Reality

2 weeks has passed, and I'm back at work. This is not fun.

To take my mind off things, i thought I'd add a few bits in here to catch up on what's been going on in the background recently. 90% of this happened before Oliver was born, and the car is currently in pieces still as I've not had the time or desire to go out and finish it off.

Having identified an issue with the brake plumbing, I needed to try and get access to the pipes to swap them round to fix the issue. I looked from above but it seemed impossible, so I turned my attention to below.

I'd noticed some nasty oil residue appearing on top of the splitter, which needed investigation too.

First note, my wear blocks are now well and truly worn, these need replacing, but they're done well for 3 years!

The sacrificial captive mounting blocks have also seen better days and are now in need of replacement too:

Splitter off and the extent of the oil spread was a little worrying. No pools of it, but a fine film of oil, over just about everything!

It seemed to be originating from around the DV area. Being MAFless I run my DV to atmosphere, and in the recent assembly, we installed the DV facing downwards for space reasons.

The DV venting oil vapour suggested one thing - there was oil in the charge pipes.

So off they came:

Number 1:

Oh Crap.

Number 2:

Same story!

Discharge pipe from the turbo:

Yup. you get the picture.

Very first thoughts at this point turn towards turbo seals, but this seemed unlikely as the current core has done less than 1000 miles from new.

Further strip down and I discovered a small amount of oil dripping from the end of the air filter too. Eek!

Oil in the charge pipes post turbo could well be caused by turbo seals, but oil in the air filter PRE turbo could only get there via my catch can system, which returns to the TIP just after the filter.

Now, here's the embarassing bit.

Since i hooked my catch can up to the TIP and PCV return, it appeared to be self cleaning.

it has a little tap on the low point drain, which I open monthly with a cup under it, and I've never got anything out.

For this reason, I assumed the system was self maintaining, and that nothing ever actually stopped in the can. So I've never actually removed the can.

I unbolted the can, and removed the tap entirely to see what would come out.

Oh.

Oh again.

the second picture is a second glass, not just a different angle!

Oh feck I'm thinking at this point.

Then it dawned on me. This wasn't typical catch can brownly watery sludge crap. This was pure engine oil.

I''d actually NEVER removed and properly emptied the can. Not even on the old engine, I'd only ever opened the tap, which I've now discovered has such a tiny hole through the middle that even the slightest emulsified sludge blocks it entirely.

D'oh!

I also thought back to conversations with Bill and others about oil level and baffled sumps. Whenever I've filled my oil to max, it's always found it's own level, neared half way very quickly, then stabilised and not dropped any further. This is thought to be the quantity of oil that sits ABOVE the front baffle under braking, which is able to go up and out of the filter housing and fill the breather system. I'd forgotten this in my absence from trackdays, and been filling the oil level to max.

The can was actually SO full, the the oil level was AT the height of the TIP breather return, meaning that any positive pressure into the can, or negative pressure at the tip return was drawing in pure oil at the turbo inlet!

How long as it been like this? I honestly don't know. Was it drawing oil through even when on the dyno at Bills? I'm unsure.

Either way, it feels like a pretty schoolboy error to make!

Many systems similar to mine incorporate a sump return drain, but I had genuinely thought my system didn't need it.

I'm now looking at the easiest way to add a drain in.

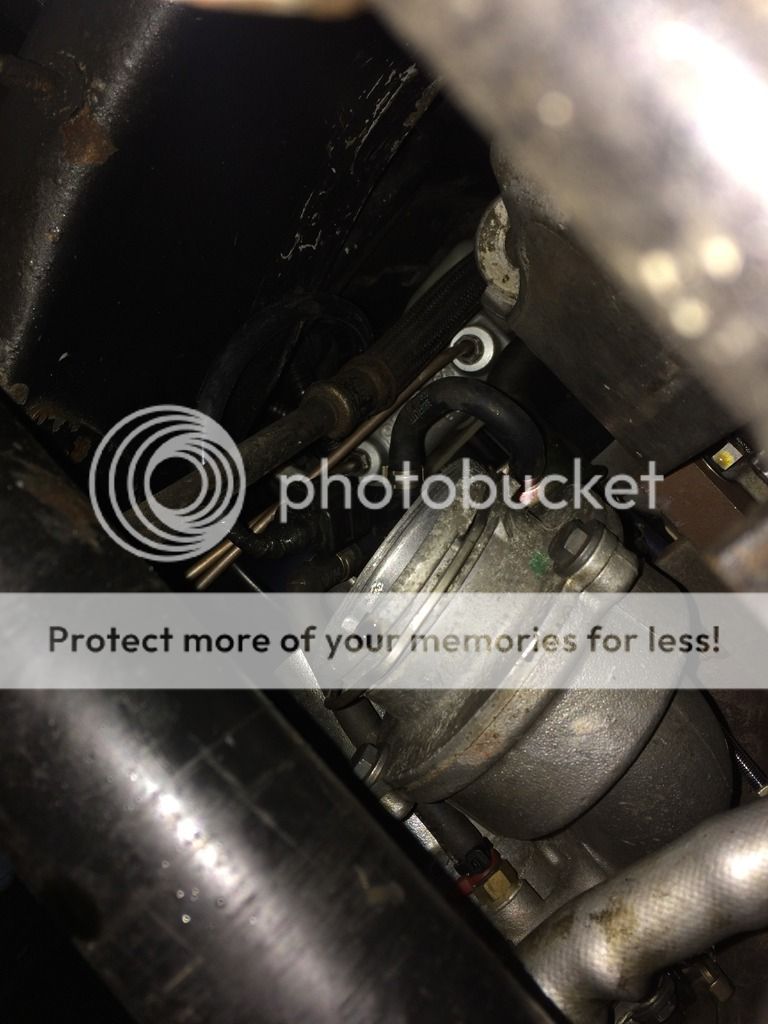

This is the current arrangement, minus the TIP and return pipe:

And this is what I'm currently considering. Running a simple drain pipe from the low point, back into the oil filter housing breather line:

In an ideal world, you'd drain directly to the sump, but my thinking is, that during normal running, pressure is normalised anyway, as they both go to the same point, then during points where the engine isn't breathing heavily, or when parked up, oil will drain back down into the sump.

With the system being plumbed in full time I see no huge issue with doing it this way, as the quantities of oil draining back will be so tiny, given how long it takes to build up.

In an ideal world I'd drop the sump and add a fitting, but time is not on my side for that currently, so I'll look at that option this winter.

Can anyone suggest any good reason why I shouldn't T a return line in as per my picture above?

the second picture is a second glass, not just a different angle!

the second picture is a second glass, not just a different angle!