon to me!

whats's the odd looking silver thing sat between your alternator and PAS pump?

Looks uncommon to me!

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Because roadcarPT,

whats's the odd looking silver thing sat between your alternator and PAS pump?

Looks uncommon to me!

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

The head came back in the week but currently still waiting on the exhaust valves to arrive so just cracked on with the inlets for now...

Light skim to clean the face...

Gave the head a final wash to ensure it was free from debris and lapped in the inlet valves....

Once that little lot was done I fitted new stem seals, lubed the valves and fitted them in...

Valve springs next...

...then the followers and roller rockers...

...and finally the inlet cam...

Thats about all I can do with the head at the moment as I need the exhaust valves to proceed...

<tuffty/>

Light skim to clean the face...

Gave the head a final wash to ensure it was free from debris and lapped in the inlet valves....

Once that little lot was done I fitted new stem seals, lubed the valves and fitted them in...

Valve springs next...

...then the followers and roller rockers...

...and finally the inlet cam...

Thats about all I can do with the head at the moment as I need the exhaust valves to proceed...

<tuffty/>

how much easier is it on this head? hahaha

timing is just as "simple"

Getting along nicely @<tuffty/> ! Can't wait to see it all set up with the snail on

timing is just as "simple"

Getting along nicely @<tuffty/> ! Can't wait to see it all set up with the snail on

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Its awkward in its own little ways but not missing doing the fiddly inlets on the 20v....how much easier is it on this head? hahaha

timing is just as "simple"

Getting along nicely @<tuffty/> ! Can't wait to see it all set up with the snail on

Not got a timeline for the turbo as yet... be happy enough just getting the ****** thing in there and running as is for now

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

More done....

...more partz!!!...

Started with finishing the head build...

Lapped the Supertech exhaust valves in....

Fitted with the single groove collets...

Exhaust cam fitted...

VVT manifold fitted but I forgot to order the VVT unit bolts as they need renewing being torque angle fitted....

No matter... placed the spacer plate head gasket ready to finally fit the head....

....only to find to my disappointment that I had been supplied with 6 long bolts and not 7...

Bit of a **** up on the picking then... so cracked on with other stuff... new water pump...

Laid some some paper wipe over the block and placed the head on the block held on with a couple of bolts nipped up to hold it there... so close!!!

That was it for Saturday's jobs... Sundays task was to sort a few things out on the car itself in readiness for fitting the engine...

New doughnut... hopefully this one will last a bit better than the last one...

Nearside driveshaft had seen better days so the idea was to replace both boots...

Outer CV grease looked ok but obvs needs cleaning out before repacking...

...all clean

Make sure the get the washer and bush for the outer CV fitted correctly... and don't forget the locking spring clip on the end (new items come with the kit)

And all done...

Refitted that back to the car (240nm + 1/4 turn on the bolt!)...

Last but not least... I had bought a cheap pattern part engine mount to try and manage my budget a bit... it was listed for the car and was the correct part number however when it turned up it was not even close to being the right one so sent it back and got this one instead

Nice bit of progress... was a little disappointed not to have been able to bolt the head on but there you go... will get some more parts sorted in the week hopefully and really want to finish the putting the engine together next weekend...

Still waiting on the powder coating to be done (the place I use is good but tends to be slow) but hoping that will be done in time to get the engine back together

<tuffty/>

...more partz!!!...

Started with finishing the head build...

Lapped the Supertech exhaust valves in....

Fitted with the single groove collets...

Exhaust cam fitted...

VVT manifold fitted but I forgot to order the VVT unit bolts as they need renewing being torque angle fitted....

No matter... placed the spacer plate head gasket ready to finally fit the head....

....only to find to my disappointment that I had been supplied with 6 long bolts and not 7...

Bit of a **** up on the picking then... so cracked on with other stuff... new water pump...

Laid some some paper wipe over the block and placed the head on the block held on with a couple of bolts nipped up to hold it there... so close!!!

That was it for Saturday's jobs... Sundays task was to sort a few things out on the car itself in readiness for fitting the engine...

New doughnut... hopefully this one will last a bit better than the last one...

Nearside driveshaft had seen better days so the idea was to replace both boots...

Outer CV grease looked ok but obvs needs cleaning out before repacking...

...all clean

Make sure the get the washer and bush for the outer CV fitted correctly... and don't forget the locking spring clip on the end (new items come with the kit)

And all done...

Refitted that back to the car (240nm + 1/4 turn on the bolt!)...

Last but not least... I had bought a cheap pattern part engine mount to try and manage my budget a bit... it was listed for the car and was the correct part number however when it turned up it was not even close to being the right one so sent it back and got this one instead

Nice bit of progress... was a little disappointed not to have been able to bolt the head on but there you go... will get some more parts sorted in the week hopefully and really want to finish the putting the engine together next weekend...

Still waiting on the powder coating to be done (the place I use is good but tends to be slow) but hoping that will be done in time to get the engine back together

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

The stray headbolt turned up this week so finally got the head on

The spacer head gasket is heavy having a substantial metal piece in it...

Timed up the cam chain and fitted the tensioners..

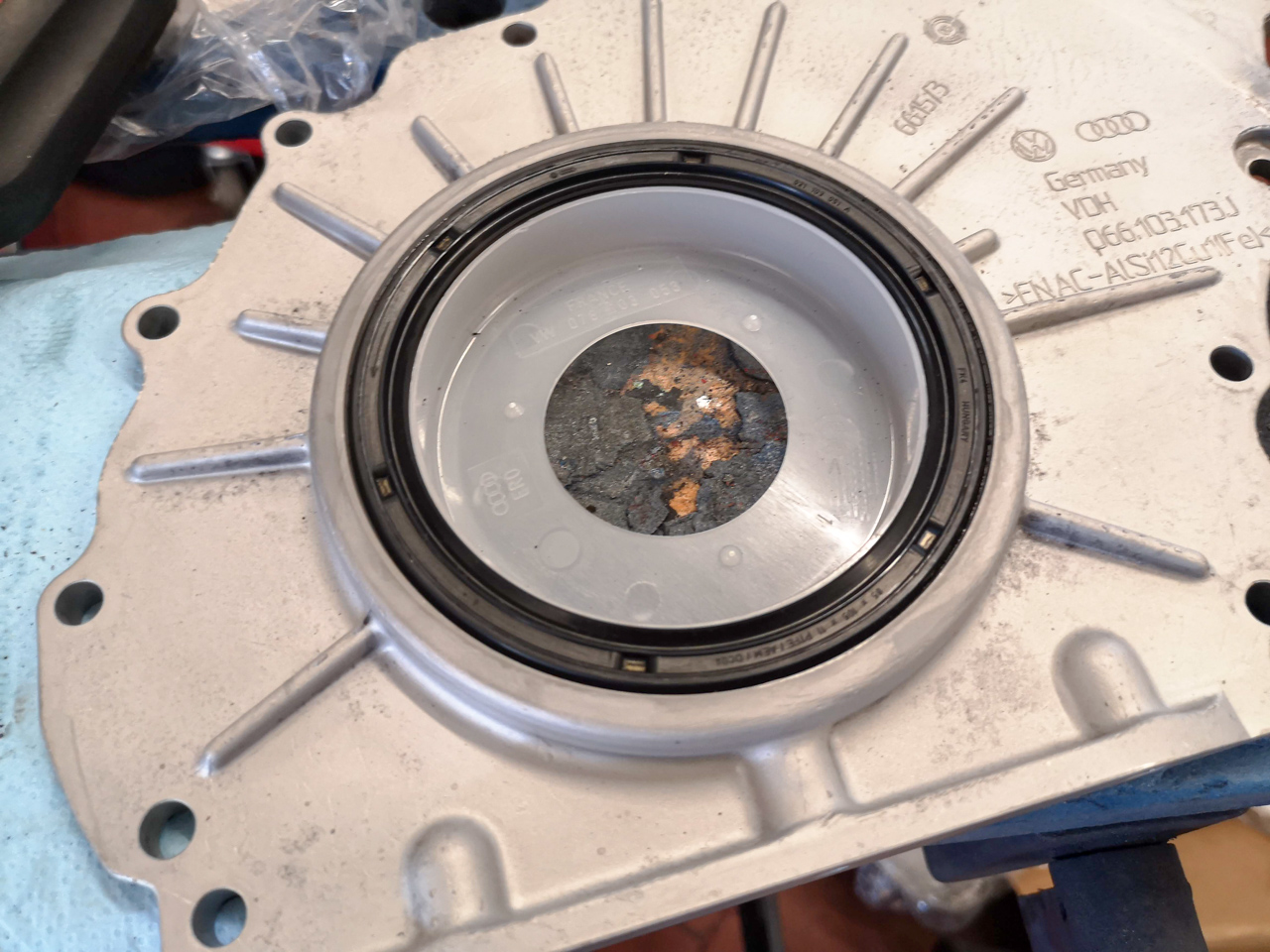

New crank seal fitted into the lower cover...

...and new seals in the top cover...

Sealant applied to the lower cover...

...and fitted...

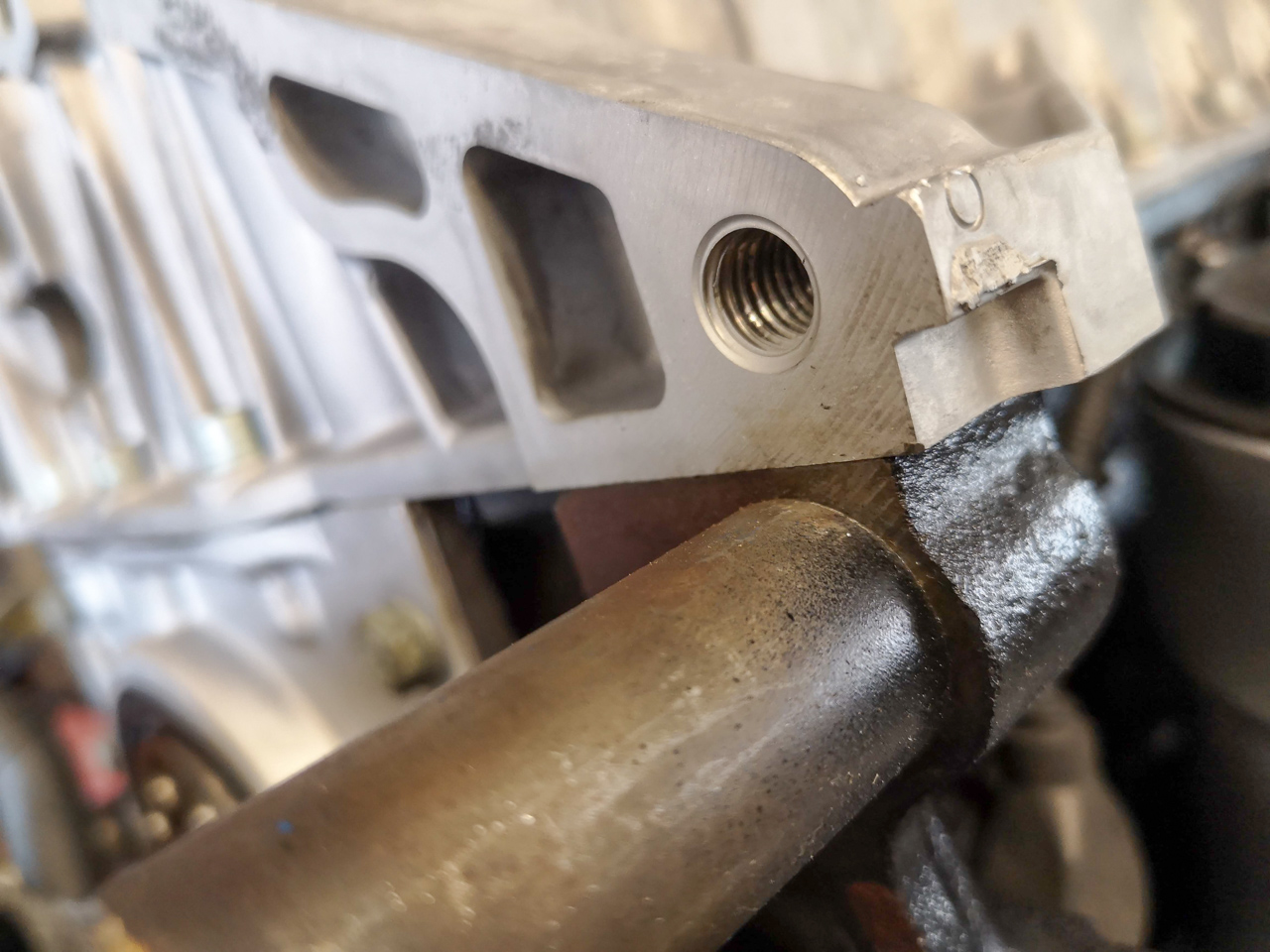

Went to fit the upper cover but...

Nothing was lining up and was a ballache to try and get the dowels into the head... looking at the tensioner pad it was clearly fowling the cover..

The issue being that the thicker head gasket has lifted the head enough to take some slack out of the chain forcing the tensioner over too far...

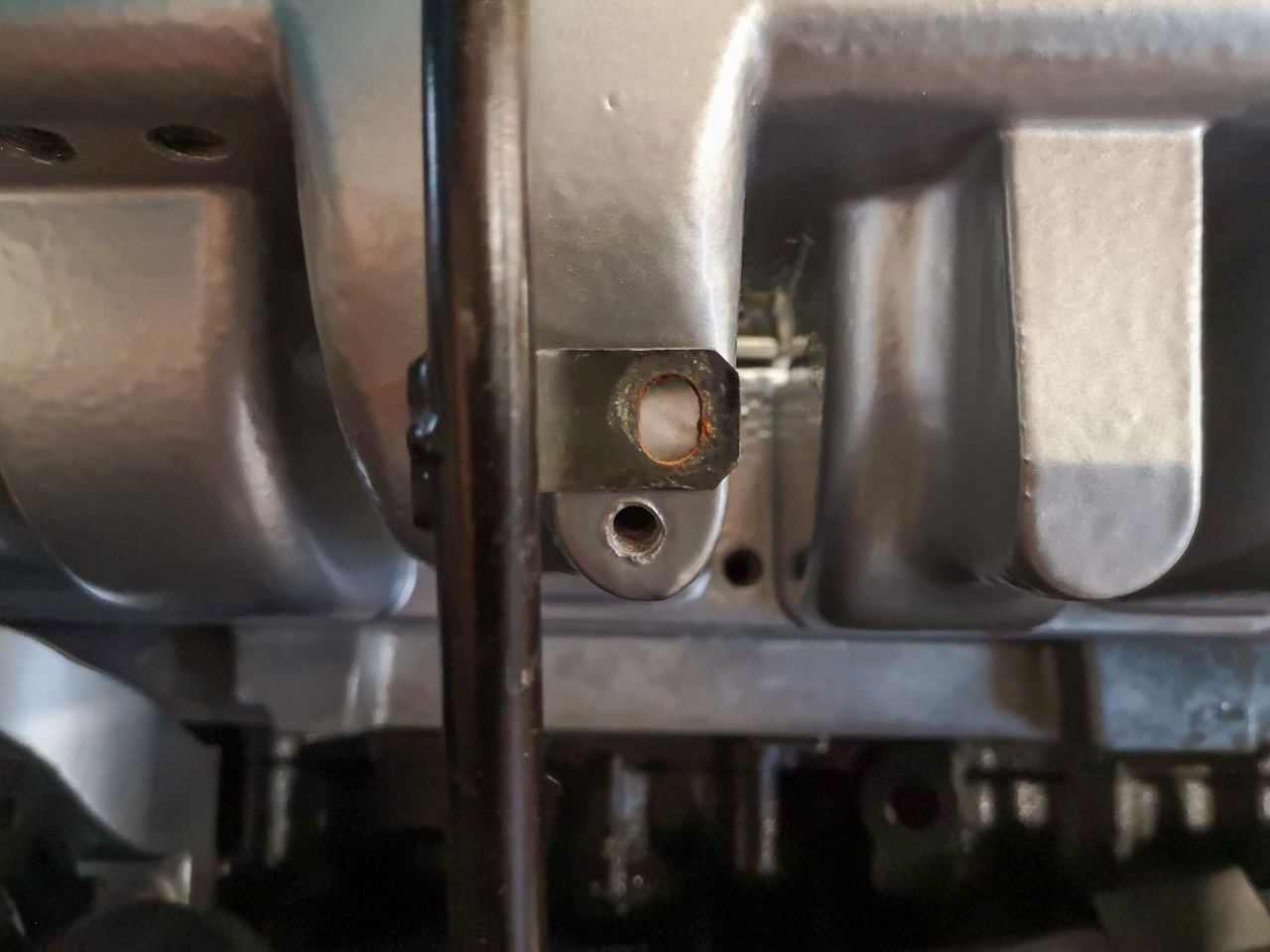

As you can see in this pic the tensioner is not even clearing one of the threaded holes used to bolt the cover onto the head...

....disappointing...

A bit of googling later and it seems there are a couple of approaches to 'fix' this... however there is also another potential issue that tbh I didn't think about... it seems that the cam timing can be affected by this too... this is determined by the chains length between the smaller sprocket on the intermediate shaft and the inlet cam... by moving the head up a bit it pulls the cams anti clockwise which I believe 'advances' the cam timing...

By how much I have yet to determine so that will be tomorrows job...

As for a fix... one thats gets mentioned is to reposition the intermediate sprocket... this is keyed to the larger sprocket thats driven from the crank so would need the keyway modding... this seems a bit extreme and I would need to engineer something I would be happy about using as I wouldn't want it slipping at all..

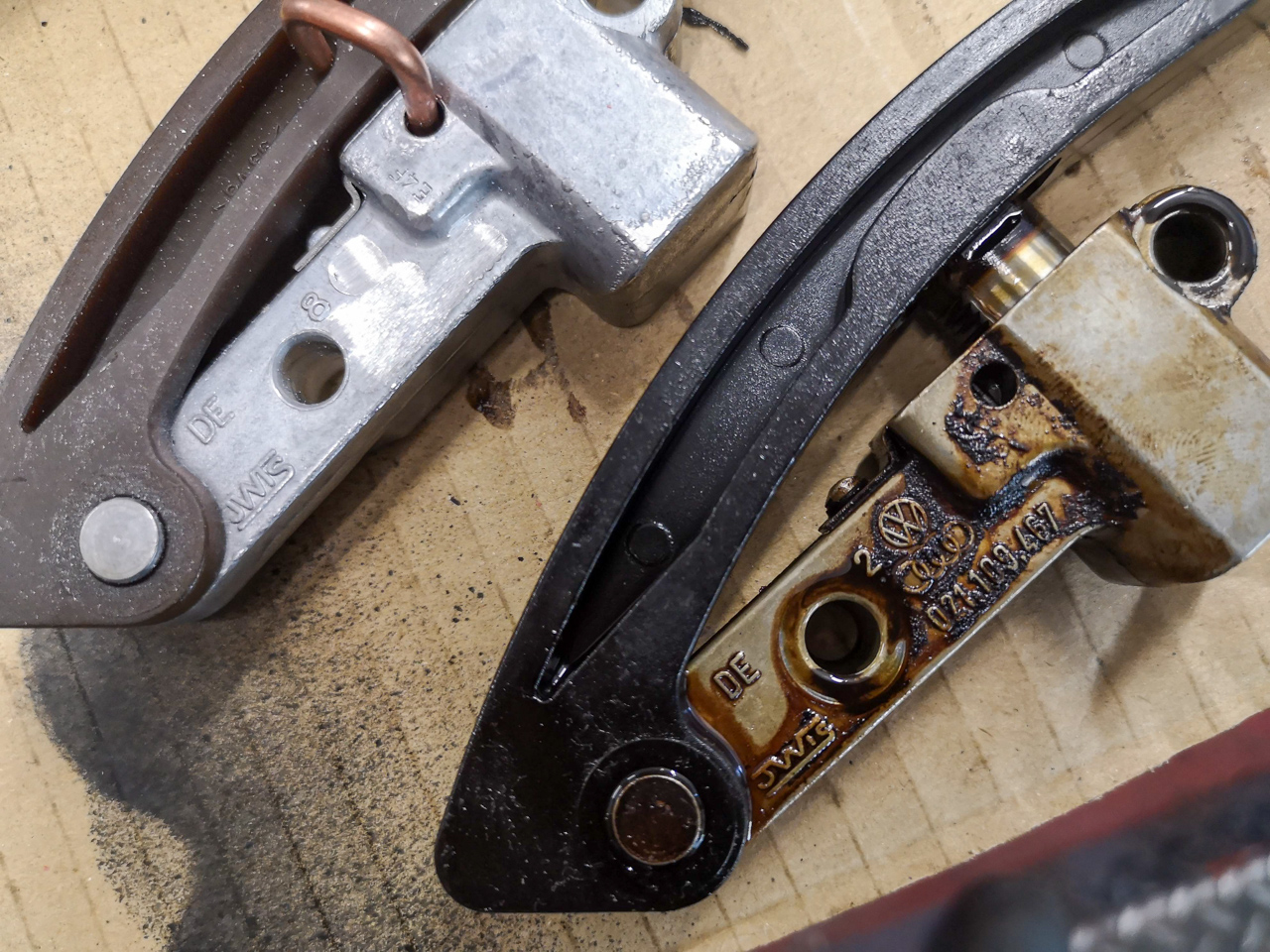

An alternative approach is to modify the chain guide... this is a common thing to do in the 12v VR6 world by all accounts and to that end I had a look at modding the old guide as proof of concept...

First I drilled the fixing inserts from 9mm to 9.5mm to allow the guide to sit back a bit

I also need to open the slot at the bottom a bit too as it needs to move on the same plane really... I then linished the surface of the guide to move this in a little further..

This seemed to give me a bit more slack in the chain and made the cover easier to fit... so I dry fitted the lot including the hydraulic tensioner piston and rotated the engine a few times... all 'appeared' ok and on stripping it back there were no obvious wear marks..

I have a few more ideas for this and I am still having a look about for info (which seems thin on the ground like all VRt conversion info)...

First thing I need to double check though is the actual cam position... I am confident that the cam to cam and top to bottom is right in context of the chains but I need to validate if the cams have advanced by any significant amount by double checking the timing marks then come up with a solution as needed...

Just when I thought I was close to having the engine ready to go in the car!!! joys of modding

<tuffty/>

The spacer head gasket is heavy having a substantial metal piece in it...

Timed up the cam chain and fitted the tensioners..

New crank seal fitted into the lower cover...

...and new seals in the top cover...

Sealant applied to the lower cover...

...and fitted...

Went to fit the upper cover but...

Nothing was lining up and was a ballache to try and get the dowels into the head... looking at the tensioner pad it was clearly fowling the cover..

The issue being that the thicker head gasket has lifted the head enough to take some slack out of the chain forcing the tensioner over too far...

As you can see in this pic the tensioner is not even clearing one of the threaded holes used to bolt the cover onto the head...

....disappointing...

A bit of googling later and it seems there are a couple of approaches to 'fix' this... however there is also another potential issue that tbh I didn't think about... it seems that the cam timing can be affected by this too... this is determined by the chains length between the smaller sprocket on the intermediate shaft and the inlet cam... by moving the head up a bit it pulls the cams anti clockwise which I believe 'advances' the cam timing...

By how much I have yet to determine so that will be tomorrows job...

As for a fix... one thats gets mentioned is to reposition the intermediate sprocket... this is keyed to the larger sprocket thats driven from the crank so would need the keyway modding... this seems a bit extreme and I would need to engineer something I would be happy about using as I wouldn't want it slipping at all..

An alternative approach is to modify the chain guide... this is a common thing to do in the 12v VR6 world by all accounts and to that end I had a look at modding the old guide as proof of concept...

First I drilled the fixing inserts from 9mm to 9.5mm to allow the guide to sit back a bit

I also need to open the slot at the bottom a bit too as it needs to move on the same plane really... I then linished the surface of the guide to move this in a little further..

This seemed to give me a bit more slack in the chain and made the cover easier to fit... so I dry fitted the lot including the hydraulic tensioner piston and rotated the engine a few times... all 'appeared' ok and on stripping it back there were no obvious wear marks..

I have a few more ideas for this and I am still having a look about for info (which seems thin on the ground like all VRt conversion info)...

First thing I need to double check though is the actual cam position... I am confident that the cam to cam and top to bottom is right in context of the chains but I need to validate if the cams have advanced by any significant amount by double checking the timing marks then come up with a solution as needed...

Just when I thought I was close to having the engine ready to go in the car!!! joys of modding

<tuffty/>

****** hell what a ball ache, I’m glad yours is moving along quicker than mine is as I’d be lost with that

Still can’t believe b100dy is a swear word

Still can’t believe b100dy is a swear word

Good effort mate! Adapt and overcome.... that’s some serious head gasket spacer.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Hope you don’t mind but I have quoted abit if this in the r32 forced induction section see if any of them boys can shed some light on how they got over itThe stray headbolt turned up this week so finally got the head on

The spacer head gasket is heavy having a substantial metal piece in it...

View attachment 185734

Timed up the cam chain and fitted the tensioners..

View attachment 185740

New crank seal fitted into the lower cover...

View attachment 185738

...and new seals in the top cover...

View attachment 185739

View attachment 185741

Sealant applied to the lower cover...

View attachment 185742

...and fitted...

View attachment 185743

Went to fit the upper cover but...

View attachment 185744

View attachment 185745

Nothing was lining up and was a ballache to try and get the dowels into the head... looking at the tensioner pad it was clearly fowling the cover..

View attachment 185746

The issue being that the thicker head gasket has lifted the head enough to take some slack out of the chain forcing the tensioner over too far...

As you can see in this pic the tensioner is not even clearing one of the threaded holes used to bolt the cover onto the head...

View attachment 185750

....disappointing...

A bit of googling later and it seems there are a couple of approaches to 'fix' this... however there is also another potential issue that tbh I didn't think about... it seems that the cam timing can be affected by this too... this is determined by the chains length between the smaller sprocket on the intermediate shaft and the inlet cam... by moving the head up a bit it pulls the cams anti clockwise which I believe 'advances' the cam timing...

By how much I have yet to determine so that will be tomorrows job...

As for a fix... one thats gets mentioned is to reposition the intermediate sprocket... this is keyed to the larger sprocket thats driven from the crank so would need the keyway modding... this seems a bit extreme and I would need to engineer something I would be happy about using as I wouldn't want it slipping at all..

An alternative approach is to modify the chain guide... this is a common thing to do in the 12v VR6 world by all accounts and to that end I had a look at modding the old guide as proof of concept...

First I drilled the fixing inserts from 9mm to 9.5mm to allow the guide to sit back a bit

View attachment 185751

I also need to open the slot at the bottom a bit too as it needs to move on the same plane really... I then linished the surface of the guide to move this in a little further..

View attachment 185752

This seemed to give me a bit more slack in the chain and made the cover easier to fit... so I dry fitted the lot including the hydraulic tensioner piston and rotated the engine a few times... all 'appeared' ok and on stripping it back there were no obvious wear marks..

I have a few more ideas for this and I am still having a look about for info (which seems thin on the ground like all VRt conversion info)...

First thing I need to double check though is the actual cam position... I am confident that the cam to cam and top to bottom is right in context of the chains but I need to validate if the cams have advanced by any significant amount by double checking the timing marks then come up with a solution as needed...

Just when I thought I was close to having the engine ready to go in the car!!! joys of modding

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Thanks dude... I understand the problem... and can engineer a fix but obvs an informed solution would be better

<tuffty/>

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I will dude... its why this thread is here

As a lad I always had a Haynes manual to help me out... pictures were invaluable to give you an idea of what you were looking at and obvs the instructions were great too...

Never set out to replicate that or turn this into a how-to but if it gives peeps a bit of insight into what can be done and maybe a little inspiration then I am happy with that...

<tuffty/>

As a lad I always had a Haynes manual to help me out... pictures were invaluable to give you an idea of what you were looking at and obvs the instructions were great too...

Never set out to replicate that or turn this into a how-to but if it gives peeps a bit of insight into what can be done and maybe a little inspiration then I am happy with that...

<tuffty/>

I tried to get a manual for the 3.2 engine but the online workshop isn’t that good it so will try and find a proper manual

Nice work!

So how thick is your gasket that it's made the OEM tension "too tight" and the top cover wasn't fitting?

It's strange because lots of others report no need to mod the guides - i guess their decomp. plates aren't as thick...

So how thick is your gasket that it's made the OEM tension "too tight" and the top cover wasn't fitting?

It's strange because lots of others report no need to mod the guides - i guess their decomp. plates aren't as thick...

I tried to get a manual for the 3.2 engine but the online workshop isn’t that good it so will try and find a proper manual

what manual are you looking for?

Something like the Haynes one that would show all the bolts torques and stuff I know there wasn’t one for the s3, I got a copy one off eBay for a tt bhe but never even got it working they send a link that didn’t work

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Mines 3.15mm (will check properly tomorrow) and supposed to be 8.9:1... most seem to go 8.5:1 so not sure why its not an issue...Nice work!

So how thick is your gasket that it's made the OEM tension "too tight" and the top cover wasn't fitting?

It's strange because lots of others report no need to mod the guides - i guess their decomp. plates aren't as thick...

Trouble is... there is no way to tell if people realise there is an issue and that its just a bit tight to fit... so info may not make it out there

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Fun and games today...

Double checked the timing of the cams and was happy that the chains were correct... there are no timing marks to speak of as the ECU will base line it through adaptions in ME7 from what I understand... this is a similar system to the TFSI (pretty much the same VVT units... as well as roller rocker setup)

Punched out the inserts from the old guide... rather wreck that testing and playing than the new one at this time..

I test fitted the guide after holding the tensioner in a decent placement to clear the cover... you can see the challenge..

I was feeling confident that my idea would work so went to work on the new guide...

I didn't fancy the idea of shaving material off the guide face like most of the internet has suggested so the next obvious step was to mod the mounting positions to allow the guide to sit back and relieve tension between the intermediate shaft and cam sprocket...

First I opened up the lower part of the guide that slots onto a stud just inside the lower cover... the idea being that this will help the whole guide sit further back across the same plane as the mounting bolt holes... I marked up the position the bolt would be to give me a sense of direction (god knows I need it lol)

Using a dremel I elongated the holes... Doing this will let the guide sit back a bit...

I then cut the metal inserts in half...

...this will still give the required platform to be able to tighten the bolt up to (10nm remember) while allowing the guide to sit further back...

I also had to grind some material out of the top cover where the tensioner pad was just to be sure of a bit of clearance... the scribed marks are either side of the tensioner so needed a little work to make sure it was all clear...

Test fitted everything (more than a few times!!!) and I was able to fit the cover by hand without having to manhandle it over on the dowels and use a hammer to get it to seat properly...

I am as yet unsure if this is a 100% fix... the engine turned fine with the cover on and the hydraulic tensioner fitted but time will tell I guess..

I am happy with the theory of the solution but less happy about its execution... my OCD is leaning towards reengineering this a bit better by drilling out the mount hole to be larger and to fabricate a cam/offset insert to give me a bit more control over the fitment and a little more slack for the tensioner... but before I do that I might have a look at the setup on a standard engine (Bills spare maybe) and get an idea of how much travel the tensioner has in a standard setup... something I didn't check but probably should have.... hind sight... its a glorious thing

I do wonder how others have managed to deal with it... I also wonder if the 3.15mm spacer gasket I have is actually too thick... I went off the listing (again due to lack of info out there) so who knows...

I plan to get hold of another guide once the engine is in the car and running and see if I can do something more engineered...

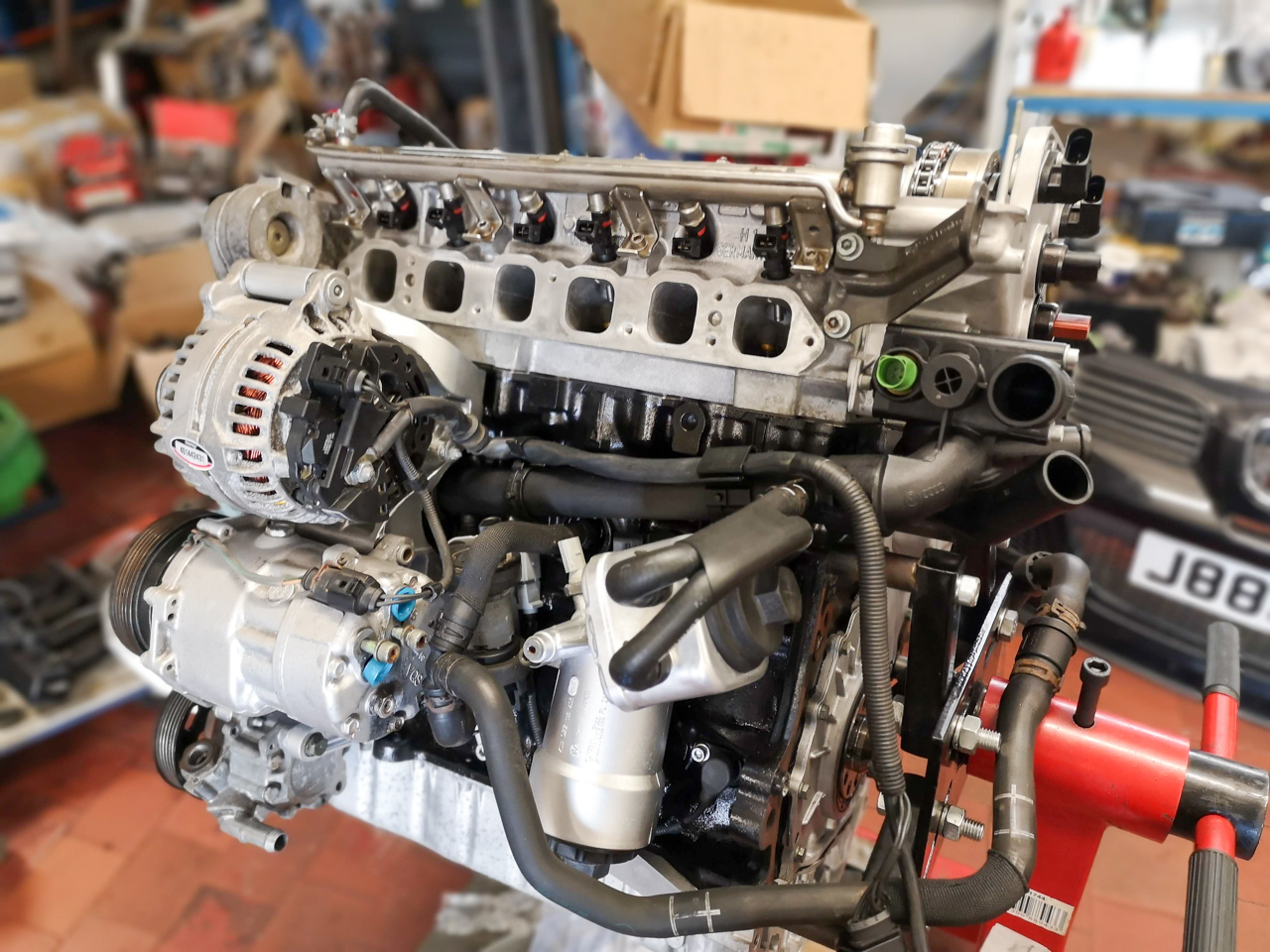

Bolted everything together... feeling good

Next on the list...

Now that the lower cover is on its a bit easier to fit the sump other wise you have to slide it on and while this is 'normal' I'd rather make sure the seal is good...

Lots and lots of bolts later and its bolted down... one thing to look out for is fitment gearbox end... if dropping a sump with the gearbox on then its best practice to have a few sump bolts nipped up then fit the bolts that pass from the box to the sump so it fits flush to the box with the right torque but as I didn't have the box on the engine at this time I just tried to make sure the sump was flush with the end of the block..

Next up... coolant housing and other animals...

Looking more like an actual engine now

...I also fitted the 630cc injectors and the fuel rail..

Need to get a serpentine belt and pick up the cam cover from the powder coaters and she is pretty much ready to go into the car!!

Another little purchase arrived this week too... after a little research and actual bit of test fitting by Alex (who has just bought a V5 engine to put in his Ibiza and was test fitting my gearbox on it to make sure an 02M will go on ok) it seems there is a fair amount of grinding of the normal 1.8t transfer box to get it to fit...

It can be done and this was my original plan but I spotted a transfer box on ebay listed by the same guys I got the box from... pretty sure it was from my box and was going cheap enough to take a punt..

Interesting differences... for the most part they are the same except here..

S3 transfer box...

R32/VR transfer box..

Case has had a flat machined/cast into it and an M8 bolt used instead of the M10 of the S3 one...

When I fit the box I'll take some pics of the modded transfer box for comparison...

<tuffty/>

Double checked the timing of the cams and was happy that the chains were correct... there are no timing marks to speak of as the ECU will base line it through adaptions in ME7 from what I understand... this is a similar system to the TFSI (pretty much the same VVT units... as well as roller rocker setup)

Punched out the inserts from the old guide... rather wreck that testing and playing than the new one at this time..

I test fitted the guide after holding the tensioner in a decent placement to clear the cover... you can see the challenge..

I was feeling confident that my idea would work so went to work on the new guide...

I didn't fancy the idea of shaving material off the guide face like most of the internet has suggested so the next obvious step was to mod the mounting positions to allow the guide to sit back and relieve tension between the intermediate shaft and cam sprocket...

First I opened up the lower part of the guide that slots onto a stud just inside the lower cover... the idea being that this will help the whole guide sit further back across the same plane as the mounting bolt holes... I marked up the position the bolt would be to give me a sense of direction (god knows I need it lol)

Using a dremel I elongated the holes... Doing this will let the guide sit back a bit...

I then cut the metal inserts in half...

...this will still give the required platform to be able to tighten the bolt up to (10nm remember) while allowing the guide to sit further back...

I also had to grind some material out of the top cover where the tensioner pad was just to be sure of a bit of clearance... the scribed marks are either side of the tensioner so needed a little work to make sure it was all clear...

Test fitted everything (more than a few times!!!) and I was able to fit the cover by hand without having to manhandle it over on the dowels and use a hammer to get it to seat properly...

I am as yet unsure if this is a 100% fix... the engine turned fine with the cover on and the hydraulic tensioner fitted but time will tell I guess..

I am happy with the theory of the solution but less happy about its execution... my OCD is leaning towards reengineering this a bit better by drilling out the mount hole to be larger and to fabricate a cam/offset insert to give me a bit more control over the fitment and a little more slack for the tensioner... but before I do that I might have a look at the setup on a standard engine (Bills spare maybe) and get an idea of how much travel the tensioner has in a standard setup... something I didn't check but probably should have.... hind sight... its a glorious thing

I do wonder how others have managed to deal with it... I also wonder if the 3.15mm spacer gasket I have is actually too thick... I went off the listing (again due to lack of info out there) so who knows...

I plan to get hold of another guide once the engine is in the car and running and see if I can do something more engineered...

Bolted everything together... feeling good

Next on the list...

Now that the lower cover is on its a bit easier to fit the sump other wise you have to slide it on and while this is 'normal' I'd rather make sure the seal is good...

Lots and lots of bolts later and its bolted down... one thing to look out for is fitment gearbox end... if dropping a sump with the gearbox on then its best practice to have a few sump bolts nipped up then fit the bolts that pass from the box to the sump so it fits flush to the box with the right torque but as I didn't have the box on the engine at this time I just tried to make sure the sump was flush with the end of the block..

Next up... coolant housing and other animals...

Looking more like an actual engine now

...I also fitted the 630cc injectors and the fuel rail..

Need to get a serpentine belt and pick up the cam cover from the powder coaters and she is pretty much ready to go into the car!!

Another little purchase arrived this week too... after a little research and actual bit of test fitting by Alex (who has just bought a V5 engine to put in his Ibiza and was test fitting my gearbox on it to make sure an 02M will go on ok) it seems there is a fair amount of grinding of the normal 1.8t transfer box to get it to fit...

It can be done and this was my original plan but I spotted a transfer box on ebay listed by the same guys I got the box from... pretty sure it was from my box and was going cheap enough to take a punt..

Interesting differences... for the most part they are the same except here..

S3 transfer box...

R32/VR transfer box..

Case has had a flat machined/cast into it and an M8 bolt used instead of the M10 of the S3 one...

When I fit the box I'll take some pics of the modded transfer box for comparison...

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Yes mate... its a Febi one and new hoses too.. the original was damaged assumedly during transport..Is that a new oil cooler or have you just cleaned your old one?

In other news... picked up the cam cover and inlet from the powder coaters....

<tuffty/>

Looking good the finish on the inlet is 100x better than how it came, how much was the febi one mine didn’t come with one and a new Audi one is at the £200 mark I’m just trying to get all the part numbers for all the oil,and coolant hoses as it’s another thing I might aswell be done whilst it’s out

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Oil cooler..Looking good the finish on the inlet is 100x better than how it came, how much was the febi one mine didn’t come with one and a new Audi one is at the £200 mark I’m just trying to get all the part numbers for all the oil,and coolant hoses as it’s another thing I might aswell be done whilst it’s out

https://www.ebay.co.uk/itm/173629433420

I got all the part numbers for hoses etc from 7zap

<tuffty/>

God that’s a well better price! yeah that’s where I’m getting mine just writing them all Down to get a list togetherOil cooler..

https://www.ebay.co.uk/itm/173629433420

I got all the part numbers for hoses etc from 7zap

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Little more done today...

I needed to mod the dipstick tube to fit the inlet..

The top is pitched over a bit too much as well

So cut a metal tab out and sprayed some molten metal randomly at it and...

...tweaked the top of the tube to sit away from the inlet..

...and painted it of course...

I suspect that due to the way the engine leans forward I may need to tweak the position further as it will be close to the slam panel... needs to be in the engine bay for that of course but its getting pretty close to being there now

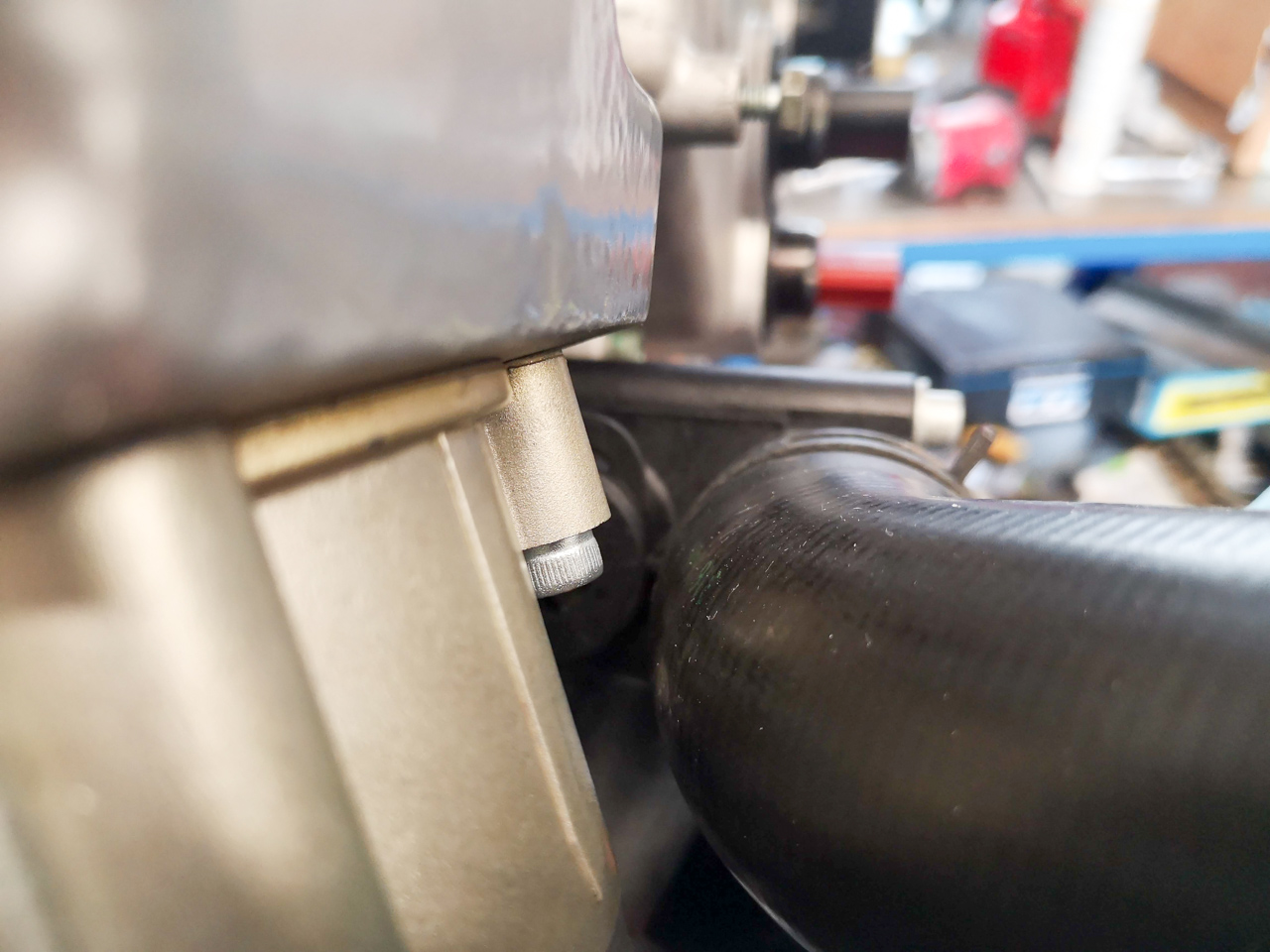

Next issue to look at was how close the throttle body appeared to be to the coolant housing outlet...

So fitted the relevant hose to see what was what...

So close then...

No idea how the R32 TB is supposed to fit here without leaning on the coolant hose but I have a plan which I will sort out tomorrow..

I bolted down the cam cover, fitted the plugs and then the coil packs...

The inlet mani is not bolted on as yet... I need to source some replacement M7 bolts the right length... I did cut the originals down but the threads are a bit iffy so need to either file some more (cba), run then through an M7 die (not got one) or buy new ones the right length... so the latter will be done

I fitted the vacuum outlets to the inlet and sealed the MAP sensor in... I need to get some M6 grub screws to put in the R32 TB threaded holes to seal them as I am using the 70mm TB....

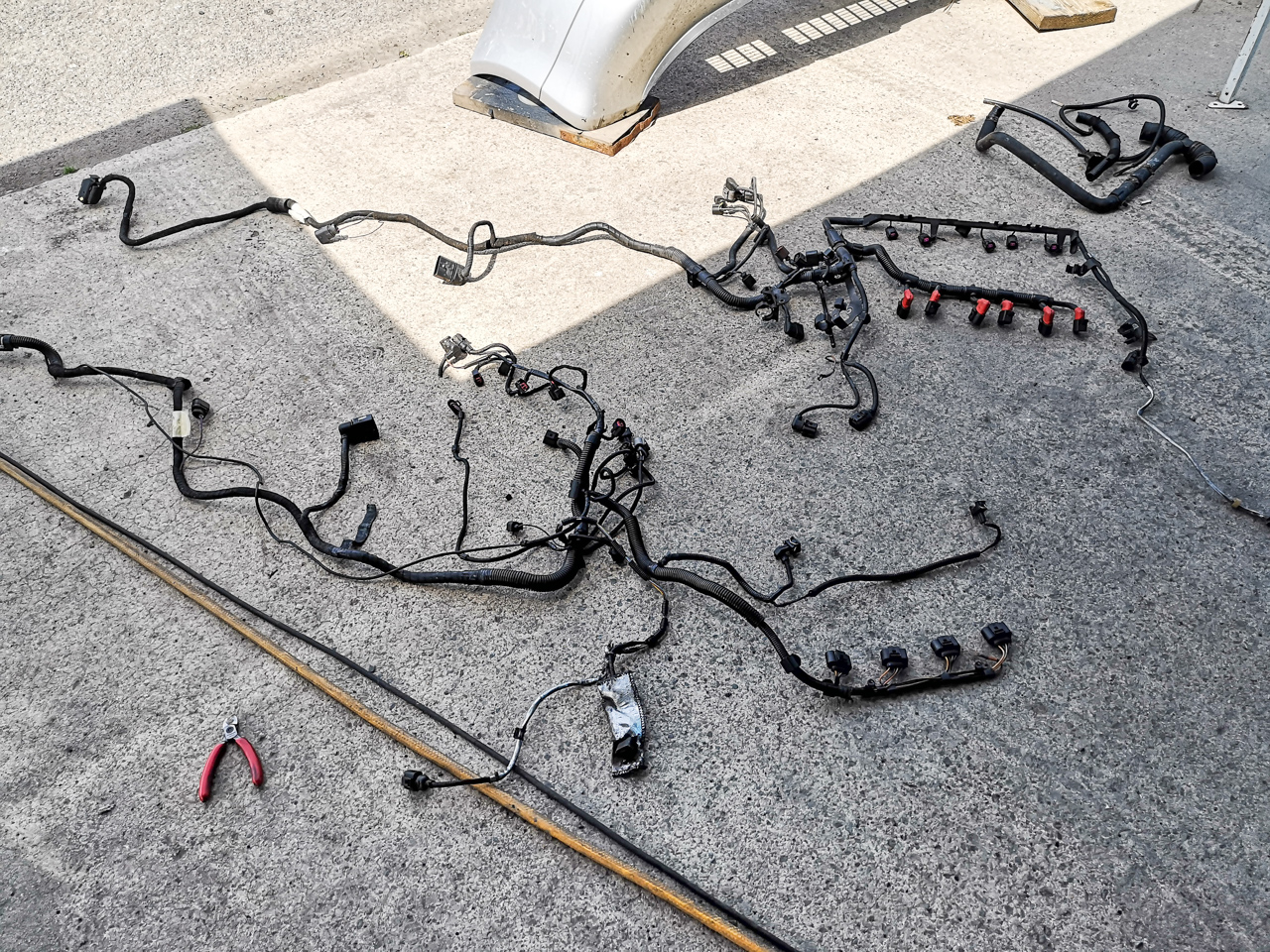

One last task... grab the wiring loom to work out what needs doing...

Not too bad a loom tbh... will give it a thorough clean before taking off the tape to remove the bits I am not going to use and add the bits I am missing... I won't go into the details for now but of course will post up when I do the work..

<tuffty/>

I needed to mod the dipstick tube to fit the inlet..

The top is pitched over a bit too much as well

So cut a metal tab out and sprayed some molten metal randomly at it and...

...tweaked the top of the tube to sit away from the inlet..

...and painted it of course...

I suspect that due to the way the engine leans forward I may need to tweak the position further as it will be close to the slam panel... needs to be in the engine bay for that of course but its getting pretty close to being there now

Next issue to look at was how close the throttle body appeared to be to the coolant housing outlet...

So fitted the relevant hose to see what was what...

So close then...

No idea how the R32 TB is supposed to fit here without leaning on the coolant hose but I have a plan which I will sort out tomorrow..

I bolted down the cam cover, fitted the plugs and then the coil packs...

The inlet mani is not bolted on as yet... I need to source some replacement M7 bolts the right length... I did cut the originals down but the threads are a bit iffy so need to either file some more (cba), run then through an M7 die (not got one) or buy new ones the right length... so the latter will be done

I fitted the vacuum outlets to the inlet and sealed the MAP sensor in... I need to get some M6 grub screws to put in the R32 TB threaded holes to seal them as I am using the 70mm TB....

One last task... grab the wiring loom to work out what needs doing...

Not too bad a loom tbh... will give it a thorough clean before taking off the tape to remove the bits I am not going to use and add the bits I am missing... I won't go into the details for now but of course will post up when I do the work..

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Before I can 'swing it in' I needed to sort the engine bay out which hasn't seen the light of day since the 20v was removed...

Yanked the front off and dived into the wiring

...which was a little messy so will be making an effort to clean this up nicely...

Removed the 20v small plug loom as this is the main one that changes between the VR and 20v... laid it out next to the VR TT loom to see how they compare..

There are a few obvious omissions.. N75, IAT and something I hadn't thought about speedo sender!... looks like the TT takes speedo signal from ABS which is fine as I can configure the IECU to use that too but I will look into adding the wiring all the same...

Next job on that is to pick the TT loom apart and add in bits I need while removing bits I don't (like the vacuum valve for the inlet and the SAI)...

Gave the bay a clean and removed the ECU so I could bench flash the VR file in... still looks a bit of a state but once I have sorted the loom out it will look much better

Next job was to sort the clearance required for the aircon pump... on K04 based 20v's there is a metal pipe that joins the two SMIC's... I have long since binned mine but there is extra bracketry on the chassis legs to mount it... unfortunately this bracket gets in the way of the aircon pump... not an issue on a VR engined car as the brackets are not fitted but as my car has them I need to mod them for clearance...

Armed with my favourite tools (a disc cutter and grinder) I went in!..

Most of the images I had seen on the interwebs were a little vague but got enough of an idea to make an informed attempt..

Cleaned up the area with the grinder and some files... then primed with etch primer and sprayed silver...

Once fully gone off I will spray the entire area with waxoyl...

Next job in the bay was to swap the gearchange bracket as the VR one is a little different on the third fixing point..

VR left, 20v right...

You have to remove the cable ends to get the cables through the holes... as the position of these is pretty critical I decided to measure before I removed them and did them one at a time.. you can of course recalibrate by locking the change tower and gear lever out but decided to have it somewhere handy at least then adjust if I really need too..

That was all I could for today but the bay is ready to take have the engine hung in there so hopefully if all goes to plan that will be next weekends little job

It was rather warm and as I was already getting a little rouge I finished off a few jobs inside... if you remember I had an issue with the throttle body contacting the coolant hose...

The fix for this was pretty straight forward....

Bit more clearance

...then a new potential issue presented itself...

b*gger!... so grabbed the wiring loom and plugged the CTS in...

Phew... not as bad as I first thought... might need to trim the plug a little just to be sure but clearly (as is always the way with a build like this) there is an assembly order so the loom will be fitted prior to the inlet mani..

Another thing I noticed was that the alternator part of the loom was longer on the S3 so removed that to compare to the TT VR one...

So I will be using the S3 one then lol... only issue is that the aircon wiring is too short so will need to extend that to fit...

Last couple of jobs of the day.... With fitting up some of the coolant lines it was obvious I needed to add the original support for them but that just happened to be on the same bracket for the SAI which of course I deleted... so dug out the bracket, modded it as I didn't need the full bracket with no SAI and painted it

While I was at it I painted the throttle body too

Happy with the progress... car is ready for the engine now so if all goes well I hope to have that in next weekend..

<tuffty/>

Yanked the front off and dived into the wiring

...which was a little messy so will be making an effort to clean this up nicely...

Removed the 20v small plug loom as this is the main one that changes between the VR and 20v... laid it out next to the VR TT loom to see how they compare..

There are a few obvious omissions.. N75, IAT and something I hadn't thought about speedo sender!... looks like the TT takes speedo signal from ABS which is fine as I can configure the IECU to use that too but I will look into adding the wiring all the same...

Next job on that is to pick the TT loom apart and add in bits I need while removing bits I don't (like the vacuum valve for the inlet and the SAI)...

Gave the bay a clean and removed the ECU so I could bench flash the VR file in... still looks a bit of a state but once I have sorted the loom out it will look much better

Next job was to sort the clearance required for the aircon pump... on K04 based 20v's there is a metal pipe that joins the two SMIC's... I have long since binned mine but there is extra bracketry on the chassis legs to mount it... unfortunately this bracket gets in the way of the aircon pump... not an issue on a VR engined car as the brackets are not fitted but as my car has them I need to mod them for clearance...

Armed with my favourite tools (a disc cutter and grinder) I went in!..

Most of the images I had seen on the interwebs were a little vague but got enough of an idea to make an informed attempt..

Cleaned up the area with the grinder and some files... then primed with etch primer and sprayed silver...

Once fully gone off I will spray the entire area with waxoyl...

Next job in the bay was to swap the gearchange bracket as the VR one is a little different on the third fixing point..

VR left, 20v right...

You have to remove the cable ends to get the cables through the holes... as the position of these is pretty critical I decided to measure before I removed them and did them one at a time.. you can of course recalibrate by locking the change tower and gear lever out but decided to have it somewhere handy at least then adjust if I really need too..

That was all I could for today but the bay is ready to take have the engine hung in there so hopefully if all goes to plan that will be next weekends little job

It was rather warm and as I was already getting a little rouge I finished off a few jobs inside... if you remember I had an issue with the throttle body contacting the coolant hose...

The fix for this was pretty straight forward....

Bit more clearance

...then a new potential issue presented itself...

b*gger!... so grabbed the wiring loom and plugged the CTS in...

Phew... not as bad as I first thought... might need to trim the plug a little just to be sure but clearly (as is always the way with a build like this) there is an assembly order so the loom will be fitted prior to the inlet mani..

Another thing I noticed was that the alternator part of the loom was longer on the S3 so removed that to compare to the TT VR one...

So I will be using the S3 one then lol... only issue is that the aircon wiring is too short so will need to extend that to fit...

Last couple of jobs of the day.... With fitting up some of the coolant lines it was obvious I needed to add the original support for them but that just happened to be on the same bracket for the SAI which of course I deleted... so dug out the bracket, modded it as I didn't need the full bracket with no SAI and painted it

While I was at it I painted the throttle body too

Happy with the progress... car is ready for the engine now so if all goes well I hope to have that in next weekend..

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk