Not another Nogaro!!!

- Thread starter IPG

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It runs out the back of the cluster, behind the stereo & glovebox then trough the firewall grommet. Down the loom wiring channel behind the headlight and about 10cm in of the wiring corrugated cover stuff.How did you route the wire for the boost pressure to the map sensor? Did you heat wrap aswell?

Just pulled the black cover back, stripped a 1cm section, tinned that part, tinned the tap, solder together, cover with the black corrugated wiring cover. Boost gauge on your cluster!

Ok cheers I've asked them to slider that wire and leave a length loose sticking out of cluster so all I need to do is run it to map sensor

Yeah I don't fancy soldering on pcb board if I can get the clocks back so I don't have to open them up again if he happy and if I didn't see your post on that sight I would of never new I'd have to do that

Yeah I don't fancy soldering on pcb board if I can get the clocks back so I don't have to open them up again if he happy and if I didn't see your post on that sight I would of never new I'd have to do that

yeah it would mean you would just have to tear it down to do one wire. lol

In the latest developments...

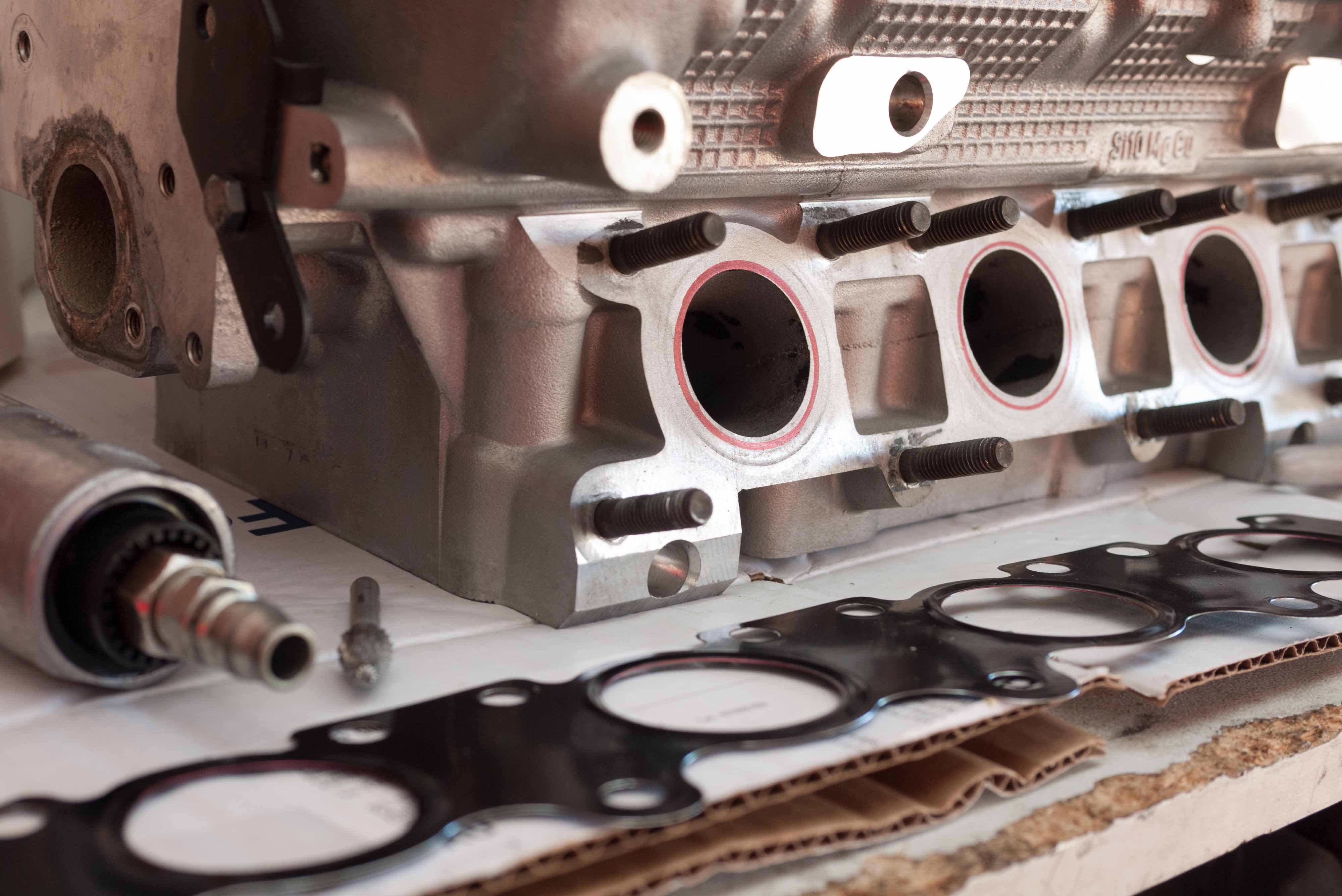

Off comes the SEM inlet manifold

Along with the turbo lines

Leaving the back of the engine nice and clean... sort of

Now to remove the rest of the hoses & electricals

THE dumbest bolt of them all! Why not just use a regular allen head bolt just like the rest of the bolts on that side!

Loom off and belts off!

Chemistry brain in me liked the elements stamped on the head - however i do not like the grease splurted from the driveshaft LOL

Weapon of choice!!!

Now i feel like working on it! Time to focus on the head...

Unbolting sequence on my phone

Pistons look like they're alright, no scoring on the bores, smooth to rotate by hand...

The oil pump - removed easily (as everyone says) and even this tensioner is pushed over with no effort

Taking a look closer ....

#1

#2

#3

#4

- Joined

- Nov 9, 2015

- Messages

- 1,060

- Reaction score

- 577

- Points

- 113

Great bit of stripping mate,not so good having a boomerang driving a piston I guess  is that due to your power?

is that due to your power?

No doubt you'll have it up and running in no time going by the way you ripped it down.

is that due to your power?

is that due to your power?No doubt you'll have it up and running in no time going by the way you ripped it down.

I've got a lot of porting that I wanna work on the head and turbo. I feel that's going to take the most of the time.

Seems like people down here go ahead and build their engines stronger but not many people seem to take the time to massage out the flow. I feel going that extra step will help make the most of everything.

Boomerang rod was probably due to NLS overload. Lol

Seems like people down here go ahead and build their engines stronger but not many people seem to take the time to massage out the flow. I feel going that extra step will help make the most of everything.

Boomerang rod was probably due to NLS overload. Lol

Yay i can count to 4

They don't look that bad?

Oh wait... sorry i take that back!

This explains where the metal chippings came from... 2 & 3 are proper rooted!

Bore #3 has a chunk missing from it's bottom too.

Is the block re usable???

Otherwise does anyone know if the AGN block (N/A 1.8) is suitable? There are a couple of places i know that has them...

Last edited:

View attachment 118925

Yay i can count to 4

They don't look that bad?

View attachment 118924

Oh wait... sorry i take that back!

View attachment 118927

This explains where the metal chippings came from... 2 & 3 are proper rooted!

View attachment 118928

Bore #3 has a chunk missing from it's bottom too.

View attachment 118926

View attachment 118929

Is the block re usable???

Otherwise does anyone know if the AGN block (N/A 1.8) is suitable? There are a couple of places i know that has them...

Cant you Re Sleeve the block ?

take mine

I know the AGN and turbo blocks are literally the same but the turbo blocks has about 3 has extra holes which are on the agn block pre moulded (they used the same die to make all the blocks), you just need a good engineer to drill it out. Otherwise in my personal opinion, rather search for an AGU block, you will have less hassles in the long run.

On a serious note i hope your blue devil is back on the road asap.

thanks for the info @Dohcwp

re sleeve? as in bore it out? kind of wanting to avoid going stroker...

right so the AGN need some extra holes drilled.... i have a couple guys interstate who have AMK blocks... might just wait and see what they say - this one might even still be salvagable but then i wanna err on the side of caution. The chip only goes up from the bottom of the bore about 1cm and it doesn't look like there are any cracks around it.

re sleeve? as in bore it out? kind of wanting to avoid going stroker...

right so the AGN need some extra holes drilled.... i have a couple guys interstate who have AMK blocks... might just wait and see what they say - this one might even still be salvagable but then i wanna err on the side of caution. The chip only goes up from the bottom of the bore about 1cm and it doesn't look like there are any cracks around it.

there should be engineering companies in aus that can change the cylinder sleeves out for new ones, I think they press out the old sleeves, kind of like how you press out a wheelbearing and then fit new ones.

heres an example from the net

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

Where on the bore is that notch? I'm pretty sure the piston doesn't use the entire stroke of the bore. Fit the straightest rod/piston you have and rotate the crank and see.

Sleeving isn't an option on a iron block that can be bored out, easier, cheaper.

Sleeving tends to be done on alloy blocks or blocks with open decks

Sleeving isn't an option on a iron block that can be bored out, easier, cheaper.

Sleeving tends to be done on alloy blocks or blocks with open decks

Where on the bore is that notch? I'm pretty sure the piston doesn't use the entire stroke of the bore. Fit the straightest rod/piston you have and rotate the crank and see.

Sleeving isn't an option on a iron block that can be bored out, easier, cheaper.

Sleeving tends to be done on alloy blocks or blocks with open decks

It's right at the bottom. Goes up about 1cm. Looks like the rod wanted to say hello to the block ... but just a tad roughly. Lol

I can see a mark on all cyclone era which I'm assuming are the ring's stop point... which is a good 1.5-2 inches away from the top of the triangle shaped chip

What do you reckon @superkarl ?

1.9litres? Hmmm...

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

It's right at the bottom. Goes up about 1cm. Looks like the rod wanted to say hello to the block ... but just a tad roughly. Lol

I can see a mark on all cyclone era which I'm assuming are the ring's stop point... which is a good 1.5-2 inches away from the top of the triangle shaped chip

What do you reckon @superkarl ?

1.9litres? Hmmm...

You don't ideally want the skirt hitting that mark. And it would have to be less than 1mm deep in order to bore out to 83mm

Sent from my iPhone using Tapatalk

- obtained the crank locking tool (apparently quite famous in Australia) and got the big breaker out and trusty rusted pole!!!

Removing this seal by using the smaller bolts to push it out

- oh joy! more broken stuff

- and more bent stuff!

- crank out... this is where you realise "is that how it all works!!!"

- better view of the ding in the block

- block off the engine stand and pushed onto a conveniently tall stool so that it rested on it as i took the bolts off. Ready to go in for an assessment...

- 1.8t crank down below, 2.0 FSI up top. Bit more chunky that one eh!?

Yip stroker it is by the looks of it!! AWESOME!! One of theee best mod I did I rate! Low down power is just so much better... I went with a 82.5mm bore( therefore I still have a choice to go over size 82.7mm if anything happens.. touch wood)with wossner stroker pistons.wouldn't recommend 83mm unless you intend tracking it

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

83mm is the most common, it's perfectly safe.

Your 82.5 bore in case of some bore damage is logical, but it would be more expensive to go 83 if you do as you'll need new pistons. As opposed to just a new block, which are peanuts.

Your 82.5 bore in case of some bore damage is logical, but it would be more expensive to go 83 if you do as you'll need new pistons. As opposed to just a new block, which are peanuts.

Yip stroker it is by the looks of it!! AWESOME!! One of theee best mod I did I rate! Low down power is just so much better... I went with a 82.5mm bore( therefore I still have a choice to go over size 82.7mm if anything happens.. touch wood)with wossner stroker pistons.wouldn't recommend 83mm unless you intend tracking it

Sent from my iPhone using Tapatalk

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

Btw I found my crank gear to have about 3 teeth missing when I opened everything up too. Sucks. At the time I didn't know where to get a replacement, I.E. being the best option. Luckily an ASN member rescued me

SamHendry

Registered User

- Joined

- Nov 10, 2014

- Messages

- 827

- Reaction score

- 165

- Points

- 43

Nice work Ian. Your making it look easy. I thought you were just going to rod and ring the engine but it looks like your not holding back on anything. Fair play dude.

What power/turbo were you running when rods got bent?

What turbo are you using for the rebuild engine?

Nice work. Things moving quick!

What power/turbo were you running when rods got bent?

What turbo are you using for the rebuild engine?

Nice work. Things moving quick!

yeah going stroker - i thought "look i'm going to bore it anyway.... i'm going to have to get new pistons because two of them are chipped" do i go 1.9T?

I asked old mate Gordie (he's got his silver S3 on here somewhere) if he knew someone with a 2.0L crank - turns out he had a spare. Got it at a good price plus borrowed the crank bolt locking tool. Nekminit stroker.

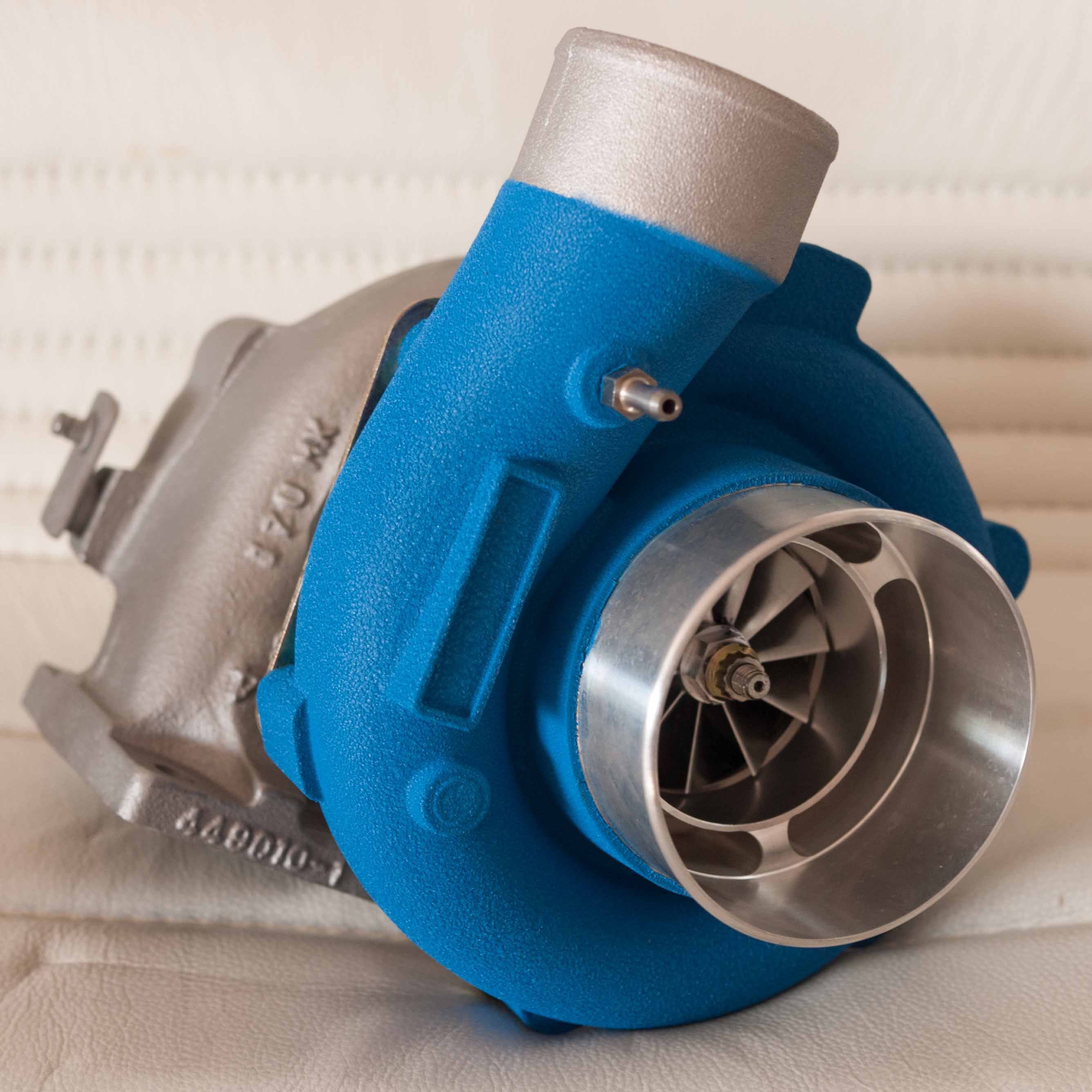

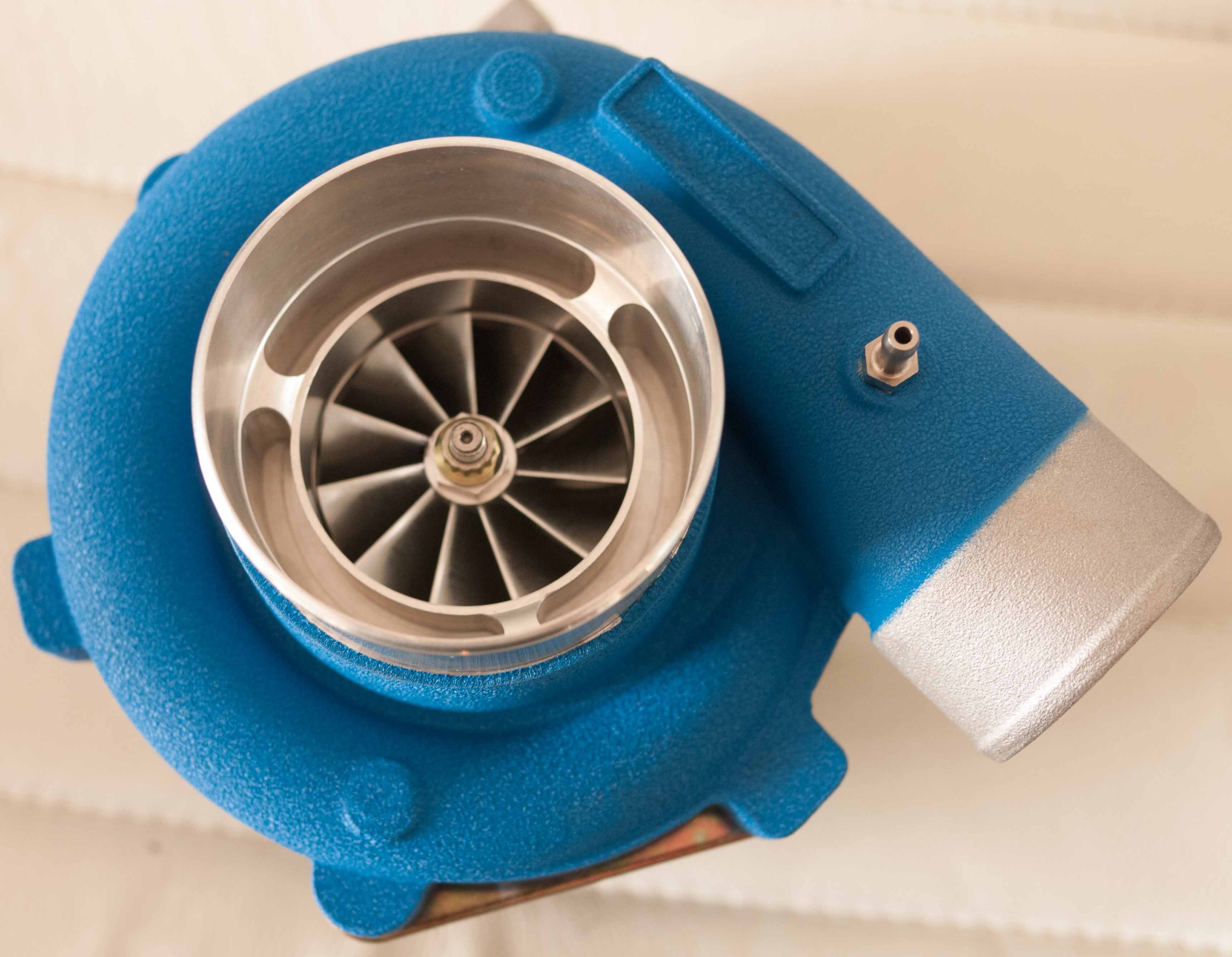

I'm thinking high compression for better down low response to go along with the gtx2871r ceramic BB i've got waiting in the wings.

Shopping list for the block so far

ARP flywheel

ARP crank bolt

oil gear sprocket

ARP main studs - align hone is required here i think?

acl main bearings

supertech 9.5:1 pistons

oil pump, chain, tensioner

squirters and bolts

Work to be done on the block

bore

hone

linish crank

balance rotating assembly

Anything else i've missed???

@SamHendry - just biting things off chunks at a time - i need to get her back on the road she's my daily so i need the car again to have some form of social life... but for now... heads down, work on! LOL

I asked old mate Gordie (he's got his silver S3 on here somewhere) if he knew someone with a 2.0L crank - turns out he had a spare. Got it at a good price plus borrowed the crank bolt locking tool. Nekminit stroker.

I'm thinking high compression for better down low response to go along with the gtx2871r ceramic BB i've got waiting in the wings.

Shopping list for the block so far

ARP flywheel

ARP crank bolt

oil gear sprocket

ARP main studs - align hone is required here i think?

acl main bearings

supertech 9.5:1 pistons

oil pump, chain, tensioner

squirters and bolts

Work to be done on the block

bore

hone

linish crank

balance rotating assembly

Anything else i've missed???

@SamHendry - just biting things off chunks at a time - i need to get her back on the road she's my daily so i need the car again to have some form of social life... but for now... heads down, work on! LOL

yeah going stroker - i thought "look i'm going to bore it anyway.... i'm going to have to get new pistons because two of them are chipped" do i go 1.9T?

I asked old mate Gordie (he's got his silver S3 on here somewhere) if he knew someone with a 2.0L crank - turns out he had a spare. Got it at a good price plus borrowed the crank bolt locking tool. Nekminit stroker.

I'm thinking high compression for better down low response to go along with the gtx2871r ceramic BB i've got waiting in the wings.

Shopping list for the block so far

ARP flywheel

ARP crank bolt

oil gear sprocket

ARP main studs - align hone is required here i think?

acl main bearings

supertech 9.5:1 pistons

oil pump, chain, tensioner

squirters and bolts

Work to be done on the block

bore

hone

linish crank

balance rotating assembly

Anything else i've missed???

@SamHendry - just biting things off chunks at a time - i need to get her back on the road she's my daily so i need the car again to have some form of social life... but for now... heads down, work on! LOL

That's pretty much spot on. Make sure all clearance are within tolerance. I used green plasti gauge for mine.. it works fine but if you can get someone to measure it precise then even better!

82.5mm bore = 1984cc with TFSI crank 92.8mm

83mm bore = 2008cc with TFSI crank 92.8mm

I personally prefer 82.5mm but it all depends with what you want.

Really like where this is going.very nice

What size turbine housing A/R you going for? On that GTX2871R

I'm deciding on CR of for the 83mm pistons.

9.25, 9.5 or 9.6:1?

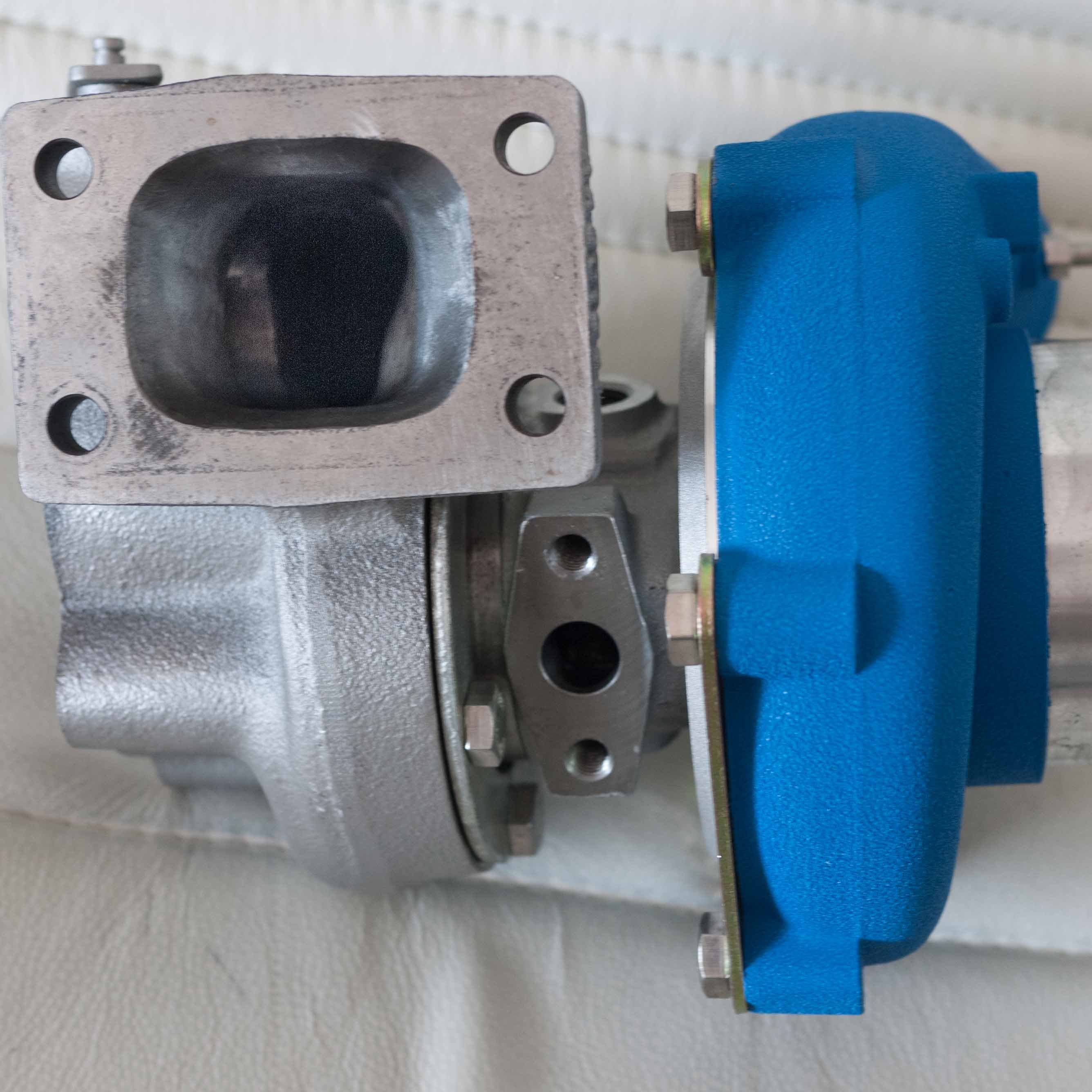

It's a .64 housing @Ash-S3. I'm gunna port the crap out the WG and inlet flange and match it to the cast mani.

Street setup so would like it as responsive as possible. Is there going to be advantages/disadvantage with the 9.25 vs 9.5 vs 9.6? Or is the difference minimal? Has anyone done higher CR's on 2.0 strokers? Apologies for the questions but like i said - i like to get my head around things and go from there

Priced up the machining work - missed that there's a massive gash on cylinder 3 but engineer assures me it'll go within the first pass

9.25, 9.5 or 9.6:1?

It's a .64 housing @Ash-S3. I'm gunna port the crap out the WG and inlet flange and match it to the cast mani.

Street setup so would like it as responsive as possible. Is there going to be advantages/disadvantage with the 9.25 vs 9.5 vs 9.6? Or is the difference minimal? Has anyone done higher CR's on 2.0 strokers? Apologies for the questions but like i said - i like to get my head around things and go from there

Priced up the machining work - missed that there's a massive gash on cylinder 3 but engineer assures me it'll go within the first pass

Last edited:

Ian so your block is salvageable ?

yep - the chip being at the bottom post bore and hone won't be an issue being that the rings don't travel that far down and the main thing was burrs that will be gone after the machining. *phew*

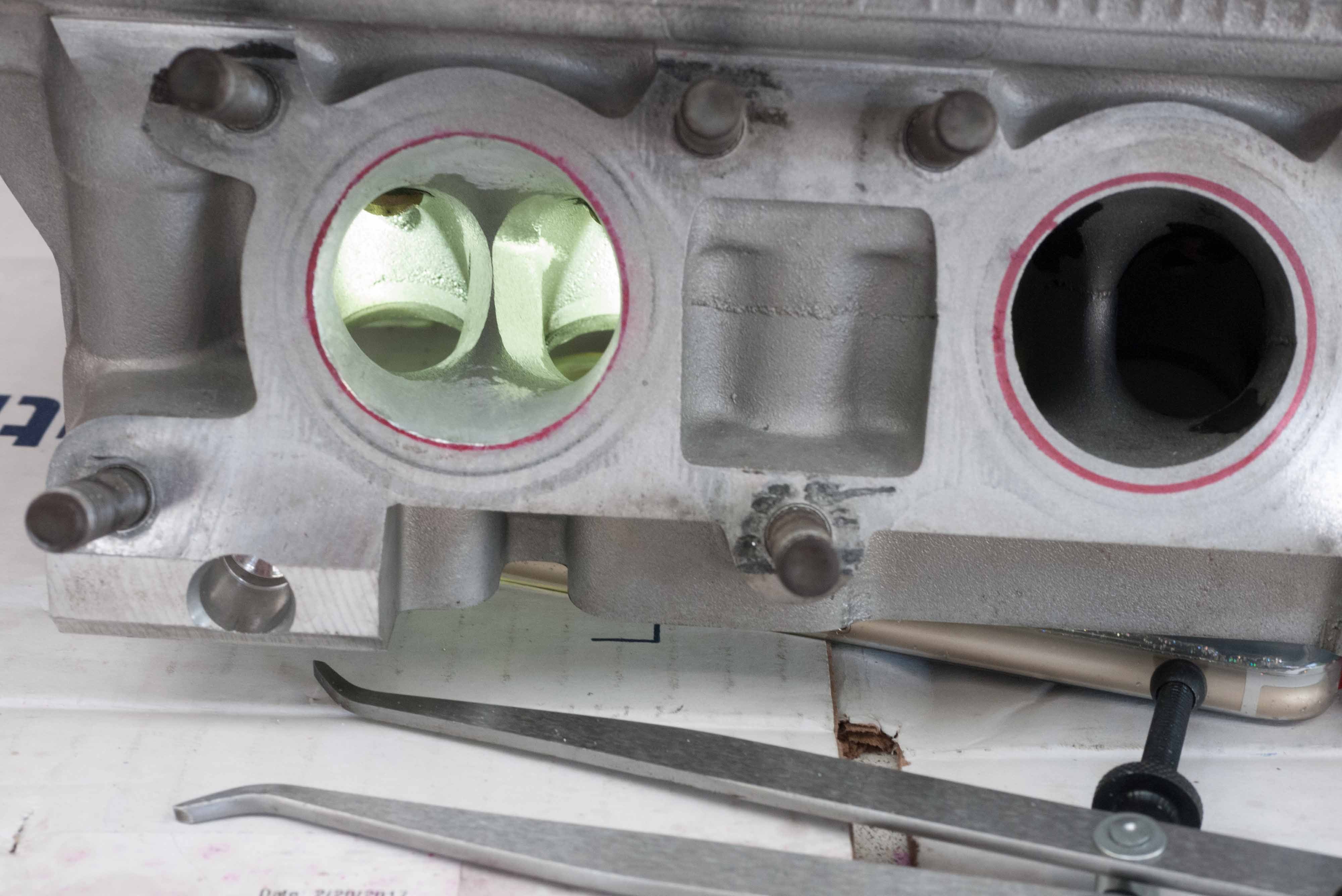

While i wait for parts to come i'm tackling the head.

First time doing any of this so any constructive criticism is very welcome!!!

Marking up...

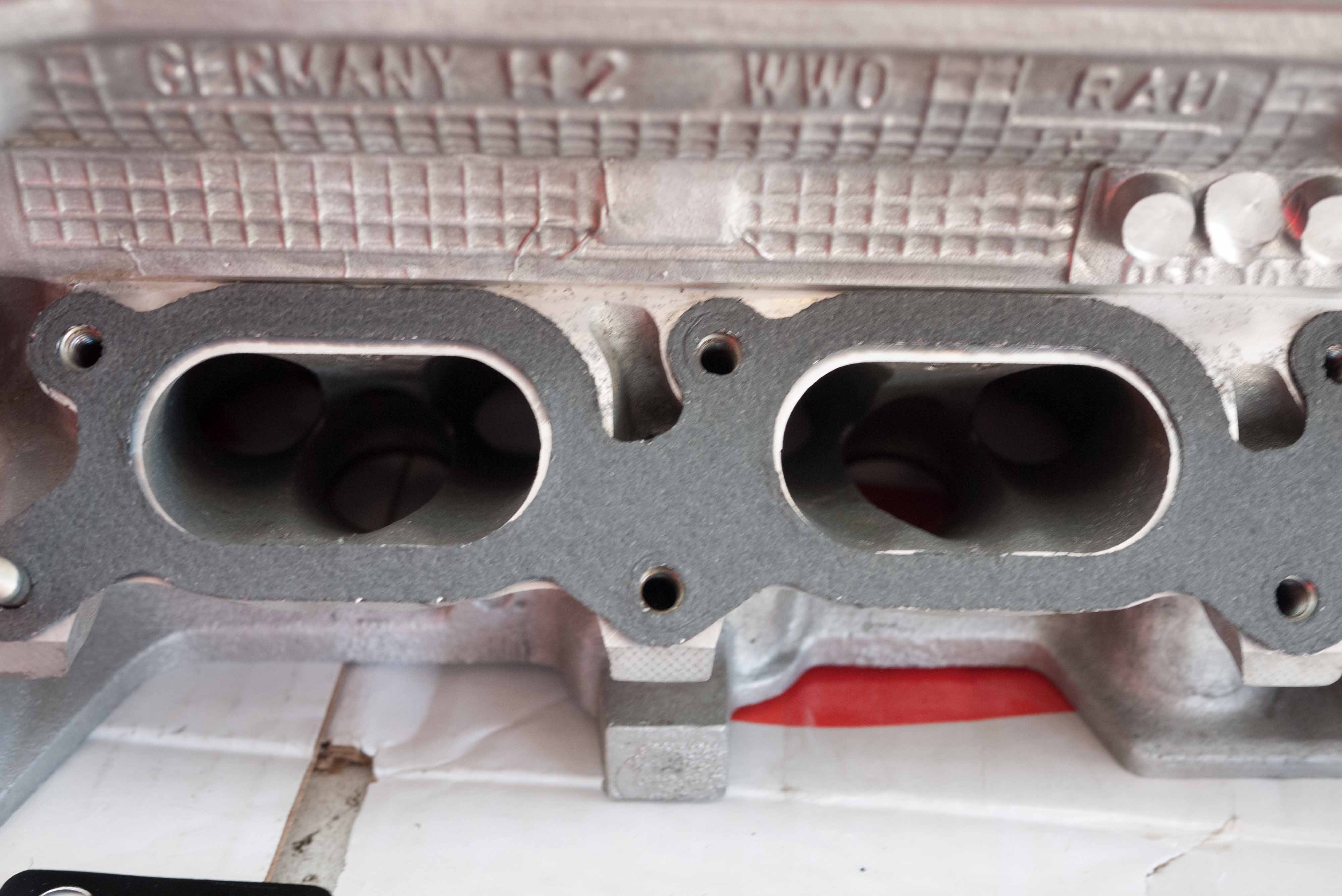

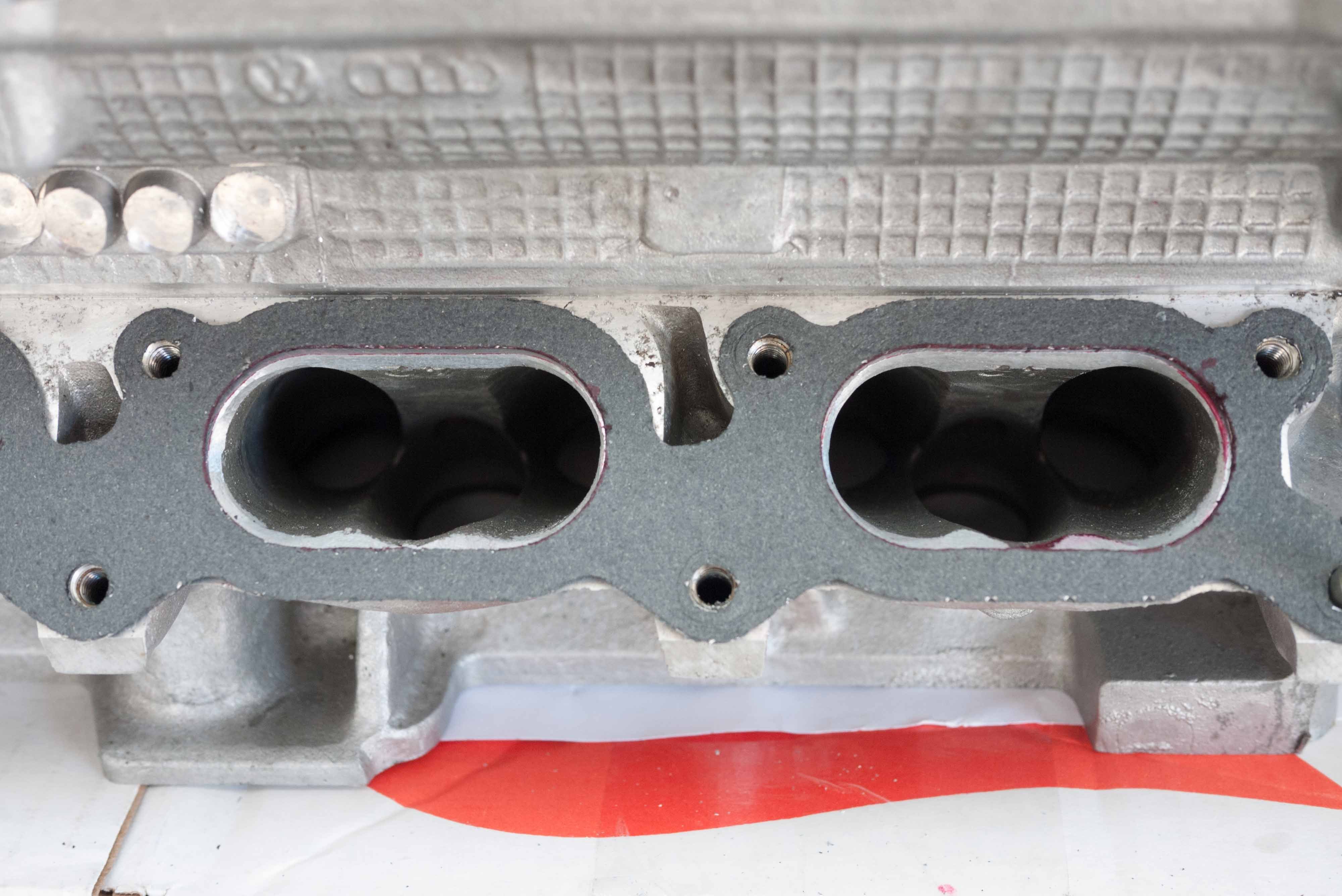

- so i've matched these to the gasket: how far IN do i need to go??? I was feeling where i'd gasket matched and would try and smooth the "ramp" from the newly carved edge into the original port.

Lets look at the exhaust side...

stock exhaust ports measure at 36.39mm

opened up a tad...

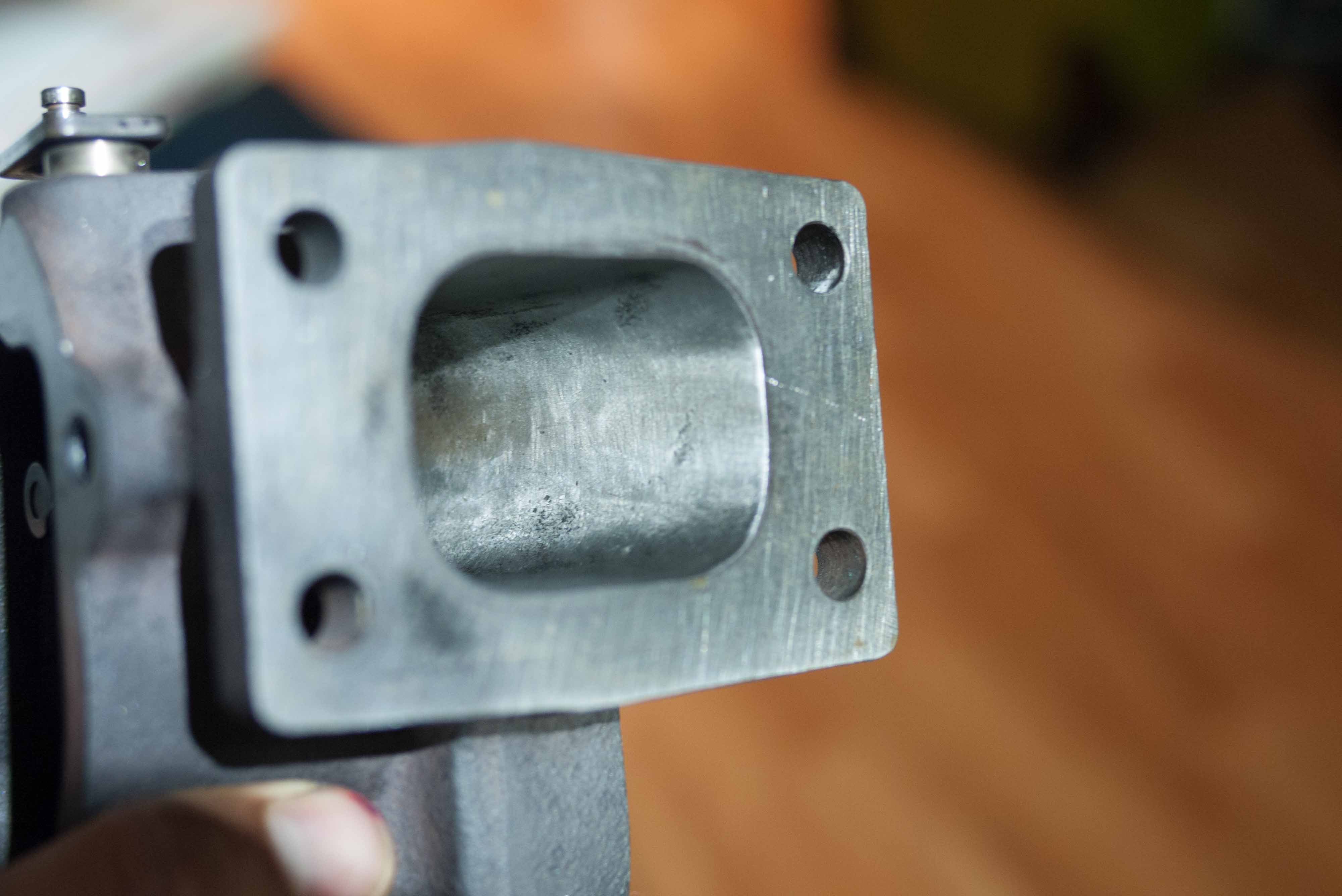

The exhaust manifold ports to which the head is mating to

Going by this diagram to prevent "reversion"

hope i'm doing this right... Was using the caliper at the bottom to measure at diagonals to make sure i can fit it in at all angles

Billet action - GTRS on the right w/upgraded billet (gt2860R spec)

You can appreciate the difference when you look at them side on

First time doing any of this so any constructive criticism is very welcome!!!

Marking up...

- so i've matched these to the gasket: how far IN do i need to go??? I was feeling where i'd gasket matched and would try and smooth the "ramp" from the newly carved edge into the original port.

Lets look at the exhaust side...

stock exhaust ports measure at 36.39mm

opened up a tad...

The exhaust manifold ports to which the head is mating to

Going by this diagram to prevent "reversion"

hope i'm doing this right... Was using the caliper at the bottom to measure at diagonals to make sure i can fit it in at all angles

Billet action - GTRS on the right w/upgraded billet (gt2860R spec)

You can appreciate the difference when you look at them side on

Last edited:

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

You've cut quite a lot with that bur on the divider. If you have flap wheels or anything less cutty, more abrasive, you won't have to remove so much (and risk ******* up), and can instead refine things with the sanding wheels etc. Get the exhaust as smooth as possible.

I tapered my inlets as much as possible.

The main benefits are on the bowl areas of the ports and behind the seats. Apparently.

Set of spring calipers would help you out in getting every port close

Sent from my iPhone using Tapatalk

I tapered my inlets as much as possible.

The main benefits are on the bowl areas of the ports and behind the seats. Apparently.

Set of spring calipers would help you out in getting every port close

Sent from my iPhone using Tapatalk

You've cut quite a lot with that bur on the divider. If you have flap wheels or anything less cutty, more abrasive, you won't have to remove so much (and risk ******* up), and can instead refine things with the sanding wheels etc. Get the exhaust as smooth as possible.

I tapered my inlets as much as possible.

The main benefits are on the bowl areas of the ports and behind the seats. Apparently.

Set of spring calipers would help you out in getting every port close

Sent from my iPhone using Tapatalk

I thought I would do one, stop and get some feedback. Thanks for the insight!

I have definitely made sure to use the spring calipers on each of the exhaust runners before the divider so they are even. Will be using the sanding rolls/wheels for the area behind the seat as I think my burrs are a bit large anyway.

Think I'm going to try knife edging the intake ports too... gunna take forever but since stuff takes so long to get here I might as well.

you are doing amazing work as usual Ian - after you do this massive rebuild are you still going to run your car with the pops and bangs switched on?

Yes it will stay. Will just make sure not to use NLS about 15 times within 20 minutes

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

I thought I would do one, stop and get some feedback. Thanks for the insight!

I have definitely made sure to use the spring calipers on each of the exhaust runners before the divider so they are even. Will be using the sanding rolls/wheels for the area behind the seat as I think my burrs are a bit large anyway.

Think I'm going to try knife edging the intake ports too... gunna take forever but since stuff takes so long to get here I might as well.

Yes it will stay. Will just make sure not to use NLS about 15 times within 20 minutes

Andrew has a couple threads on his port jobs you could maybe have a look at to see how he does things

Sent from my iPhone using Tapatalk

Got an oil gear sprocket - including all teeth - from the wreckers today. The 2.0 (bottom) has too many teeth so got the heat gun out, let it point to the sprocket on high for about 5 minutes.

Froze the bajeezus out of the crank pin(?) and quickly picked up the hot sprocket and it slid right on! Eeeeaaasssyyyy!!!

Froze the bajeezus out of the crank pin(?) and quickly picked up the hot sprocket and it slid right on! Eeeeaaasssyyyy!!!

Yeah I've been studying that thread a lot.Andrew has a couple threads on his port jobs you could maybe have a look at to see how he does things

Sent from my iPhone using Tapatalk

I happened to stumble on these while checking the differences between AGN and AGU/BAM heads

https://www.ebay.com.au/itm/252784241509

https://www.ebay.com.au/itm/172052664212

Gives a really good idea of what to aim for as well!!!

I Found this re: camshaft info

Intake shaft

058109021 = ADR AFY (with tensioner) 8.78 mm, 210 °, 4 ° n.OT

058109021.B = APX, ANB, AEB, APU, AJL, AGU, AQA, ARZ, AJQ, APP, APY, AUL 7.67 mm, 190 °, 18 ° n.OT

058109021.K = ADR, APT, ARG, AVV 8.41 mm, 202 °, 16 ° n.OT

058109021.M = AWT, AUM, ARX, ARY, AUQ, AMK, BAM, AUL, APP 7.67 mm, 190 °, 18 ° n.OT

058109021.F = AGN, APG 8.41 mm, 202 °, 18 ° after OT

058109021.E AWB = 8.6 mm, 207 °, 9 ° n.OT

OT 058109021.D = ADR, AGN 8.41 mm, 202 °, 12 ° after OT

Outlet

058109022.B = AQA, ARZ, AJQ, APP, APY, AEB, APU, ANB, AJL, AWT, AGU, AUM, ARX, ARY, AUQ, AMK, BAM 9.3 mm, 210 °, 10 ° v.OT

058109022.C = ADR, AFY, APT, ARG, AVV 10.25 mm, 210 °, 8 ° v.OT

058109022.D = AGN, APG 10.4 mm, 210 °, 8 ° v.OT

Intake shaft

058109021 = ADR AFY (with tensioner) 8.78 mm, 210 °, 4 ° n.OT

058109021.B = APX, ANB, AEB, APU, AJL, AGU, AQA, ARZ, AJQ, APP, APY, AUL 7.67 mm, 190 °, 18 ° n.OT

058109021.K = ADR, APT, ARG, AVV 8.41 mm, 202 °, 16 ° n.OT

058109021.M = AWT, AUM, ARX, ARY, AUQ, AMK, BAM, AUL, APP 7.67 mm, 190 °, 18 ° n.OT

058109021.F = AGN, APG 8.41 mm, 202 °, 18 ° after OT

058109021.E AWB = 8.6 mm, 207 °, 9 ° n.OT

OT 058109021.D = ADR, AGN 8.41 mm, 202 °, 12 ° after OT

Outlet

058109022.B = AQA, ARZ, AJQ, APP, APY, AEB, APU, ANB, AJL, AWT, AGU, AUM, ARX, ARY, AUQ, AMK, BAM 9.3 mm, 210 °, 10 ° v.OT

058109022.C = ADR, AFY, APT, ARG, AVV 10.25 mm, 210 °, 8 ° v.OT

058109022.D = AGN, APG 10.4 mm, 210 °, 8 ° v.OT

I Found this re: camshaft info

Intake shaft

058109021 = ADR AFY (with tensioner) 8.78 mm, 210 °, 4 ° n.OT

058109021.B = APX, ANB, AEB, APU, AJL, AGU, AQA, ARZ, AJQ, APP, APY, AUL 7.67 mm, 190 °, 18 ° n.OT

058109021.K = ADR, APT, ARG, AVV 8.41 mm, 202 °, 16 ° n.OT

058109021.M = AWT, AUM, ARX, ARY, AUQ, AMK, BAM, AUL, APP 7.67 mm, 190 °, 18 ° n.OT

058109021.F = AGN, APG 8.41 mm, 202 °, 18 ° after OT

058109021.E AWB = 8.6 mm, 207 °, 9 ° n.OT

OT 058109021.D = ADR, AGN 8.41 mm, 202 °, 12 ° after OT

Outlet

058109022.B = AQA, ARZ, AJQ, APP, APY, AEB, APU, ANB, AJL, AWT, AGU, AUM, ARX, ARY, AUQ, AMK, BAM 9.3 mm, 210 °, 10 ° v.OT

058109022.C = ADR, AFY, APT, ARG, AVV 10.25 mm, 210 °, 8 ° v.OT

058109022.D = AGN, APG 10.4 mm, 210 °, 8 ° v.OT

thats like spanish to me, what does it mean ? cam lobe differences ?

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

Its lift (mm), duration (degrees) and valve opening time (degrees after TDC)thats like spanish to me, what does it mean ? cam lobe differences ?

I can translate spanish, but not thatthats like spanish to me, what does it mean ? cam lobe differences ?

Not much going on in camp Nogaro. Just a whole lot of waiting for parts - so... while I wait... i port and make things different colours.

First up ... bit of porting

Before

After

Matching this up to gasket too

... and gave it a bit of a polish

Marked up - think i'll leave this for another time!

Gave the housing a bit of a sprucing up

... and then the comp housing

... and why not the bearing housing too!? LOL

Installing snap ring

Mocking up my turbo

Going to send the block away next week for machining and once I get the rest of the rotating assembly they'll be joining the block for balancing.

First up ... bit of porting

Before

After

Matching this up to gasket too

... and gave it a bit of a polish

Marked up - think i'll leave this for another time!

Gave the housing a bit of a sprucing up

... and then the comp housing

... and why not the bearing housing too!? LOL

Installing snap ring

Mocking up my turbo

Going to send the block away next week for machining and once I get the rest of the rotating assembly they'll be joining the block for balancing.

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west