SDHA4SLine

Registered User

I'm a little confused about the method of replacing front control arms, recently I read that the upper & lower control arm fixings should only be fully tightened when the suspension is under load at normal ride height. However looking at what I believe to be an online Audi workshop manual it looks like this is not the case. quote from manual for lower arms....

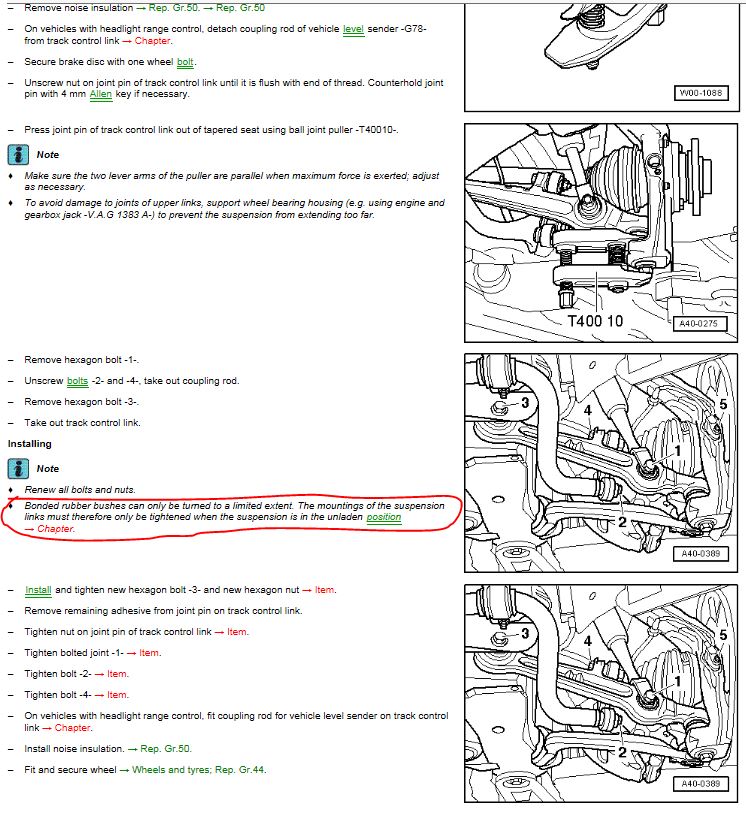

Bonded rubber bushes can only be turned to a limited extent. The mountings of the suspension links must therefore only be tightened when the suspension is in the unladen position

Am I misunderstanding the manual or is this the correct method?

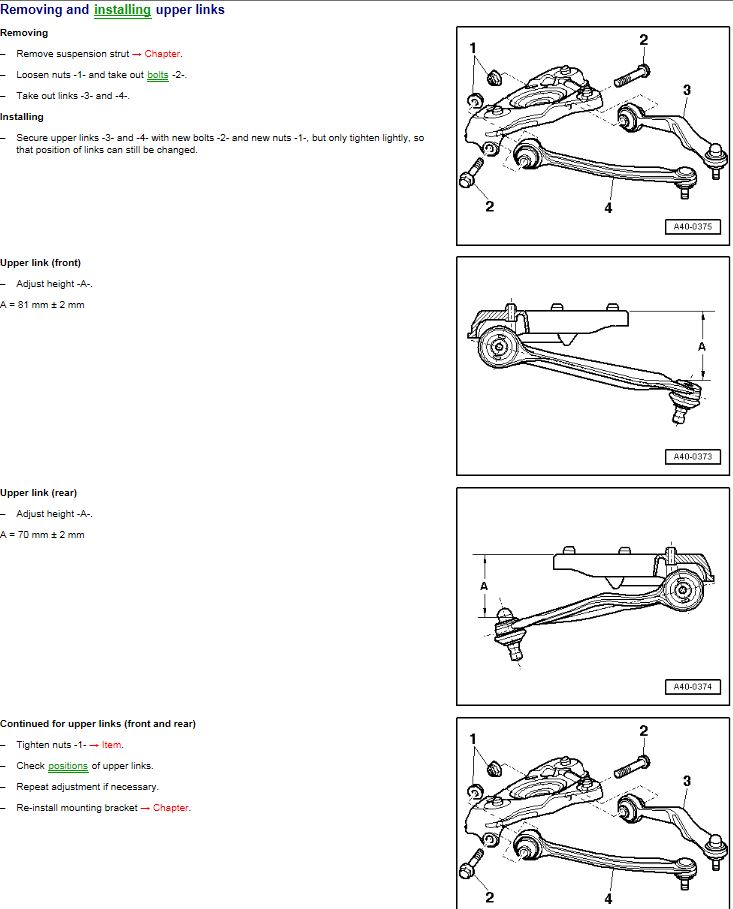

upper arms

lower arms

Bonded rubber bushes can only be turned to a limited extent. The mountings of the suspension links must therefore only be tightened when the suspension is in the unladen position

Am I misunderstanding the manual or is this the correct method?

upper arms

lower arms