Mk1 TT 225 track day car, Officially a ten second car 10.8 seconds at 127 mph.

- Thread starter desertstorm

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A few more hours in the garage and removed the gearbox , exhaust manifold with turbo and got it on the engine stand. How on earth you are supposed to remove the standard turbo when the engine is in the car I am not sure.

It was hard enough doing it when I have full and easy access to the back of the engine, to remove it when the engine is in the car must be a nightmare.

Gearbox came off fairly easy after I discovered the extra bolt that comes from the transfer box side and hides well out the way, Thank god for ElsaWin.

Not in any great rush to get this done so taking my time not trying to break anything or strip bolts/ threads. Refitting bolts a lot of the time where I can back to where they came from so hopefully I won't be spending a lot of time working out what goes where.

Clutch seems to have a fair bit left in it, the DMF also seems pretty good, compared to the nearly new one I have, there's not a lot in it.With only 90K on the clock I suppose it's what you should expect.

More dismantling tomorrow, may even fit the turbo and manifold and work out how I am going to run the oil and coolant for the turbo so I can order some bits. The G25 isn't that much bigger than the standard turbo in physical size terms, there is a marked difference in compressor and turbine size though.

It was hard enough doing it when I have full and easy access to the back of the engine, to remove it when the engine is in the car must be a nightmare.

Gearbox came off fairly easy after I discovered the extra bolt that comes from the transfer box side and hides well out the way, Thank god for ElsaWin.

Not in any great rush to get this done so taking my time not trying to break anything or strip bolts/ threads. Refitting bolts a lot of the time where I can back to where they came from so hopefully I won't be spending a lot of time working out what goes where.

Clutch seems to have a fair bit left in it, the DMF also seems pretty good, compared to the nearly new one I have, there's not a lot in it.With only 90K on the clock I suppose it's what you should expect.

More dismantling tomorrow, may even fit the turbo and manifold and work out how I am going to run the oil and coolant for the turbo so I can order some bits. The G25 isn't that much bigger than the standard turbo in physical size terms, there is a marked difference in compressor and turbine size though.

Well the engine dismantling is coming along well. Everything looking OK at the moment, just a few questions. Engine has done 90K.

Keeping the standard pistons as they look fine, no marks on the bores at all and no wear ridges that I can feel in the bore. There is still some signs of the original hone but to me look like it definitely needs deglazing.

I have some new standard size Kolbenschmidt rings on the way.

I have looked around for honing tools and they aren't expensive but wondering what grade stone would be the best. It seems standard stones are 180 and you can get 220 and 280 grit stones. I believe the rings on the 225 are different to the lower power 1.8t engines in that they are chrome on the top rings so possibly need a finer hone, more like 280 than 180.

Anybody have an idea on the best ring gaps to aim for bearing in mind I will be running 450bhp plus hopefully.

The engine has great oil pressure, around 1.8 bar idle even when the oil temp is well over 100 degrees. So I am not planning on changing the main bearings, I did buy some plastigauge and have a set of TDI main bolts so am going to check all appears OK and fit the uprated bolts.

Anybody have any idea on what kind of clearances I should be seeing ?

This is what I have found on Elsa Win.

Obviously it probably won't be within the original clearances but I would of thought a little looser than new is better from a performance point of view.

Think I am going to have some fun trying to get the cotters back in for the valves on the head. The inlets were fiddly enough to get out let alone get back in.

Any help advice greatly appreciated. @badger5 @<tuffty/> @superkarl @Prawn

Keeping the standard pistons as they look fine, no marks on the bores at all and no wear ridges that I can feel in the bore. There is still some signs of the original hone but to me look like it definitely needs deglazing.

I have some new standard size Kolbenschmidt rings on the way.

I have looked around for honing tools and they aren't expensive but wondering what grade stone would be the best. It seems standard stones are 180 and you can get 220 and 280 grit stones. I believe the rings on the 225 are different to the lower power 1.8t engines in that they are chrome on the top rings so possibly need a finer hone, more like 280 than 180.

Anybody have an idea on the best ring gaps to aim for bearing in mind I will be running 450bhp plus hopefully.

The engine has great oil pressure, around 1.8 bar idle even when the oil temp is well over 100 degrees. So I am not planning on changing the main bearings, I did buy some plastigauge and have a set of TDI main bolts so am going to check all appears OK and fit the uprated bolts.

Anybody have any idea on what kind of clearances I should be seeing ?

This is what I have found on Elsa Win.

Obviously it probably won't be within the original clearances but I would of thought a little looser than new is better from a performance point of view.

Think I am going to have some fun trying to get the cotters back in for the valves on the head. The inlets were fiddly enough to get out let alone get back in.

Any help advice greatly appreciated. @badger5 @<tuffty/> @superkarl @Prawn

Think I have got the ring gaps sorted, there seems to be quite a consensus on the net about the kind of gaps required, very unusual.

Ordered a 3 Draper egged hone from Fleabay and a set of 280 grit stones as the normal 180 ones are too aggressive because of the chrome/moly rings.

Checked the gap on the main bearings and it all looks good, only 0.05mm across all 5 journals with no signs of wear or any other issues. As the initial build tolerance is 0.02- 0.04mm and the wear limit is 0.15mm the wear looks very good to me for a 90k mile engine.

It seems some people seem to think a slightly larger gap is preferable especially on higher power engines due to distortion and twisting that can occur when you get to 400bhp plus. Either way the engine has very good oil pressure so will be leaving the mains alone.

I bought some ARL TDI main bolts to replace to originals which are single use only stretch items. The OE items are 10.9 , the TDI items 12.9.

Apparently the TFSI bolts also fit and are 12.9.

The car last had a new cambelt fitted 15K miles ago. It looks like they changed the water pump and hydraulic tensioner. I didn't know this before I took it apart so bought new items anyway, they aren't that expensive.

The water pump fitted looks like it wouldn't pump as well as the Febi item I bought. The original has a pretty agricultural metal impellor where as the Febi has the more OE design of impellor. Looking at the water pump location the top of the pump impellor runs very closely to the opening and pulls water through and pushes it out to the side. You can see the end of the thermostat in the picture .

Hopefully the Febi will move more water than the cheap looking metal impellor pump, maybe the car will run a little cooler.

Picking up the cylinder head tomorrow, acid dipped with new Mahle exhaust valve guides and refaced. So going to be having lots of fun trying to get the inlet valve cotters back in.

Ordered a 3 Draper egged hone from Fleabay and a set of 280 grit stones as the normal 180 ones are too aggressive because of the chrome/moly rings.

Checked the gap on the main bearings and it all looks good, only 0.05mm across all 5 journals with no signs of wear or any other issues. As the initial build tolerance is 0.02- 0.04mm and the wear limit is 0.15mm the wear looks very good to me for a 90k mile engine.

It seems some people seem to think a slightly larger gap is preferable especially on higher power engines due to distortion and twisting that can occur when you get to 400bhp plus. Either way the engine has very good oil pressure so will be leaving the mains alone.

I bought some ARL TDI main bolts to replace to originals which are single use only stretch items. The OE items are 10.9 , the TDI items 12.9.

Apparently the TFSI bolts also fit and are 12.9.

The car last had a new cambelt fitted 15K miles ago. It looks like they changed the water pump and hydraulic tensioner. I didn't know this before I took it apart so bought new items anyway, they aren't that expensive.

The water pump fitted looks like it wouldn't pump as well as the Febi item I bought. The original has a pretty agricultural metal impellor where as the Febi has the more OE design of impellor. Looking at the water pump location the top of the pump impellor runs very closely to the opening and pulls water through and pushes it out to the side. You can see the end of the thermostat in the picture .

Hopefully the Febi will move more water than the cheap looking metal impellor pump, maybe the car will run a little cooler.

Picking up the cylinder head tomorrow, acid dipped with new Mahle exhaust valve guides and refaced. So going to be having lots of fun trying to get the inlet valve cotters back in.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

I hadn't realised you were planning on using the stock pistons and bore on this build Karl.

I fear you will live to regret that decision in time if I'm honest.

I fear you will live to regret that decision in time if I'm honest.

Hopefully not, I did think about new pistons, going to 1.9L etc. I realise a lot of people go for more capacity to try and improve spool on the larger turbo, I went for the G25 in the first place as it looked very promising as regards spool. If I got it all right in the first place I wouldn't have anything else to play with. If it doesn't do what I want then I can take it apart and have another go, you have doing that for years  .

.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

It's more the concern that it probably won't last too long and when one does melt you'll have to do the whole lot again, assuming no debris eats the turbo on its way out!

A 660 is definitely not something I would be fitting to an engine wkth stock pistons.

A 660 is definitely not something I would be fitting to an engine wkth stock pistons.

I hear what your saying. The standard pistons do seem to be pretty good. I am not going to be running more than 7500 rpm and am planning on running a fairly safe tune most of the time. EGT's look to be lower on a 470bhp car running the right set up compared to a 350 bhp hybrid k04 thats working it's nadgers off.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I suspect it will be the cylinder pressures from boost and timing required to get to 470hp that will kill them rather than EGT's as EGT issues will melt any piston

<tuffty/>

<tuffty/>

Bit of an update on things with the engine rebuild.

After some discussions on line and some wisdom imparted from Prawn I decided to bin the idea of keeping the standard pistons and get some aftermarket forged items. Although I believe the standard pistons would work in the short term they have already done 90K miles and the bore etc is not exactly factory fresh.

So bought some Wossner 9.5:1 82.5mm pistons. These are the same as what Prawn uses in his car and that's currently making over 500bhp so they can't be all that bad. At least until they wear out .

.

With this size piston capacity increases from 1780cc to 1850cc so another 70cc capacity which all helps.

Found a place to do the rebore work I thought. Dropped the block and pistons off last Monday and was hoping to pick it up last Friday. Rang on Thursday last week and told that machinist had been busy and had not had time to do the work. He was not going to be in this week so work wouldn't be done till next week at the earliest.

Slightly annoyed as I could do with putting the engine back together . Anyway rang on Friday just to check something and got transferred to the main office. I am now told that the place I took the engine too which is part of a larger group of companies is being closed down???.

They are still going to honor the work but I am not entirely sure I am happy with that, however I can't find anybody else locally who I think could do a better job than them.

So hopefully awaiting to get the block back next week sometime so I can start rebuilding the engine.

Head is all built up, ready to go on. Rosten uprated springs, new exhaust valve guides, supertech Inconel exhaust valves.

Did a very small amount of porting just cleaning up some of the rough casing marks at the back of the valves and removing a bit here and there that was obviously in the way.

Wrapped the manifold and down pipe to try and reduce the underbonnet temps a bit.

Filled the engine mounts with liquid polyeurethane. Went for the slightly softer 60 shore stuff. Not completely solid it allows a very small amount of movement.

Bought a tool as well so I could get the crank bolt undone. Jeez that's tight. I really would hate to try and tighten or undo an ARP item.

Bought one of the diamond coated washers as used on the 2.0 TFSI engines for when I put it back together.

After some discussions on line and some wisdom imparted from Prawn I decided to bin the idea of keeping the standard pistons and get some aftermarket forged items. Although I believe the standard pistons would work in the short term they have already done 90K miles and the bore etc is not exactly factory fresh.

So bought some Wossner 9.5:1 82.5mm pistons. These are the same as what Prawn uses in his car and that's currently making over 500bhp so they can't be all that bad. At least until they wear out

With this size piston capacity increases from 1780cc to 1850cc so another 70cc capacity which all helps.

Found a place to do the rebore work I thought. Dropped the block and pistons off last Monday and was hoping to pick it up last Friday. Rang on Thursday last week and told that machinist had been busy and had not had time to do the work. He was not going to be in this week so work wouldn't be done till next week at the earliest.

Slightly annoyed as I could do with putting the engine back together . Anyway rang on Friday just to check something and got transferred to the main office. I am now told that the place I took the engine too which is part of a larger group of companies is being closed down???.

They are still going to honor the work but I am not entirely sure I am happy with that, however I can't find anybody else locally who I think could do a better job than them.

So hopefully awaiting to get the block back next week sometime so I can start rebuilding the engine.

Head is all built up, ready to go on. Rosten uprated springs, new exhaust valve guides, supertech Inconel exhaust valves.

Did a very small amount of porting just cleaning up some of the rough casing marks at the back of the valves and removing a bit here and there that was obviously in the way.

Wrapped the manifold and down pipe to try and reduce the underbonnet temps a bit.

Filled the engine mounts with liquid polyeurethane. Went for the slightly softer 60 shore stuff. Not completely solid it allows a very small amount of movement.

Bought a tool as well so I could get the crank bolt undone. Jeez that's tight. I really would hate to try and tighten or undo an ARP item.

Bought one of the diamond coated washers as used on the 2.0 TFSI engines for when I put it back together.

C

Cornish John

Guest

Well a day I was wondering if I would ever see. The engine back in one piece with the gearbox and ready to put back in the car. I

Unfortunately the weather looks to be really poor tomorrow so probably start putting it back in Sunday.

A few pictures of the build.

IE H beam rifled drilled rods

Wossner 82.5mm pistons

Bosch 1000cc injectors

Manifold doing a mummy impression.

Made up my own coolant and oil lines. Braided stainless lines with PTFE inners from Torques. Bit more heat protection from some high temperature sleeving.

Bit of heat shielding to try and keep the coolant and oil drain a little less toasty.

Oil drain was made up using a few bits I already had. A spare oil drain pipe for a B8 3.0 TDI , A piece of 20mm conduit and the original oil drain pipe. Welded it all up and gave it a coat of paint. Have wrapped it in exhaust heat wrap so hopefully it should be OK.

New air filter arrived today. Gone for a K & N item RG-1002RD , Intake will be 4" down to 3" at the turbo intake.

Unfortunately the weather looks to be really poor tomorrow so probably start putting it back in Sunday.

A few pictures of the build.

IE H beam rifled drilled rods

Wossner 82.5mm pistons

Bosch 1000cc injectors

Manifold doing a mummy impression.

Made up my own coolant and oil lines. Braided stainless lines with PTFE inners from Torques. Bit more heat protection from some high temperature sleeving.

Bit of heat shielding to try and keep the coolant and oil drain a little less toasty.

Oil drain was made up using a few bits I already had. A spare oil drain pipe for a B8 3.0 TDI , A piece of 20mm conduit and the original oil drain pipe. Welded it all up and gave it a coat of paint. Have wrapped it in exhaust heat wrap so hopefully it should be OK.

New air filter arrived today. Gone for a K & N item RG-1002RD , Intake will be 4" down to 3" at the turbo intake.

She's alive !!!.

Just seem to have 1 small issue with the coolant after run pump not working. But other than that it's running and idling fine with no fault codes, noises or issues.

Just seem to have 1 small issue with the coolant after run pump not working. But other than that it's running and idling fine with no fault codes, noises or issues.

Found the issue with the after run coolant pump. Tapped the body of the pump with a spanner and it burst into life. looks like the brushes may have lost tension . Might invest in a new one, you can get a Bosch item for around £50.

Got the car all back together and took it for a spin. Surprised the handbrake came straight off with no issues, car has been sitting on the drive on axle stands for many weeks now. Brakes were pretty rusty as well although they have cleared up ok.

The poly filled engine mounts are definitely noticeable at idle. There is a bit of a buzz throughout the car at idle. Fine when driving. The clutch started off fine but when it bedded in a bit it became more grippy so I stalled it twice at junctions. It's not as bad as I thought it might be.When I get used to it should be fine.

Have a boost leak somewhere that I need to find. Had a very similar noise on my Passat when I fitted an intercooler high pitched farting noise when the turbo comes on boost.

4 inch intake pipe tapering to 3 inch at the turbo. No MAF to get in the way. Will be putting some shielding around the filter so it isn't pulling in hot air from the rad. If you look at the calculated correction values for power on a dyno with a 10 degree increase it's worth near enough 10bhp at 450bhp level.

http://www.bigdynodatabase.com/DynoCF.php

Plug in 400Lb/ft 450bhp 20 degrees c and 1000mb on the SAE standard and you get 391Lb/ft and 440 bhp change the temp to 30 degrees C and you now get 399Lb/ft and 449 Bhp. The heated air off the back of the rad is probably going to be more than 10 degrees warmer than ambient.

Oil catch tank breather and dump valve will probably get changed around. As will the pipe across the top of the engine. Just recycling a few bits , set up for the moment so I can drive it.

Tried to keep a bit of a tunnel free for air from the rad to move through the engine bay, may divert some of the flow to the back of the engine to cool the wastegate and manifiold.

Added some ally sheeting here and there to try and minimise the heating effects of a turbo. Hopefully heat wrap has finished smoking now .

Got the car all back together and took it for a spin. Surprised the handbrake came straight off with no issues, car has been sitting on the drive on axle stands for many weeks now. Brakes were pretty rusty as well although they have cleared up ok.

The poly filled engine mounts are definitely noticeable at idle. There is a bit of a buzz throughout the car at idle. Fine when driving. The clutch started off fine but when it bedded in a bit it became more grippy so I stalled it twice at junctions. It's not as bad as I thought it might be.When I get used to it should be fine.

Have a boost leak somewhere that I need to find. Had a very similar noise on my Passat when I fitted an intercooler high pitched farting noise when the turbo comes on boost.

4 inch intake pipe tapering to 3 inch at the turbo. No MAF to get in the way. Will be putting some shielding around the filter so it isn't pulling in hot air from the rad. If you look at the calculated correction values for power on a dyno with a 10 degree increase it's worth near enough 10bhp at 450bhp level.

http://www.bigdynodatabase.com/DynoCF.php

Plug in 400Lb/ft 450bhp 20 degrees c and 1000mb on the SAE standard and you get 391Lb/ft and 440 bhp change the temp to 30 degrees C and you now get 399Lb/ft and 449 Bhp. The heated air off the back of the rad is probably going to be more than 10 degrees warmer than ambient.

Oil catch tank breather and dump valve will probably get changed around. As will the pipe across the top of the engine. Just recycling a few bits , set up for the moment so I can drive it.

Tried to keep a bit of a tunnel free for air from the rad to move through the engine bay, may divert some of the flow to the back of the engine to cool the wastegate and manifiold.

Added some ally sheeting here and there to try and minimise the heating effects of a turbo. Hopefully heat wrap has finished smoking now .

Having some fun today putting some miles on the car running it in. Still haven't located the boost leak yet.

When driving it was looking at the boost gauge and the ignitron trying to see what the wastegate was opening at. It didn't seem to be opening to limit the boost, I was expecting something between 1 and 1.4 bar of boost. Just before I set off back home I thought I would run it upto 6K and see what it was doing.

I had omitted to connect the wastegate up to the boost connection. Car accelerated at a ridiculous rate and I figured that something was not quite right. 2.4bar of boost will give you some decent acceleration.

After getting the car home I had a look around and connected the bottom port up to the boost port.

Done another 40 miles today with a more sedate 1.2 bar of boost peak, very impressed with the way it drives. Will change the oil and filter tomorrow and hopefully get some more miles on the car.

When driving it was looking at the boost gauge and the ignitron trying to see what the wastegate was opening at. It didn't seem to be opening to limit the boost, I was expecting something between 1 and 1.4 bar of boost. Just before I set off back home I thought I would run it upto 6K and see what it was doing.

I had omitted to connect the wastegate up to the boost connection. Car accelerated at a ridiculous rate and I figured that something was not quite right. 2.4bar of boost will give you some decent acceleration.

After getting the car home I had a look around and connected the bottom port up to the boost port.

Done another 40 miles today with a more sedate 1.2 bar of boost peak, very impressed with the way it drives. Will change the oil and filter tomorrow and hopefully get some more miles on the car.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Why are you running anything other than actuator pressure while running in and sorting initial fuelling?

<tuffty/>

<tuffty/>

It was supposed to be running on actuator pressure. I had neglected to connect the boost connection to the bottom port on the actuator. The wastegate has a 14lb spring. I am surprised that the exhaust pressure didn't open the wastegate and limit the boost.

With the bottom port on the wastegate connected to the boost pressure side of the turbo it doesn't make any more than 1.2 bar of boost. Which seems a reasonable amount of boost to run the car in.

With the bottom port on the wastegate connected to the boost pressure side of the turbo it doesn't make any more than 1.2 bar of boost. Which seems a reasonable amount of boost to run the car in.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I would unroute the n75 in ignitron... It will run on pure actuator pressure than and as Brian said you want to set a limp mode boost limit while you are running in...With the bottom port on the wastegate connected to the boost pressure side of the turbo it doesn't make any more than 1.2 bar of boost.

Once your VE map is good (shouldn't really be driving full throttle yet until trims are in a decent place) then you can start looking at adding boost back in

<tuffty/>

I will look into updating the software/firmware to the latest level. The N75 is unrouted. The trims looks reasonable the STFT are around +5% or less most of the time.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Glad to see it's up and running and going well Karl!

Odd that you're getting 1.2 bar of boost if the N75 is unrouted though. That's a fairly strong spring too.

Look forward to seeing how this progresses.

Will it be going on the dyno for final mapping? Where abouts?

Odd that you're getting 1.2 bar of boost if the N75 is unrouted though. That's a fairly strong spring too.

Look forward to seeing how this progresses.

Will it be going on the dyno for final mapping? Where abouts?

The wastegate is a 14PSI Gen 4 turbosmart item. It has two 7Lb springs, I did ask Bill about removing one of the springs and he said it was fine with running the 2 springs. It does seem to work Ok actually connecting the wastegate, now limiting boost to a flat 1.1 to 1.2 bar maximum.

Oil and filter change completed. Spent some time looking for my boost leak. Pressure tested all the intake hoses and found one very small leak. Got the wife to rev the car whilst I poked around under the bonnet looking for the whistle. Then had a light bulb moment and retired to the computer.

First turbo I have owned with a ported shroud. Listened to a few dyno videos of these turbos in action and sure enough they have the same whistle.

Upgraded the firmware on the ECU and setup a boost limit of 1.3 bar. Also defined a soft rev limit of 6000 rpm to stop myself from getting carried away.

Updated the VE map and reset the trims as per the excellent Tuning checklist document.

First turbo I have owned with a ported shroud. Listened to a few dyno videos of these turbos in action and sure enough they have the same whistle.

Upgraded the firmware on the ECU and setup a boost limit of 1.3 bar. Also defined a soft rev limit of 6000 rpm to stop myself from getting carried away.

Updated the VE map and reset the trims as per the excellent Tuning checklist document.

Few more jobs done whilst I add some miles on running the engine in.

Sorted the one headlight that has been bugging me for a while, I have tried polishing it twice but withing a few weeks it starts going dull again. So bought a secondhand good headlight off Fleabay. A stripped headlight shell with a very good lens on from the TTshop. Dropped it in the oven and popped the front off then swapped it over with my modified headlight.

New and old together.

Changed out the after run pump as it looks like it's gone intermittent. Quick enough job to do, just drill rivets on original bracket and re rivet on new pump. Didn't even lose any coolant as you can lift the pump higher then the coolant bottle .

Made up a shield on the air filter to try and keep the hot air in the bay away from the intake, opened up the OE air feed hole in the wing a bit.

And the brake upgrade arrived today courtesy of Herpes couriers. Some second hand very light use Pagid RS29 pads. These are a silly price new but are one of the best pads for track day use. These have had very little use and were near enough half price, look in pretty good condition.

Sorted the one headlight that has been bugging me for a while, I have tried polishing it twice but withing a few weeks it starts going dull again. So bought a secondhand good headlight off Fleabay. A stripped headlight shell with a very good lens on from the TTshop. Dropped it in the oven and popped the front off then swapped it over with my modified headlight.

New and old together.

Changed out the after run pump as it looks like it's gone intermittent. Quick enough job to do, just drill rivets on original bracket and re rivet on new pump. Didn't even lose any coolant as you can lift the pump higher then the coolant bottle .

Made up a shield on the air filter to try and keep the hot air in the bay away from the intake, opened up the OE air feed hole in the wing a bit.

And the brake upgrade arrived today courtesy of Herpes couriers. Some second hand very light use Pagid RS29 pads. These are a silly price new but are one of the best pads for track day use. These have had very little use and were near enough half price, look in pretty good condition.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

They look like they've hardly been used at all Karl!

You'll enjoy those. Always a pad I've liked running.

You'll enjoy those. Always a pad I've liked running.

Hotelaltfel

Registered User

Awesome build mate. I have a concern right now, i am stock displacement , wiseco pistons, should be a problem? I am after 380-400hp because fwd. Turbo choice is g25-550 0.49ar or 0.72

Few more bits and pieces on the car whilst I continue to run it in and get some miles on the clock.

Checking the compressor wheel on the turbo for any play and make sure it's spinning nice and freely. Easy to do with a 4 inch intake just drop off the air filter and put your arm down the intake. All was well with the turbo.

I moved the bracket mounting for the Ignitron screen to the bottom of the stereo mounting hole so I can alter the stereo controls easily just by dropping the screen down. Also now exposes the top half of the centre vents so I can get some fresh air.

Lost another 5Kg off the weight by removing the side impact reinforcement bars and plates. I have a rear roll cage so they are a little redundant.

Revamped the boost dump and catch can piping, It looks a lot more tidy now with less joins and clips. Ditched the curly BAM specific PCV pipe on the rocker cover and bought some stuff off Fleabay . Fits really well. Catch can is virtually empty after nearly 300 miles. Just 1-2mm of oil in the bottom. Removed the oil filler cap adaptor as well to save a small amount of weight.

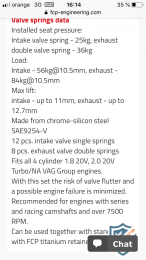

Had a slight issue doing some logging just to see what the engine was doing. Ignitron is great for catching stuff as it logs everything. Too busy looking at the screen in the centre rather than concentrating and went from 2nd to 1st instead of 2nd to 3rd. Just over 8600 RPM . [smiley=bigcry.gif]

Fortunately all appears to be OK done another 50 miles since with no issues. Timing hasn't slipped at all which I thought might be an issue. Must pay more attention.

Checking the compressor wheel on the turbo for any play and make sure it's spinning nice and freely. Easy to do with a 4 inch intake just drop off the air filter and put your arm down the intake. All was well with the turbo.

I moved the bracket mounting for the Ignitron screen to the bottom of the stereo mounting hole so I can alter the stereo controls easily just by dropping the screen down. Also now exposes the top half of the centre vents so I can get some fresh air.

Lost another 5Kg off the weight by removing the side impact reinforcement bars and plates. I have a rear roll cage so they are a little redundant.

Revamped the boost dump and catch can piping, It looks a lot more tidy now with less joins and clips. Ditched the curly BAM specific PCV pipe on the rocker cover and bought some stuff off Fleabay . Fits really well. Catch can is virtually empty after nearly 300 miles. Just 1-2mm of oil in the bottom. Removed the oil filler cap adaptor as well to save a small amount of weight.

Had a slight issue doing some logging just to see what the engine was doing. Ignitron is great for catching stuff as it logs everything. Too busy looking at the screen in the centre rather than concentrating and went from 2nd to 1st instead of 2nd to 3rd. Just over 8600 RPM . [smiley=bigcry.gif]

Fortunately all appears to be OK done another 50 miles since with no issues. Timing hasn't slipped at all which I thought might be an issue. Must pay more attention.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

****** hell Karl! Be careful on those gear changes man!

So so easy to buzz the engine by grabbing 1st.

Have you got a billet timing gear or pinned the crank at all?

When's it going on the dyno? Look forward to seeing what it does!

So so easy to buzz the engine by grabbing 1st.

Have you got a billet timing gear or pinned the crank at all?

When's it going on the dyno? Look forward to seeing what it does!

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Awesome build mate. I have a concern right now, i am stock displacement , wiseco pistons, should be a problem? I am after 380-400hp because fwd. Turbo choice is g25-550 0.49ar or 0.72

@Hotelaltfel I'd go with the 0.72. The 0.72 550 spools almost like a stock K04 anyway so traction will already be an issue FWD with so much early torque available, and I think you need all the flow you can get higher up.

Hotelaltfel

Registered User

@Hotelaltfel I'd go with the 0.72. The 0.72 550 spools almost like a stock K04 anyway so traction will already be an issue FWD with so much early torque available, and I think you need all the flow you can get higher up.

Yeah but that is on 1.9, would be a limit for 0.49A/R at 400hp? I dont think so. I want my car to be torquey

Will deffo try and avoid doing that again. I don't need to be looking at the Ignitron screen whilst driving as it logs everything and I can review it all easily afterwards so will hopefully not happen again. No fancy bits on the bottom sprocket, new OE bolt and a 2.0 TFSI diamond washer. The Hall 1 timing for the cam sensor seems the same as before and there are no extra noises from the engine.

Won't be going near a dyno for a while off to LA for 3 weeks. Was hoping to get the TT all sorted before now but all the messing around with the block and pistons delayed that.

Many years ago built a robot and did robot wars for a few years. My daughter Sarah is part of a team that competed at Battlebots last year and they are going back there again. They did really well last year making it to the last eight, and were unlucky to go out. So going with them this year to watch and help out a bit.

https://www.facebook.com/MonsoonBattlebot/

A fight they lost last year shows you what these things are like, Monsoon was actually still mobile at the end of this fight, Tom just played dead figuring they had enough damage. This was a qualifying fight for the last 16 which they made it into. The armor on the robot is 6mm Hardox plate. Yet it still gets ripped apart. They use Hardox for things like digger buckets and construction equipment that is subjected to a lot of abrasion.

Won't be going near a dyno for a while off to LA for 3 weeks. Was hoping to get the TT all sorted before now but all the messing around with the block and pistons delayed that.

Many years ago built a robot and did robot wars for a few years. My daughter Sarah is part of a team that competed at Battlebots last year and they are going back there again. They did really well last year making it to the last eight, and were unlucky to go out. So going with them this year to watch and help out a bit.

https://www.facebook.com/MonsoonBattlebot/

A fight they lost last year shows you what these things are like, Monsoon was actually still mobile at the end of this fight, Tom just played dead figuring they had enough damage. This was a qualifying fight for the last 16 which they made it into. The armor on the robot is 6mm Hardox plate. Yet it still gets ripped apart. They use Hardox for things like digger buckets and construction equipment that is subjected to a lot of abrasion.

- Joined

- Aug 1, 2015

- Messages

- 54

- Reaction score

- 25

- Points

- 18

You should be fine, but do not do it too often  .

.

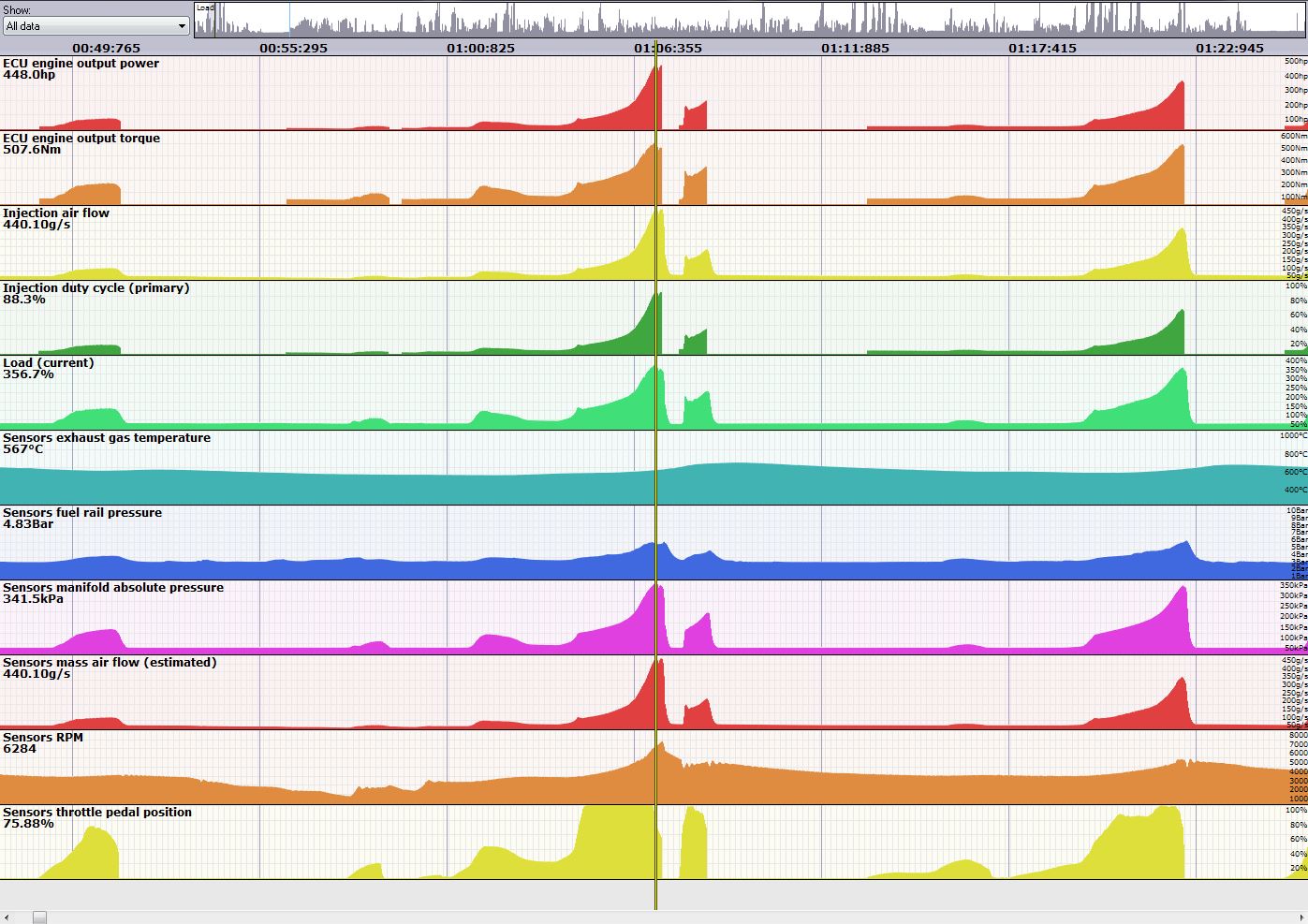

You are not alone with this bad habit btw , here is an autolog which shows a similar situation.

, here is an autolog which shows a similar situation.

In this case the cam timing got a few degrees off (meanwhile and after over revving), supertech inconel exhaust valves hit pistons but did not bend, so the car ran fine afterwards this incident... Valves have been replaced. Stock head apart from the supertech inconel valves.

You are not alone with this bad habit btw

In this case the cam timing got a few degrees off (meanwhile and after over revving), supertech inconel exhaust valves hit pistons but did not bend, so the car ran fine afterwards this incident... Valves have been replaced. Stock head apart from the supertech inconel valves.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Yeah but that is on 1.9, would be a limit for 0.49A/R at 400hp? I dont think so. I want my car to be torquey

You're looking to cap power as it's FWD, but at the same time create a torque monster with mega early spool, which really won't work well being FWD!

The 0.72 spools up PLENTY early enough even on a 660 to break traction at very low RPM.

The whole benefit of going to something like this is to make decent use of a better frame size. I think a 0.49 housing will kill it up top myself and give you bags of low down torque you can't use.

Hotelaltfel

Registered User

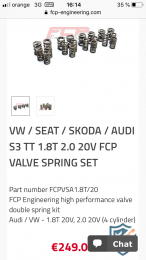

Thanks Prawn! Did anybody hear something about fcp valve springs?You're looking to cap power as it's FWD, but at the same time create a torque monster with mega early spool, which really won't work well being FWD!

The 0.72 spools up PLENTY early enough even on a 660 to break traction at very low RPM.

The whole benefit of going to something like this is to make decent use of a better frame size. I think a 0.49 housing will kill it up top myself and give you bags of low down torque you can't use.

Attachments

Wow nearly 10K RPM. I have Supertech Inconel valves and Rosten Uprated springs so hopefully the springs will have kept the valves away from the pistons.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Rather than hope I'd probably check... when I buzzed mine the engine performed fine... the only indication something was up was from the DMF's shim plate as it rubbed the back to the engine from distorting at high revs...Wow nearly 10K RPM. I have Supertech Inconel valves and Rosten Uprated springs so hopefully the springs will have kept the valves away from the pistons.

Granted I also had a correlation error but that didn't appear straight away...

OE crank pulley is made of cheese... mechanical loading from a gear change like that was enough to shear two tool steels pins on mine

<tuffty/>

Hotelaltfel

Registered User

You're looking to cap power as it's FWD, but at the same time create a torque monster with mega early spool, which really won't work well being FWD!

The 0.72 spools up PLENTY early enough even on a 660 to break traction at very low RPM.

The whole benefit of going to something like this is to make decent use of a better frame size. I think a 0.49 housing will kill it up top myself and give you bags of low down torque you can't use.

As speaking about torque, should AGN/ADR cams help for a better torque hold ? Not looking for power increase.

Are they plug and play ? Same springs required?

Mark Bridges

Registered User

Similar threads

- Replies

- 1

- Views

- 2K