You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

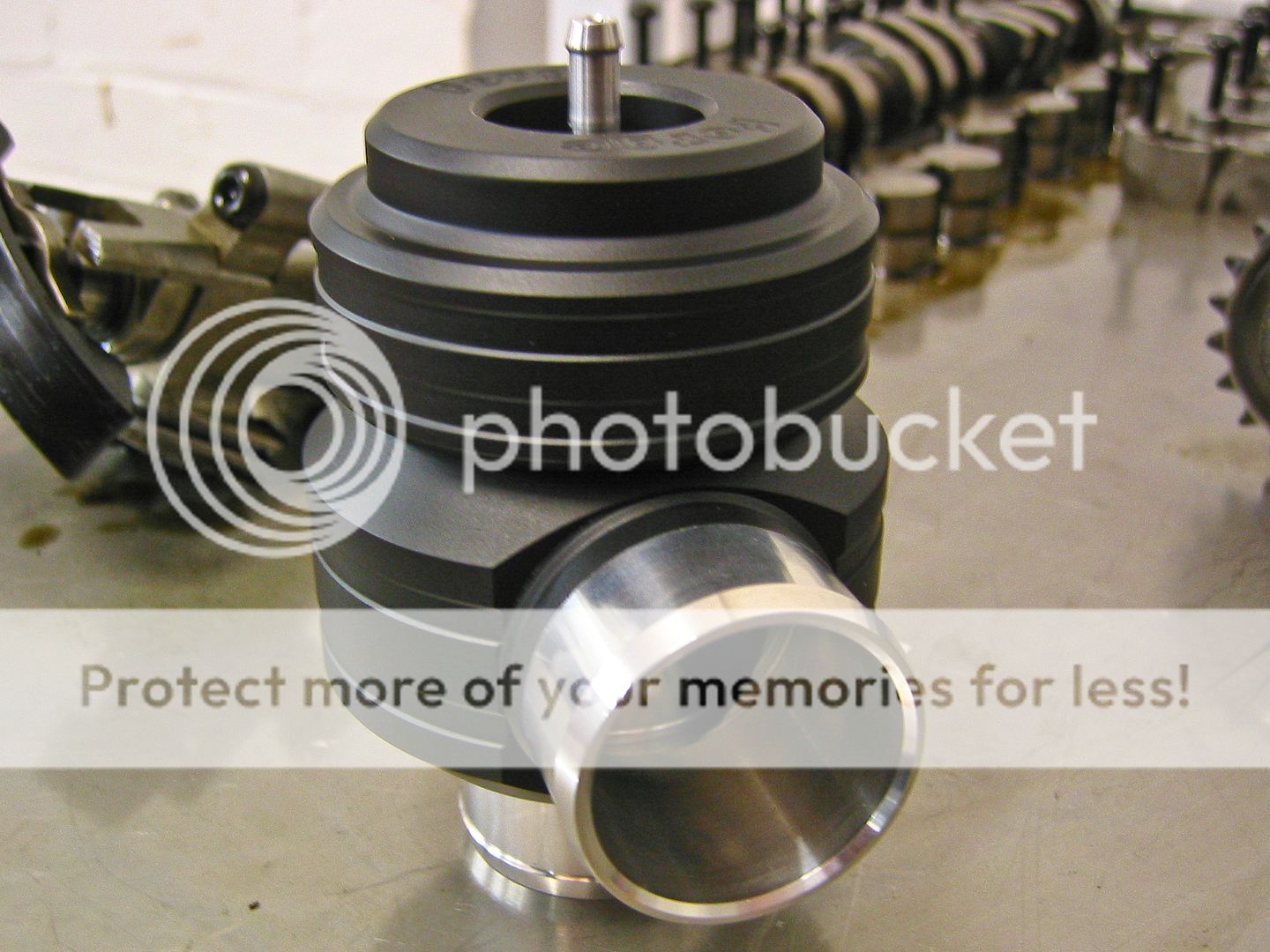

Did you get the DV black mate? as all i can see on the forge website for that is the gash alloy coloured one.

cheers

Painted it... was silver when I got it...

<tuffty/>

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

did you have any celebrations for reaching 1000 posts??

lol, thanks a good question Tuffty, this thread is getting sizeable...

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

the rolling road day should be a /1000postparty for tufty. he has to get the beers in though

He needs an 'I Am Tuffty' T Shirt me thinks....

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

Painted it... was silver when I got it...

<tuffty/>

Aah, cheers mate, think ill be doing that...

finesse

Registered User

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

tuffty, did you remanufacture your autobahn88 tip?

looking for one...

No mate, was sold with the K04..

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Little update....

After popping the throttle body hose for the second time (at low boost) in a country lane in the middle of the night I asked Bill to weld some beads onto the throttle body to stop this happening again... R32 TB's don't have the bead around the edge like the std 60mm TB as its not a turbo car... lack of a bead for the hose/clamp to sit up against is the main contributor to hoses popping off...

Thanks mate :thumbsup:

While Bill was happy in TIG land fabricating bits for a GT30 powered Mk2 Golf, I got my car on the dyno to take a few logs and see where the N75 was in the grand scheme of things as I want to use the N75 again albeit in parallel with the MBC... part throttle with MBC's is a little erratic at times and I want to see if I can sort that...

I have found a page where someone uses an N75 normally but uses a switch on WOT (wide open throttle) to switch an N249 valve into re-routing boost control from the N75 to the MBC... this way you get ECU control over boost when driving normally and MBC boost sustainability under WOT

The link is here:

MBC/N75 Boost Control results - NewBeetle.org Forums

I may well have a go at this at some point...

Anyhoo.... operating a car on a dyno is a very unnatural experience... first thing I wanted to do is release the handbrake (which is left on while the car is on the dyno) and then once I started off in first gear I wanted to put my seat belt on!!!... lol!

Did a couple of runs on actuator pressure... pretty evident I am getting bad boost creep as the internal gate is now far to restrictive for all the extra flow the charge system and head now provide... its a 1 bar actuator but with preload starts opening about 0.8 bar... boost then creeps up to over 24psi at over 7k rpm... this will be manageable once the mapping is sorted as this will be around the boost I will end up running but not the best thing that could happen... Basically it means I have to have the head off again and either port the crap out of the internal gate (as Bill did to Welly's) or go external gate as my manifold supports this... I am of course going external gate as I want to do it right, first time...

I did a couple of runs logging timing pull etc (there was no timing pull at all) and AFR was far too rich killing any hope of power higher up the rev range... I didn't run the car today to see what power I had anyway but its pretty evident there is some work to do as the current map is way out...

Last run I did was to see what the N75 was up to.... I pulled out about 4k rpm as the boost hit 33psi!!!!... N75 is now unplugged

After the runs I pulled the graphs together including one from before I fitted the large port head etc...

The red lines are the current setup with actuator (and boost creep) pressure only... running my previous map etc... the teal coloured lines are from my previous setup with the unmodded FMIC and charge pipes + small port head.... the orange lines are from the aborted run with the N75 connected... I have included this as you can see the potential the engine now has once I throw some boost at it...

In the second pic you can see where the boost was heading before I aborted (orange line) and the boost creep (red line)... I didn't log boost on the runs before the large port but was running about 1.5bar at the time..

The interesting thing is I am potentially getting full boost (1.6bar) well under 4k rpm, which (from memory) is much earlier than before... also when you compare the power lines from before (teal) to now (red and orange) everything is happening much earlier in the rev range than before....

Thats about it for now... got a bit of work to do but she is showing potential for plenty of power

<tuffty/>

After popping the throttle body hose for the second time (at low boost) in a country lane in the middle of the night I asked Bill to weld some beads onto the throttle body to stop this happening again... R32 TB's don't have the bead around the edge like the std 60mm TB as its not a turbo car... lack of a bead for the hose/clamp to sit up against is the main contributor to hoses popping off...

Thanks mate :thumbsup:

While Bill was happy in TIG land fabricating bits for a GT30 powered Mk2 Golf, I got my car on the dyno to take a few logs and see where the N75 was in the grand scheme of things as I want to use the N75 again albeit in parallel with the MBC... part throttle with MBC's is a little erratic at times and I want to see if I can sort that...

I have found a page where someone uses an N75 normally but uses a switch on WOT (wide open throttle) to switch an N249 valve into re-routing boost control from the N75 to the MBC... this way you get ECU control over boost when driving normally and MBC boost sustainability under WOT

The link is here:

MBC/N75 Boost Control results - NewBeetle.org Forums

I may well have a go at this at some point...

Anyhoo.... operating a car on a dyno is a very unnatural experience... first thing I wanted to do is release the handbrake (which is left on while the car is on the dyno) and then once I started off in first gear I wanted to put my seat belt on!!!... lol!

Did a couple of runs on actuator pressure... pretty evident I am getting bad boost creep as the internal gate is now far to restrictive for all the extra flow the charge system and head now provide... its a 1 bar actuator but with preload starts opening about 0.8 bar... boost then creeps up to over 24psi at over 7k rpm... this will be manageable once the mapping is sorted as this will be around the boost I will end up running but not the best thing that could happen... Basically it means I have to have the head off again and either port the crap out of the internal gate (as Bill did to Welly's) or go external gate as my manifold supports this... I am of course going external gate as I want to do it right, first time...

I did a couple of runs logging timing pull etc (there was no timing pull at all) and AFR was far too rich killing any hope of power higher up the rev range... I didn't run the car today to see what power I had anyway but its pretty evident there is some work to do as the current map is way out...

Last run I did was to see what the N75 was up to.... I pulled out about 4k rpm as the boost hit 33psi!!!!... N75 is now unplugged

After the runs I pulled the graphs together including one from before I fitted the large port head etc...

The red lines are the current setup with actuator (and boost creep) pressure only... running my previous map etc... the teal coloured lines are from my previous setup with the unmodded FMIC and charge pipes + small port head.... the orange lines are from the aborted run with the N75 connected... I have included this as you can see the potential the engine now has once I throw some boost at it...

In the second pic you can see where the boost was heading before I aborted (orange line) and the boost creep (red line)... I didn't log boost on the runs before the large port but was running about 1.5bar at the time..

The interesting thing is I am potentially getting full boost (1.6bar) well under 4k rpm, which (from memory) is much earlier than before... also when you compare the power lines from before (teal) to now (red and orange) everything is happening much earlier in the rev range than before....

Thats about it for now... got a bit of work to do but she is showing potential for plenty of power

<tuffty/>

Last run I did was to see what the N75 was up to.... I pulled out about 4k rpm as the boost hit 33psi!!!!

All the boost then..... lol.

On a side note, I see that losses between flywheel and wheels have increased quite substantially since the run there in July... Any idea why?

Interesting that again it looks like the cylinder filling capability of the large port heads shines through - I'm looking forward to final maps of this, will be very interesting.

I'm standing by my 401 bhp predicted....

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

....On a side note, I see that losses between flywheel and wheels have increased quite substantially since the run there in July... Any idea why?...

No mate.... may have just been an issue with that particular run.... maybe the ramp rate.... regardless of 'figures' its the curve etc that counts... ;p

<tuffty/>

clean the tb and pipe although i dont think yours is oilly and spray a bit of hairspray on then clamp up, works on my impreza and is a ****** to get apart!

Anyone thought of using a twin plenum intake like the skoda wrc's? just wonder if theres any gains? maybe because they use alot of compression? would like to know!.....

Anyone thought of using a twin plenum intake like the skoda wrc's? just wonder if theres any gains? maybe because they use alot of compression? would like to know!.....

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

clean the tb and pipe although i dont think yours is oilly and spray a bit of hairspray on then clamp up, works on my impreza and is a ****** to get apart!

Anyone thought of using a twin plenum intake like the skoda wrc's? just wonder if theres any gains? maybe because they use alot of compression? would like to know!.....

All clean mate... bead rolled on ali pipework or beads like this is the only way to prevent silicon popping off... some cheap ebay kits come with non at all on the pipework... as soon as a bit of boost goes through them they pop off... simples

Sheer clamping force isn't really enough...

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

I like that link Tufty, thinking outside the box

Wish it was my idea but still a good one non the less... simple yet effective...

<tuffty/>

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

On a side note, I see that losses between flywheel and wheels have increased quite substantially since the run there in July... Any idea why?

WD40 on the tyres, much grippier & stickier.

I'm standing by my 401 bhp predicted....

Already seen that from slighly exagerated rollers.LOL

Time will tell, by the time he has finished re specing and building it will be a solid 420, then when Bill has his way ( GT35) it will keep going up and up. Snigger

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Anyone thought of using a twin plenum intake like the skoda wrc's? just wonder if theres any gains? maybe because they use alot of compression? would like to know!.....

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

While Bill was happy in TIG land fabricating bits for a GT30 powered Mk2 Golf

tiggy-tastic

GT3071/0.63, 38mm tial external gate.

tiggy-tastic

GT3071/0.63, 38mm tial external gate.

That's looking good now dude, I will have a good ganders later on....

- Joined

- Jun 19, 2009

- Messages

- 3,883

- Reaction score

- 619

- Points

- 113

- Location

- Leeds

- Website

- www.aldevelopments.com

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Will you be going external gated do you think?

As mentioned in post #1014, yes... :thumbsup:

As can be seen in the pic below, there is a platform for 38mm bolt on external gate, it just needs to be machined... I may look at using a v-band one though and make up an adaptor plate... the v-band wastegates tend to be smaller physically which is a little better in terms of getting it to fit nicely..

<tuffty/>

Last edited:

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

not to detract from tufftys thread... but i cant resist

another gt30 kinda installation going on presently

another gt30 kinda installation going on presently

- Joined

- Nov 11, 2009

- Messages

- 10,099

- Reaction score

- 739

- Points

- 38

- Location

- west yorks

- Website

- www.stainless-engineering.co.uk

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

looks like it goes back in to me. orrrrr does it. they sound insane

im guessin its not in an s3, no way will that fit. would be nice to see that huge blower though!

p.s you have the cleanest workshop i've ever seen

im guessin its not in an s3, no way will that fit. would be nice to see that huge blower though!

p.s you have the cleanest workshop i've ever seen

Last edited:

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Is that a screamer pipe?

looks like it goes back in to me. orrrrr does it. they sound insane

im guessin its not in an s3, no way will that fit. would be nice to see that huge blower though!

p.s you have the cleanest workshop i've ever seen

Not a screamer no, goes back into the exhaust...

That setup is actually going into the Golf in the background but would potentially go into an S3... fits better with the compact comp housing like mine... thats the same spec cartridge (GT3071r) as my turbo but its using a T3 0.63 A/R turbine housing rather than the T25 0.64 A/R I have... did similar installations on an A3 TQS (GT2871r), Polo GTI (T3 somat or other) and an Ibiza Cupra (GT3071r... Polo was well tight but got into Redline magazine and was dyno'd at 485bhp...

<tuffty/>

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

its hard to see how that would fit it being top mounted and freekin huuuuge. serious piece of kit though. and in a mk2 golf, that will be one bonkers car!

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Is that a screamer pipe?

kind of.. but not.. it joins the exhaust system. Too loud otherwise and not track friendly (this is a track car toy for someone)

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

its hard to see how that would fit it being top mounted and freekin huuuuge. serious piece of kit though. and in a mk2 golf, that will be one bonkers car!

the fmic picture a few posts up is the same car.

Almost identical setup going into a mk3 ibiza cupra also. 400bhp cars when done (and some)

Polo was well tight but got into Redline magazine and was dyno'd at 485bhp...

<tuffty/>

I read about that Polo in Redline and read most of his build on Edition 38, awesome stuff.

Nathan

Speedy Steve

Registered User

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Not had time to do much to the car recently but had a chance today to do a minor mod I have been planning for a while...

I have been running an MBC for some time now and while it does exactly what it says on the tin, part throttle situations can be a little rough so I really wanted to go back over to the N75 as a method of boost control to see if it would smooth things over...

The first attempt at this resulted in 33psi at 4k rpm... not the best... duty cycle of the N75 needs a tweak in the map then :thumbsups:

After reading about running an MBC in parallel I thought I would give that a go... here is a pic I found on how to connect it all up...

I bought a couple of t-pieces and had a go...

The turbo holds 1.5bar once spooled to the redline... brilliant

Spoke to Bill before I left the unit this evening about mapping and will hopefully be looking to get this sorted as soon as he has a slot to fit me in.... ME7.5 ECU's are pretty damn clever and can compensate really well for the differences my recent mods have made but I am still getting no timing pull and there is more power to be had and some improvement in spool...

Only other thing I have done is fitted a JR cone filter after being inspired by seeing the jolly decent OEM look install by Warleydaddy when he was over for the ASN dyno day at Badger 5 earlier this month. I will of course be developing this a little further and do a write up with pics once I am happy with it all...

<tuffty/>

I have been running an MBC for some time now and while it does exactly what it says on the tin, part throttle situations can be a little rough so I really wanted to go back over to the N75 as a method of boost control to see if it would smooth things over...

The first attempt at this resulted in 33psi at 4k rpm... not the best... duty cycle of the N75 needs a tweak in the map then :thumbsups:

After reading about running an MBC in parallel I thought I would give that a go... here is a pic I found on how to connect it all up...

I bought a couple of t-pieces and had a go...

The turbo holds 1.5bar once spooled to the redline... brilliant

Spoke to Bill before I left the unit this evening about mapping and will hopefully be looking to get this sorted as soon as he has a slot to fit me in.... ME7.5 ECU's are pretty damn clever and can compensate really well for the differences my recent mods have made but I am still getting no timing pull and there is more power to be had and some improvement in spool...

Only other thing I have done is fitted a JR cone filter after being inspired by seeing the jolly decent OEM look install by Warleydaddy when he was over for the ASN dyno day at Badger 5 earlier this month. I will of course be developing this a little further and do a write up with pics once I am happy with it all...

<tuffty/>

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Yarp... think of it like the bleed hole of an MBC....

<tuffty/>

LOL, don't worry, I was.

Thats cool dude, glad this has worked out well as per our discussions about it.

May follow suit if all good.... :thumbsup:

tuftythread t-shirts

tuftythread t-shirts