OllieH

Registered User

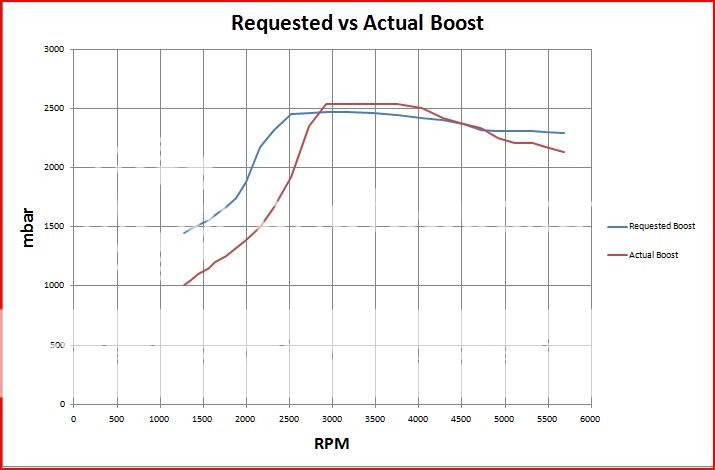

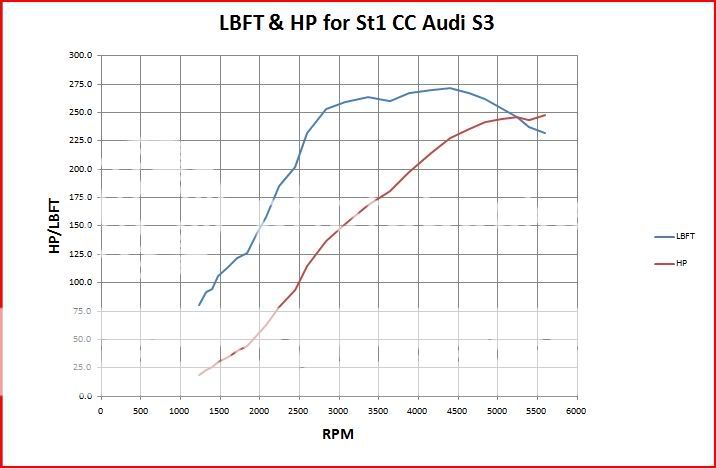

Only just fixed the coilpack problem I had on the weekend and now I've got another fault! It actually appeared as soon as I fitted the new coil pack and took the car for a test drive. The misfire had gone but the idle is still crappy, hunting up and down very slightly and coughing occasionally. The main problem though is when I accelerate I don't get any real power until above 3k revs, whereas before I used to get progressive power from 2.5k onwards. I thought at first it might just be in my head, but now I'm certain that it's not as it was. When I floor it in 3rd I can hear the screech (for want of a better word) of the turbo boosting up but the car doesn't accelerate in proportion to it, and then all of a sudden at just over 3k revs the car takes off. It doesn't feel as fast as it used to aswell, but that may just be that I've got used to it?? Any ideas?

I disconnected the MAF earlier today to see if that made a difference but had no change. On a side note, when the maf was disconnected the ESP light lit up continously?! Should it not be the CEL?

I need to replace the battery aswell, but can't see this causing it. I will also be changing the DV this week from the Split-R to the 007P. Could a faulty DV be causing this? although it only appears to be dumping when changing gear.

Any help is appreciated. I've decided that I'm gonna purchase VCDS, but in the meantime I want to try and sort this as it's making me feel like I don't want to drive the car in fear of causing more problems.

I disconnected the MAF earlier today to see if that made a difference but had no change. On a side note, when the maf was disconnected the ESP light lit up continously?! Should it not be the CEL?

I need to replace the battery aswell, but can't see this causing it. I will also be changing the DV this week from the Split-R to the 007P. Could a faulty DV be causing this? although it only appears to be dumping when changing gear.

Any help is appreciated. I've decided that I'm gonna purchase VCDS, but in the meantime I want to try and sort this as it's making me feel like I don't want to drive the car in fear of causing more problems.

I'll make my next job checking all the vac lines coming off the inlet manifold and go from there. Just need to get myself some stud extractors first! I take it you reused all the non return valves on the PCV system, and just replaced all the rubber hoses?

I'll make my next job checking all the vac lines coming off the inlet manifold and go from there. Just need to get myself some stud extractors first! I take it you reused all the non return valves on the PCV system, and just replaced all the rubber hoses? I knew that, lol... No, honestly..... :icon_thumright:

I knew that, lol... No, honestly..... :icon_thumright: