There seems to be a lot of questions/issues regarding injector clearances floating around at the moment - Especially after the injector recall. For anyone who feels competent enough and has access to the right tools (nothing too specialist) below is a basic guide on how to adjust/check your injector clearance/pre load.

I have included hyperlinks for the tools used, purely for anybody wishing to know what I am talking about, and some useful links at the bottom of the page.

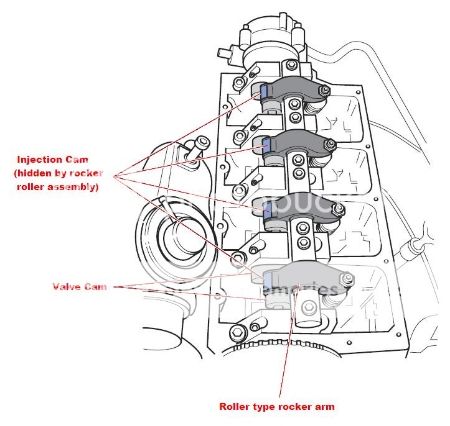

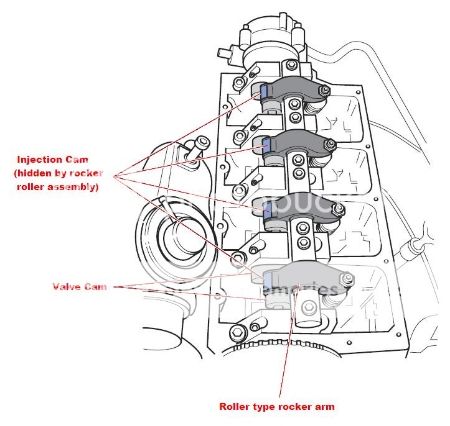

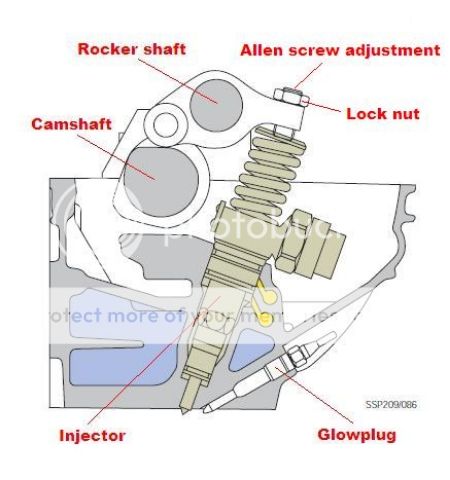

N.B. The illustration pictures all show a single cam setup, however it is identical procedure to adjust the injectors on a 16v engine as it runs on the front cam. Please note on the 16v the rear cam is for the exhaust valves only and has no bearing on the injector setup - Do not touch the rear cam.

I have included hyperlinks for the tools used, purely for anybody wishing to know what I am talking about, and some useful links at the bottom of the page.

N.B. The illustration pictures all show a single cam setup, however it is identical procedure to adjust the injectors on a 16v engine as it runs on the front cam. Please note on the 16v the rear cam is for the exhaust valves only and has no bearing on the injector setup - Do not touch the rear cam.

Before we proceed any further I will categorically state that if you attempt this procedure it is at your own risk!

If you do not feel competent enough to do this work, seek the services of a professional - There are plenty of sponsors on this forum who can carry out this work for you.

The tools required are:

Torx Head Screwdriver

Spanner (17mm or 18mm)

Hex Key/Hex bit (6mm)

Dial gauge

Angle gauge

Torque Wrench

THIS PROCEDURE MUST BE DONE ON A COLD ENGINE

Use your Torx head screwdriver to undo the cam cover bolts and remove the cam cover. You will now be presented with the inner workings of your cylinder head. Our focus will be on the injector rocker assembly running on the front camshaft (nearest the front of the car).

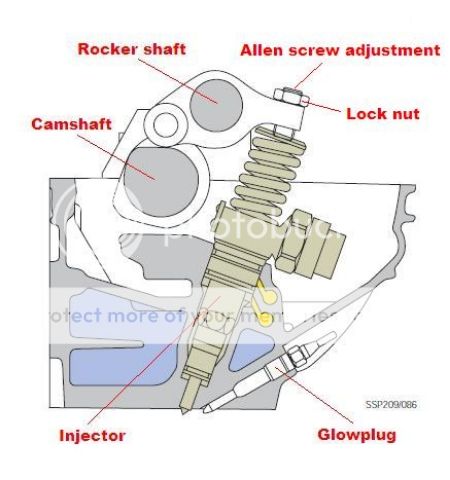

Now place/mount your Dial gauge somewhere stable on the cylinder head so that it does not move around, and adjust it so the measuring tip touches the top of the rocker arm adjustment nut (see below). This job can also be done without a Dial gauge, but unless you really know what youâre doing, this is the only sure fire way to be 100% that you get this right.

Rotate the camshaft, this can be done with a Spanner on the front cam pulley centre bolt, or (much safer) by putting the car into 1[SUP]st[/SUP] gear, releasing the handbrake and gently rocking the car â Only rock the car forwards to make sure the cam rotates in the correct direction. To make turning the camshaft easier you can remove the glowplugs to relieve cylinder pressure, but I would not really advise this for several reasons.

Keep rotating the camshaft and adjusting the Dial gauge so that it maintians contact with the top of the rocker adjustment nut. When you are sure that the rocker arm is at its lowest possible point and you have established this measurement to be 100% accurate, you can remove the dial gauge.

Now place your Hex Key/Hex bit in the top of the adjustment screw, hold it in position, and with a Spanner loosen the locking nut (counter clockwise) that holds it on top of the rocker arm (See below).

When the locking nut has been slackened (do not remove or loosen to far), turn the Hex key screw (clockwise) until firm resistance can be felt. The injector will now be at its limit stop.

Do not keep turning after firm resistance is felt, or damage to the injector can occur.

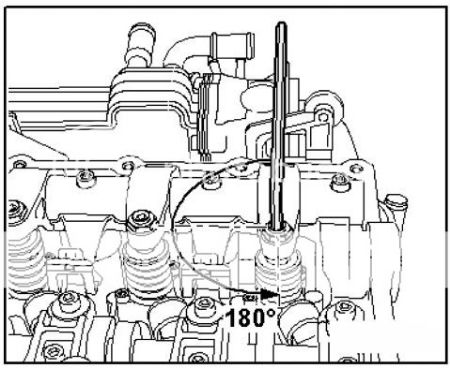

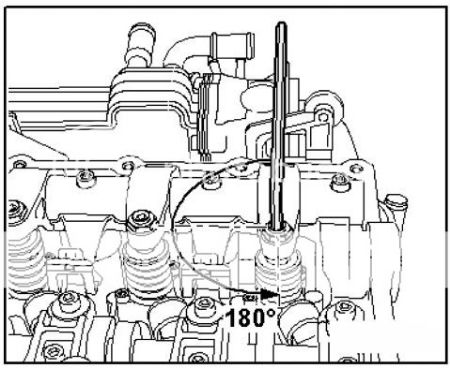

Now set your Angle gauge to 0 (ZERO) degrees, and with the relevant Hex Key/Hex bit attached turn the adjustment screw back (counter-clockwise) 180 degrees. Hold the screw in position, then re-tighten the locking nut with a spanner, and then torque to 30Nm with a Torque wrench. The 180 degree adjustment can be done visually but greater accuracy is possible when using the Angle gauge and relevant Hex bit.

REPEAT THIS PROCEDURE FOR ALL OF THE INJECTORS

Refit the cam cover & ensure anything moved, removed, or disconnected is put back to its original position or state. Job Done!

USEFUL LINKS...

HOW TO USE AN DIAL GAUGE

HOW TO USE AN ANGLE GAUGE

HOW TO USE AN TORQUE WRENCH

If you do not feel competent enough to do this work, seek the services of a professional - There are plenty of sponsors on this forum who can carry out this work for you.

The tools required are:

Torx Head Screwdriver

Spanner (17mm or 18mm)

Hex Key/Hex bit (6mm)

Dial gauge

Angle gauge

Torque Wrench

THIS PROCEDURE MUST BE DONE ON A COLD ENGINE

Use your Torx head screwdriver to undo the cam cover bolts and remove the cam cover. You will now be presented with the inner workings of your cylinder head. Our focus will be on the injector rocker assembly running on the front camshaft (nearest the front of the car).

Now place/mount your Dial gauge somewhere stable on the cylinder head so that it does not move around, and adjust it so the measuring tip touches the top of the rocker arm adjustment nut (see below). This job can also be done without a Dial gauge, but unless you really know what youâre doing, this is the only sure fire way to be 100% that you get this right.

Rotate the camshaft, this can be done with a Spanner on the front cam pulley centre bolt, or (much safer) by putting the car into 1[SUP]st[/SUP] gear, releasing the handbrake and gently rocking the car â Only rock the car forwards to make sure the cam rotates in the correct direction. To make turning the camshaft easier you can remove the glowplugs to relieve cylinder pressure, but I would not really advise this for several reasons.

Keep rotating the camshaft and adjusting the Dial gauge so that it maintians contact with the top of the rocker adjustment nut. When you are sure that the rocker arm is at its lowest possible point and you have established this measurement to be 100% accurate, you can remove the dial gauge.

Now place your Hex Key/Hex bit in the top of the adjustment screw, hold it in position, and with a Spanner loosen the locking nut (counter clockwise) that holds it on top of the rocker arm (See below).

When the locking nut has been slackened (do not remove or loosen to far), turn the Hex key screw (clockwise) until firm resistance can be felt. The injector will now be at its limit stop.

Do not keep turning after firm resistance is felt, or damage to the injector can occur.

Now set your Angle gauge to 0 (ZERO) degrees, and with the relevant Hex Key/Hex bit attached turn the adjustment screw back (counter-clockwise) 180 degrees. Hold the screw in position, then re-tighten the locking nut with a spanner, and then torque to 30Nm with a Torque wrench. The 180 degree adjustment can be done visually but greater accuracy is possible when using the Angle gauge and relevant Hex bit.

REPEAT THIS PROCEDURE FOR ALL OF THE INJECTORS

Refit the cam cover & ensure anything moved, removed, or disconnected is put back to its original position or state. Job Done!

USEFUL LINKS...

HOW TO USE AN DIAL GAUGE

HOW TO USE AN ANGLE GAUGE

HOW TO USE AN TORQUE WRENCH

Last edited: