My wife has a 25TDi Avant, and she is sure it is not running right.

It was not the best starting in the cold, but it would(we're talking down to -15). The MPGs are around 39-40. It sounds to me to have a bit more of a 'bark' than it should, as if the pump timing is a little advanced. It doesn't really smoke when you plant it, but it feels gutless until about 1500-2000 RPM. After that, it is a scalded cat - faster than mine, I think.

I can compare it against my saloon, and they are totally different, mine has 120,000 miles on the clock, it pulls steadily throughout the rev range, I get 40-45 MPG, starts on the button and is less noisy!

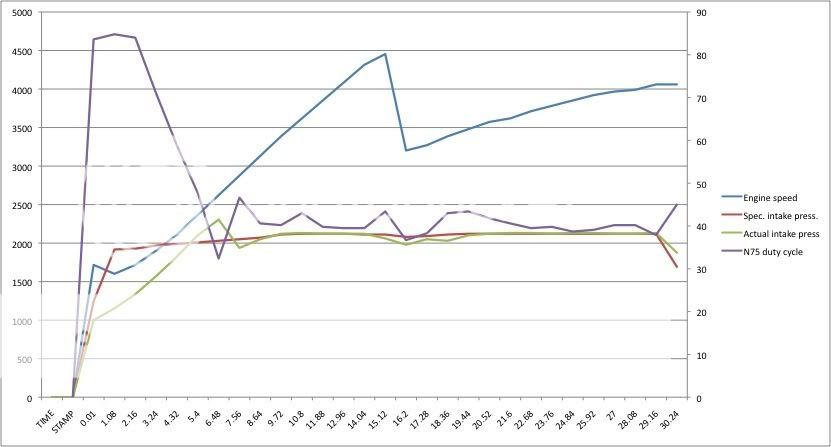

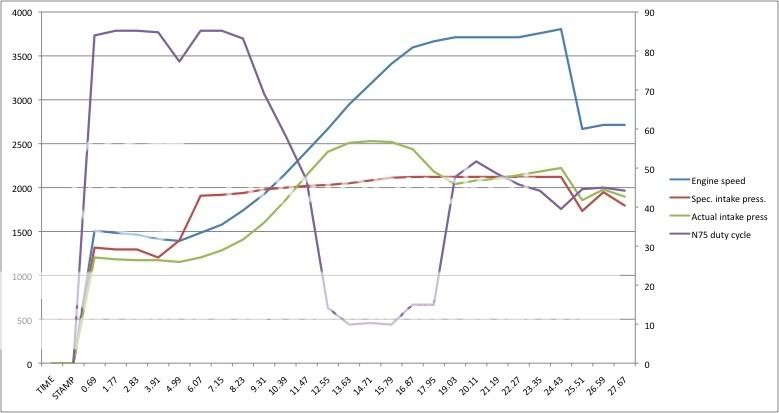

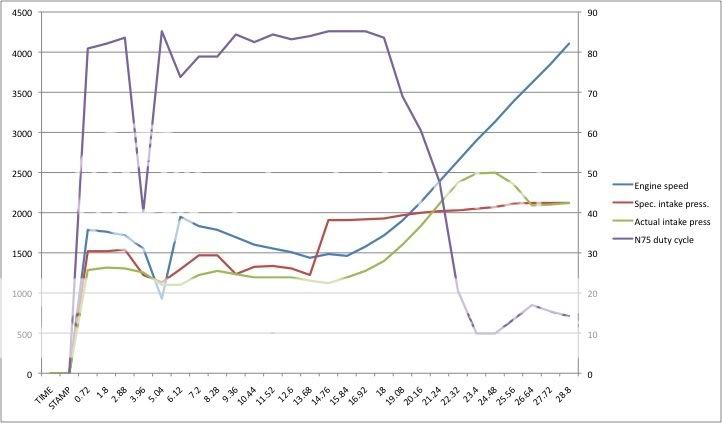

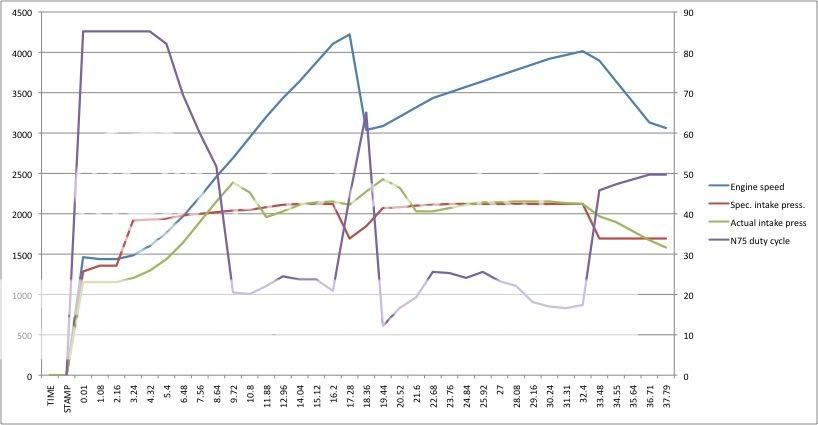

To date, the engine is a remanufactured 'zero hours' (as new) unit, done by Vege Engines, as is the turbo - now on 30,000 miles. The glow plugs are less than a year old, from Audi. The MAF is less than a year old, from Audi. To double check the MAF, I swapped it with mine, fault didn't transfer. N75 valve tested on VCDS, and turbo actuator seen to move full travel. After a chat with Addamss4, I checked the actuator rod length against mine, and shortened it. The pump and injectors were overhauled by Diesel Bob about a year ago. The pump timing is bang on the line, against my saloon being at the retarded end of the scale. There does not appear to be any leaking hoses - although I have not had a pressure check - but I would not expect a boost leak to cause low down torque problems and nothing at the top of the rev range. The fault does appear to get worse over time - but with swapping between the two cars, it may be psychosomatic!

It hasn't helped diagnosis that during this time, at least one of her brakes has been dragging at some point - even after fitting new parts!!

I'm pretty sure that isn't the case now, though......

There are no fault codes on VCDS.

I'm starting to wonder if one of the banks has a cam out by a tooth?

I really would like to get to the bottom of this, as there has been a LOT of money spent on this one, and my wife is starting to lose heart over it all. (We're going through a 'jinxed cars' stage at the moment, if you see some of my other posts!)

It was not the best starting in the cold, but it would(we're talking down to -15). The MPGs are around 39-40. It sounds to me to have a bit more of a 'bark' than it should, as if the pump timing is a little advanced. It doesn't really smoke when you plant it, but it feels gutless until about 1500-2000 RPM. After that, it is a scalded cat - faster than mine, I think.

I can compare it against my saloon, and they are totally different, mine has 120,000 miles on the clock, it pulls steadily throughout the rev range, I get 40-45 MPG, starts on the button and is less noisy!

To date, the engine is a remanufactured 'zero hours' (as new) unit, done by Vege Engines, as is the turbo - now on 30,000 miles. The glow plugs are less than a year old, from Audi. The MAF is less than a year old, from Audi. To double check the MAF, I swapped it with mine, fault didn't transfer. N75 valve tested on VCDS, and turbo actuator seen to move full travel. After a chat with Addamss4, I checked the actuator rod length against mine, and shortened it. The pump and injectors were overhauled by Diesel Bob about a year ago. The pump timing is bang on the line, against my saloon being at the retarded end of the scale. There does not appear to be any leaking hoses - although I have not had a pressure check - but I would not expect a boost leak to cause low down torque problems and nothing at the top of the rev range. The fault does appear to get worse over time - but with swapping between the two cars, it may be psychosomatic!

It hasn't helped diagnosis that during this time, at least one of her brakes has been dragging at some point - even after fitting new parts!!

I'm pretty sure that isn't the case now, though......

There are no fault codes on VCDS.

I'm starting to wonder if one of the banks has a cam out by a tooth?

I really would like to get to the bottom of this, as there has been a LOT of money spent on this one, and my wife is starting to lose heart over it all. (We're going through a 'jinxed cars' stage at the moment, if you see some of my other posts!)

Last edited: