Casual day today as I know I am not gonna finish the car before Bill goes away and I am back at work next week

Priority was to fettle the transfer box and comp housing and jiggle the mani about to try and give me more clearance.

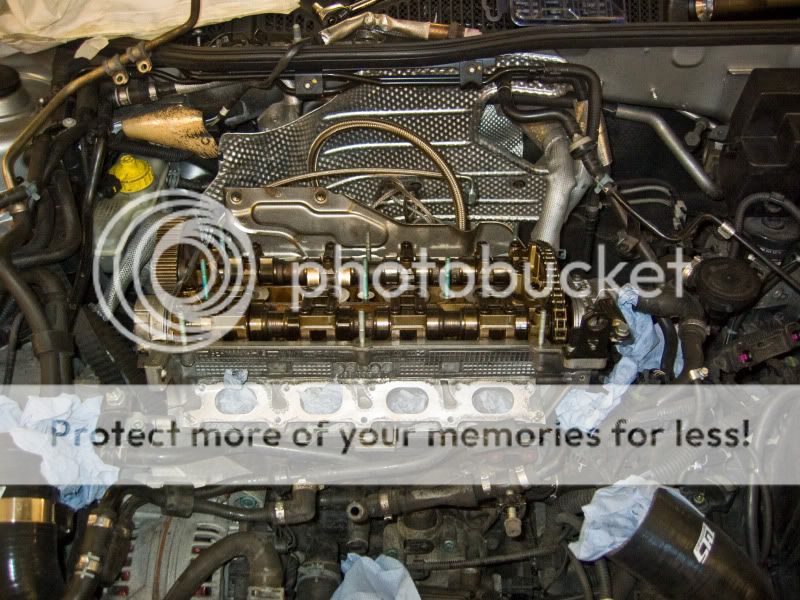

After a little playing about I was ready to try it out. Lifted the head into the engine bay (quite heavy with a GT30 turbo on it) and located it gasketless on the dowels... so far so good... previous attempts had the head not sitting down on the back, now it rocked pivoting on the back... looking good... had a butchers underneath and result!! it clears and the head sits square on the block...

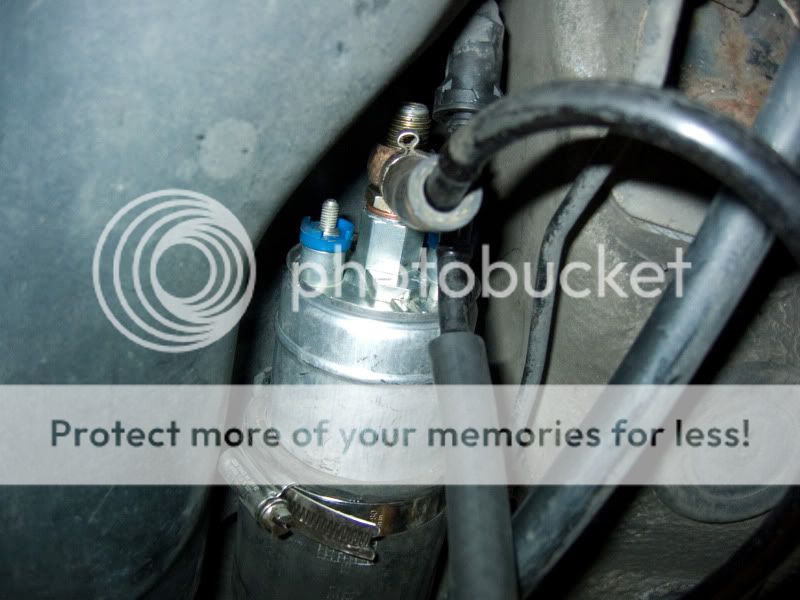

Tight but more than enough clearance

(not massively obvious from this angle I know but trust me its there...)

I then moved on to have a look at how to fab the TIP... I wanted to use a hump hose off the turbo initially so that it would help prevent vibrations from the engine (stiffer mounts now) destroying MAF's however....

...exiting straight out the turbo inlet isn't an option... too small a gap for 3" pipework and straight into the gear linkage... everything about this build seems to present its own challenges

So I tried a different approach by coming up and out of the turbo at 90 degrees towards the back then work it back to the airbox. Bill came up with an idea for a variation and it looks like the TIP will consist of a couple of 90 degree silicon hoses for the MAF and turbo with a 90 degree alloy pipe and a 45 degree alloy pipe to make up the rest.

Pics of the TIP mock up...

While I was waiting for Bill to pop into the workshop after work, I thought I would do something about the coil pack wiring as quite frankly it was shocking.....

Heat had got the better of the insulation so I patched the breaks up with tape and reloomed it...

Bill finished work and turned up at the workshop, had a quick look around the turbo and said that it looks ok so....

...Woo (actual) Hoo!!! the head is now bolted on... phew!!! next problem please!!

tomorrows job... connecting stuff up and getting some bits together for the TIP...

<tuffty/>