- Joined

- Nov 16, 2016

- Messages

- 95

- Reaction score

- 17

- Points

- 8

I have to change it and i saw somebody searcing instructions before, so here we go:

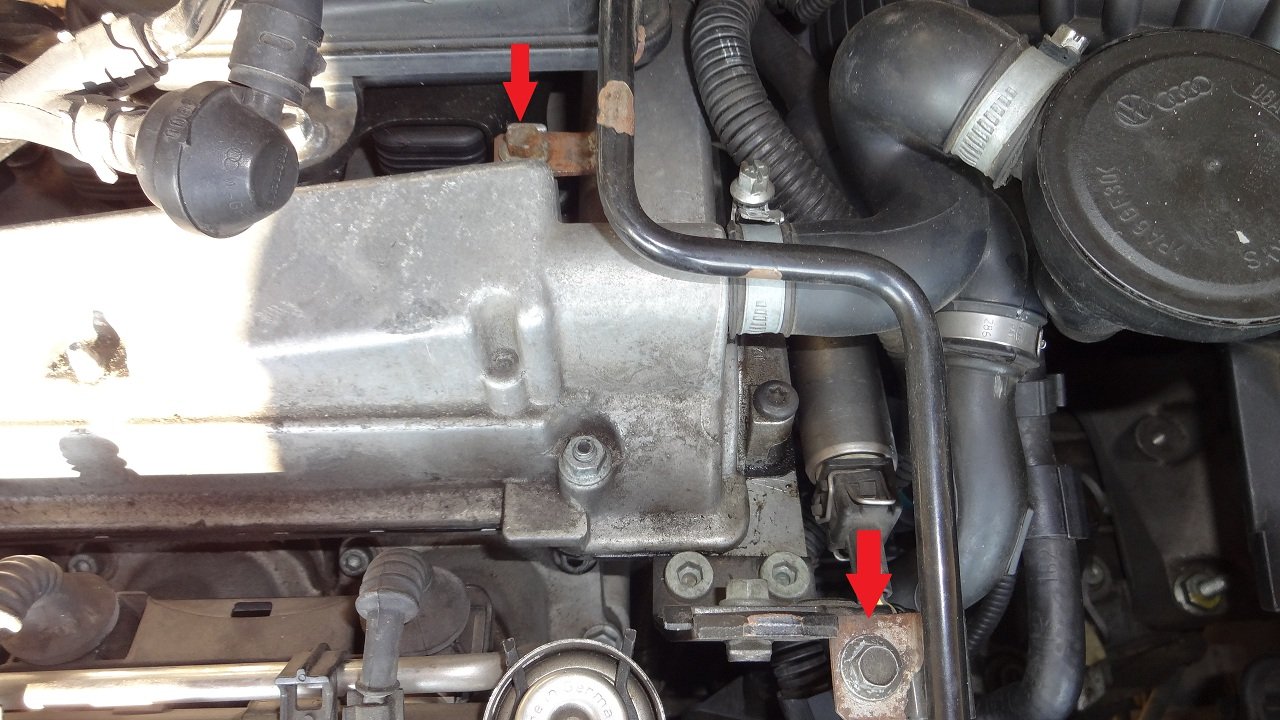

1.

There is two snap screws, after that you can take off the engine cover.

2.

First you have to unplug, after you can slide it down where is the rubber holding the sensor.

Finally take a wrench and take off the hose fixer.

3.

Remove that two bolts.

4.

Remove the bolt and after you can put it away the box.

5.

Remove the coilpack cover. There is 4 bolts.

6.

Remove the bolt and the two tube fixer. Remove the tubes.

7.

Remove the bolt and a tube fixer.

8.

You can find a tube fixer under the heat cover. Remove that and the tube, now you can take off the pipe.

You can find a tube fixer under the heat cover. Remove that and the tube, now you can take off the pipe.

9.

Remove the two bolts and take off the holder.

10.

Remove the four bolts.

11.

Unplug the four coilpack connections. Remove the grounding. The left and right corners( maybe just on right, under the heat cover) there is a screw, you can spring out easily. After that you can take off the wires.

12.

Remove all coilpacks, you can do it with your hands, just pull out. If u cant, then use something flat

and just pop out. Mark your coilpacks and when you gonna putting back then make sure you putting in the right place.

13.

Remove the tube fixer and the tube.

14.

Disconnect the cover clips. There is two. You dont have to take it off.

15.

Remove the ten bolts. The top right bolt holding a piece so make sure you not gonna drop.

You can see it in the next picture.

16.

Remove the bolt and now you can take off the valve cover.

17.

Im already taked off the old seals. Clean it with a break cleaner and replaced your new gasket seal.

I also have used a gasket sealant around and the new seal.

18.

Put it back the cover gently and tighten the screws. There is numbers. First gently tighten the middle one and after the following ones. If you tighted gently then do it again and make sure all perfect. Put back everything. If you used sealant then you have to wait. Start the engine when correctly dried up the sealant.

I hope its gonna help somebody. My english is not really good, so if any Admin see this, he/she can edit my

description. Merry Christmas and Happy New Year to all!

1.

There is two snap screws, after that you can take off the engine cover.

2.

First you have to unplug, after you can slide it down where is the rubber holding the sensor.

Finally take a wrench and take off the hose fixer.

3.

Remove that two bolts.

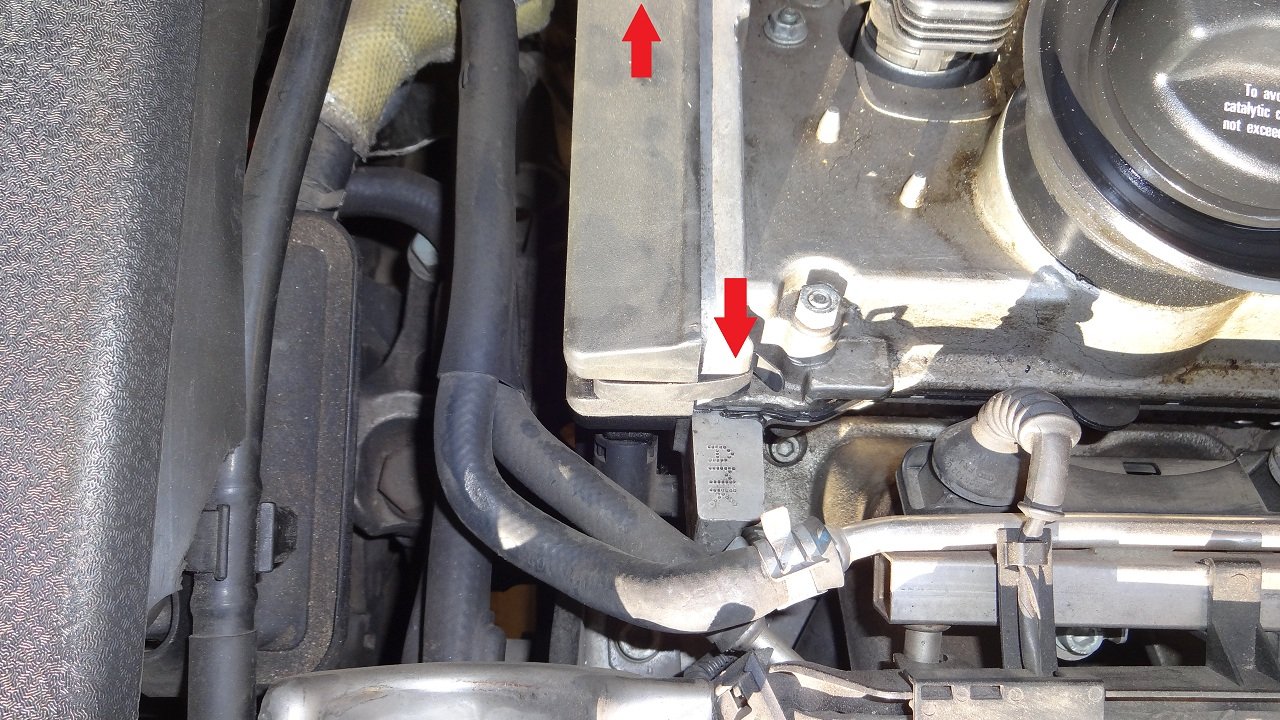

4.

Remove the bolt and after you can put it away the box.

5.

Remove the coilpack cover. There is 4 bolts.

6.

Remove the bolt and the two tube fixer. Remove the tubes.

7.

Remove the bolt and a tube fixer.

8.

9.

Remove the two bolts and take off the holder.

10.

Remove the four bolts.

11.

Unplug the four coilpack connections. Remove the grounding. The left and right corners( maybe just on right, under the heat cover) there is a screw, you can spring out easily. After that you can take off the wires.

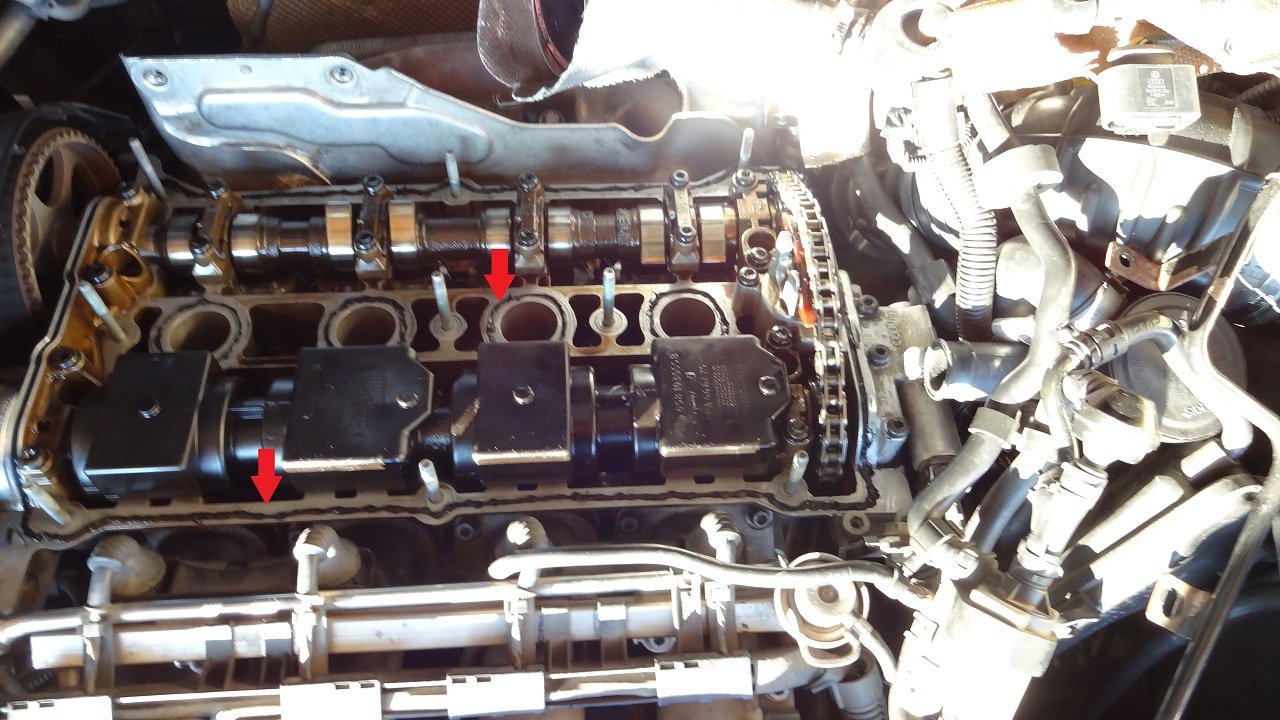

12.

Remove all coilpacks, you can do it with your hands, just pull out. If u cant, then use something flat

and just pop out. Mark your coilpacks and when you gonna putting back then make sure you putting in the right place.

13.

Remove the tube fixer and the tube.

14.

Disconnect the cover clips. There is two. You dont have to take it off.

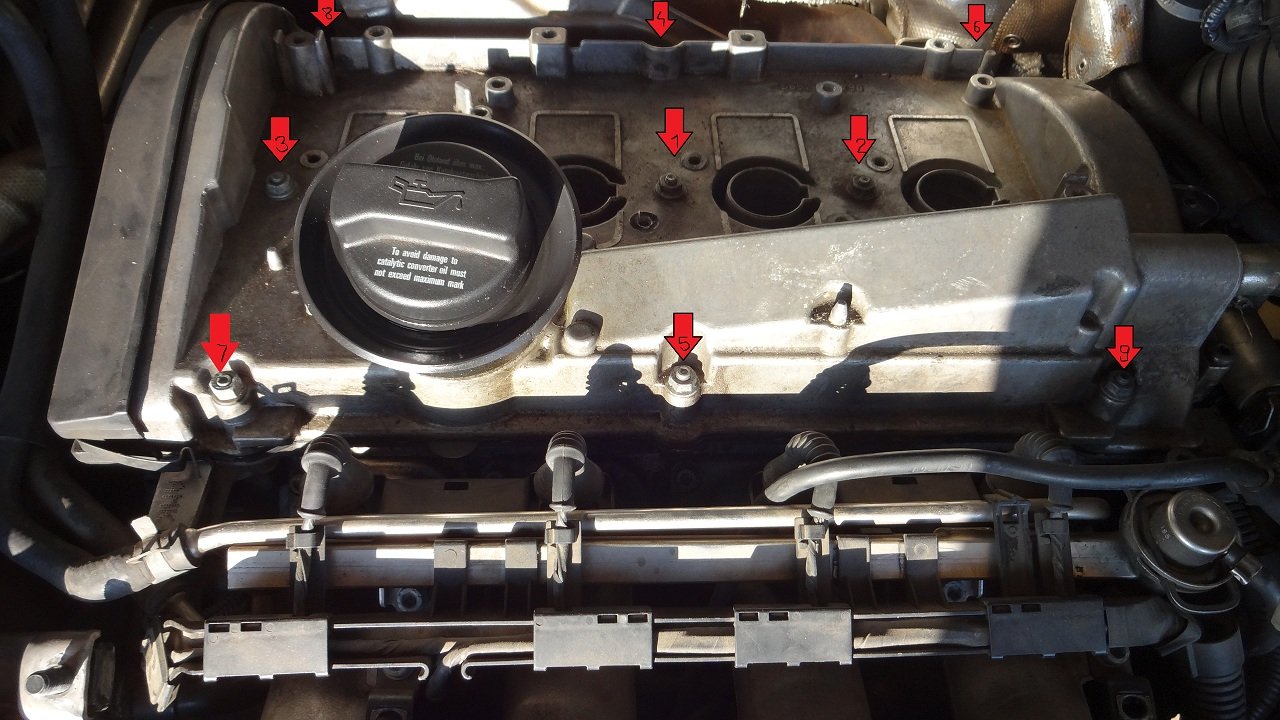

15.

Remove the ten bolts. The top right bolt holding a piece so make sure you not gonna drop.

You can see it in the next picture.

16.

Remove the bolt and now you can take off the valve cover.

17.

Im already taked off the old seals. Clean it with a break cleaner and replaced your new gasket seal.

I also have used a gasket sealant around and the new seal.

18.

Put it back the cover gently and tighten the screws. There is numbers. First gently tighten the middle one and after the following ones. If you tighted gently then do it again and make sure all perfect. Put back everything. If you used sealant then you have to wait. Start the engine when correctly dried up the sealant.

I hope its gonna help somebody. My english is not really good, so if any Admin see this, he/she can edit my

description. Merry Christmas and Happy New Year to all!