OK so i feel like an update is needed. The tear down process was relatively fast... everything you need to break apart is there!

The build up... however... is not so fast! LOL I thought I had everything then came across things that i'd either forgotten or not even considered. From big to small parts. As usual - this is going to be told through photos.... sorry if i kill your bandwidth!

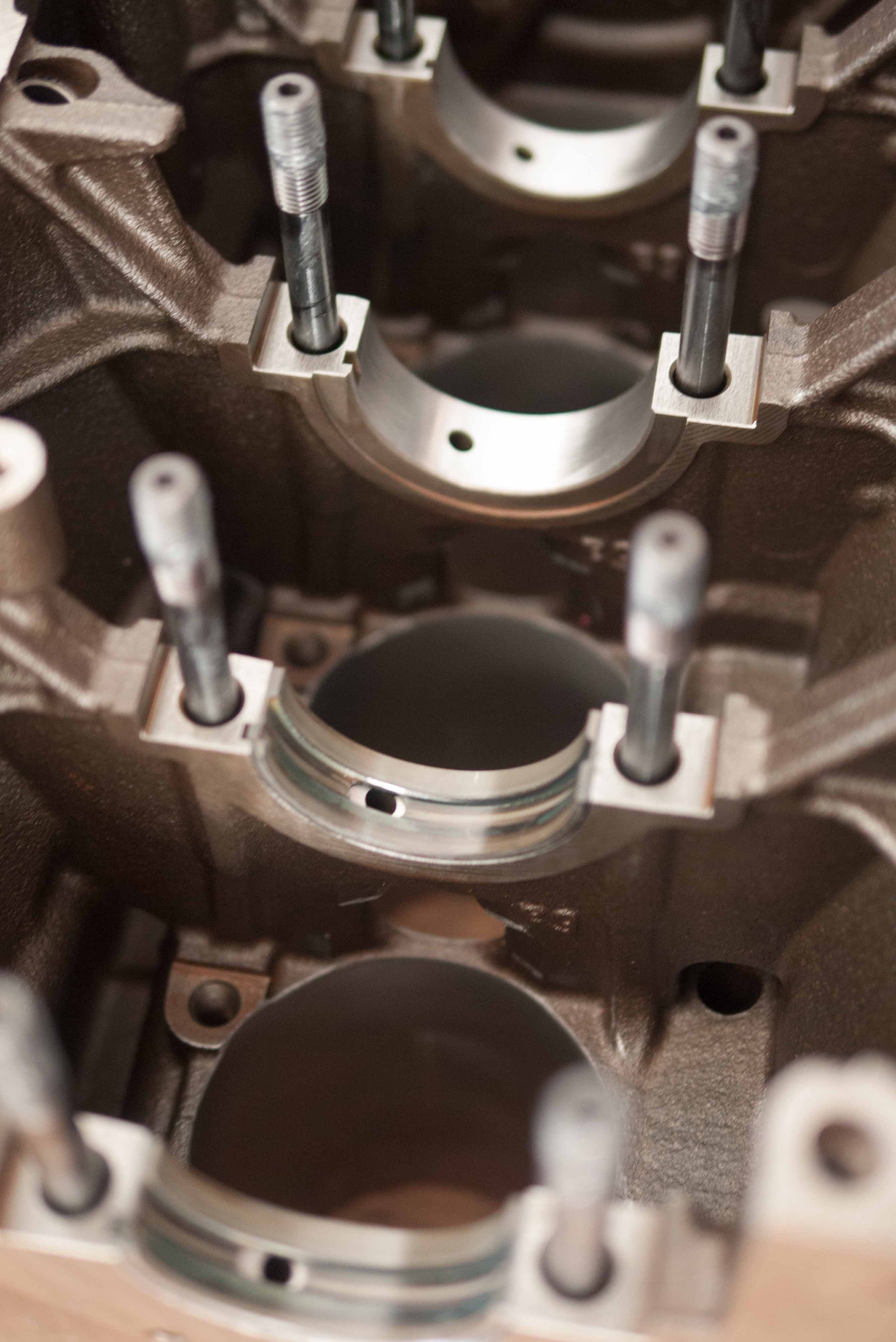

Building up the 9.5:1 CR stroker pistons and connecting rods.

The state of my old rods...

Finishing off the port & polish

Ring gapping - this is a slow process! Some good background tunes were definitely on for this part!

Bearings on

ARP cam studs and ACL calico main bearings

Hung up for a bit of a wash & refresh

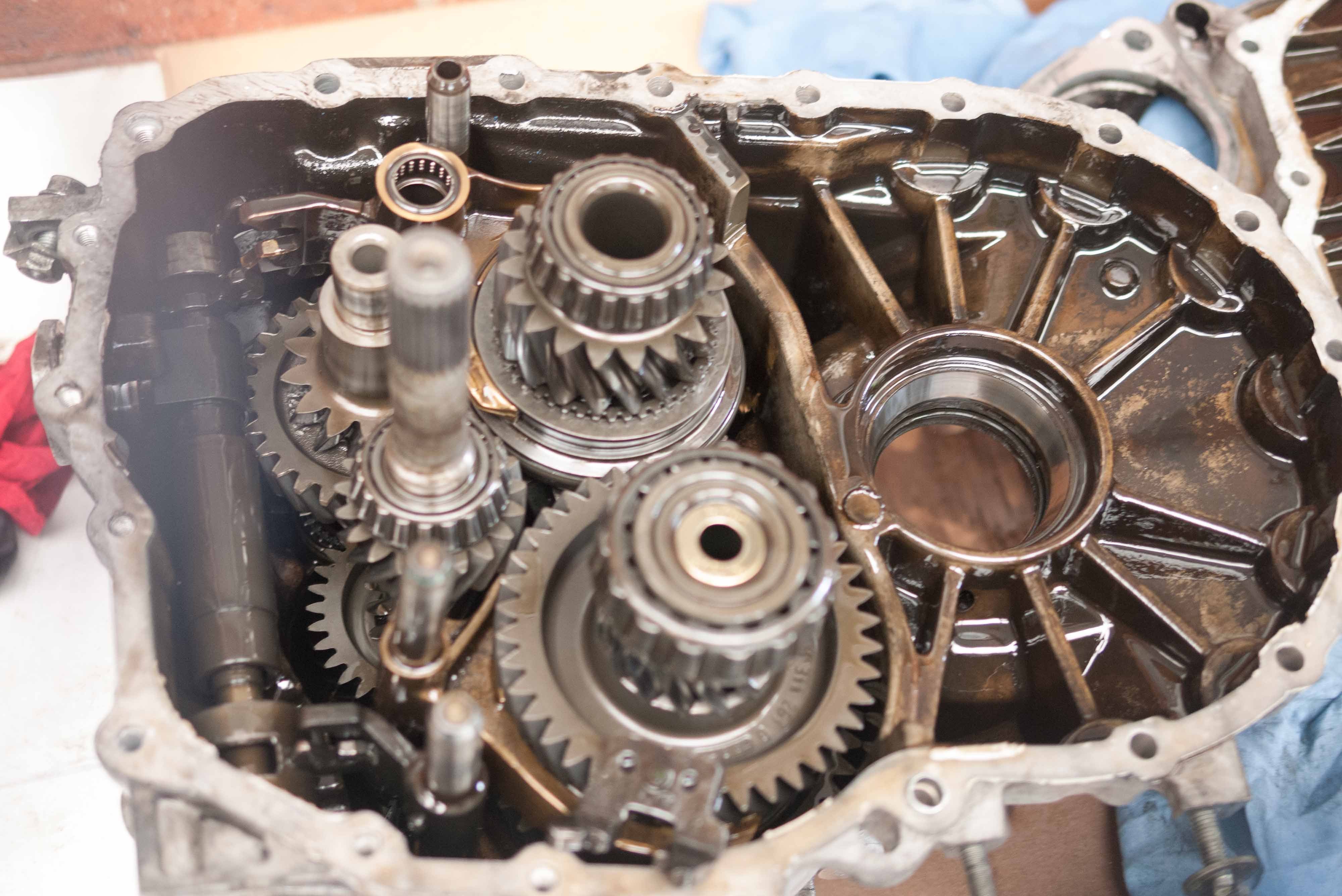

Cracking open the gearbox - this one was from the daily that had no 1st and 2nd gear

Bolts were easy enough to get off. Cracking the gearbox open however - needed many good whacks with the mallet!

I could feel this straight away as soon as i put my fingers in between the casings - the common broken shifter fork

Taking a reference picture before removing the stacks... dunno why but they came out with this side of the housing instead of staying on the other side i had to build it up "backwards"

My method of keeping the part that swings about in place while putting the sealing plate on

Uprated 1,2 & 3,4

Turning my attention to my transfer case - which i had noticed was leaking with a line of dried fluid on my downpipe... this nut... is a bitch!

The torque that's meant to go on this is something like 470Nm!!! ummmm HOW!?

Think i found my issue. Don't think the seal should be folded over like that! LOL

Putting these into their new home

Had to work on shaving a bit off of the sump (can see how i've angled the top "hump" down) because it wouldn't sit right with the ARP main cap studs. Using the left over carbide bits from the porting job!

Turning the attention to the brakes

The build up... however... is not so fast! LOL I thought I had everything then came across things that i'd either forgotten or not even considered. From big to small parts. As usual - this is going to be told through photos.... sorry if i kill your bandwidth!

Building up the 9.5:1 CR stroker pistons and connecting rods.

The state of my old rods...

Finishing off the port & polish

Ring gapping - this is a slow process! Some good background tunes were definitely on for this part!

Bearings on

ARP cam studs and ACL calico main bearings

Hung up for a bit of a wash & refresh

Cracking open the gearbox - this one was from the daily that had no 1st and 2nd gear

Bolts were easy enough to get off. Cracking the gearbox open however - needed many good whacks with the mallet!

I could feel this straight away as soon as i put my fingers in between the casings - the common broken shifter fork

Taking a reference picture before removing the stacks... dunno why but they came out with this side of the housing instead of staying on the other side i had to build it up "backwards"

My method of keeping the part that swings about in place while putting the sealing plate on

Uprated 1,2 & 3,4

Turning my attention to my transfer case - which i had noticed was leaking with a line of dried fluid on my downpipe... this nut... is a bitch!

The torque that's meant to go on this is something like 470Nm!!! ummmm HOW!?

Think i found my issue. Don't think the seal should be folded over like that! LOL

Putting these into their new home

Had to work on shaving a bit off of the sump (can see how i've angled the top "hump" down) because it wouldn't sit right with the ARP main cap studs. Using the left over carbide bits from the porting job!

Turning the attention to the brakes