Well i thought id crack on and gap the rings ready for when i find a crank

The oil ring were straight forward enough and only 2 needed some material removing, but have to say the extra oil support ring that sits under the usual 3 was a bit of a pita to get on as this one hugs the piston tight rather than the bore compressing it, but once had got the hang of it, it was alright

JE's advised gaps

The middle rings where really inconsistant and had gaps of up to 23 thou before any material was removed which is strange??

This then lead to checking the bore dimensions and clearances but all was ok there??

After putting the rings one by one into the same bore at the same position it become clear that 3 out of the 4 had a reasonably bigger gap than they possibly should do and the last one was 16 thou which is alright as it gave me something to play with to get the correct gap of 18 thou

The top rings all had 12-13 thou gap and i took all of these to the required 16 thou, so this leads me to believe that i may have got some middle things that must have passed Q.C or something?

Will be in touch with IE and JE shortly to see if they could send me 3 more rings?

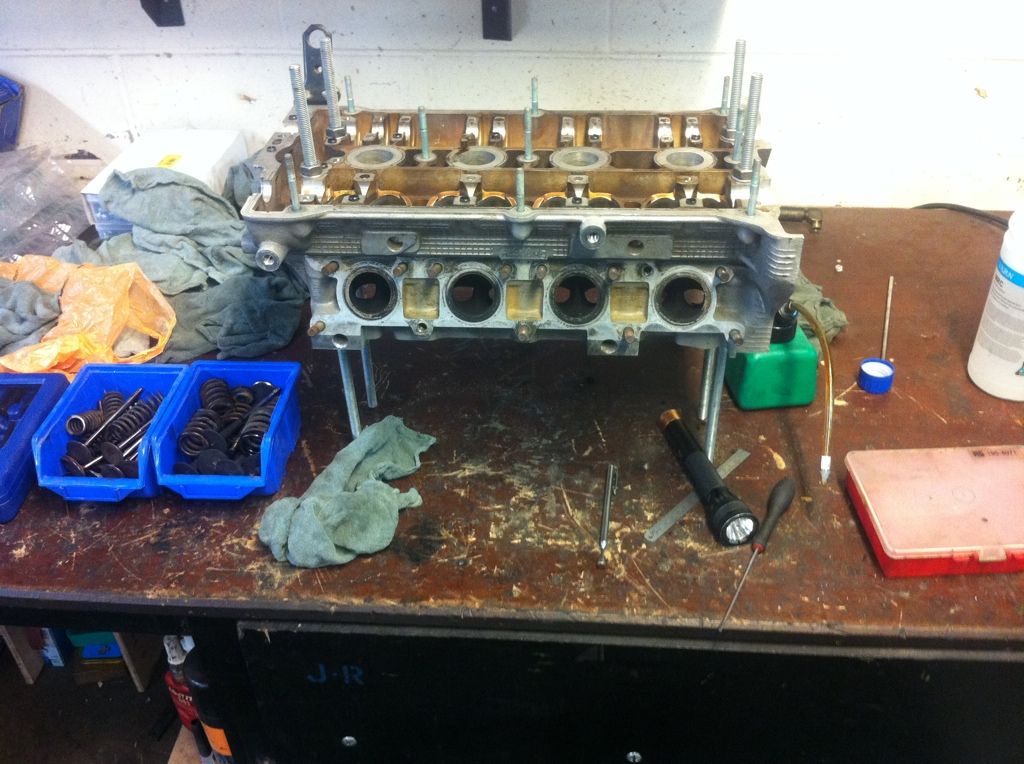

Heres a couple of pics although nothing to interesting

Like to say cheers to Prawn for pointing me towards this

And also a cheers to Bill for the usual question answering and advice