- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

this one is 10psi currentlyBill - to what preload do you have the wastegate set?

this one is 10psi currentlyBill - to what preload do you have the wastegate set?

haha. ****** actuator! What's it doing? Not enough pre load?

Can Wellys final map in 338bhp form not be used on yours straight away? or is his ECU too different to yours?

wellys is non wideband non egt, 512k ecu

Westle the actuators are set to one of 3 different values (I think) and then Bill just changes it to what he wants it to be lol.

I'm on to thigh rubbing now lol

Bill has a small pressure gun that is used to apply pressure to the actuator. That way you can physically see when the actuator is opening. You can then adjust the actuator rod length to apply more or less preload to get it to open at more or less PSI.

Simples.

fitted with hybrid fitted

Was it a new actuator fitted an refurb dude?

Actuator "was'nt" the one which went to them... I marked all components.. a.n.other returned! oh so typically from CR

I thought the rod looked at the end of the adjuster on that pic compared to mine......

Uploaded with ImageShack.us

dont know if that had been adjusted then of course...

Bill -- actuator behavior is impacted by two specs: its crack pressure and the rod lift necessary to achieve that given preload. So for example, you can have two differently configured actuators which are set to a 10psi crack pressure. One needs a rod lift of 2mm. The other requires a rod lift of 8mm. That amount of rod lift will indicate how well the two actuators can maintain boost. Simply put, your actuator might need a stiffer spring.

will be good to compare as im interested in the JBS one if it ever comes out

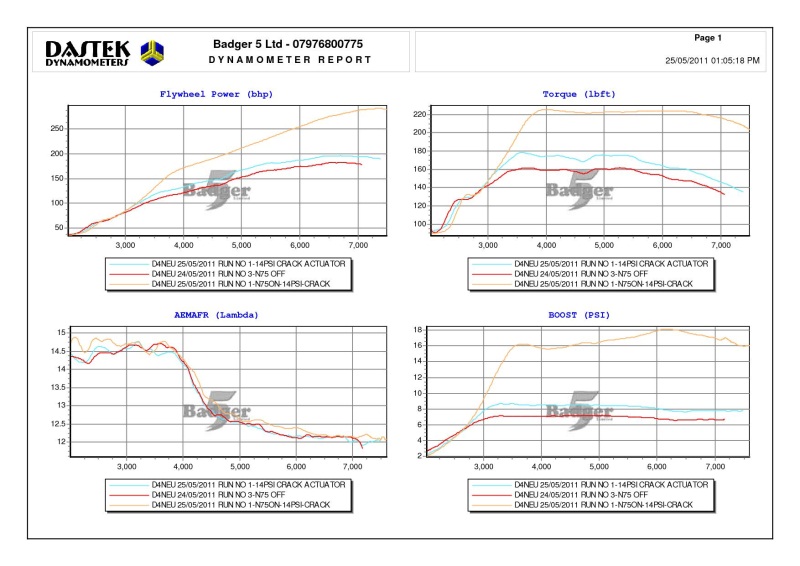

ok, last night was aborted.. Actuator I had collected had been built with 1/4" rod, not 6mm, so it would'nt fit thru the turbos wastegate actuator arm. got it replaced this morning, and will try again. 14psi crack pressure on bench, no preload currently. (yellow spring)

onwards

CR deserving the name I gave them there then, 296 isn't too shabby though!

He'll be happy to see the back of it and ill be happy to see the front of it

Nice one Bill, The car will probably stop wanting to be flashed next... lol

Good going thus far and more to come - it wouldn't be an S3 without the problems mate, take heart in that fact... :thumbsup:

Group A: '020 Group B: '112 Group C: '115

Idle Stabilization Idle Stabilization Idle Stabilization Idle Stabilization Temperature Load RPM Load Absolute Pres. Absolute Pres.

TIME TIME TIME

STAMP °KW °KW °KW °KW STAMP °C % STAMP /min % mbar mbar

22.6 0 0 0 0 22.99 455 0 23.39 1640 76.7 1700 1060

23.81 0 0 0 0 24.19 460 0 24.61 1680 82 1720 1110

25.02 0 0 0 0 25.4 480 0 25.81 2200 91.7 2000 1210

26.22 0 0 0 0 26.62 495 0 27 2720 108.3 2030 1400

27.32 0 0 0 0 27.73 530 0 28.14 3360 152.6 2010 1880

28.52 0 0 0 3 28.91 570 0 29.32 4440 167.7 2210 2030

29.73 0 0 0 3 30.15 645 0 30.52 5440 178.2 2500 2070

30.84 0 0 0 3 31.25 690 0 31.65 6120 175.9 2550 2050

32.04 0 0 0 3 32.47 740 0 32.86 6680 160.9 2550 2030

33.27 0 0 0 2.3 33.68 770 0 34.07 7000 154.1 2550 2010

34.49 0 0 3 1.5 34.87 790 0 35.28 7200 154.9 2550 1970