Well its been another busy few weeks in the workshop but the BDM race car project is still slowly evolving and progressing. So here are some more pictures for you to cast your eyes on...

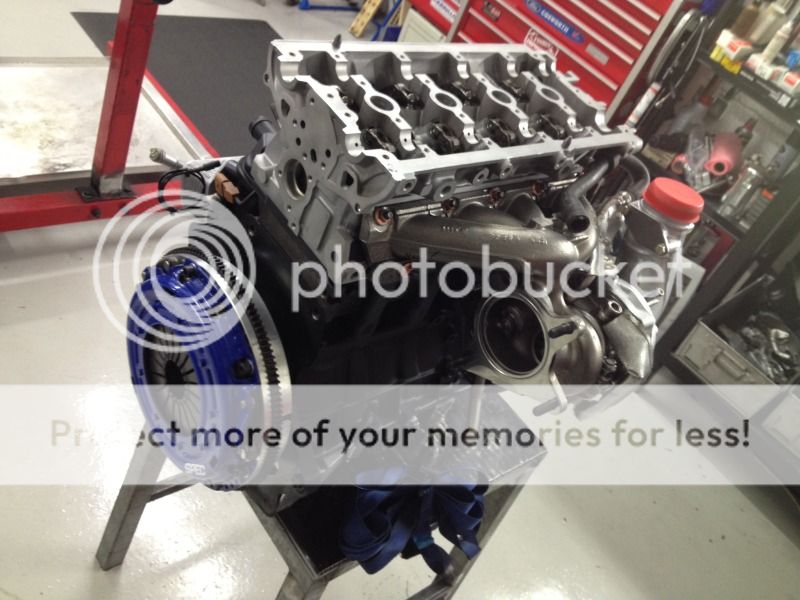

This is the race engine. As you can see, it's quite busy in the engine building room. The latest addition/modifcation is the new oil filter housing.

The OEM oil filter housing is completly replaced and gets rid of the plastic housing and OEM heat exchanger. This should be a much more robust design more suitable for a race car. It also gives us the use of a oil cooler that is thermostaticly activated. We plan to be able to sell this a complete conversion kit in the not to distant future.

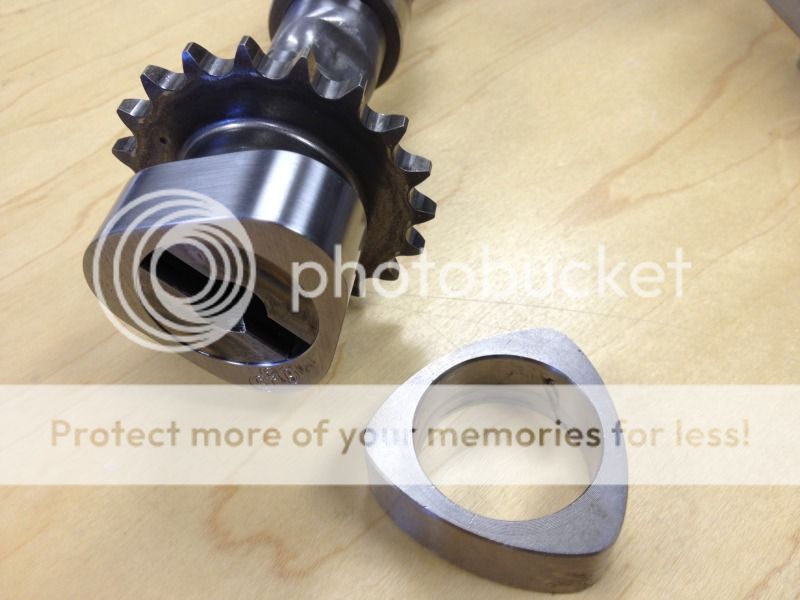

Parts include...

- 06A > 06F conversion plate.

- 1.8T 06A oil filer housing, oil filter & gasket.

- Thermostatic sandwich plate.

- Machined oil breather cap (which will be made to take dash 8 fitting which will go to an oil catch tank).

- Mocal oil cooler.

- Braided oil lines and aeroquip fittings.

This picture clearly shows the oil temperautre sensor (blue plug) and the oil pressure sensor. Both will be connected to the AIM LCD dash and data logging system where the peramiters can be monitered.

Another part we havent mentioned but should is the clutch. Spec have supplied us with their stage 3 clutch and lightened aluminium flywheel. The cluch will handle 517 lbft torque and the light weight single mass flywheel will help improve acceleration.

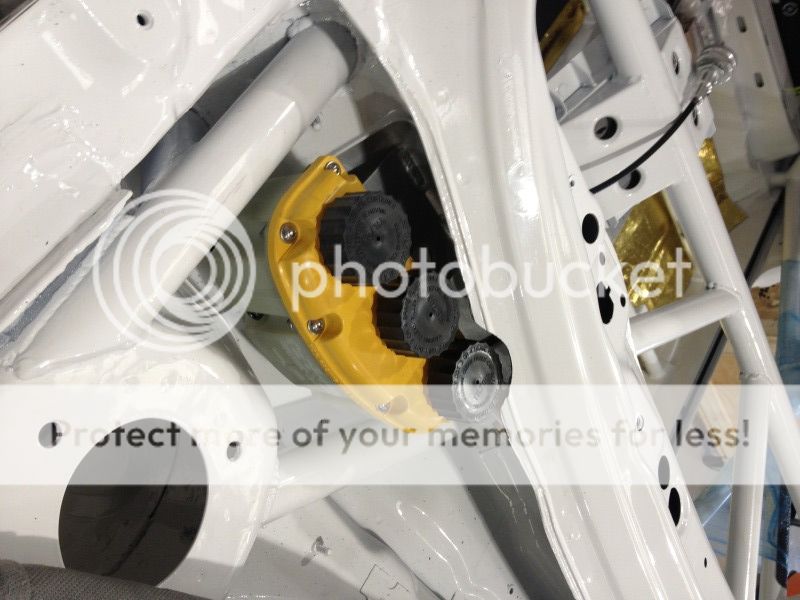

A neat little touch. The air jack air intake fitting is hidden nicley in the fuel cap. Once the air lance is plugged into the fitting the legs shoot down from the car so that all four wheels are off the ground.

Hard lines to the air jacks have been installed nicley, following the contours of the car where possible.

The clutch & brake hydraulic fluid resevoir is fitted under the scuttle.

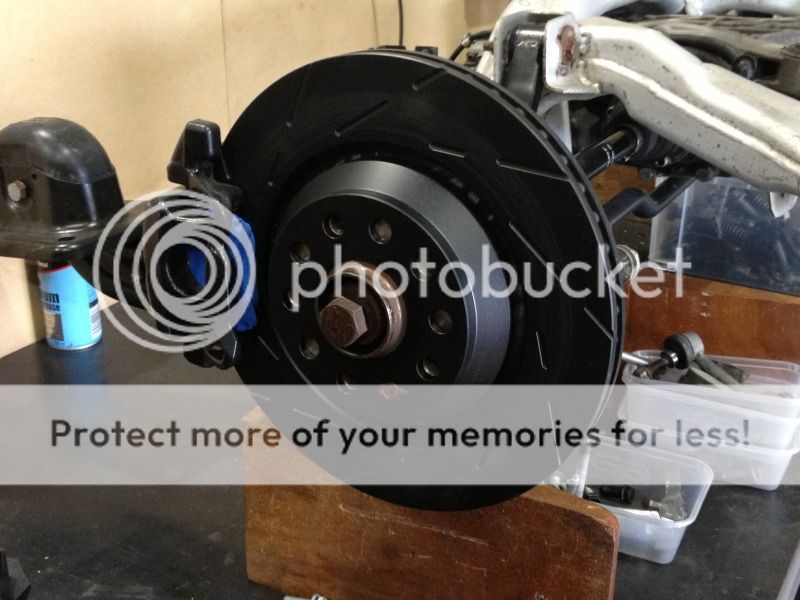

The rear axel is sub assembled on the bench. We will use the std rear calipers to start with. EBC USR discs are fitted as well as Japanese firm, Endless brake pads. I know the name sound a little corney but they really do go for ever and the stopping performance is fantastic! We completed a whole 24hr race on 1 set of the Endless pads in the Gallardo.

H&R rear anti roll bar is fitted as well as Superpro bushes.

More to come soon