Very busy this week and coming weekend at work so no real time to progress much on the car

I managed to sneak out for a couple of hours as really want to get my turbo oil drain and downpipe sorted before the Christmas holidays as am worried it will hold me up as should be able time permitting start looking at dropping the engine in.

All of the turbo lines and downpipe need tweaking due to the bigger comp cover meaning turbo has to be spun on the v-band to allow clearance.

First off started with the most crucial, the oil drain. The flanges for the drain even though supposed to be the same CHRA for GT30 and Gt35 turbo's have different hole spacings.

First of I tried just elongating the holes but wasn't happy with the result so cut the flange off to get the new one welded on, here's them both side by side

I filled the pipe to angle desired to get fitment and scribed the position as well as a more obvious pen mark

Should sit something like this once a friend has welded it

Next up was the coolant feed, this just required a little persuasion with a mallet and vice to bend and tweet it a little.

From turbo to block

For the lines this then leaves the oil feed which is flexible and the coolant return but this will be in AN6 line and will have to wait until I'm decided on a few other bits like header tank etc

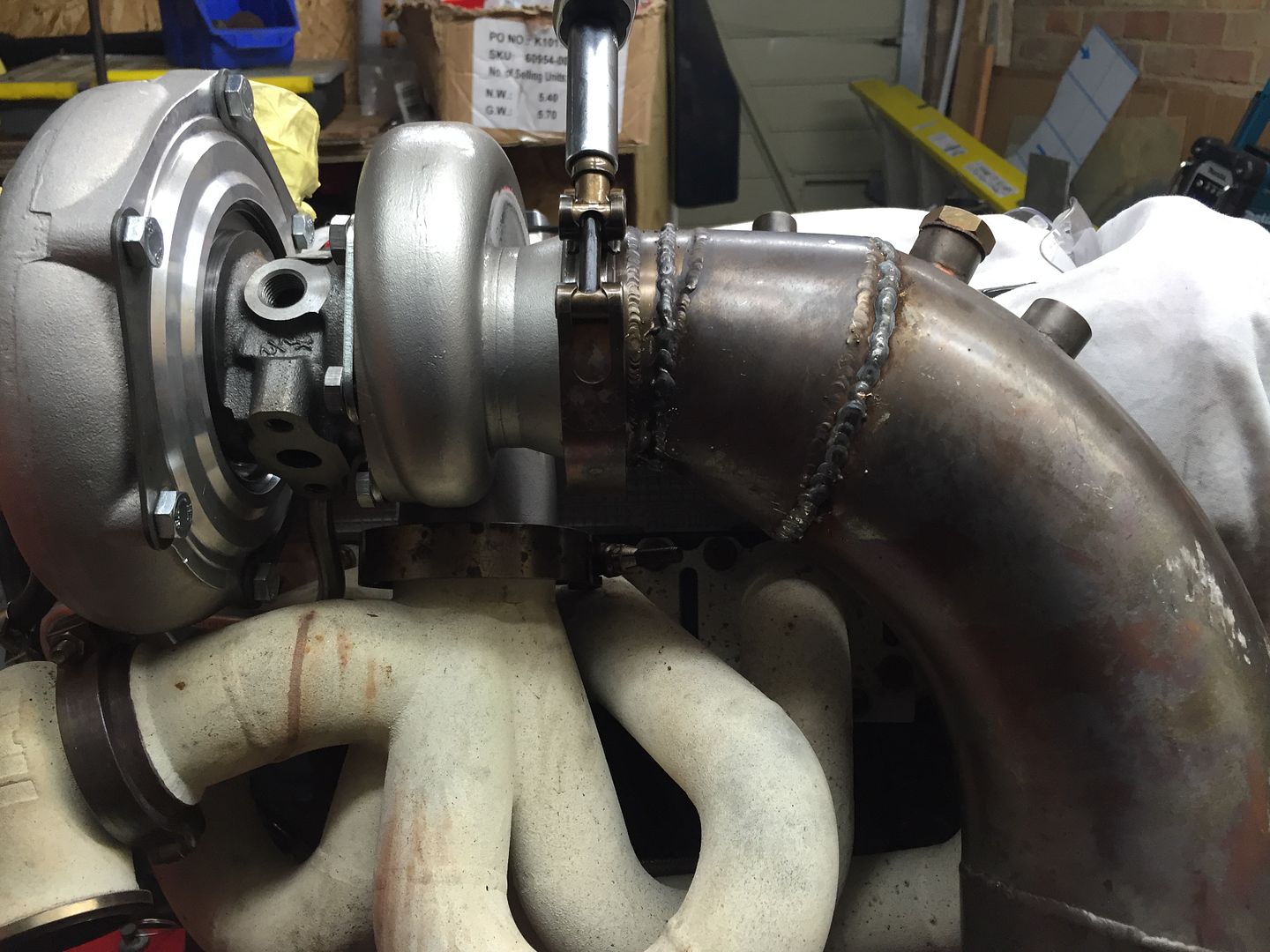

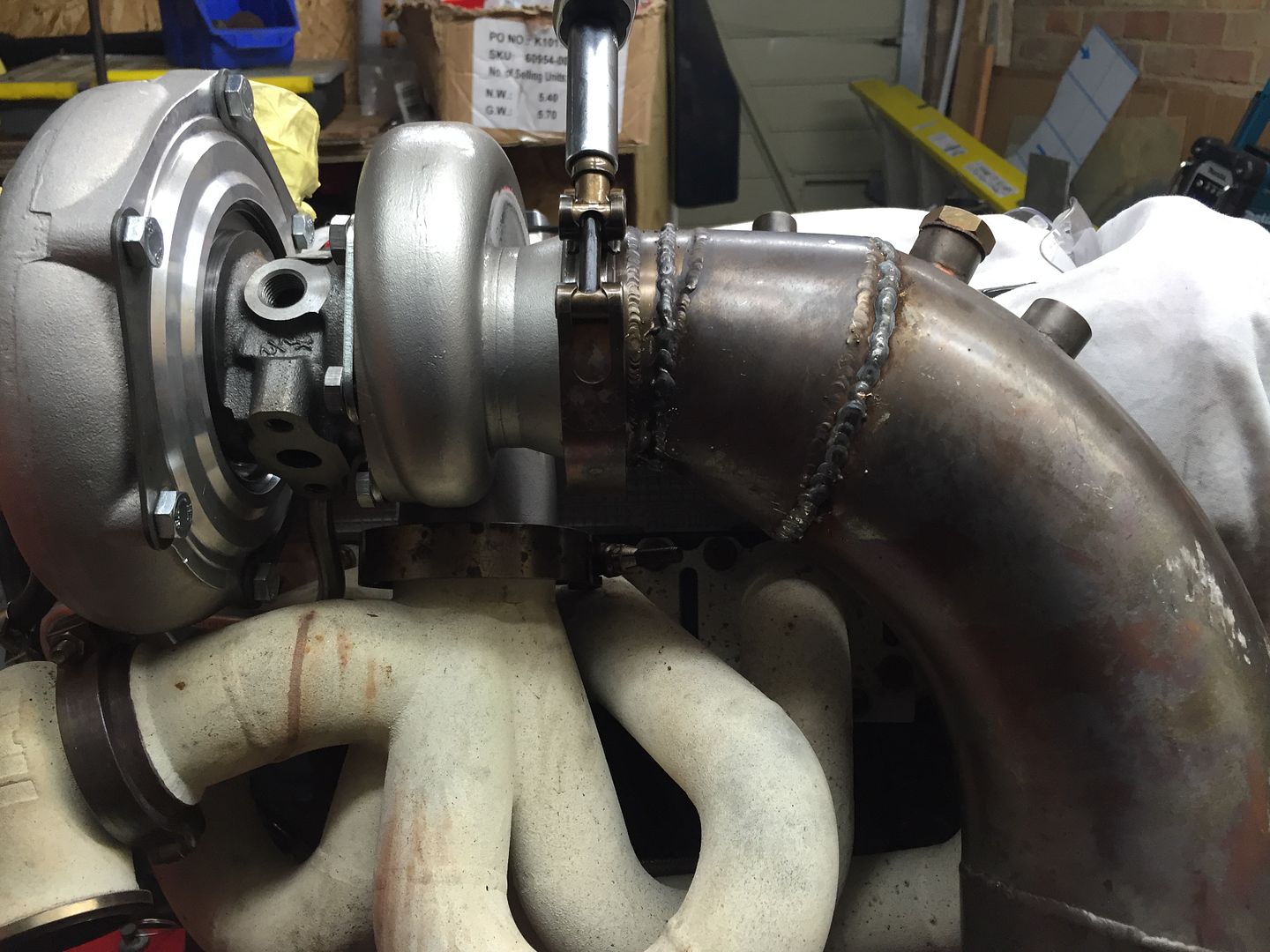

The end result with turbo position allows me to just about remove the back right cam cover bolt and sits pretty tight to the wastegate

Last but not least I had the exhaust to sort, from spinning the turbine and changing over to the snail turbo turbine has without a doubt moved to a place it needed to be cut and shut

I couldn't get it anywhere near the temp bracing mounting holes until I cut this off

After a bit of fettling and cutting slithers off here and there it sat in like so

I had previously bought some stainless wire for the MIG to get me out of trouble if need be even though I've only got argoshield gas and not pure argon or helium.

I went to use this wire to which I quickly realised the tiny hole in the spool was about a third of the diameter of the spool holder...doh

I got a little creative and used a big M12 bolt with a combination of spring washers for preload and nuts to hold it to create my own holder lol

Now I'd got over that I put a couple of tacs on ready for a friend to weld it

Only thing was I got q bit carried away

All in all it felt criminal cutting up some beautifully crafted stuff and barstardising it but needs must and all that.

Also I've now decided I definitely need a TIG welder in my life! But I feel it's to late for my request to get to Santa this year so one may have to sneak it's way into the garage next year

Hope may get out in the garage a fair bit next week as only got one shift