You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Yeah... already did... made no odds to the DS1.11's... in other news though the cleanup of the rotors and pads has made all the difference... the brakes are loads better and starting to have confidence in them again... still not as 'pull yer face off' bitey as the DS1.11's but comparable enough to give me much more confidence in them... and they are now creating dust on the wheels so clearly workingWhen you’ve got back round to sorting out your wheels , try this if you haven’t already ?

View attachment 148864

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

So today I did some more car stuff...

Seeing as I am now running a VE based fuelling strategy it was time for the MAF to go... so I made a thing from 4" alloy tube...

...and of course painted it

Last time this will be seen on the car

...and replaced it with the MAF 'delete' tube.... oooor did I!!!

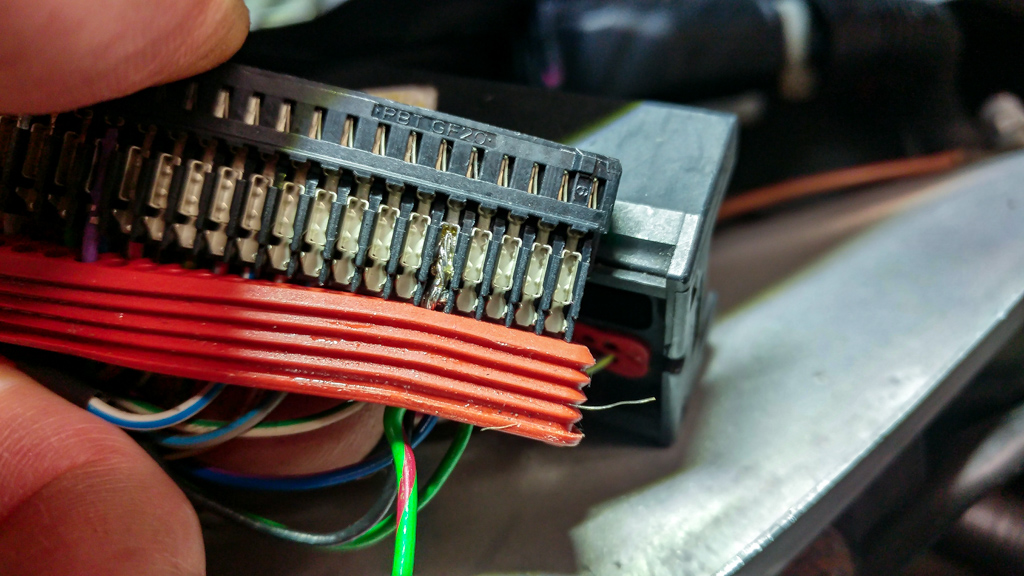

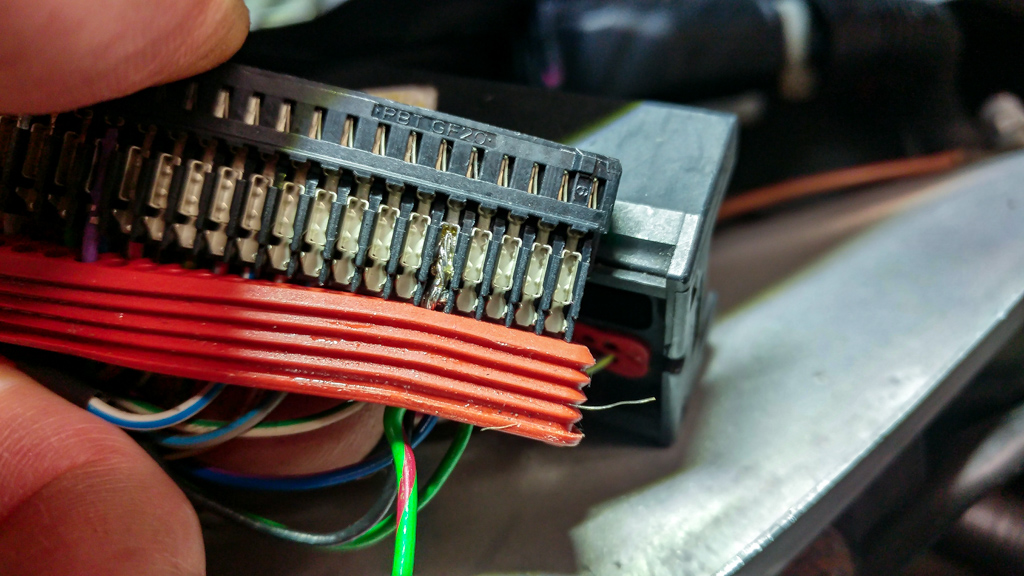

Next thing was to pin the ECU to use an input for the oil pressure sensor... pulled the ECU plug apart and removed the terminal at the ECU pin number I wanted to use...

...soldered in the wire to it...

and all back together again...

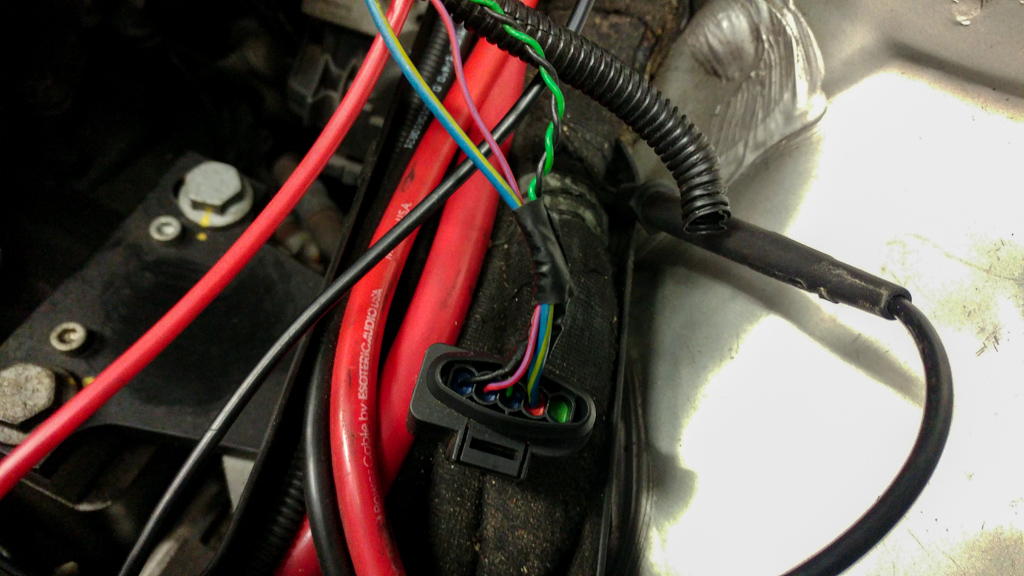

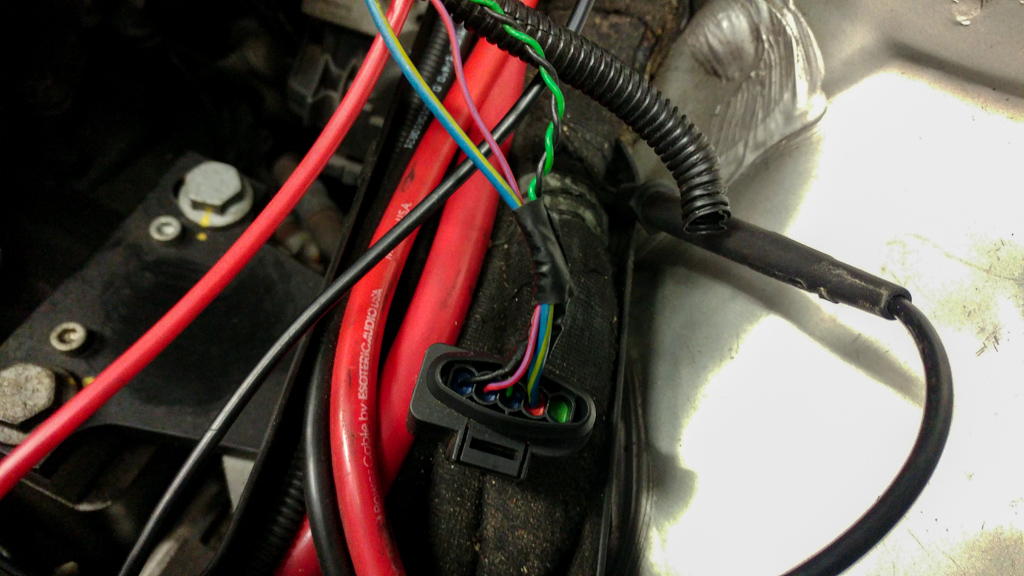

On to the MAF sensor plug... as the ECU is configurable I can use the now redundant MAF input as a sensor input and this will be for the fuel pressure sensor...

As the MAF plug already has sensor ground and +5v so picked these up there for both sensors meaning I only needed to run a sensor signal wire from the ECU for the oil pressure, use the MAF sensor signal wire for the fuel pressure and share the gnd/+5v

Tidied up all the wiring...

I used part of the original oil pressure/temp wiring from the FIS as the FIS will be coming out soon and run the fuel pressure sensor wiring through the injector loom tying it out the way for now until I can fit the fuel rail..

Tested the wiring by connecting the one sensor I have and used the mitivac to give it 2 bar at the sensor which was dutifully reported back by the ECU software as 2bar too... I have removed the mapping for now as it will go into limp mode without the sensor being connected and I need to fit the fuel rail first plus I am waiting on a replacement sensor for the oil pressure.

Once they are added of course they will be logged with the rest of the data the ECU logs and can be used to trip limp mode if fuel or oil pressure drops below the configurable levels... I love this thing!

<tuffty/>

Seeing as I am now running a VE based fuelling strategy it was time for the MAF to go... so I made a thing from 4" alloy tube...

...and of course painted it

Last time this will be seen on the car

...and replaced it with the MAF 'delete' tube.... oooor did I!!!

Next thing was to pin the ECU to use an input for the oil pressure sensor... pulled the ECU plug apart and removed the terminal at the ECU pin number I wanted to use...

...soldered in the wire to it...

and all back together again...

On to the MAF sensor plug... as the ECU is configurable I can use the now redundant MAF input as a sensor input and this will be for the fuel pressure sensor...

As the MAF plug already has sensor ground and +5v so picked these up there for both sensors meaning I only needed to run a sensor signal wire from the ECU for the oil pressure, use the MAF sensor signal wire for the fuel pressure and share the gnd/+5v

Tidied up all the wiring...

I used part of the original oil pressure/temp wiring from the FIS as the FIS will be coming out soon and run the fuel pressure sensor wiring through the injector loom tying it out the way for now until I can fit the fuel rail..

Tested the wiring by connecting the one sensor I have and used the mitivac to give it 2 bar at the sensor which was dutifully reported back by the ECU software as 2bar too... I have removed the mapping for now as it will go into limp mode without the sensor being connected and I need to fit the fuel rail first plus I am waiting on a replacement sensor for the oil pressure.

Once they are added of course they will be logged with the rest of the data the ECU logs and can be used to trip limp mode if fuel or oil pressure drops below the configurable levels... I love this thing!

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

It still mostly is lol... the menu to change it to english is there though... took me a few minutes to find itNice!

Last time I checked it was mostly in Hungarian

He is currently translating the docs to english too but there is a somewhat awkward (ignitrons own words lol) google/microsoft translated one online

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Flashed a revised file into the ECU tonight... adaptions are coming along... LTFT's are down to around 10% now and cold start pretty much bob on...

Dug out and charged up the HPA controllers little android tablet to make sure what setting I was on... its not a fantastic thing tbh... the screen is not capacitive so needs a decent stab to make it work and the battery goes flat in no time at all but seeing as the IECU software shows Haldex status I thought it would be interesting to see what the settings actually did..

Here is a short and somewhat dodgy video of it... clearly I am better at stills than video but you get the idea

The IECU will log haldex engagement too so you can potentially see level of engagement in context of all the engine parameters too

<tuffty/>

Dug out and charged up the HPA controllers little android tablet to make sure what setting I was on... its not a fantastic thing tbh... the screen is not capacitive so needs a decent stab to make it work and the battery goes flat in no time at all but seeing as the IECU software shows Haldex status I thought it would be interesting to see what the settings actually did..

Here is a short and somewhat dodgy video of it... clearly I am better at stills than video but you get the idea

The IECU will log haldex engagement too so you can potentially see level of engagement in context of all the engine parameters too

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

is it possible to connect the HPA software up onto a different android device? some flashy RNSE navigation etc have android or can take a feed from another device - or is this setup and forget unless you want to change the setup, is this device essentially what they put into the Golf R and new S3?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Its a modded version of android to run in a 'kiosk' mode and load the app on start... I am sure it can be hacked of course but I did mention they should consider creating an app but at the time the fractured nature of Android OS makes it quite tricky to keep control of... this way they keep control although dunno what happens should the tablet pack up... which can happenis it possible to connect the HPA software up onto a different android device? some flashy RNSE navigation etc have android or can take a feed from another device - or is this setup and forget unless you want to change the setup, is this device essentially what they put into the Golf R and new S3?

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

so does your controller keep the last setting on the tablet or rely on the tablet in real time - to stop the controller going into some default mode? eg you put it into dynamic and then switch off the tablet?

I was reading up about some "unified motorsports" standard Haldex software flash which turns it essentially into a Blue+ controller

I was reading up about some "unified motorsports" standard Haldex software flash which turns it essentially into a Blue+ controller

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

so does your controller keep the last setting on the tablet or rely on the tablet in real time - to stop the controller going into some default mode? eg you put it into dynamic and then switch off the tablet?

I was reading up about some "unified motorsports" standard Haldex software flash which turns it essentially into a Blue+ controller

Its just a client... you push the setting to the controller and it remains there... set and forget essentially...

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Nope... the unit I bought was originally acquired from the launch batch and so was part of the deal... paid 350 for the whole thing new and unfitteddid you spend the extra $50 to show 0-60, 60-0 and 1/4 mile?

<tuffty/>

We need to talk about this !!!I was reading up about some "unified motorsports" standard Haldex software flash which turns it essentially into a Blue+ controller

Anymore info ???

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Not on this thread you don'tWe need to talk about this !!!

Anymore info ???

http://unitedmotorsport.net/products/haldex-software/?vehicleId=1449&productId=1491

...as its yank stuff they list it for the Mk4 R32 which is the same controller... prefer the HPA concept myself even if the tablet idea is a little flawed

http://forums.vwvortex.com/showthread.php?6947845-United-motorsport-performance-haldex-software

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Little update...

I have this to fit at the weekend now... assuming of course I worked out all the ends correctly... soon adds up on all the extra bits!!!

Tuning is going well too... VE table is mostly there... I have timing and stuff added and now boost! 1.2bar of it currently plus VVT is switched on...

EGT's are nice, little bit of fine tuning of the VE table top end and more boost on the way... the ECU will calculate hp and torque based on VE table and with the current state of my fuel trims its works out (very) roughly to be 430hp at 1.2bar boost... which is plausible... I won't know for sure until she gets on the dyno of course...

Be nice to add fuel rail pressure into the mix which will happen when the rail is fitted... I do need to replace the intank pump with something 'new'... its still on the original intank which while hasn't had as hard a life as most over the past 8 years with the inline doing all the heavy lifting its probably not got much life left so will get replaced with a DW65 in due course...

I may still have to upsize the lines from the factory 6mm ID to dash 6 which is 8mm ID... rather wait for that if thats the case as pricing up that little lot (AN-6 fittings and suitably resilient fuel hose) came as a bit of a shock so if it seems the lines are maxxed out then I will run less boost for now...

<tuffty/>

I have this to fit at the weekend now... assuming of course I worked out all the ends correctly... soon adds up on all the extra bits!!!

Tuning is going well too... VE table is mostly there... I have timing and stuff added and now boost! 1.2bar of it currently plus VVT is switched on...

EGT's are nice, little bit of fine tuning of the VE table top end and more boost on the way... the ECU will calculate hp and torque based on VE table and with the current state of my fuel trims its works out (very) roughly to be 430hp at 1.2bar boost... which is plausible... I won't know for sure until she gets on the dyno of course...

Be nice to add fuel rail pressure into the mix which will happen when the rail is fitted... I do need to replace the intank pump with something 'new'... its still on the original intank which while hasn't had as hard a life as most over the past 8 years with the inline doing all the heavy lifting its probably not got much life left so will get replaced with a DW65 in due course...

I may still have to upsize the lines from the factory 6mm ID to dash 6 which is 8mm ID... rather wait for that if thats the case as pricing up that little lot (AN-6 fittings and suitably resilient fuel hose) came as a bit of a shock so if it seems the lines are maxxed out then I will run less boost for now...

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Did a thing today....

Sadly I couldn't fit the fuel pressure sender as the 90 degree fitting was too much... I need a 45 degree one so will wait for that to turn up...

...not only that but I ended up having to cut some material off the rails brackets... it doesn't seem to like fitting AEB runners/bungs and I didn't want to use the supplied spacers to stand it off and use the unspacers...

Lastly I pulled out the FIS control... its a shame this has to go but the money will come in handy

As for mapping... I am now at 1.5 bar

...once the fuel pressure sender is in I can look at adding a bit more boost past the surge line and see how it goes from there

<tuffty/>

Sadly I couldn't fit the fuel pressure sender as the 90 degree fitting was too much... I need a 45 degree one so will wait for that to turn up...

...not only that but I ended up having to cut some material off the rails brackets... it doesn't seem to like fitting AEB runners/bungs and I didn't want to use the supplied spacers to stand it off and use the unspacers...

Lastly I pulled out the FIS control... its a shame this has to go but the money will come in handy

As for mapping... I am now at 1.5 bar

...once the fuel pressure sender is in I can look at adding a bit more boost past the surge line and see how it goes from there

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

blimey.. btw does your inlet manifold still have vacuum connectors to work the brakes servo etc - or do you have a different source?

http://www.audi-sport.net/xf/threads/my-minor-modding-thread.76389/page-44#post-1687439

All under the inlet dude out the way

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

Cool, something I can't quite get my head around with a turbo car and brake servos?!&_£# the inlet maybe is under negative vacuum or positive pressure but traditional power assisted brakes used the vacuum from the inlet, do turbo cars have a different servo?

I'm not mechanical enough to "get it". It's one of those science things the teacher explains away as "it just does!" When you ask how or why.

I'm not mechanical enough to "get it". It's one of those science things the teacher explains away as "it just does!" When you ask how or why.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Still have vacuum on idle and under cruise... as I lift off the throttle I see -0.7bar...Cool, something I can't quite get my head around with a turbo car and brake servos?!&_£# the inlet maybe is under negative vacuum or positive pressure but traditional power assisted brakes used the vacuum from the inlet, do turbo cars have a different servo?

I'm not mechanical enough to "get it". It's one of those science things the teacher explains away as "it just does!" When you ask how or why.

Its not ideal of course which is why TFSI's have a vacuum pump like dervs

<tuffty/>

- Joined

- Oct 2, 2015

- Messages

- 3,565

- Reaction score

- 770

- Points

- 113

So under boost with positive pressure does this mean the brakes are not powered? It's all just science, I still don't know how a tiny little hose sucking on a massive chunk of metal can push fluid down a pipe hard enough to stop a 2 tonne mass going 100mph.

There are 10 types of people, those who understand binary and those that don't.

There are 10 types of people, those who understand binary and those that don't.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

With all the logging I have been doing and the fragility of the 8L's glove box door I decided to add a USB port to make it easier to plug the laptop into the ECU...

Found a female to panel mount female USB lead and epoxy'd it to the underside of the glove box..

Cable tied it securely...

...job done

Happy with that and makes it a bit easier to plug in now

A while back I took my camber plates off after the near side bearing popped for the second time... I did say they wouldn't be going back on again but... an advert popped up on Facebook recently...

(more info here... https://yt-motorsport.eu/shop/adjustable-top-mount-camber-plate-vw-golf-mk4/)

These are made from alloy and more interestingly the bearing seems much more substantial than the Silver Projects one... this gave me an idea... so stripped mine and into the aquablast to clean up...

The YT Motorsport ones reference the spherical bearing they use so found some info on it...

In comparison the SP bearing measured 10mm vs 15mm for the bearing case and 14mm vs 21mm for the spherical insert... the GXSW16 bearing of the YT Motorsport pictured above is as you can see much bigger...

Looking at the SP bearing mount I think it could be modded or even remade to house this bearing... the overall diameter of the SP bearing is 30mm, the GXSW16 is only 1.5mm larger so easy enough to deal with... the inserts that come with the SP plates will need turning a little I think too but no big drama..

Next step will be to acquire a couple of the GXSW16 bearings and see what is needed to mod/make to house them.. and maybe I'll refit them if succesful

I have already eliminated to main cause of the bearing failure... this was the B8 dampers bottoming out from the Apex springs going soft over time... if I can make the bearing more substantial too then I would happily refit them

<tuffty/>

Found a female to panel mount female USB lead and epoxy'd it to the underside of the glove box..

Cable tied it securely...

...job done

Happy with that and makes it a bit easier to plug in now

A while back I took my camber plates off after the near side bearing popped for the second time... I did say they wouldn't be going back on again but... an advert popped up on Facebook recently...

(more info here... https://yt-motorsport.eu/shop/adjustable-top-mount-camber-plate-vw-golf-mk4/)

These are made from alloy and more interestingly the bearing seems much more substantial than the Silver Projects one... this gave me an idea... so stripped mine and into the aquablast to clean up...

The YT Motorsport ones reference the spherical bearing they use so found some info on it...

In comparison the SP bearing measured 10mm vs 15mm for the bearing case and 14mm vs 21mm for the spherical insert... the GXSW16 bearing of the YT Motorsport pictured above is as you can see much bigger...

Looking at the SP bearing mount I think it could be modded or even remade to house this bearing... the overall diameter of the SP bearing is 30mm, the GXSW16 is only 1.5mm larger so easy enough to deal with... the inserts that come with the SP plates will need turning a little I think too but no big drama..

Next step will be to acquire a couple of the GXSW16 bearings and see what is needed to mod/make to house them.. and maybe I'll refit them if succesful

I have already eliminated to main cause of the bearing failure... this was the B8 dampers bottoming out from the Apex springs going soft over time... if I can make the bearing more substantial too then I would happily refit them

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

So under boost with positive pressure does this mean the brakes are not powered? It's all just science, I still don't know how a tiny little hose sucking on a massive chunk of metal can push fluid down a pipe hard enough to stop a 2 tonne mass going 100mph.

There is a check valve so vacuum in the servo is retained and boost cannot get to the servo.... under braking the ECU automatically cuts the throttle plate so generates vacuum topping up what you use...

There are 10 types of people, those who understand binary and those that don't.

<tuffty/>

Silva bullet

Registered User

Wow mate what a build you got..

I can only dream at the moment and every moment for that lol

Your bullet looks clean as do your rstt's

I can only dream at the moment and every moment for that lol

Your bullet looks clean as do your rstt's

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

With the really cold weather I have had a chance to play with the worst thing abut tuning standalone ECU's... coldstart... I had got it working fine at the 0-5 degrees and up but with the temperatures being sub zero the cranking enrichment fell into another bunch of cells which turned out to be a little on the rich side so spent a couple of days playing with that...

Unfortunately you only really get one go a day at it as the coolant temps will rise and hold for hours after even a quick start... this took its toll on the battery and so I had to remove it and do a proper full charge..

Then of course the snow happened!!...

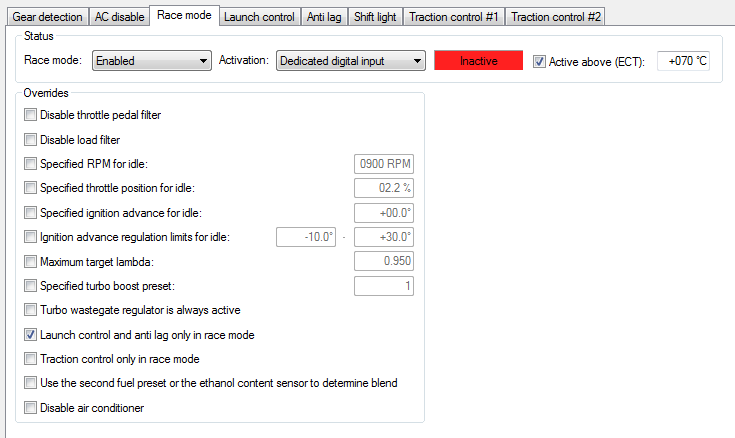

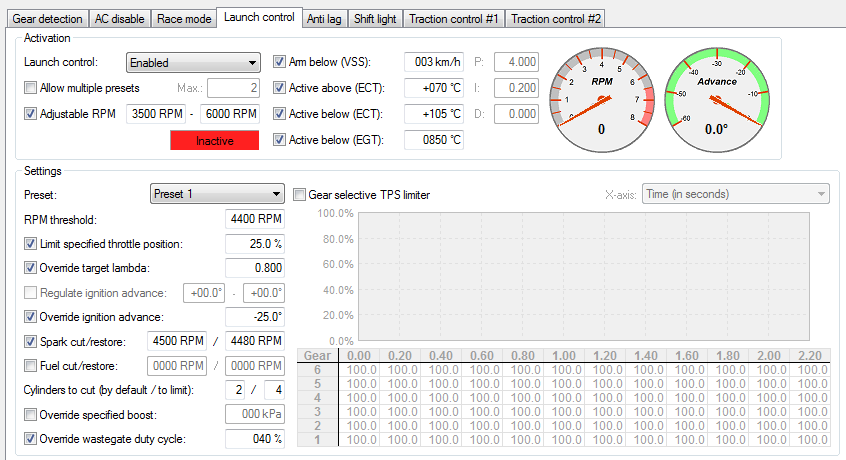

Not refitted the battery as yet but hopefully will over the weekend when the weather is due to improve... I have also turned on the 'toys' just for curiosity..

Race mode is currently turned on/off via the cruise stalk as cruise is not implemented in the firmware yet (but it will be )

)

Its not something I really plan to use often if at all but... the ECU has it so I thought I would try it...

If I can set my camera up I will take some vids of course

<tuffty/>

Unfortunately you only really get one go a day at it as the coolant temps will rise and hold for hours after even a quick start... this took its toll on the battery and so I had to remove it and do a proper full charge..

Then of course the snow happened!!...

Not refitted the battery as yet but hopefully will over the weekend when the weather is due to improve... I have also turned on the 'toys' just for curiosity..

Race mode is currently turned on/off via the cruise stalk as cruise is not implemented in the firmware yet (but it will be

Its not something I really plan to use often if at all but... the ECU has it so I thought I would try it...

If I can set my camera up I will take some vids of course

<tuffty/>

I love how easily you can just tick boxes to turn these features on

Unlike me7 coding....

change this chunk of code

Make sure this directs to that sectIon of code

Get a map definition file that can read alley stuff you need it to. Etc etc etc

Unlike me7 coding....

change this chunk of code

Make sure this directs to that sectIon of code

Get a map definition file that can read alley stuff you need it to. Etc etc etc

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

The new bearings for the camber plates turned up... next job is to make them fit

The new bearing is quite a bit beefier...

The ID of the old SP bearing is a little larger than the new M16 bearing... this means I will need to turn the strut nut and spacer down a little for them to fit...

Obviously the deeper bearing requires a deeper housing ....

...and the housing is a little larger diameter...

But it looks like I can turn a bit of the housing down to get it to sit a little lower...

Next task it to see what room I have to make the plate a little larger as while the difference is only 1.5mm in overall diameter (0.75mm either side) it will require the plate to be enlarged to allow it to be welded...

Will have a play when I am next at the unit...

<tuffty/>

The new bearing is quite a bit beefier...

The ID of the old SP bearing is a little larger than the new M16 bearing... this means I will need to turn the strut nut and spacer down a little for them to fit...

Obviously the deeper bearing requires a deeper housing ....

...and the housing is a little larger diameter...

But it looks like I can turn a bit of the housing down to get it to sit a little lower...

Next task it to see what room I have to make the plate a little larger as while the difference is only 1.5mm in overall diameter (0.75mm either side) it will require the plate to be enlarged to allow it to be welded...

Will have a play when I am next at the unit...

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

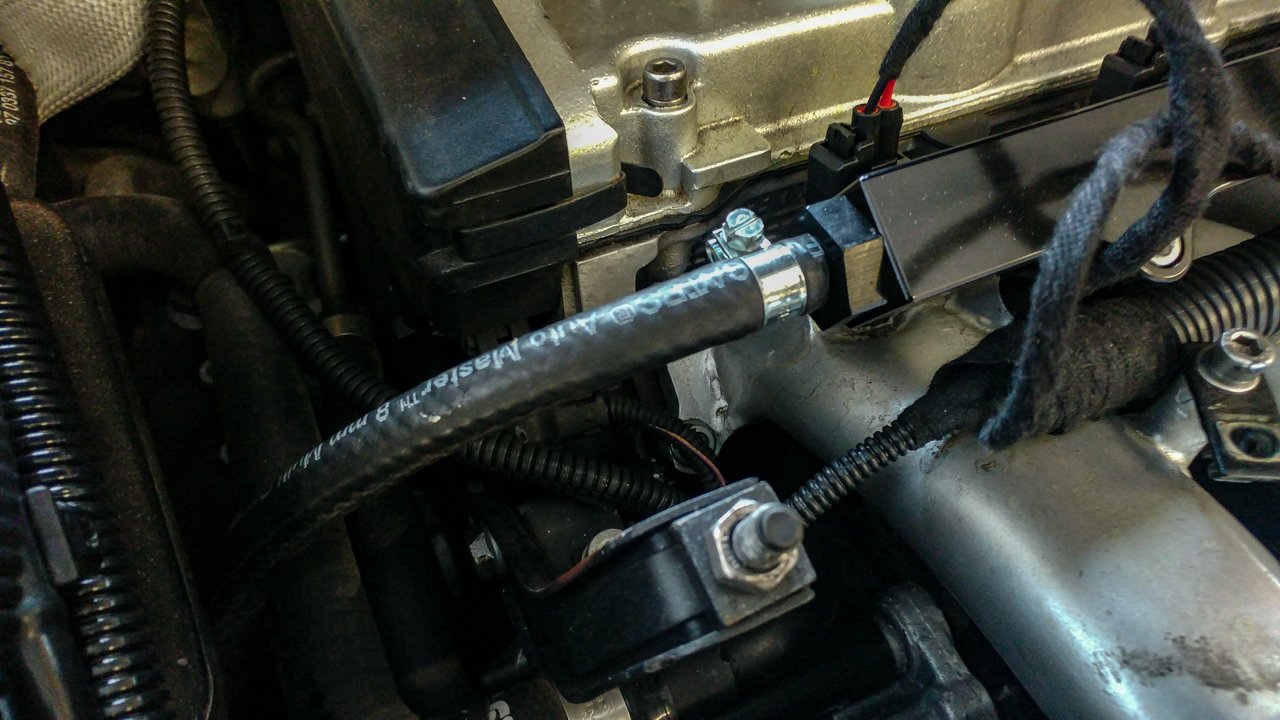

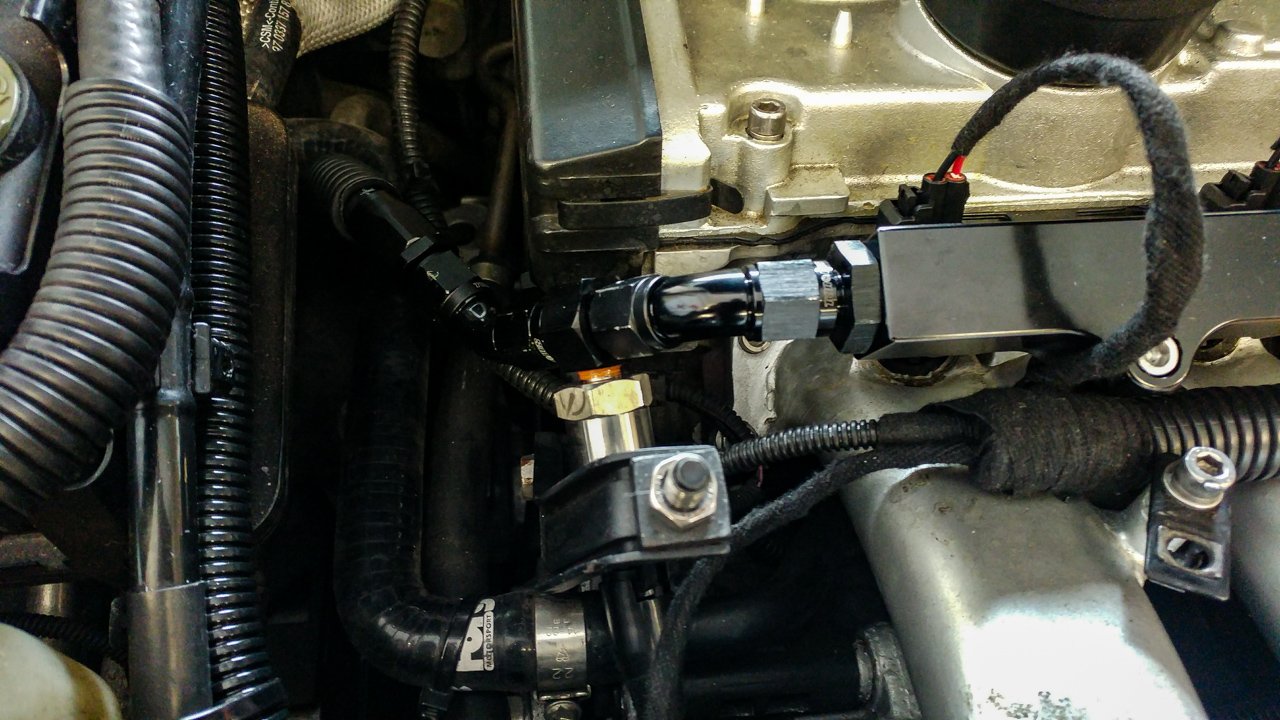

Today I did some more stuff...

Bit of a pain ordering fittings when you are not sure what you need but thankfully I can return them easily so eventually settled on the following...

Looks a bit complicated compared to the setup below but was the best way to get the sender in for the fuel pressure....

Had to do a bit of re-routing of the fuel feed but happy with the setup...

So now fuel pressure will be logged with all the other data...

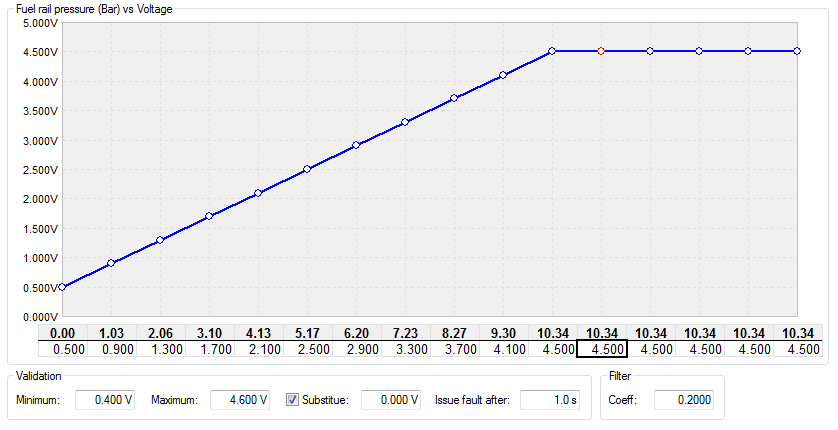

Nice to see it in there so exported the data to see if my fuel pressure is keeping up with everything... something didn't look quite right until I was reminded that the sender was actually a 150psi one not 10bar... when I asked for the data from Zada Tech to be able to calibrate the sender they told me 0.5v = 0 bar and 4.5v = 10bar so thought nothing more of it... the reality was that 150psi is 10.34bar so calibration was 3.4% out...

So recalibrated the sender map...

and ran the numbers...

Average deviation appears to be -0.096 bar now with the corrected pressure which is fine...

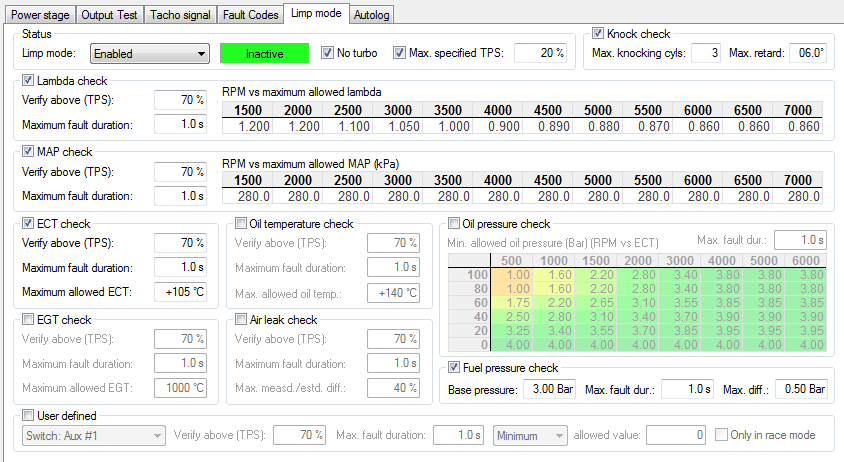

Now means I can add fuel pressure into limp mode so if pressure drops off it will trigger limp..

Latest file has more boost... I need to change back to my 18's from the winters first though as the car is squirrely enough as it is

<tuffty/>

Bit of a pain ordering fittings when you are not sure what you need but thankfully I can return them easily so eventually settled on the following...

Looks a bit complicated compared to the setup below but was the best way to get the sender in for the fuel pressure....

Had to do a bit of re-routing of the fuel feed but happy with the setup...

So now fuel pressure will be logged with all the other data...

Nice to see it in there so exported the data to see if my fuel pressure is keeping up with everything... something didn't look quite right until I was reminded that the sender was actually a 150psi one not 10bar... when I asked for the data from Zada Tech to be able to calibrate the sender they told me 0.5v = 0 bar and 4.5v = 10bar so thought nothing more of it... the reality was that 150psi is 10.34bar so calibration was 3.4% out...

So recalibrated the sender map...

and ran the numbers...

Average deviation appears to be -0.096 bar now with the corrected pressure which is fine...

Now means I can add fuel pressure into limp mode so if pressure drops off it will trigger limp..

Latest file has more boost... I need to change back to my 18's from the winters first though as the car is squirrely enough as it is

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Added a bit more boost and went to do some more logs... also played with the launch control which was a bit lacklustre on the first attempt...

Now generates about 1bar of boost at 4.5k rpm... which is nice

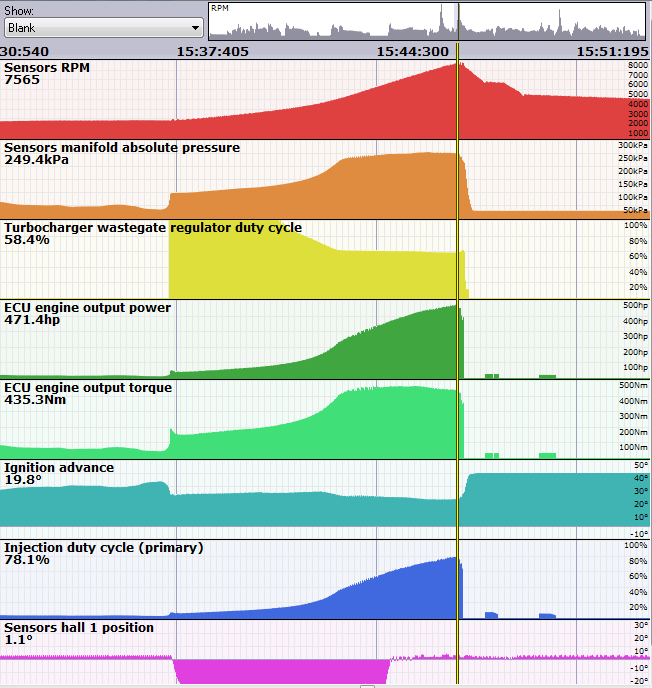

The logging is insane on this thing... the start of the 0-60 run... (note the time stamp)

...and at 96.6kmh which is 60mph...

... that I believe equates to 3.87 seconds....

Gear changes were not fast either... I hit the ignition cut of the rev limiter before I changed gear (despite the change light flashing away at me)

Notice ignition cut #1 bit is set at 1 but still not changed gear at this time...

This time is just as the clutch switch turns off and boost starts to build from me putting my foot down as I have changed to second gear... thats just over half a second which actually felt longer than it sounded lol but in reality about a second lost changing gear and getting back on it...

Not quite DSG huh...

Fuel pressure seems ok although it went a bit wobbly at high RPM then settled again...

Not entirely sure whats thats indicative off as lack of pressure normally shows a continual drop off on fuel pressure... however... I am now going to replace the intank with a DW65 as mine is still the original 17yr, 134k miles pump... will see if that makes any difference...

<tuffty/>

Now generates about 1bar of boost at 4.5k rpm... which is nice

The logging is insane on this thing... the start of the 0-60 run... (note the time stamp)

...and at 96.6kmh which is 60mph...

... that I believe equates to 3.87 seconds....

Gear changes were not fast either... I hit the ignition cut of the rev limiter before I changed gear (despite the change light flashing away at me)

Notice ignition cut #1 bit is set at 1 but still not changed gear at this time...

This time is just as the clutch switch turns off and boost starts to build from me putting my foot down as I have changed to second gear... thats just over half a second which actually felt longer than it sounded lol but in reality about a second lost changing gear and getting back on it...

Not quite DSG huh...

Fuel pressure seems ok although it went a bit wobbly at high RPM then settled again...

Not entirely sure whats thats indicative off as lack of pressure normally shows a continual drop off on fuel pressure... however... I am now going to replace the intank with a DW65 as mine is still the original 17yr, 134k miles pump... will see if that makes any difference...

<tuffty/>

Replaced the intank pump on the TT today with a DW65v . Pretty straight forward job, hardest thing I had to do was try and pull the original pipe off the pump. Warmed it up with an electric paint stripper in the end after getting rid of as much petrol as possible and it pulled straight off. Very impressive logging facilities with that ECU. I checked the fuel trims on mine the idle was -0.9% and the partial 3.0%,reset them by checking the fault codes, be interesting to see if the partial one comes down.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Aye... have replaced a few pumps now.... seems to be a standard job these days... was FWD cars not so long back and now the quattro pumps are dyingReplaced the intank pump on the TT today with a DW65v . Pretty straight forward job, hardest thing I had to do was try and pull the original pipe off the pump. Warmed it up with an electric paint stripper in the end after getting rid of as much petrol as possible and it pulled straight off. Very impressive logging facilities with that ECU. I checked the fuel trims on mine the idle was -0.9% and the partial 3.0%,reset them by checking the fault codes, be interesting to see if the partial one comes down.

Rather not have to replace the inline as well as thats done very little mileage comparatively but if it needs doing then it needs doing...

I love cars me

<tuffty/>

Sweet, sweet build and very informative!! Also very interesting to see how that ignitron ECU is capable of doing so many things! I've send them a message to ask if they can do the same for the 5-cylinder engines

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

So this mornings task was to fit this....

Hoping that would address the fuel pressure drop off I was experiencing and would then mean I could fine tune the map on the dyno...

However... this happened instead

Transfer box sh@t itself :/

And before you ask... no... I didn't launch it this time.... although the launch from a few weeks ago could well have been the final nail in the coffin...

Managed to nurse the car home... no idea what state it is under there as yet but... I have a low mileage LCR gearbox that I got a while back to convert into an AWD case and I have my reardiff/haldex that I refurbished... I just need to get a transfer box now and will do the full drive train refurb I had planned...

Just not today... or maybe for a month or so... who knows

Watch this space... but don't hold your breath

<tuffty/>

Hoping that would address the fuel pressure drop off I was experiencing and would then mean I could fine tune the map on the dyno...

However... this happened instead

Transfer box sh@t itself :/

And before you ask... no... I didn't launch it this time.... although the launch from a few weeks ago could well have been the final nail in the coffin...

Managed to nurse the car home... no idea what state it is under there as yet but... I have a low mileage LCR gearbox that I got a while back to convert into an AWD case and I have my reardiff/haldex that I refurbished... I just need to get a transfer box now and will do the full drive train refurb I had planned...

Just not today... or maybe for a month or so... who knows

Watch this space... but don't hold your breath

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

lol... drive train is fairly capable as long as its not too abused but its life span will be much much shorter non the less at this level of power...wow... didn't even know this could happen!

... and you said i'd probably break my turbo

I have already broken the prop shafts CV joint and there are plenty of people that have broken gearboxes and driveshafts too so with more than 130k on the gearbox it was inevitable really...

Just wasn't expecting it to go from a rolling start... ah well

<tuffty/>